Format - IV - Precommissioning Checklist For Tank

Format - IV - Precommissioning Checklist For Tank

Uploaded by

Su KaCopyright:

Available Formats

Format - IV - Precommissioning Checklist For Tank

Format - IV - Precommissioning Checklist For Tank

Uploaded by

Su KaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Format - IV - Precommissioning Checklist For Tank

Format - IV - Precommissioning Checklist For Tank

Uploaded by

Su KaCopyright:

Available Formats

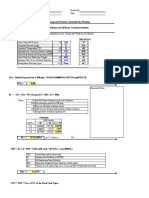

PRE-COMMISSIONING CHECKLIST FOR NEW TANK

Sr.

Pre-commissioning Activities/Checks Remarks

No

1 Tank completion certificate of the tank.

2 Approved calibration charts of the tank in triplicate.

3 Earthing certificate of the tank.

4 Hydro test certificate of the tank.

5 CCOE certificate for New tanks.

6 Surrounding tank field should be clean.

7 Tank foundation should be free of cracks.

8 Tank shell thickness and corrosion and paint status, relative records are available.

9 Shell ladder, all the steps (of non-skidding surface) should be intact and no bolts

and steps should be missing.

10 Support to electrical cables supporting properly

11 Tank inside clean, to be ensured that there is no foreign material inside tank.

12 Datum plate properly fixed and surface clean.

13 Bob touching datum properly.

14 Thermal relief valve of tank manifold & TRV line to be checked.

15 Tank bottom slope is towards the center sumps.

16 Foam deflectors inside the tanks to be checked.

17 Ref. height to be checked and the same to be painted near gauging hatch on the

roof.

18 Earthing / bonding of the tank flanges to be checked.

19 Dyke walls to be checked for any visible cracks.

20 Gauge hatch (should be lined with non-ferrous material to prevent sparking) is

provided with inner brass ring with cover and gasket.

21 Guide in tank hatch is provided

22 Electrical continuity of earthing contacts to be checked.

23 Water sprinkler is installed and checked for its performance.

24 Ensure that the glass on the foam pourer is in place.

25 The foam pourers have accessibility.

26 Check whether insulating gaskets/ has been introduced between tank and all

pipelines.

27 All valves/MOVs are free and easily operatable.

28 Ensure that the tank is properly boxed up.

29 Drain valves (water draw off) leading to OWS and storm water drains to be kept

closed / blinded

30 Visual inspection of tanks for any abnormality (bulge and dent).

31 Auto tank gauging (ENRAF) system and other instruments are provided.

32 All manways and connected flanges are boxed up with proper gaskets and correct

size and number of bolts.

33 All platforms for valve operation are as per requirement.

34 Tank approach/approach path is free from obstacles.

35 Tank external painting is completed.

36 Tank identification tag no, material stored, capacity, colour code and hazard

classification.

37 OWS system is in working condition.

38 Isolation valves of the OWS and storm water drain are in working condition.

39 Dip hatch cover is fitted properly.

40 Tank settlement, records of the same with comparison with the permissible

standard limit.

41 Tank bottom thickness and corrosion and paint status, relative records.

42 Flame arrestor and breather valve working properly and all nuts and bolts are tight.

43 All enclosure surrounding tanks should be provided with proper drainage.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5939)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1107)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (886)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (925)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (598)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (545)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (353)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (476)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (831)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (274)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (419)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2272)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (99)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (270)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (235)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (232)

- Tank Trailer Guide BookDocument66 pagesTank Trailer Guide BookSu KaNo ratings yet

- Tank Trailer Guide BookDocument66 pagesTank Trailer Guide BookSu KaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (75)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pressure Relief Valve: Special Features and AdvantagesDocument2 pagesPressure Relief Valve: Special Features and AdvantagesSu KaNo ratings yet

- Elbows LongRadius30° 45° 60°Document2 pagesElbows LongRadius30° 45° 60°Su KaNo ratings yet

- cm015 TransdockDocument1 pagecm015 TransdockSu KaNo ratings yet

- Catalog PFCI-FV-2055Document2 pagesCatalog PFCI-FV-2055Su KaNo ratings yet

- Slotted Pipe Oil SkimmerDocument1 pageSlotted Pipe Oil SkimmerSu KaNo ratings yet

- Pressure/Vacuum Relief Valve Protego Vn-A-Pcpf: Pilot-Operated Diaphragm ValveDocument5 pagesPressure/Vacuum Relief Valve Protego Vn-A-Pcpf: Pilot-Operated Diaphragm ValveSu KaNo ratings yet

- Belt Type Oil SkimmerDocument1 pageBelt Type Oil SkimmerSu KaNo ratings yet

- Api P Ti Sgi Q MW Voc PatmDocument2 pagesApi P Ti Sgi Q MW Voc PatmSu KaNo ratings yet

- Datasheet of Bitumen Penetration 60-70Document1 pageDatasheet of Bitumen Penetration 60-70Su KaNo ratings yet

- Hydrocarbon Processing TOV Offer Advantages in Emergency Services PDFDocument4 pagesHydrocarbon Processing TOV Offer Advantages in Emergency Services PDFSu KaNo ratings yet

- Epimastic 7200: Product DescriptionDocument2 pagesEpimastic 7200: Product DescriptionSu KaNo ratings yet

- Tank Cleaning: Hydrojetting MethodDocument18 pagesTank Cleaning: Hydrojetting MethodSu Ka100% (2)

- LT Valves Controlvalves WebDocument3 pagesLT Valves Controlvalves WebSu KaNo ratings yet

- 3517 - HUL - Pureit Marvella RO+UV (RDRO) Manual - v1 - 3jul15Document17 pages3517 - HUL - Pureit Marvella RO+UV (RDRO) Manual - v1 - 3jul15Su KaNo ratings yet

- A Comparative Study of Chinese and Pakistani Cultures: June 2016Document51 pagesA Comparative Study of Chinese and Pakistani Cultures: June 2016Muhammad Junaid HussainNo ratings yet

- E-WAY BILL DetailsDocument1 pageE-WAY BILL DetailsAnkit guptaNo ratings yet

- Operations Management - MRPDocument4 pagesOperations Management - MRPsadayNo ratings yet

- Weather VocabDocument2 pagesWeather VocabElena OMNo ratings yet

- Tidal Prediction Form2Document1 pageTidal Prediction Form2Sunny Bebs R. BasasNo ratings yet

- Social Responsibility Towards The ContractorsDocument17 pagesSocial Responsibility Towards The ContractorsMariella Angob67% (3)

- Meyer 2001Document14 pagesMeyer 2001pipoquinha123No ratings yet

- Central Information Commission: Appeal No. CIC/WB/A/2007/00830 Relevant Facts Emerging From The AppealDocument4 pagesCentral Information Commission: Appeal No. CIC/WB/A/2007/00830 Relevant Facts Emerging From The AppealRajeshwari MgNo ratings yet

- Contoh Bentuk Soal Akm Kelas 7Document2 pagesContoh Bentuk Soal Akm Kelas 7Agym Mansiz100% (2)

- Cabatit Rex Luigi Grade 1 Care Our FamilyDocument7 pagesCabatit Rex Luigi Grade 1 Care Our FamilyAlleoh AndresNo ratings yet

- Social and Modern Studies - SMS Grade 7 Mock Examinations 2022Document10 pagesSocial and Modern Studies - SMS Grade 7 Mock Examinations 2022Stephan Rambhoro100% (3)

- Problem Solving 2Document20 pagesProblem Solving 2Yeppeudda100% (1)

- Field Study Activity ContinuationDocument12 pagesField Study Activity ContinuationHelzven Junvy VegoNo ratings yet

- OCW23Pre-reg ListDocument16 pagesOCW23Pre-reg Listtanwarhimanshi00No ratings yet

- OU Quick Game (Lincoln Riley)Document23 pagesOU Quick Game (Lincoln Riley)GBO98100% (3)

- Effervescent Meaning - Google SearchDocument1 pageEffervescent Meaning - Google Searchsara baileyNo ratings yet

- PMP Credential Exam Preparation CourseDocument24 pagesPMP Credential Exam Preparation Coursesubin_mampallyNo ratings yet

- Elon Musk Text Exhibits Twitter V MuskDocument40 pagesElon Musk Text Exhibits Twitter V MuskZhao XianNo ratings yet

- The Utilization of Crabgrass (Digitaria Sanguinalis) As An Alternative of Marker InkDocument56 pagesThe Utilization of Crabgrass (Digitaria Sanguinalis) As An Alternative of Marker InkPeterJohn SimonNo ratings yet

- Technical Assistance Consultant's Report: Northeastern Integrated Flood and Riverbank Erosion Management Project (Assam)Document25 pagesTechnical Assistance Consultant's Report: Northeastern Integrated Flood and Riverbank Erosion Management Project (Assam)Achinta_b11No ratings yet

- Final Resharch ProposalDocument34 pagesFinal Resharch ProposalAr Ambuj SharmaNo ratings yet

- Chapter 4 - The Coming of SpaniardsDocument21 pagesChapter 4 - The Coming of SpaniardsKimberly SauraNo ratings yet

- Adrenal CrisisDocument13 pagesAdrenal CrisisNisa UcilNo ratings yet

- Terms of Reference Communication Specialist For The Public Sector Services and Efficiency Enhancement ProgrammeDocument5 pagesTerms of Reference Communication Specialist For The Public Sector Services and Efficiency Enhancement ProgrammeNatasa ZdravkovskaNo ratings yet

- 17-OnAPAL Philippines Commodities Inc. v. CourtDocument9 pages17-OnAPAL Philippines Commodities Inc. v. Courtdenbar15No ratings yet

- Action Plan On Bullying 2013Document126 pagesAction Plan On Bullying 2013Bloom SarinasNo ratings yet

- Case Study Analysis - PhilipsDocument1 pageCase Study Analysis - PhilipsRohit MathurNo ratings yet

- Mohammad Ali Jauhar University,: Jauhar Nagar, Rampur (U.P) - 244901 Admission To Doctoral (PH.D.) ProgrammeDocument7 pagesMohammad Ali Jauhar University,: Jauhar Nagar, Rampur (U.P) - 244901 Admission To Doctoral (PH.D.) ProgrammeJauhar PsychologyNo ratings yet

- Pharmaceutical Process ValidationDocument33 pagesPharmaceutical Process ValidationMithila HasanNo ratings yet

- Hindu Undivided Family (HUF) Tax Benefits: 1. What Is A HUF?Document4 pagesHindu Undivided Family (HUF) Tax Benefits: 1. What Is A HUF?ashankarNo ratings yet