Carbon Footprints of Tyre Production - New Versus Remanufactured

Carbon Footprints of Tyre Production - New Versus Remanufactured

Uploaded by

Lucky Ginanjar AdhipurnaCopyright:

Available Formats

Carbon Footprints of Tyre Production - New Versus Remanufactured

Carbon Footprints of Tyre Production - New Versus Remanufactured

Uploaded by

Lucky Ginanjar AdhipurnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Carbon Footprints of Tyre Production - New Versus Remanufactured

Carbon Footprints of Tyre Production - New Versus Remanufactured

Uploaded by

Lucky Ginanjar AdhipurnaCopyright:

Available Formats

Carbon footprints of tyre

production – new versus

remanufactured

A report comparing the carbon footprint of a

new and a retread tyre for use by light

commercial vehicles

www.remanufacturing.org.uk

July 2008

© Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

© Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Prepared for

Oakdene Hollins Ltd

Centre for Remanufacturing and Re-use

22-28 Cambridge Street

Aylesbury

HP20 1RS

Contact person: Ben Walsh

Email: info@remanufacturing.org.uk

Web: http://www.remanufacturing.org.uk/

Phone: +44 (0)1296 423915

Prepared by

Best Foot Forward Ltd.

9 Newtec Place

Magdalen Road

Oxford

OX4 1RE

July 2008

Gregor Pecnik

Simon Miller

E-mail: mail@bestfootforward.com

Web: www.bestfootforward.com

Tel: 01865 250818

Fax: 01865 794586

Company Registration 3409491

© Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Executive summary

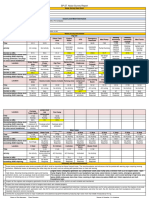

This report compares the carbon footprint of a new and a retread 17.5” tyre for use

by light commercial vehicles. Retread tyres are tyres where a new tread is applied to

a used tyre casing. This process effectively increases the number of cycles for a tyre

casing, and this project was commissioned to assess the carbon balance of new tyre

production compared to retreading.

This study shows that a 17.5” new tyre produces 86.9 kg CO2 emissions compared to

60.5 kg CO2 for an equivalent retread tyre. These figures are based on each retread

tyre being resurfaced an average of 1.3 times (which is a figure supplied by a

remanufacturer). This equates to a reduction of emissions by 30%. Figure 1 below

shows a comparison of the impacts arising from each stage of the product lifecycle

Figure 1: Comparison of carbon footprintof a new and a retread tyre

100

90 End of life

80 Waste-retread

70

Energy-retread

60

kg CO2 per tyre

Materials-retread

50

Transport-retread

40

30 Waste

20 Energy

10

Materials

0

new tyre retread Transport

-10

Note: The impact of a retread tyre is based on the assumption of 1.3 retreads per tyre.

The embodied carbon of materials required to produce a tyre accounts for the

biggest portion of the carbon footprint of both tyre types - more than half of the total

carbon footprint for each. The material used in new tyre manufacture is responsible

for 48 kg CO2, while for retreading it is 31 kg of CO2.

The second largest impact is attributed to the energy needed in the manufacturing

and retreading process, which accounts for 31 kg CO2 for a new tyre and for 22 kg

CO2 for a retread. A relatively significant impact is associated with transport, which

accounts for almost 10 kg CO2 of a new tyre and 8.3 kg CO2 for a retread. Although

transport impacts for retreading include the collection of casings, the absolute impact

is slightly lower than for new tyres which require long distance import of raw

© Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

materials. Impacts from waste and end of life are relatively low but have been

accounted to reduce the overall carbon footprint of the tyre because the waste

materials displace other fuels and materials in the economy. This approach is

explained in detail in the body of the report.

Figure 1 shows that the impacts of a new tyre account for almost 70% of total retread

impacts (including end of life). This is because the initial manufacturing process and

material used in a tyre casing form the most significant impact of the production of

the retread tyres and therefore these must be accounted for. This accounting means

that the carbon savings from retreading are a result of reusing a tyre casing several

times over. With each re-use cycle the impacts of the casing (manufacture and end

of life) are amortised over the multiple use cycles which therefore account for a

significant net carbon saving.

Figure 0.2 below demonstrates the effect of multiple retread cycles compared to

production of a new tyre. The figure shows the impact per tyre produced and per km

drivena, and demonstrates that with each progressive retread cycle the carbon

footprint decreases.

Figure 2: Relation between the carbon footprint per tyre, per tyre km and the number of tyre

retreads

100 2.500

90

g CO2 per tyre km

80 2.000

kg CO2 per tyre

70

60 1.500

50

40 1.000

30

carbon footprint per tyre

20 0.500

carbon footprint per tyre km

10

0 0.000

new tyre one two three four

retread retreads retreads retreads

This analysis has found that retreading 17.5” tyres improves the carbon efficiency of

tyre production. Retreading requires less inputs than new tyre manufacture at each

stage of a product life cycle. The impacts of the new casing production and end of

life are amortised over retread cycles and the results show that the more times each

casing is retreaded, the bigger the carbon savings achievable by retreading.

aAssumes comparable performance of new and retread tyres. The authors are unaware of

definitive data comparing performance of the two products.

© Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Contents

1 Introduction 2

1.1 Purpose and objectives of the study 2

2 Methodology 3

2.1 Carbon footprint 3

2.2 Scope of the study - definition of boundaries 3

2.3 Calculations 4

2.4 Data quality 6

3 Carbon footprint analysis 8

3.1 Total footprint overview 8

3.2 Materials 9

3.3 Transport 12

3.4 Energy 13

3.5 Waste 14

3.6 End of life 15

4 Interpretation of results and scenarios 17

5 References 20

Appendix 1: Input data and assumptions 21

Page 1 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

1 Introduction

1.1 Purpose and objectives of the study

This document presents the carbon footprint of a remanufactured 17.5” tyre and

compares it with the carbon footprint from production of a new tyre. In this study, the

terms ‘remanufactured’ and ‘retread’ tyres will be used interchangeably as definitions of

tyres produced by resurfacing used casings to produce functional products which can be

used equivalently to new tyres.

Retreading tyres is a proven technique and there are many companies performing the

process. One element of retreading which has not been categorically determined is the

relative eco-efficiencies of the entire lifecycle of retreading compared to new tyre

equivalents. This study was commissioned by the Centre for Remanufacturing and Re-

use to objectively assess the carbon footprint of new and retread 17.5” tyres. The study

was commissioned to cover the entire product lifecycles, and to include CO 2 emissions

but not other greenhouse gases.

Page 2 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

2 Methodology

2.1 Carbon footprint

Carbon footprint analysis is the measurement of carbon dioxide (CO2) emissions from

fossil fuel combustion. Carbon dioxide is an important contributor to climate change and

one of the key greenhouse gases covered by the Kyoto Protocol.

Carbon dioxide emissions occur during the everyday operations of an organisation,

business or enterprise; and include energy use, material flows, and transportation to and

from the workplace. The emissions from products, also called embodied energy, refer to

the amount of energy required to manufacture and supply the product to the point of use.

Individual or household emissions refer to the CO2 generated by the daily lives of people.

2.2 Scope of the study - definition of boundaries

It is critical that project boundaries used in footprint analyses are appropriately defined to

capture all of the impacts associated with the activity under investigation. Although

standards for carbon footprinting exist (including WBSCD’s GHG Protocol, ISO14064

and the draft PAS 2050) there is no absolute guidance for deriving boundaries for a study

of this type. The boundaries of this project therefore encompass all the stages in the life

cycle of a tyre except for the impacts arising from its usage. In order to directly and fairly

compare impacts of retreading and manufacturing, boundaries of both life cycles have to

be consistent. However, because the retreaded product depends on new manufacture

for the casing at its core, the new tyre impacts are nested within the boundaries of the

retread lifecycle.

These boundaries are schematically presented in Figure 3 below, which shows the

relationship between the new and remanufactured lifecycles. The diagram shows that

the retreading lifecycle encompasses new tyre manufacture but additionally includes

dedicated activities for the retreading process. The lifecycle stages for each tyre type are

listed below in Table 1.

Table 1: Comparison of impacts arising from a new and a retread tyre

New tyre Retread tyre

Raw material Raw material

Transport of raw material from the country of Transport of raw material from the country of origin

origin to the manufacturing site to the manufacturing site

Tyre manufacturing Tyre manufacturing

Distribution of new tyres Distribution of new tyres

Collection of used tyres

Raw materials for retread

Transport of retread material

Tyre retreading

Distribution of retreaded tyres

End of life End of life

Page 3 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Figure 3: New and retread tyre lifecycles and project boundaries

Retread

Raw material

material

Transport of retread

Transport of raw material

raw material

Tyre retreading

Tyre

manufacturing

Distribution of Collection of

Distribution of tyres tyres

tyres

Use of tyres

End of life (re-

use , recycle)

IMPACT OF A NEW TYRE IMPACT OF A RETREAD TYRE

2.3 Calculations

The calculation of the carbon footprint was performed by firstly identifying and mapping

out the inputs of each life cycle stage. In the next step conversion factors for each input

were applied to convert material use and energy/fuel consumption into carbon dioxide

emissions.

The objective of the study was to compare remanufacturing to new tyre production. As

explained above, impacts of a new tyre encompass all emissions associated with the

lifecycle while the impacts of tyre retreading consist of dedicated retread inputs and the

Page 4 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

discounted impacts of the casing from the new tyre. Emissions from tyre end of life are

included in the final result and because of the Landfill Directive the different waste

treatment routes must be considered. A full account of the impact of alternative end of

life destinations is included in Appendix 1.

The accounting methodology is critical to the result of the study, and the calculation

methodology is presented in Box 1.

Box 1: Calculation steps for the calculation of the carbon footprint of both tyre types

New tyre

The carbon footprint of a new tyre comes from the emissions from making a new tyre (N)

and those arising from disposing of the tyre at the end of life (EOL). This can be written

as:

New tyre N EOL

The emissions from making a new tyre (N) can be subdivided into transport (T), materials

(M), manufacturing energy (E) and waste (W). Superscript n denotes impacts associated

with a new tyre. Thus the above equation can be rewritten as:

New tyre T n M n E n W n EOL

Retread tyre

The carbon footprint of a retread tyre over its life span can be calculated by adding the

emissions from retreading (R), a portion of those from making a new tyre (N), and a

portion of the emissions from the product end of life (EOL). Unlike a new tyre which is

produced and used once, the retread product can be a function of multiple retread

production cycles. The impact of an average retread tyre can therefore be obtained by

dividing the total lifecycle emissions by the number of production cycles (PC) through

which a retread tyre typically passesb. The carbon footprint of retread tyre can thus be

written as:

N ( PC 1) * R EOL

Re tread tyre

PC

In this equation (PC-1) denotes the number of retread cycles and is used to multiply the

retread inputs (R) required each time. Written out fully the above equation can be

expressed as:

Re tread tyre

T n

M n E n W n PC 1 T r M r E r W r EOL

PC

Superscript r denotes impacts associated with a retread.

Two complex elements of the equations in Box 1 are the production cycles and end of life

are complex elements so it is useful to consider these further.

b The value of PC for a new tyre is equal to 1 and is therefore not shown for the first equation

representing emissions for a new tyre.

Page 5 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

The production cycle (PC) value enables calculation of the average impacts of a typical

retread across its entire lifespan. Tyre casings are made during new tyre manufacture,

and then used as the core unit for resurfacing during retreading. There is a direct

relationship between the number of times a casing is resurfaced, and the resource inputs

related to retread tyre production. If casings are used multiple times, fewer casings are

required and the impact of the initial casing manufacture is amortised across the average

number of production cycles for a retread tyre.

Tyres have been identified as a problem waste stream and it is important to consider end

of life in more detail. Tyres have been excluded from landfill since 2003 when the EU

Landfill Directive was passed. Alternative disposal methods include: incineration of tyres

to produce electricity; incineration of tyres in cement kilns; recycling of materials; and

reusing tyres for physical structures (e.g. landfill engineering, boat fenders, etc). The

waste treatment method has significant implications for the carbon footprint and is

discussed in Section 3.6 and Appendix 1, but the overall calculation methodology

amortises EOL impacts over product cycles. This accounting rule has been used

because retreading casings effectively reduces disposal as the ‘old’ tyres enter the

retread production cycle. Therefore, EOL impacts are amortised in a similar way to ‘new

production’ impacts.

2.4 Data quality

The project was planned with the expectation of receiving primary data on manufacturing

inputs for new and remanufactured tyre production processes. During data collection the

authors were informed that the expected source of primary data for new tyre manufacture

was unable to provide the necessary information. Consequently all data used for new

tyre manufacture has been derived from secondary sources (which largely report results

for car tyres only). In contrast, data for retread inputs have been supplied as primary

data collected in collaboration with Vaculug, one of Europe's largest independent

retreaders of commercial and industrial vehicle tyres.

Table 2.2 presents the data sources and data quality assessment. The unavailability of

primary data for new tyres is a weakness of the study because the secondary data

available is variable in quality, especially in relation to energy required for manufacture.

Furthermore, these data are not specifically for 17.5” tyres so the authors have

extrapolated available data for other tyre sizes. Although this data shortage reduces

confidence in the final outputs, the report has been structured to readily enable input of

primary data for new tyres should this become available.

The data related to retreading has been directly provided by a remanufacturing company.

There is therefore high confidence in the data received, although ideally multiple

remanufacturers’ data would be used to produce average figures.

Page 6 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Table 2: Assessment of data quality

Data quality

Life cycle stage

(red = low, orange = medium, green = high)

1. New tyre Raw material for new tyres Primary data unavailable during study. Wide range of

data sources used to generate average values.

Transport of raw material

Extrapolation of figures from studies of tyres of different

for new tyres

dimensions reduces data confidence.

New tyre manufacturing

Distribution of new tyres Manipulation of primary data obtained from retreader.

Low confidence but consistent for both tyre types.

2. Retread Collection of used tyres Primary data obtained directly from retreader. High

tyre confidence in data quality, although single manufacturer

Raw materials for retread

may not be representative of wider industry

Transport of retread

material

Tyre retreading

Number of production

cycles

Distribution of retread tyres Manipulation of primary data obtained from retreader.

Low confidence but consistent for both tyre types.

3. End of life End of life Treatment methods from secondary reports, EOL

destinations from official UK source. Medium confidence

overall.

Page 7 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

3 Carbon footprint analysis

3.1 Total footprint overview

Carbon footprints of a new and a retread 17.5” tyre are obtained by applying the formulae

developed in the previous chapter. The analysis shows that a new tyre produces 86.9 kg

CO2 emissions, while a retread is responsible for 30% less emissions with a total of 60.5

kg CO2 per tyre. Retread impacts calculated in this study are specific to a tyre that has

been retreaded 1.3 times (from primary data) and this figure will vary for different

retreaders and tyre types.

The breakdown of the carbon footprint of a new and a retread tyre are presented in Table

3.1. This allows comparison of impacts arising from different product stages. It shows

that the embodied carbon of materials is the largest component for both tyres accounting

for more than 50% of the total impact. It is responsible for 49 kg of CO2 in new tyres

compared to 31 kg CO2 in retreads.

The second largest impact is attributed to the energy needed in the manufacturing and

retreading process. The energy used to manufacture a new tyre produces 31 kg CO2,

while retread energy is 22 kg CO2.

The footprint of transport is roughly the same for both tyre types. In total transport

emissions add almost 10 kg CO2 for a new tyre and over 8 kg CO2 for a retread. The

higher emissions for transport of new tyres come from the long distance import of raw

materials from overseas.

In total the impact of production waste from both tyres is low. The production process

generates very little waste and the waste rubber material is useful in other applications

with little additional processing.

End of life emissions are accounted with consideration of the final destination and of old

casings. In some instances, waste tyres may act as a more carbon efficient substitute

and can therefore be shown to contribute to a reduction of the overall footprint. End of

life destinations are discussed in detail in Appendix 1, but the largest net savingc is

derived from displacing coal with tyres as a fuel in cement kilns.

Results show that remanufactured tyres are overall more carbon efficient to produce than

new tyre equivalents. The distribution of the carbon footprint for discrete components of

each tyre type is presented in Table 3 and demonstrated graphically in Figure 4

cDisposing of tyres is not a ‘carbon positive’ activity as such. The study accounts for the impacts

of producing tyres at earlier life cycle stages and these are significant. However, when examining

end of life only, net savings can be attributed to tyres through displacement of other

fuels/materials.

Page 8 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Table 3: Carbon footprint of a new and a retread tyre

New tyre Retread tyre

Retread total Casing Retreading process

Total impact kg CO2 % kg CO2 % kg CO2 % kg CO2 %

Materials 48.6 55.7 31.1 51.2 21.1 55.6 10.0 43.9

Transport 9.9 11.3 8.3 13.7 4.3 11.3 4.0 17.7

Energy 31.4 36.0 22.5 37.1 13.6 35.9 8.9 39.0

Waste -0.1 -0.1 -0.1 -0.2 0.0 0.1 -0.2 -0.7

End of life -2.5 -2.8 -1.1 -1.8 -1.1 -2.8 - -

Total carbon

87.2 100 60.7 100 38.0 100 22.7 100

footprint

Note: numbers may not add up due to rounding.

Figure 4: Carbon footprint of a new and a retread tyre

100

90 End of life

80 Waste-retread

R

70 E

Energy-retread

T

60 R

kg CO2 per tyre

Materials-retread E

50 A

D

Transport-retread

40

30 Waste

20 Energy

N

E

10

Materials W

0

new tyre retread Transport

-10

3.2 Materials

Tyre manufacturers produce different tyre types for different weather conditions, loads

and road conditions. To make a tyre suitable for most conditions manufacturers use

composite/blended materials so it is very difficult to typify an “average” tyre. The

composition of the new tyre used for this study is based on publicly available sources

and the authors recognise that the robustness of the study would be improved with direct

data from manufacturers. Conversely, data on material needed for a tyre retread is

based on information provided directly by Vaculug. The type and quantities of material

inputs are presented in Table 4 below.

Page 9 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

The total weight required for the new tyre is almost three times that of the retread. The

main material savings attributed to retreading are a result of not needing to manufacture

the casing (effectively reusing the steel and textile components) which account for a

substantial part of a tyre’s structure and weight.

Table 4: Structure and weight of material components need for manufacturing a new and a retread 17.5”

tyre

New tyre Retread tyre

Material Weight (kg) Structure (%) Weight (kg) Structure (%)

Synthetic rubber 3.8 14.5 3.3 37.4

Natural rubber 8.1 30.5 0.3 3.7

Carbon black 5.8 22.0 3.0 33.5

Steel 6.6 25.0

Rayon/polyester 0.5 2.0

Plasticizers (oils and 1.8 20.2

resins)

Zinc oxide 0.3 1.0

Sulphur 1.3 5.0

Other 0.5 5.2

Total 26.5 100 8.9 100

When the materials figures are translated into carbon dioxide emissions the result for a

new tyre is 48.6 kg CO2 and for a retread is 31.1 kg CO2 of which old casing is

responsible for 21.1 kg while the remaining 10 kg CO2 are attributed to the

remanufacturing process. The carbon footprint of retread materials is about 35% smaller

than for new tyres. Lower material consumption represents the first carbon saving that

can be attributed to retreading.

Table 5: Carbon Footprint per tyre

New tyre Retread tyre

Retread total Casing Retreading

process

kg % kg CO2 % kg CO2 % kg %

CO2 CO2

Synthetic rubber 16. 33. 15.1 48.7 7.1 33.6 8.0 80.6

3 6

Natural rubber 12. 25. 5.7 18.3 5.4 25.6 0.3 2.9

4 6

Carbon black 4.7 9.7 3.4 11.0 2.1 9.8 1.4 13.8

Steel 12. 24. 5.2 16.9 5.2 24.8 0

1 8

Rayon/polyester 2.9 6.0 1.3 4.1 1.3 6.0

Plasticizers (oils and 0.0 0.0 0.2 0.7 0.0 0.0 0.2 2.2

resins)

Zinc oxide 0.1 0.2 0.0 0.1 0.0 0.2 0

Other 0.0 0.0 0.1 0.2 0.0 0.0 0.1 0.6

Total 48. 100 31.1 100 21.1 100 10. 100

6 0

Note: figures may not add up due to rounding.

The highest materials impact can be attributed to synthetic rubber in both tyre types. It

accounts for almost half of the carbon impact of a retread tyre and almost a third for a

new tyre. The second and the third largest materials impacts come from natural rubber

and steel. These are each responsible for around 25% of new tyre material emissions

and just under 20% for a retread tyre. Carbon black accounts for about 10% of the

Page 10 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

material impacts for both tyres, and the impact of other materials is relatively small. All of

these results are presented graphically in Figure 5 and Figure 6 below.

Figure 5: Carbon footprint of materials of a new tyre

Carbon black Steel

10% 25%

Rayon/polyester

6%

Zinc oxide

Natural rubber <1%

26%

Sulphur

<1%

Synthetic rubber

33%

Figure 6: Carbon footprint of materials of a retread tyre

Carbon black

11% Steel

Natural rubber 17% Rayon/polyester

18%

4%

Sulphur

<1%

Zinc oxide

<1%

Other

Synthetic rubber components

49% <1%

Figure 7: Carbon footprint of materials of a retread tyre (casing only)

Carbon black Steel

10% 25%

Rayon/polyester

6%

Sulphur

<1%

Natural rubber

26% Zinc oxide

<1%

Other

components

Synthetic rubber <1%

33%

Page 11 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Figure 8: Carbon footprint of materials of a retread tyre (retreading process)

Natural rubber

3%

Carbon black

14%

Other

components

Synthetic rubber 3%

80%

A direct comparison of each material by weight and carbon footprint is shown in Figure

3.6 below. The figure compares the weight of materials (required to produce a new tyre)

and their corresponding carbon footprint. The purpose of this graph is to show that

weight and carbon intensity are not necessarily correlated. The highest impact materials

per kg include synthetic rubber, steel and rayon/polyester.

Figure 9: Comparison of material weight with carbon footprint (data for new tyre)

% of total weight/carbon footprint

40

35

30

25

20 weight

15

10 carbon

5 footprint

0

r

er

ur

e

k

l

be

te

ee

id

ac

bb

h

es

ox

b

lp

St

bl

ru

ru

Su

ol

on

nc

tic

l

ra

/p

Zi

b

he

on

ar

at

nt

ay

N

Sy

3.3 Transport

The carbon footprint of transport comes from bringing raw materials from the

manufacturing site, distribution of final tyre products, collection of casings (for retread

only), and collection of tyres for disposal. These separate activities are presented in Table

6 below.

Primary data was not available for either tyre types, for the distribution of the final

products to market or the collection of tyres for disposal. The shortage of primary data

for new tyres has been discussed, and for distribution and disposal the impacts were

assumed to be the same for both tyre types. In reality, distribution emissions may vary

considerably if new tyres are manufactured abroad but for this study a conservative

position (i.e. consistent figures for both types) was adopted when data was unavailable.

Page 12 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Table 6: Impacts of transport related to a new and a retread tyre

Transport New tyre Retread tyre

Transport of raw Transport of raw materials required Transport of raw materials required

materials for construction of a new tyre. for construction of a new tyre and

transport of raw materials required

for a retread.

Distribution of tyres Distribution of finished tyres to authorised sellers.

Collection of retread N/a Collecting tyres for retreading.

tyres

Collection of old tyres Collecting tyres for disposal.

Table 7 below shows that the largest portion of the transport footprint is related to the

transportation of raw materials. These figures were derived using primary data where

available, and assumptions based on common production centres for materials of

unspecified origin. The methodology used to derive these figures is shown in Appendix

1. Retreading requires smaller quantities of material than making a new tyre and

consequently produces a smaller transport footprint.

Collecting old tyres for disposal contributes about 20% of transport impacts for both tyre

types. Collection of old casings for retreading has a relatively small impact, shown by the

low fuel use per casing collected (about 0.6 litres diesel). In other words, the logistics of

casing collection is very fuel efficient and therefore does not significantly add to the

remanufacturing footprint.

Overall, transport associated with retreads contributes further savings compared to new

tyres even accounting for the collection of casings.

Table 7: Transport carbon footprint

New tyre Retread tyre

Retread total Casing Retreading

process

kg CO2 % kg CO2 % kg CO2 % kg CO2 %

Transport of raw material 6.1 62.1 3.6 43.5 2.7 62.1 1.0 23.7

Collecting casings for / / 1.0 11.5 / / 1.0 23.8

retreading

Distribution of 2.0 20.7 2.0 24.6 0.9 20.7 1.2 28.7

new/retread tyres

Collecting old tyres for 1.7 17.2 1,7 20.4 0.7 17.2 1.0 23.8

disposal

Transport 9.9 100 8.3 100 4.3 100 4.0 100

Note: figures may not add up due to rounding.

3.4 Energy

Energy is required for new manufacturing and retreading tyres. Retreading is taking

place in the UK and, without primary data for new tyres, it was assumed that

manufacturing of a new tyre also took place in the UK (for consistent analysis).

Production is an extensive process during which different materials and components are

combined to produce the final product.

Secondary data sources were used for the manufacturing energy for new tyres. A

number of reports were consulted but the authors only felt sufficiently confident in one

Page 13 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

result which was a report commissioned for Environment Australiad. This report

measured the energy inputs for several different tyre sizes which were scaled up or down

to account for the 17.5” tyre focussed on in this study. The carbon intensity of Australia

differs from the UK so adjustments were also made here, all of which are explained in

Appendix 1. These figures were proportionally scaled down to derive results for the 17.5”

tyre weighing 26.5 kg. As a result of applying this assumption, emissions arising from

energy for production of a 17.5” new tyre were calculated as 31 kg CO2.

Data on the energy required to retread a tyre was obtained directly from Vaculug and

shows that retreading a tyre consumes 13.69 kWh of electricity and 41.57 kWh of gas

producing 15.56 kg CO2 in total. As explained in section 2.3, after including the energy

inputs for making a new tyre (amortised over the use cycles) the energy emissions for a

retread tyre are more than 22 kg CO2. Table 3.6 has the results for both tyres, and

shows retreading of a 17.5” tyre saves approximately 8 kg CO2 per tyre from reduced

energy demand.

Table 8: Carbon footprint from energy (kg CO2)

New tyre Retread tyre

Total retread Casing Retreading process

Energy 31.4 22.5 13.6 8.9

3.5 Waste

Waste is accounted as a residual material that is generated in the production process but

is not part of the product and is subsequently landfilled or recycled. This section does

not include end of life impacts, which are described in Section 3.6.

To estimate the quantity of waste arising from the new tyre manufacturing, secondary

datae was extrapolated to apply to a 17.5” tyre. This estimation calculated that producing

a new tyre was responsible for over 0.4 kg of waste, which was either landfilled, recycled

or re-use d.

Data from Vaculug shows that the retreading process generates 71,455 kg of buffing

dust (5 kg per tyre). This dust is all recycled as an input material for matting. Other

waste generated from the site includes 643 kg of plastic packaging and 972 kg of pallets

which are recycled.

Tyre waste has valuable properties which make it useful for other applications. If this

material is used as an input to other products it reduces/eliminates the need for other

material inputs which can be accounted for as a ‘saving’ through displacement. The

degree of saving is calculated as the difference between the emissions needed to

produce the material that is being displaced, and the emissions needed to make the

waste material a suitable input. This methodology means that tyre waste has scope for

reducing the footprint, particularly for retreads because the rubber removed by buffing

can be used for surfacing.

Primary data on waste from new tyre manufacture was not available, but secondary

sources show it is of mixed materials and relatively low volume. This waste is assumed

dhttp://www.environment.gov.au/settlements/publications/waste/tyres/national-

approach/pubs/national-approach.pdf

e

AEA Technology Environment, Overcoming Market Barriers for Key Stakeholders in Retread

Tyre Markets, 2003

Page 14 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

to go to mixed disposal routes, and is responsible for some additional emissions. Owing

to the absence of new tyre data, the known impact of production waste for retread tyres

was applied consistently to both tyre types. This extrapolation appears justifiable for

such a low (arguably de minimis) impact

Table 8: Carbon footprint of waste

Carbon footprint (kg CO2)

New tyre Tyre retread

Waste -0.1 -0.1

3.6 End of life

The EU Landfill Directive states that tyres cannot be landfilled and therefore other

methods of disposal must be used. Using data from the Used Tyre Working Group

(UTWG)f the main end of life options for tyres were identified:

Re-use for purposes such as motorway embankments, crash barriers, various

marine applications (erosion control, artificial reefs), tree guards, fences.

Retreads (remoulds).

Reprocessing and recycling by shredding granulating or crumbling old tyres in

order to use them in other applications (sports and play surfaces, shoe soles,

carpet backing/underlay, adhesives, road surfacing.

Burning (energy recovery) to produce energy

Landfill engineering.

In order to make the lifecycles of new and retread tyres comparable in this study, the

‘retread’ destination was excluded and is included in the accounting methodology used.

The end of life emissions of a tyre were determined by calculating the weighted average

of the alternative destinations. As waste tyres can be used in different applications their

disposal is likely to reduce the need for the use of other materials. A consistent

approach was used as for waste above, whereby the waste value was calculated as the

difference between the emissions needed to produce the material that is being displaced,

and the emissions needed to make the waste material a suitable input. Examples

include: incineration of tyres replacing coal in cement kilns; or re-use of tyres (landfill

engineering, guards, embankments) in place of other materials. It is not easy to readily

determine what materials old tyres replace in all instances, so for some routes (e.g.

landfill engineering) the displacement value used was zero. Detailed explanations of the

calculations completed are presented in Appendix 1.

The net savings from end of life are primarily achieved by using tyres in place of coal in

cement kilns. This net saving is derived because the carbon intensity of whole tyres is

77kgCO2/GJ compared to 90kgCO2/GJ for thermal coalg. However, as stated in Section

f

www.tyredisposal.co.uk

g

http://www.environment.gov.au/settlements/publications/waste/tyres/national-

approach/pubs/national-approach.pdf

Page 15 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

3.1, the ‘savings’ attributed to end of life are net values which apply only to this final

stage of the lifecycle and the entire lifecycle must be considered when drawing

comparisons.

The accounting methodology amortises end of life for retreads over average casing

cycles (as explained in Section 2.3). Effectively, this means there is less displacement of

coal ‘per retread tyre’ so the net saving is lower, as shown in Table 3.8.

Table 9: Carbon footprint of the end of life

Carbon footprint (kg CO2)

Retread tyre New tyre

End of life -1.1 -2.5

Page 16 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

4 Interpretation of results and

scenarios

The analysis has found that producing tyres by retreading emits less carbon dioxide than

manufacturing new tyres. The savings arising from different lifecycle stage stages are

presented in Figure 10 below (excluding end of life). It shows that the greatest savings

are associated with materials and then energy for retreading compared to manufacturing.

Figure 10: Comparison of retreading and manufacturing impacts (end of life impacts are excluded)

100

90

80

70

60 retread tyre

new tyre

50

40

30

20

10

0

-10 Transport Material Energy Waste Carbon footprint

The material savings for retreading are derived from reusing the casing which has been

previously manufactured. This means that the more often a casing is re-use d the more

carbon savings accrue. It is useful to therefore investigate the effects of increasing the

number of retread cycles per casing, and Figure 11 presents the comparison by lifecycle

stage for tyres that were retread one, two, and three times. It shows that with an average

of three retreads, emissions from tyre production can be reduced to 51.8kg CO2

(compared to 86.9 kg CO2 for a new tyre). There will be a limit to the number of cycles

for which the casing’s integrity remains intact, but the data shows the clear benefit of

extending the casings’ lifespans.

Figure 12 presents the carbon footprint per km driven by a tyre. Data from Vaculug

estimated that a new tyre can last for 45,000 km and the same distance can be covered

with every retread products irrespective of age. This shows the impact of a new tyre is ~

2 g CO2 per km while the impact of at tyre that has been retread 1.3 is approximately 1.3

grams of CO2 per km.

Figure 13 plots the footprints of the casing, new tyre and retread tyre alongside the

footprint for the retreading process The figure clearly shows that with successive retread

cycles, the emissions from the casing become lower and thus achieve greater reductions

in emissions for the retread tyre.

Page 17 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Figure 11: Comparison of impacts associated with the different number of retreads

100

90

80

70

End of life

60

Waste-retread

kg CO2 per tyre

Energy-retread

50

Materials-retread

Transport-retread

40

Waste

Energy

30

Materials

Transport

20

10

0

new tyre one retread 1.3 retreads two retreads three retreads

-10

Note: In order to present all footprint components simultaneously, the net savings from end of life are

presented below the x-axis. Although listed elsewhere, the total footprint of a tyre can be obtained by

adding the negative end of life impacts from the footprint shown above the x axis.

Figure 12: Carbon footprint reduction related to number of retreads

100 2.500

90

g CO2 per tyre km

80 2.000

kg CO2 per tyre

70

60 1.500

50

40 1.000

30 carbon footprint per tyre

20 0.500

carbon footprint per tyre km

10

0 0.000

new tyre one two three four

retread retreads retreads retreads

Page 18 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Figure 13: Carbon footprint of different stages of a tyre re-use

100

90

casing

80

retread

70

kg CO2 per tyre

new tyre production

60

retreading process

50

40

30

20

10

0

s

ad

re

s

s

ad

ad

ad

ty

t re

t re

tre

tre

w

re

ne

re

re

re

e

ur

e

on

re

tw

fo

th

number of tyre reuses

This study has found that retreading offers significant carbon savings over a tyre lifecycle

in comparison to new tyre manufacture. There are a number of critical elements to this

study which determine this outcome and where further research should be focussed to

increase confidence in the result. These include:

the data used for new tyre production was from secondary sources and had to

be manipulated to apply to 17.5” tyres

retread data came from a single manufacturer and would be expected to vary

across organisations

the number of retread cycles is a highly sensitive factor in determining the

carbon efficiency of retreading

this analysis does not consider tyre performance, and further work should link

production impacts to lifespan and durability in use.

Page 19 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

5 References

AEA Technology Environment, Overcoming Market Barriers for Key Stakeholders in

Retread Tyre Markets, 2003

Atech Group, A National Approach to Waste Tyres,2001

http://www.environment.gov.au/settlements/publications/waste/tyres/national-

approach/pubs/national-approach.pdf

Krömer, S., Kreipe E., Reichenbach D., Stark, R., Life cycle assessment of a car tyre,

Continental, 1999

Pre Consultants B.V., Life cycle assessment of an average European car tyre, 2001

Environmental Commitment and performance, Bridgestone Europe, 2007

http://www.bridgestone.eu/English/Global/FILES/LEGACY/PR/Corporate/2007/Environm

entbrochure.pdf

Last accessed 07 February 2008

Truck Tyre Basics, The materials that make up a truck tyre

http://www.conti-

online.com/generator/www/uk/en/continental/transport/themes/technical_information/liter

ature/download/tyrebasics_materials_pdf_en.pdf

Last accessed 03 February 2008

http://brookes.ac.uk/eie/tyres.htm

Last accessed 07 February 2008

http://www.retread.org/packet/index.cfm/ID/284.htm ;

Last accessed 01 February 2008

http://www.etrma.org/pdf/Retreading_process.pdf

Last accessed 24 January 2008

http://www.bandvulc.com/EnvironmentalBenefits.aspx

Last accessed 08 February 2008

http://www.etyres.co.uk/tyre-construction

Last accessed 05 February 2008

2005 UTWG statistics document, www.tyredisposal.co.uk

Last accessed 14 February 2008

http://www.wasteonline.org.uk/resources/Wasteguide/mn_wastetypes_tyres.html

Last accessed 07 February 2008

http://www.wasteonline.org.uk/resources/InformationSheets/vehicle.htm

Last accessed 29 January 2008

Page 20 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Appendix 1:

Input data and assumptions

Data and uncertainty

Footprint analyses are data driven processes, and the reliability of results is ultimately

determined by the input data used.

The quality of data supplied on retreading was very good and collected directly from

onsite operations at Vaculug. However, caution should be used when interpreting

results which are based on data from a single remanufacturer.

The authors were unable to gather primary data from a new tyre manufacturer for this

project. Consequently, the study progressed using publicly available secondary data

and BFF recognise this as a weakness of the study. Follow up work in this area should

prioritise ensuring supply of accurate and reliable primary data to supplement the results

for new tyre manufacture.

Caution with result interpretation

The conversion factors used for calculating footprints are constantly changing as new

studies are completed and data released from official sources. BFF commits to having

the most up to date information available. As a reader of this report, you should realise

that the conversion factors used were appropriate at the time of writing but may be

subject to change in the future.

This study considered carbon dioxide emissions only in line with the agreement made

during commissioning. Recent developments in environmental accounting (including the

draft PAS 2050) guide practitioners to account for all greenhouse gases, not just carbon

dioxide. BFF would encourage further studies to extend the scope of work to include all

greenhouse gases, although this data may not be readily available for all materials.

Assumptions

Material assumptions

Information on new tyre materials came from public sources as listed in the References

section. The central source used for the study was the material specification of a

Bridgestone truck tyreh. Information about the quantities of materials used in the

retreading process was provided directly by the tyre remanufacturing company ‘Vaculug’.

The average weight of a 17.5” retread tyre used in this study was 26.5 kilograms.

hhttp://www.bridgestone.eu/English/Global/FILES/LEGACY/PR/Corporate/2007/Environmentbroch

ure.pdf

Page 21 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Energy assumptions

Data on energy required to manufacture a new tyre has been based on the Australian

report: “A National Approach to Waste Tyres”. This estimated an energy requirement of

553 MJ (153.6 kWh) to produce a 45 kg tyre. It was assumed that energy used in tyre

manufacture comes from oil and electricity (in the ratio stated on energy consumption in

the AEA report). By applying conversion factors the whole process produced more than

53.2 kg of CO2. In order to derive emissions for the 17.5” tyre, emissions were

appropriately scaled down proportional to tyre dimensions to produce 31.3 kg CO2. The

necessity to manipulate and derive energy data in this way is a weakness in the study

caused by the lack of primary data from the manufacturer.

Energy required to produce a retread tyre was provided by Vaculug. Overall energy

figures (electricity and gas) for the remanufacturing site were collected and allocated to

the 17.5” production line.

Waste assumptions

Figures for waste produced for a new tyre were derived from the AEA report for an

average car tyre. Since a 17.5” tyre is more than three times as heavy as a car tyre,

these figures were scaled up accordingly. Then the weights were multiplied by

appropriate conversion factors to reflect the impact of the various waste management

options.

Waste from new tyre production is composed of a mix of the material needed for the

construction of a tyre. The impact of landfilling is accounted for by the transport of these

materials to landfill only. For recycling, it was assumed that steel and textiles were

recycled in equal proportions. Rubber compounds were assumed to go for incineration

and these impacts were calculated as the difference between burning rubber in place of

coal.

Data obtained from Vaculug was used to calculate footprints associated with waste

arising from the retread process. The main waste arising from tyre retreading is buffing

dust which displaces other materials used in manufacturing matting.

Transport assumptions

In order to derive emissions from the transport of raw materials for different assumption

have been made. The majority of the input materials used in both tyre types have been

transported by road and sea from overseas. Tables A1.1 and A1.2 show the

assumptions made about transport for new and retread tyres respectively.

Page 22 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Table A1.1: Transport assumptions – New tyre

Country of Distance by Distance by

Material City Mode of transport

origin road (km) sea (km)

Synthetic rubber Russia Kazan Ship & Road transport 5,063 41

Natural rubber Brasil Manaus Ship & Road transport 230 8,966

Carbon black Egypt Alexandria Ship & Road transport 230 5,446

Coated wires (steel) China Jiangsu Ship & Road transport 230 19,086

Other Netherlands Eijsden Ship & Road transport 641 41

Zinc oxide Netherlands Eijsden Ship & Road transport 641 41

Rayon India Mumbai Ship & Road transport 230 11,301

Table A1.2: Transport assumptions – retread tyre

Distance Distance

Material Country of origin City Mode of transport by road by sea

(km) (km)

Natural Rubber Ship & Road 295 7.322

West Africa (Nigeria)

transport

Synthetic 117 0

United Kingdom West Bromwich Road transport

Elastomer SBR

Synthetic 351 254

Netherlands Antwerp Road transport

Elastomer BR

Carbon Black Ship & Road 511 9.038

Mexico Mexico City

transport

Process Oil Germany Hamburg Road transport 351 713

Others Germany Hamburg Road transport 351 713

End of life

Data on tyre end of life is taken from the Used Tyre Working Group (UTWG)i and for the

analysis the latest available data (2005) were used.

The main options for used tyres were landfill engineering, re-use, recycling, retreading

and energy recovery. The data available showed retreading as one of the end of life

options so for this study (to make impacts of retreading and manufacturing comparable)

tyres destined for retreading were proportionally divided among the remaining four

alternatives. The end uses of tyres are presented in table A1.3 below.

i

http://www.tyredisposal.co.uk/cms/index.php

Page 23 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

Table A1.3: End of life uses of used tyres

Weight (tonnes) %

Re-use 101,488 22

Recycling 186,073 41

Landfill engineering 67,559 15

Energy recovery 98,189 22

Total 453,308 100

Source: UTWG (2005), own calculations.

The carbon footprint of the tyre end of life impacts was obtained by the weighted average

of impacts associated with the different the end of life options. The impact of re-use is

difficult to determine because of the range of materials the tyres can displace. Therefore

the impact of re-use was assumed to be zero on the basis that the emissions from

transportation of tyres to site cancel out the benefits of displacing other (low grade)

material that would be used otherwise.

Similarly to re-use , recycling waste tyres enables displacement of a new material.

Savings arising from recycling waste tyres were obtained by deducting the impact of

shredding the old tyres from the displacement of new rubber.

Conventional conversion factors for landfill impact were used for landfill engineering.

Impacts from energy recovery were obtained by deducting emissions from burning coal

in cement kilns from the emissions that arise from burning tyres. As tyres have high

calorific content than and lower carbon intensity than coal they are a valuable fuel source

in cement kilns. Thus the impact of burning tyres is lower than the current alternative of

burning coal, but would not compare favourably if cement kilns obtained their energy

from alternative, low carbon (or renewable) sources. If gas or renewable fuels were

used commonly then incinerating tyres would further add to their impact.

Page 24 of 24 © Centre for Remanufacturing and Reuse

Used under Creative Commons license

http://creativecommons.org/licenses/by-nc-sa/2.0/uk/

You might also like

- EMS LAC ExamDocument27 pagesEMS LAC ExamAzhar GulzarNo ratings yet

- SOP 02 Yard Operations PDFDocument4 pagesSOP 02 Yard Operations PDFakhmadbay0% (1)

- This Form Must Be Completed For Each Container Destuffing. A Copy Must Be Annexed To The File Related To The ContainerDocument1 pageThis Form Must Be Completed For Each Container Destuffing. A Copy Must Be Annexed To The File Related To The ContainerdnmuleNo ratings yet

- 5387843-Quantum Tantra - DMT-Extraction PDFDocument30 pages5387843-Quantum Tantra - DMT-Extraction PDFdhfdhgfNo ratings yet

- Monthly Environmental Monitoring Report April 2017 - 163ADocument6 pagesMonthly Environmental Monitoring Report April 2017 - 163ADaniel KariukiNo ratings yet

- Technical Guideline No 8 Hazardous Waste DisposalDocument17 pagesTechnical Guideline No 8 Hazardous Waste DisposalJahubar SadiqueNo ratings yet

- Spill Response Procedure: Immediately Notify SupervisorDocument4 pagesSpill Response Procedure: Immediately Notify SupervisorMedimlight PopoNo ratings yet

- Presentation For RiggingDocument18 pagesPresentation For RiggingRameese MuhammedNo ratings yet

- Best Practice Guide For Environmental Protection On Construction SitesDocument216 pagesBest Practice Guide For Environmental Protection On Construction SitesWL TamNo ratings yet

- Bash-P General CatalogueDocument123 pagesBash-P General CatalogueAri Rizki RivaldoNo ratings yet

- Traffic Management & Road SafetyDocument51 pagesTraffic Management & Road SafetyHemant Tiwari67% (3)

- Nitotile 489Document2 pagesNitotile 489Venkata RaoNo ratings yet

- Tyre Stock RegisterDocument35 pagesTyre Stock RegisterSalman KhanNo ratings yet

- Road Tire Safety Your Life Rides On It: Saudi Aramco: Company General UseDocument2 pagesRoad Tire Safety Your Life Rides On It: Saudi Aramco: Company General UseicNo ratings yet

- KQLP Safety Management Plan Draft Web2Document284 pagesKQLP Safety Management Plan Draft Web2Arthur OllivierreNo ratings yet

- Guide 02-Fire Safety PDFDocument143 pagesGuide 02-Fire Safety PDFAhmad SamhanNo ratings yet

- Higg Index-Water Module: - Why It Is Used As Business Tool and - How To Score in ItDocument36 pagesHigg Index-Water Module: - Why It Is Used As Business Tool and - How To Score in Itshahed81No ratings yet

- 594 MeDocument2 pages594 MeMuhammad Bin Abdul AzizNo ratings yet

- Ground Water Information Booklet of Idukki District, Kerala StateDocument26 pagesGround Water Information Booklet of Idukki District, Kerala StateReshab RathiNo ratings yet

- Accounting & Financial Management: Finance ReportDocument37 pagesAccounting & Financial Management: Finance ReportNabeel AshrafNo ratings yet

- HSE Monthly PerformanceDocument12 pagesHSE Monthly PerformanceMD AZHER ULLAH BAIGNo ratings yet

- L4.Plant Layout and Material HandlingDocument9 pagesL4.Plant Layout and Material HandlingTharaka PathiranaNo ratings yet

- SASB Standards - Auto-Parts-Standard - En-GbDocument20 pagesSASB Standards - Auto-Parts-Standard - En-GbbhanuprakashbadriNo ratings yet

- Waste Management PlanDocument56 pagesWaste Management PlanmuhaiminNo ratings yet

- IGES GRID EF v10.10 20210223Document395 pagesIGES GRID EF v10.10 20210223AakashNo ratings yet

- Air Quality AssessmentDocument45 pagesAir Quality Assessmentفردوس سليمانNo ratings yet

- ECE R117 Rev4 PDFDocument111 pagesECE R117 Rev4 PDFRanjith RNo ratings yet

- JIWG CAR-SOIL Guidance - July 2016 FINAL Publication - UploadedDocument139 pagesJIWG CAR-SOIL Guidance - July 2016 FINAL Publication - UploadedMarko CastañedaNo ratings yet

- EHS LegislationsDocument1 pageEHS LegislationsdipilkumarNo ratings yet

- Final First-NDT&LIFTING INSPECTION DIVISIONDocument12 pagesFinal First-NDT&LIFTING INSPECTION DIVISIONAhmed ElsayedNo ratings yet

- Inspection Report Offshore Oilboom Asset Saka Pangkah, LTDDocument13 pagesInspection Report Offshore Oilboom Asset Saka Pangkah, LTDsayajaswadiNo ratings yet

- SKPB HsemsDocument67 pagesSKPB Hsemsjihad jamareiNo ratings yet

- BS 349Document13 pagesBS 349kaiyoomNo ratings yet

- MSDS Knauf Gypsum BoardsDocument5 pagesMSDS Knauf Gypsum BoardsAmir SohailNo ratings yet

- HIRA Relevant Statutes StandardsDocument40 pagesHIRA Relevant Statutes StandardsAdil BeigNo ratings yet

- EPI-QEP Guide 2006Document20 pagesEPI-QEP Guide 2006Nada HajriNo ratings yet

- SP-27 - Noise Survey ReportDocument4 pagesSP-27 - Noise Survey ReportRahil QamerNo ratings yet

- Dms - Cruching IbraDocument5 pagesDms - Cruching Ibrakmohamedkeita906No ratings yet

- Personal Protective Equipment Indian StandardsDocument3 pagesPersonal Protective Equipment Indian StandardsNoor Muddassir KhanNo ratings yet

- Measuring Safety Performance Guidelines For Service ProvidersDocument24 pagesMeasuring Safety Performance Guidelines For Service ProvidersAyyaj MujawarNo ratings yet

- ForkliftDocument1 pageForkliftnellaika puspa dewiNo ratings yet

- Construction Waste Management: Hotel Jen, Penang - 26.9.2018 - Baylon ThamDocument45 pagesConstruction Waste Management: Hotel Jen, Penang - 26.9.2018 - Baylon ThamTory LowNo ratings yet

- Environmental Guidelines For Concrete Batching Plants 2016Document11 pagesEnvironmental Guidelines For Concrete Batching Plants 2016Zainal AbidhynNo ratings yet

- TOKICO - Presentation of Fuel DispenserDocument45 pagesTOKICO - Presentation of Fuel DispenserbangladetNo ratings yet

- 3 (This Document Contains Pages Excluding Annexure)Document3 pages3 (This Document Contains Pages Excluding Annexure)krish659No ratings yet

- IRC:012-1983 Fuel StationsDocument8 pagesIRC:012-1983 Fuel StationsDevela AvinashNo ratings yet

- Topic 5 Lifting Q11 - 230719 - 105008Document3 pagesTopic 5 Lifting Q11 - 230719 - 105008Mohammad Aquil BegNo ratings yet

- Less Then 1D Ops CAP437Document8 pagesLess Then 1D Ops CAP437Adnan Haji Harbi100% (1)

- Energy Use in Local Authority BuildingsDocument28 pagesEnergy Use in Local Authority BuildingsMaggie FossbergNo ratings yet

- 1 1519 Combined EIADocument1,213 pages1 1519 Combined EIADJchunautiNo ratings yet

- 20W40 MSDSDocument2 pages20W40 MSDSAbhinav SrivastavaNo ratings yet

- CREP GuidelinesDocument32 pagesCREP Guidelinesamol76No ratings yet

- Sist Iso 4346 1997Document5 pagesSist Iso 4346 1997Guilherme Ferrari100% (1)

- Cheklist 02Document1 pageCheklist 02Jawad RafiqNo ratings yet

- Survey of Conveyor BeltDocument5 pagesSurvey of Conveyor BeltAashish LambaNo ratings yet

- Environmental Management Monitoring PlanDocument4 pagesEnvironmental Management Monitoring PlanMekonen YeteshaNo ratings yet

- Departmental Safety Inspection Checklist PDFDocument518 pagesDepartmental Safety Inspection Checklist PDFBorislav VulićNo ratings yet

- Prod and Upgrading of Recovered Carbon Black 2022Document19 pagesProd and Upgrading of Recovered Carbon Black 2022yasirNo ratings yet

- Sustainability 14 15820Document8 pagesSustainability 14 15820imranasaif.aercNo ratings yet

- DR Pal Chana - UKIERI Congress Mar 2011Document32 pagesDR Pal Chana - UKIERI Congress Mar 2011Ashok Kumar TiwariNo ratings yet

- Waste Tires Pyrolysis Oil As A Source of Energy: Methods For RefiningDocument15 pagesWaste Tires Pyrolysis Oil As A Source of Energy: Methods For RefiningCarlosCristobalNo ratings yet

- RCI Hand Out Chapter 4 - PPT - 4.2 One Way Ribbed SlabDocument46 pagesRCI Hand Out Chapter 4 - PPT - 4.2 One Way Ribbed SlabNathnael Jia100% (3)

- B-Pharmacy 8 Sem sch130112071615Document1 pageB-Pharmacy 8 Sem sch130112071615Varun GuptaNo ratings yet

- Stars and Constellation Reviewer Earth SciDocument3 pagesStars and Constellation Reviewer Earth SciClarence DeitaNo ratings yet

- Questions UnansweredDocument4 pagesQuestions UnansweredAhmad KhanNo ratings yet

- Recycling Thesis IntroductionDocument8 pagesRecycling Thesis Introductionleannehoopernorman100% (1)

- Manual Bci en v1-0Document51 pagesManual Bci en v1-0Ahmed HamidNo ratings yet

- Wastewater EngineeringDocument57 pagesWastewater EngineeringAl RomanoNo ratings yet

- Effect of Quenching and Tempering On Microstructure and Mechanical Properties of 410 and 410 Ni Martensitic Stainless SteelsDocument11 pagesEffect of Quenching and Tempering On Microstructure and Mechanical Properties of 410 and 410 Ni Martensitic Stainless SteelsKumar GauravNo ratings yet

- Helical Pile Behaviour and Load Transfer Mechanism in Different SoilsDocument8 pagesHelical Pile Behaviour and Load Transfer Mechanism in Different SoilsBangun KaryaMartaNo ratings yet

- Ayoub Phillip M.,Paternotte David, 2014, LGBT Activism and The Making of Europe-A Rainbow Europe PDFDocument255 pagesAyoub Phillip M.,Paternotte David, 2014, LGBT Activism and The Making of Europe-A Rainbow Europe PDFGabriel Alexandru Gociu100% (1)

- MH PDFDocument12 pagesMH PDFfatihaNo ratings yet

- Gallano - Lab Report1Document24 pagesGallano - Lab Report1Kael Aaron GallanoNo ratings yet

- My Dearest AnnaDocument7 pagesMy Dearest AnnaShikeenga FillipusNo ratings yet

- Syllabus Upload 2019 PDFDocument55 pagesSyllabus Upload 2019 PDFMhohammad RifatNo ratings yet

- Panel Data Problem Set 2Document6 pagesPanel Data Problem Set 2Yadavalli ChandradeepNo ratings yet

- DIPRA Critical Buckling PressureDocument15 pagesDIPRA Critical Buckling Pressureestevin.r.clorado.jrNo ratings yet

- VAN VELSEN, Jaap (1965) History or Nostalgia, African Studies, 24:1, 63-66.Document5 pagesVAN VELSEN, Jaap (1965) History or Nostalgia, African Studies, 24:1, 63-66.HUGO ALEJANDRO CANO PRAISNo ratings yet

- Mob Programming Full Team Full ThrottleDocument3 pagesMob Programming Full Team Full ThrottleyedefoNo ratings yet

- Isfp - Students - University of SaskatchewanDocument8 pagesIsfp - Students - University of SaskatchewanRaphael AugustoNo ratings yet

- Analysis of Carbon and Low-Alloy Steel by Spark Atomic Emission SpectrometryDocument11 pagesAnalysis of Carbon and Low-Alloy Steel by Spark Atomic Emission SpectrometryIbtisam AbudNo ratings yet

- 2022 PosMAC3.0 Catalog - Eng - FinalDocument22 pages2022 PosMAC3.0 Catalog - Eng - Finalspk karicherlaNo ratings yet

- Deep Learning MethodsDocument336 pagesDeep Learning MethodsMuhamad Farid GeonovaNo ratings yet

- Data Sheet ASTM A517 Grade B 2020-06-26Document2 pagesData Sheet ASTM A517 Grade B 2020-06-26FAUSTINO SOLANO SUAREZNo ratings yet

- Star Wars Planet GuideDocument11 pagesStar Wars Planet GuidemaggathorpeNo ratings yet

- SDL 5-211089Document9 pagesSDL 5-211089211089No ratings yet

- TQL-MFC2000-GC60 20190416Document24 pagesTQL-MFC2000-GC60 20190416a.lifelong.partner4392No ratings yet

- Links To Protection Webinar Series With Prof. Dr. LemmerDocument3 pagesLinks To Protection Webinar Series With Prof. Dr. LemmerVlad SimizeanuNo ratings yet

- SWOT SunshineDocument1 pageSWOT SunshineChaitanyaNo ratings yet

- Template Groundwater MonitoringDocument13 pagesTemplate Groundwater MonitoringnhabetseNo ratings yet