0 ratings0% found this document useful (0 votes)

56 viewsUnited States Patent (19) : Layers', IBM Technical Disclosure Bulletin, Vol. 18, No

United States Patent (19) : Layers', IBM Technical Disclosure Bulletin, Vol. 18, No

Uploaded by

Haris AhmadThis patent describes a process for recovering gold from substrates by dissolving the gold in an etchant solution containing either iodine and an alkali metal iodide salt, or bromine and an alkali metal bromide salt. The dissolved gold can then be recovered by either precipitating it from the solution with an alkali hydroxide or by heating the solution to drive off the iodine or bromine. The gold precipitate or residue is then collected, while any other dissolved metals like copper or nickel can be removed by adding an acid to the residue.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

United States Patent (19) : Layers', IBM Technical Disclosure Bulletin, Vol. 18, No

United States Patent (19) : Layers', IBM Technical Disclosure Bulletin, Vol. 18, No

Uploaded by

Haris Ahmad0 ratings0% found this document useful (0 votes)

56 views3 pagesThis patent describes a process for recovering gold from substrates by dissolving the gold in an etchant solution containing either iodine and an alkali metal iodide salt, or bromine and an alkali metal bromide salt. The dissolved gold can then be recovered by either precipitating it from the solution with an alkali hydroxide or by heating the solution to drive off the iodine or bromine. The gold precipitate or residue is then collected, while any other dissolved metals like copper or nickel can be removed by adding an acid to the residue.

Original Title

US4375984

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This patent describes a process for recovering gold from substrates by dissolving the gold in an etchant solution containing either iodine and an alkali metal iodide salt, or bromine and an alkali metal bromide salt. The dissolved gold can then be recovered by either precipitating it from the solution with an alkali hydroxide or by heating the solution to drive off the iodine or bromine. The gold precipitate or residue is then collected, while any other dissolved metals like copper or nickel can be removed by adding an acid to the residue.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

56 views3 pagesUnited States Patent (19) : Layers', IBM Technical Disclosure Bulletin, Vol. 18, No

United States Patent (19) : Layers', IBM Technical Disclosure Bulletin, Vol. 18, No

Uploaded by

Haris AhmadThis patent describes a process for recovering gold from substrates by dissolving the gold in an etchant solution containing either iodine and an alkali metal iodide salt, or bromine and an alkali metal bromide salt. The dissolved gold can then be recovered by either precipitating it from the solution with an alkali hydroxide or by heating the solution to drive off the iodine or bromine. The gold precipitate or residue is then collected, while any other dissolved metals like copper or nickel can be removed by adding an acid to the residue.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

United States Patent (19) 11) 4,375,984

Bahl et al. 45 Mar. 8, 1983

54 RECOVERY OF GOLD FROM BROMIDE 4,319,922 3/1982 MacDonald .......................... 75/108

ETCHANTS 4,319,923 3/1982 Falanga ................................. 75/108

76 Inventors: Surinder K. Bahl, 670 Talowood Dr., OTHER PUBLICATIONS

Dayton, Ohio 45430; Gale L. Leach, Wise, Editor, Gold, D. Van Nostrand Co., Inc., Prince

1315 Carpenter Dr., Bellbrook, Ohio ton, N.J., (1964), pp. 44-50, 323-325.

45305

Flitsch, R., "Etch for Removing Gold', IBM Technical

21) Appl. No.: 178,245 Disclosure Bulletin, vol. 10, No. 4, Sep. 1967, p. 355.

22 Fied: Aug. 14, 1980 Interrante, M., "Reworking Multilayer Ceramic Metal

Layers', IBM Technical Disclosure Bulletin, vol. 18, No.

51 Int. Cl. ......................... C22B 11/04; B44C 1/22 2, Jul. 1975, p. 413.

52 U.S. C. ................................. 75/97 A; 7.5/118 R; Primary Examiner-Brian E. Hearn

75/97 A; 75/102; 75/108; 156/625; 156/664; Attorney, Agent, or Firm-Biebel, French & Nauman

252/79.1; 134/13

58 Field of Search ............. 75/108, 118 R; 156/656, 57 ABSTRACT

156/664, 642; 252/79.1, 79.2; 134/13 Gold, as well as other metals such as copper, titanium,

56 References Cited and nickel, are etched from substrates by alkali metal

U.S. PATENT DOCUMENTS iodide and bromide solutions also containing iodine and

bromine, respectively. The dissolved gold is recovered

2,283, 198 5/1942 Fink. as metallic gold either by precipitating it using an alkali

2,304,823 12/1942 Harrison . metal hydroxide or by a decomposition technique in

3,495,976 2/1970 Bazilevsky et al. . which the etchant solution is driven off. A method is

3,625,674 12/1971 Jacobs .

3,709,681 1/1973 Wilson . also taught to regenerate alkali metal iodide-iodine etch

3,957,505 5/1976 Homick et al. . ant solution.

4,190,489 2/1980 Bahl et al. .

4,260,451 4/1981 Schneckenbecher ................ 423/38 2 Claims, No Drawings

4,375,984

1. 2

tal halogen, and a halide salt, and recovering the metals

RECOVERY OF GOLD FROM BROMIDE by the addition of heat and zinc, copper, iron, or alumi

ETCHANTS num metal to precipitate the noble metals.

However, all of the above processes require the pres

BACKGROUND OF THE INVENTION 5 ence of reagents in addition to the halogen or halide

The present invention relates to a process for the salts or fail to provide complete recovery of gold. Ac

recovery of gold and more particularly to a process for cordingly, the need still exists in the art for a simple and

recovering gold from gold-plated materials by dis effective method for quantitative recovery of gold from

solving the gold in an etchant solution and then precipi 10 various substrates.

tating the gold therefron. SUMMARY OF THE INVENTION

Goid films are widely used in the electronics industry

in integrated and thin film circuitry because of their In accordance with the present invention, gold and

excellent electrically conductive properties. Because of other metals such as copper, titanium, and nickel are

gold's monetary value, it is desirable to recover the 15 dissolved by contacting them with an etchant composi

excess gold removed from electronic circuitry during tion comprising either an aqueous solution of iodine and

etching operations as well as to recover the gold from an alkali metal iodide salt or an aqueous solution of

scrap parts including gold plated printed circuit boards bromine and an alkali metal bromide salt. Gold films

and other decorative or functional gold coated metal, coated or plated on various substrate materials are rap

plastic, glass, and ceramic parts. idly etched by either of the above compositions at room

In the past, commercial processes for dissolving gold 20 temperature (i.e., 20-25 C.).

have utilized either hot aqua regia (a mixture of concen Gold is recovered from the aqueous solutions by

trated hydrochloric and nitric acids) or cyanide solu heating the solutions to dryness and then further heating

tions. However, both of these materials are extremely the residue to evolve either iodine or bromine vapors.

dangerous to handle. Aqua regia is highly corrosive and Essentially complete recovery of gold is obtained. If

emits toxic fumes while cyanide solutions can emit 25

deadly cyanide gases if proper handling techniques are other metals such as copper, titanium, or nickel are

not followed. Moreover, there are problems of safely present and etched by the etchant solution, gold is sepa

disposing of these materials. rated from these metals by adding a mineral acid such as

In the search for less toxic materials which will still hydrochloric, nitric, sulfuric, or hydrofluoric acid to

dissolve gold, others have turned to the use of halogen 30 the residue to dissolve the other metals. A gold precipi

tate will remain and can be recovered.

or halide salt solutions. For example, Harrison, U.S. Alternatively, dissolved gold is recovered from an

Pat. No. 2,304,823, teaches a process for recovering aqueous iodine-iodide etchant composition by adding a

precious metals including gold and silver from ore by sufficient amount of a base such as sodium or potassium

adding a solution containing iodine, potassium iodide, hydroxide to raise the pH of the solution to 13. Gold

and nitric acid to the ore to dissolve the precious metals. 35

metal precipitates from solution and is recovered by

Mercury is then added which forms an amalgam with

the metals which is then precipitated from solution and settling or filtration and then drying. The waste solu

recovered. Fink, U.S. Pat. No. 2,283,198, teaches sev tion, after removal of gold precipitate, is regenerated by

eral processes for recovering gold from ore including the addition of acid to the solution. Dissolved gold is

the use of chlorine in combination with sodium bromide 40 recovered from an aqueous bromine-bromide etchant

and a large excess of sodium chloride or bromine to composition by adding an alcohol and a base in an

dissolve the gold. It is taught that the gold in solution amount sufficient to raise the pH of the solution to 13.

can be precipitated and recovered by the addition of Gold metal is recovered by settling or filtration and

zinc dust or ferrous sulfate. then drying.

Jacobs, U.S. Pat. No. 3,625,674, teaches a gold recov 45 Accordingly, it is an object of the present invention

ery process in which gold ore is finely ground and then to provide a simple yet efficient process for the quanti

dissolved in an aqueous solution of ethanol and iodine. tative recovery of gold from gold-plated or gold-coated

Gold is recovered by heating the solution to a tempera substrates.

ture which evaporates the alcoholic solution and drives DESCRIPTION OF THE PREFERRED

of the iodine as vapor. Bazilevsky et al., U.S. Pat. No. 50 EMBODIMENTS

3,495,976, teach a process for recovering gold from a

plated substrate by dissolving the gold in an aqueous Etchant solutions used in the practice of the present

solution of potassium iodide and iodine. Sulfuric acid is invention may be prepared by mixing from 10 to 100

then added to the solution which is heated to a tempera grams of an alkali metal bromide or iodide with from 10

ture sufficient to drive off iodine as vapor but not evap 55 to 75 grams of bromine or iodine, respectively, in 200 ml

orate the solution. Gold precipitates from the solution of water. The bromide-bromine etchant solution can be

and is recovered as iodine is driven off. prepared as taught by our U.S. Pat. No. 4,190,489. It has

Homick et al, U.S. Pat. No. 3,957,505, teach a gold been found that these concentrations and ratios pro

recovery process which includes dissolving the gold in vides rapid etching of gold, as well as other metals such

an aqueous solution of iodine and alkali metal iodide and 60 as copper, titanium, and nickel, at room temperature.

then precipitating gold from solution by the addition of Although alkali metal halide to elemental halogen mole

either an acid or base in combination with a reducing ratios of from 1:1 to 6:1 are preferred, these ratios are

agent. It is further taught that the iodine-iodide solution not critical and may vary over a wide range. Changes in

can be regenerated by the addition of an oxidizing the concentrations and relative ratios of components

agent. Lastly, Wilson, U.S. Pat. No. 3,709,681, teaches a 65 will affect the rate of etching with stronger solutions

process for recovering noble metals including the steps generally etching metals at a more rapid rate. Heating

of finely dividing ore containing the metals, dissolving the etchant solution will also result in a more rapid

the metals in an aqueous solution of a ketone, an elemen etching rate.

4,375,984

3 4.

After the gold has been dissolved into the etchant 20gm KOH in 40 ml of water). A precipitate is formed

solution, it is recovered using either a precipitation or a and collected. Approximately 0.4 gm of gold is obtained

decomposition procedure. The precipitation procedure yielding an 80% recovery rate.

involves the addition of sodium hydroxide or potassium EXAMPLE III

hydroxide to the etchant solution to adjust the pH of the

solution to about 13 or above to cause the precipitation To show that the iodide etchant solution can be re

of metallic gold. It has been found that not all bases will generated and used repeatedly, a solution was made up

cause a metallic gold precipitate. For example, the addi by adding 250gm potassium iodide and 62.5gm iodine

tion of ammonium hydroxide to the etchant solution to 1000 ml of distilled water. The pH value of the solu

results in a black precipitate believed to be an oxide of 10 tion was 9. One gram of gold was dissolved in 300 ml of

gold. If the bromide-bromine etching solution is uti the iodide-iodine solution.in a beaker. To this solution,

lized, it has been found that the recovery of gold is 20 ml of a sodium hydroxide solution (prepared by

enhanced by the addition of a small amount of a water dissolving 50 gm NaOH in 100 ml of distilled water)

soluble alcohol such as methanol prior to the addition of was added raising the pH of the solution to 13. Gold

base. 15 precipitate formed and settled to the bottom of the

If other metals have been etched and are in solution beaker. Forty milliliters of hydrochloric acid was added

with gold, after precipitation by the addition of an alkali to the etchant solution to adjust its pH to 9. The solution

metal hydroxide the other metals may be separated color changed from clear to a dark color, and the gold

from the gold by suspending the precipitate in an aque precipitate was dissolved. The addition of sodium hy

ous solution and adding a strong mineral acid such as 20 droxide solution until a pH of 13 was reached again

hydrochloric, sulfuric, nitric, or hydrofluoric acid. The caused the gold to precipitate. The cycle was repeated

mineral acid will dissolve the other metals into solution five more times, and in each instance the gold was dis

but will not affect the gold precipitate which can be solved by the etchant solution at a pH of 9 and was

recovered separately. Typically, the gold precipitate precipitated from the etchant solution when the pH was

may be recovered by settling and decanting or by filter 25 adjusted to 13. No change in the rate of dissolution of

ing the solution through filter paper, although other gold was observed.

known recovery procedures may be utilized.

A significant advantage obtained by using the precip EXAMPLE IV

itation procedure with iodide-iodine etchant solution is To 25 ml of the iodide-iodine etchant solution of

that the etchant solution may be regenerated after the 30 Example I, 0.5gm of gold was added and dissolved.

gold has been recovered. This is achieved by adding to The solution was heated to dryness and then further

the solution a sufficient amount of a strong mineral acid heated to above about 175 C. At that point, the residue

to adjust the pH to neutral or only slightly basic, i.e., a turned light brown with the evolution of purple(iodine)

pH of about 7 to 9. As the pH is adjusted, the color of vapors. The remaining residue was mixed with water,

the solution changes from clear to a dark color similar 35 the gold precipitate was allowed to settle to the bottom

to the original fresh etchant. The regenerated etchant of the container and was collected. The recovered gold

can then be used to etch further gold coated materials. weighed 0.5gm indicating a 100% recovery.

Gold may also be recovered from the etchant solu EXAMPLE V

tion by the use of decomposition technique. Etchant

solution containing dissolved gold is slowly heated to To 25 ml of the bromide-bromine solution of Exam

above about 175 C. causing the evolution of purple(io ple II, 0.5gm of gold was added and dissolved. The

dine) or red(bromine) gas. Heating is continued until the solution was heated to dryness and then further heated

residue is dry. The residue is then mixed with water. until a red(bromine) gas evolved. Upon mixing the resi

Gold precipitate is then collected by settling and decan due with water, gold precipitate settled to the bottom of

tation or by filtering the aqueous solution. 45 the container and was collected. The recovered gold

The invention may be better understood by reference weighed 0.5gm indicating a 100% recovery.

to the following nonlimiting examples. While the methods herein described constitute pre

EXAMPLE I ferred embodiments of the invenion, it is to be under

stood that the invention is not limited to these precise

An etchant solution containing 50 gm of potassium 50 method, and that changes may be made without depart

iodide and 12.5gm of iodine is mixed with 200 ml water. ing from the scope of the invention, which is defined in

A gold plated substrate is dipped in the solution and is the appended claims.

rapidly etched at room temperature. To twenty-five What is claimed is:

milliliters of the etchant solution containing dissolved 1. A method of recovering gold from gold coated

gold, 10 ml of sodium hydroxide solution (prepared by 55 materials comprising the steps of contacting a gold

dissolving 30 gm NaOH in 60 ml water) is added. A coated material with an aqueous etchant solution com

gold precipitate is obtained which is insoluble in hydro prising an alkali metal bromide and bromine for a time

chloric acid or concentrated nitric acid but is soluble in sufficient to etch away the gold layer, adding a water

aqua regia indicating that a metallic gold precipitate is soluble alcohol to the solution, adjusting the pH of the

obtained. solution to 13 or above to cause precipitation of metallic

EXAMPLE I gold from the solution, and recovering the precipitated

gold.

To an etchant solution containing 2 gm of potassium 2. The method of claim 1 including the steps of recov

bromide and 1 gm of bromine in 25 ml of water, 0.5gm. ering the precipitate, adding a strong mineral acid to

of gold powder is dissolved. To this solution, 10 ml of 65 dissolve metals other than gold in said precipitate, and

methanol is added followed by the addition of 10 ml of recovering the remaining gold.

a potassium hydroxide solution (prepared by dissolving . Sk xs R 3. t

You might also like

- Gold Refining Process ChartDocument3 pagesGold Refining Process ChartTracey0% (1)

- Mitsubishi Process of Copper MakingDocument23 pagesMitsubishi Process of Copper MakingSwarnaRakshitNo ratings yet

- Safety Data Sheet: Product Name: UNIVIS HVI 13Document12 pagesSafety Data Sheet: Product Name: UNIVIS HVI 13Haris AhmadNo ratings yet

- Crevice Corrosion PDFDocument3 pagesCrevice Corrosion PDFPDF_user_blue0% (1)

- Vacuum Drainage Systems GuidanceDocument16 pagesVacuum Drainage Systems GuidanceBasil OguakaNo ratings yet

- Au PlatingDocument6 pagesAu PlatingAaed M. EnadNo ratings yet

- 2 2018 384us4680126d1Document7 pages2 2018 384us4680126d1sohuutritue2020No ratings yet

- Us 4131454Document11 pagesUs 4131454borgiamatriceNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2004/0156765 A1Document14 pagesPatent Application Publication (10) Pub. No.: US 2004/0156765 A1Godfrey BareNo ratings yet

- Us 4557759Document6 pagesUs 4557759borgiamatriceNo ratings yet

- United States of AmericaDocument5 pagesUnited States of Americajaylani99No ratings yet

- KAu (CN) 2Document3 pagesKAu (CN) 2Aaed M. EnadNo ratings yet

- Chloride in Iron OxideDocument6 pagesChloride in Iron OxideSaeed SarNo ratings yet

- Proceso Electolítico YodoDocument6 pagesProceso Electolítico Yodogonzalo7cornejo7ramiNo ratings yet

- US4116858-Recovery of Lithium From BrinesDocument9 pagesUS4116858-Recovery of Lithium From BrinesDiego RossoNo ratings yet

- United States Patent (10) Patent N0.: US 8,945,489 B2Document5 pagesUnited States Patent (10) Patent N0.: US 8,945,489 B2Georgi SavovNo ratings yet

- United States Patent (19) : 22 Filed: May 25, 1979 57Document4 pagesUnited States Patent (19) : 22 Filed: May 25, 1979 57Bharata BadranayaNo ratings yet

- US20150225810A1 - Iron Recovery Method 2015Document3 pagesUS20150225810A1 - Iron Recovery Method 2015Eduardo CandelaNo ratings yet

- General Principles of MetallurgyDocument7 pagesGeneral Principles of MetallurgyUtkarsh BajpaiNo ratings yet

- PT by MellorDocument16 pagesPT by MellorCesar Mera LlinasNo ratings yet

- Us 4319922Document7 pagesUs 4319922borgiamatriceNo ratings yet

- GoldDocument22 pagesGoldIsai Santamaria100% (1)

- General PrincipalDocument6 pagesGeneral PrincipalthinkiitNo ratings yet

- Depletion Gilding PDFDocument8 pagesDepletion Gilding PDFBernardDelorNo ratings yet

- Desorption of Gold From Activated Carbon - Patente US4208378Document6 pagesDesorption of Gold From Activated Carbon - Patente US4208378arodriguezhNo ratings yet

- Scale Control in Heap LeachDocument8 pagesScale Control in Heap LeachAri WijayaNo ratings yet

- US3819406Document7 pagesUS3819406Vikin JainNo ratings yet

- Us4282190 PDFDocument4 pagesUs4282190 PDFVinod AvNo ratings yet

- US4439491Document4 pagesUS4439491NITISH MAHTONo ratings yet

- Final Comp MetallurgyDocument98 pagesFinal Comp MetallurgyYODDHA ADITYANo ratings yet

- cementacao aluminioDocument5 pagescementacao aluminioG MNo ratings yet

- Aluminio ExtraccionDocument7 pagesAluminio ExtraccionjackyNo ratings yet

- Ext Met Wel DefDocument26 pagesExt Met Wel DefNamrata SharmaNo ratings yet

- Process For The Extraction andDocument11 pagesProcess For The Extraction andabaNo ratings yet

- Aminocarboxilic Acid SaltsDocument7 pagesAminocarboxilic Acid SaltsnwrplaboratoryNo ratings yet

- United States Patent Office: Patented Nov. 26, 1963Document2 pagesUnited States Patent Office: Patented Nov. 26, 1963Bharata BadranayaNo ratings yet

- Blue Rhodium Nippon Plat LTD 1981 US4416742Document6 pagesBlue Rhodium Nippon Plat LTD 1981 US4416742Dhandapani PNo ratings yet

- Umar, 04 Isyatun RodliyahDocument8 pagesUmar, 04 Isyatun Rodliyahrizky dwi anandaNo ratings yet

- Jan. 2, 1940. S. R. Mason 2,185,858: WVAW/orDocument3 pagesJan. 2, 1940. S. R. Mason 2,185,858: WVAW/orBharata BadranayaNo ratings yet

- United States Patent (191: Peasley Et A1. (45) Jun. 29, 1982Document3 pagesUnited States Patent (191: Peasley Et A1. (45) Jun. 29, 1982Ashleigh HeinNo ratings yet

- Copper Extraction TechniquesFrom WikipediaDocument9 pagesCopper Extraction TechniquesFrom WikipedialeniucvasileNo ratings yet

- Au-Ag-Cu - CN Metales PreciososDocument19 pagesAu-Ag-Cu - CN Metales PreciososAnonymous FfIxH2o9No ratings yet

- SI Selected 11 Hyvarinen 2005Document5 pagesSI Selected 11 Hyvarinen 2005Tomás HidalgoNo ratings yet

- Study Material 6: Concentration of OresDocument15 pagesStudy Material 6: Concentration of OresitishaNo ratings yet

- Processing of Economic Mineral ResourcesDocument2 pagesProcessing of Economic Mineral Resourcesterry yakuyeNo ratings yet

- Chemistry Notes For Class 12 Chapter 6 General Principles and Processes of Isolation of ElementsDocument13 pagesChemistry Notes For Class 12 Chapter 6 General Principles and Processes of Isolation of ElementsPrajapat RockNo ratings yet

- Hydrometallurgy Del Cu PDFDocument528 pagesHydrometallurgy Del Cu PDFAnonymous FfIxH2o9100% (3)

- Bansal Classes MetallurgyDocument17 pagesBansal Classes Metallurgyg_group80% (5)

- Metallurgy Notes For IIT JEE PDFDocument17 pagesMetallurgy Notes For IIT JEE PDFADIL RIZVINo ratings yet

- Introduction To Hydrometallurgy - UI - Lecture NotesDocument20 pagesIntroduction To Hydrometallurgy - UI - Lecture NotesOkky Intan50% (2)

- Roasting TemperatureDocument9 pagesRoasting Temperatureandrea ruedasNo ratings yet

- General PrinciplesDocument19 pagesGeneral PrinciplesGovardhan AshokanNo ratings yet

- United States Patent (19) : 73) Assignee: Huron Tech Corp., Delco, N.CDocument14 pagesUnited States Patent (19) : 73) Assignee: Huron Tech Corp., Delco, N.CShahid AliNo ratings yet

- Gold Extraction From ThioureaDocument7 pagesGold Extraction From ThioureaRavi ChandraNo ratings yet

- Unit-6 Principles and Processes of Extraction of Metals.: I. One Mark QuestionsDocument5 pagesUnit-6 Principles and Processes of Extraction of Metals.: I. One Mark Questionsnawal2007No ratings yet

- United States Patent (19) : (45) June 14, 1977Document10 pagesUnited States Patent (19) : (45) June 14, 1977Annisa IcaNo ratings yet

- II PU - Chemistry - Unit 6Document11 pagesII PU - Chemistry - Unit 6smitakamath6686No ratings yet

- Extraction Metallurgy: Part 2: Case StudiesDocument132 pagesExtraction Metallurgy: Part 2: Case Studiesalborz99No ratings yet

- General Principles ProcessesDocument19 pagesGeneral Principles ProcessesAnand MurugananthamNo ratings yet

- MetallurgyDocument32 pagesMetallurgyKAPISH BANSALNo ratings yet

- The Behaviour of Carbonaceous Matter in Cyanide Leaching of GoldDocument10 pagesThe Behaviour of Carbonaceous Matter in Cyanide Leaching of Gold88127907No ratings yet

- Cesium and Cesium Compounds: 1. Physical and Chemical PropertiesDocument5 pagesCesium and Cesium Compounds: 1. Physical and Chemical PropertiesjaimeNo ratings yet

- The Silversmith's Handbook: Containing full instructions for the alloying and working of silverFrom EverandThe Silversmith's Handbook: Containing full instructions for the alloying and working of silverNo ratings yet

- AP-C40 (P) Series Instruction Manual: Digital Pressure Sensor With 2-Color DisplayDocument6 pagesAP-C40 (P) Series Instruction Manual: Digital Pressure Sensor With 2-Color DisplayHaris AhmadNo ratings yet

- PSEN ma2.1p-11/PSEN2.1-10/LED/3mm/1unit 506406Document6 pagesPSEN ma2.1p-11/PSEN2.1-10/LED/3mm/1unit 506406Haris AhmadNo ratings yet

- IAG - SOP - Configure ADAM-6100EI Module in RSLogix 5000Document12 pagesIAG - SOP - Configure ADAM-6100EI Module in RSLogix 5000Haris AhmadNo ratings yet

- Pulse Code RsDocument209 pagesPulse Code RsHaris AhmadNo ratings yet

- Univis HVI Series Univis HVI Series Univis HVI Series Univis HVI SeriesDocument2 pagesUnivis HVI Series Univis HVI Series Univis HVI Series Univis HVI SeriesHaris AhmadNo ratings yet

- Motor Proposal ConfirmationDocument4 pagesMotor Proposal ConfirmationHaris AhmadNo ratings yet

- Enclosing Innovations: Order Symbol: Ean: Product NBR: El. Number: Description: RemarksDocument1 pageEnclosing Innovations: Order Symbol: Ean: Product NBR: El. Number: Description: RemarksHaris AhmadNo ratings yet

- Treadles (EU)Document1 pageTreadles (EU)Haris AhmadNo ratings yet

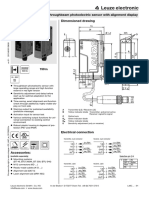

- L46C Red-Light Throughbeam Photoelectric Sensor With Alignment DisplayDocument4 pagesL46C Red-Light Throughbeam Photoelectric Sensor With Alignment DisplayHaris AhmadNo ratings yet

- Datasheet Valvula 5-2 FestoDocument2 pagesDatasheet Valvula 5-2 Festojunior mauricio lojaNo ratings yet

- B17 OMM Inspection ChecksheetsDocument8 pagesB17 OMM Inspection ChecksheetsturboshaftNo ratings yet

- Casting Dimensional Tolerances Adapted From ISO 8062-1994 (Inches) Also Used For SFSA 2000 Steel Casting TolerancesDocument1 pageCasting Dimensional Tolerances Adapted From ISO 8062-1994 (Inches) Also Used For SFSA 2000 Steel Casting TolerancesstanyeahNo ratings yet

- Hob Accuracy TolerancesDocument5 pagesHob Accuracy Tolerancesyogesh pachankarNo ratings yet

- Quick Reference Guide: IC260L/D DUO IC261L/D DUO (Firmware Rel. 1.9)Document64 pagesQuick Reference Guide: IC260L/D DUO IC261L/D DUO (Firmware Rel. 1.9)Ivaylo TodorovNo ratings yet

- Penstockshell Int PR 16 Bar and Exp 1barDocument1 pagePenstockshell Int PR 16 Bar and Exp 1barmoganna73No ratings yet

- 1 3 6 Overview of Eq Design UK NA For EN1998 2 PD 6698Document9 pages1 3 6 Overview of Eq Design UK NA For EN1998 2 PD 6698Chirianu MarianNo ratings yet

- ASTM G 98 - 91 r96 - Rzk4ltkxujk2rteDocument3 pagesASTM G 98 - 91 r96 - Rzk4ltkxujk2rteSamuel EduardoNo ratings yet

- Hu80722 BreakdownDocument5 pagesHu80722 BreakdowncconcernedNo ratings yet

- Carrier 2trDocument15 pagesCarrier 2trfernandoreyes893No ratings yet

- Earth Pit KDocument13 pagesEarth Pit KKg Chit ZawNo ratings yet

- Specification Jumbo Drill Sandvik DD311D-40CDocument4 pagesSpecification Jumbo Drill Sandvik DD311D-40CNathania Boas E SNo ratings yet

- Electropalan Imer AIRONE 200 N 300 NDocument1 pageElectropalan Imer AIRONE 200 N 300 NdiconNo ratings yet

- Ogre Kingdoms Bull Samurai Conversion: Signup Now! Why Join? Lost Password?Document34 pagesOgre Kingdoms Bull Samurai Conversion: Signup Now! Why Join? Lost Password?PaoloRoccaNo ratings yet

- JigDocument6 pagesJigArun ManoNo ratings yet

- 7 PDFDocument10 pages7 PDFAnastasia Monica KhunniegalshottestNo ratings yet

- River Hindon PDFDocument241 pagesRiver Hindon PDFR P SinghNo ratings yet

- MototaroDocument2 pagesMototaroJeanJonesNo ratings yet

- Ammonia ScrubbersDocument7 pagesAmmonia Scrubbersangelo pascuaNo ratings yet

- Rate Analysis For PCCDocument2 pagesRate Analysis For PCCAsif100% (1)

- JVC AV-27D50 Manual de ServicioDocument31 pagesJVC AV-27D50 Manual de ServicioFrancisco LópezNo ratings yet

- 1 Feeding Area - MergedDocument4 pages1 Feeding Area - MergedAlainNo ratings yet

- L&T ButterflyValves Triple OffsetDocument16 pagesL&T ButterflyValves Triple OffsetvarathapandianNo ratings yet

- Dynamic and Static Balancing of Rolls - How, Why and WhenDocument2 pagesDynamic and Static Balancing of Rolls - How, Why and WhenAbolfazl KhakiNo ratings yet

- Tech Data-Din Ford-Cups eDocument2 pagesTech Data-Din Ford-Cups eBalram JiNo ratings yet

- Calorific ValueDocument2 pagesCalorific ValueAgung RahinoNo ratings yet

- Supp Elements 17 For Machine DesignDocument35 pagesSupp Elements 17 For Machine DesignCyron Elden Senarillos-Talita Bangis-BodegasNo ratings yet

- ActiveCell Brochure WEB LTR PDFDocument4 pagesActiveCell Brochure WEB LTR PDFab5918590No ratings yet