4.000 HWDP With XT39 (4.875 X 2.5625 TJ) Conventional

4.000 HWDP With XT39 (4.875 X 2.5625 TJ) Conventional

Uploaded by

surendra kumarCopyright:

Available Formats

4.000 HWDP With XT39 (4.875 X 2.5625 TJ) Conventional

4.000 HWDP With XT39 (4.875 X 2.5625 TJ) Conventional

Uploaded by

surendra kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

4.000 HWDP With XT39 (4.875 X 2.5625 TJ) Conventional

4.000 HWDP With XT39 (4.875 X 2.5625 TJ) Conventional

Uploaded by

surendra kumarCopyright:

Available Formats

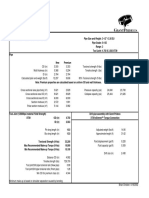

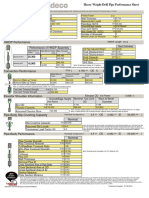

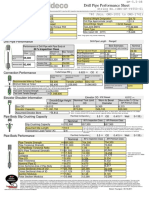

Heavy Weight Drill Pipe Performance Characteristics Pipe Size and Weight: 4.000" X 2.

5625" Heavy Weight

Workstrings International® 2011 Version 1.0 Pipe Grade: 55ksi Standard Heavy Weight

Range: 2

Tool Joint: 4.875" X 2.5625" XT39

Pipe Body

New New

(Nominal) (Nominal)

OD (in) 4.000 Cross Sectional Area of Pipe Body (in2) 7.409

2

Wall Thickness (in) 0.719 Cross Sectional Area of OD (in ) 12.566

2

ID (in) 2.563 Cross Sectional Area of ID (in ) 5.157

3

Calculated Plain End Weight (lbs/ft) 25.188 25.188 Section Modulus (in ) 5.225

3

Polar Section Modulus (in ) 10.450

Tensile Strength (lbs) 407,600

Torsional Strength (ft-lbs) 27,600

80% Torsional Strength (ft-lbs) 22,080

Burst Pressure (psi) 17,301

Collapse Pressure (psi) 16,218

Tool Joint 120,000 psi Material Yield Strength Drill Pipe Assembly with Grant Prideco

XT39 XT39 eXtreme Torque Connection

OD (in)

(i ) 4.875

4 875

ID (in) 2.563

Pin Tong Length (in) 24.0 Adjusted Weight (lbs/ft) 28.24

Box Tong Length (in) 24.0 Approximate Length (ft) 31.00

Torsional Strength (ft-lbs) 37,000 Fluid Displacement (gal/ft) 0.431

Max Recommended Make-up Torque (ft-lbs) 22,200 Fluid Capacity (gal/ft) 0.268

Min Recommended Make-up Torque (ft-lbs) 12,400 Fluid Capacity (bls/ft) 0.00638

Tensile Strength (lbs) 724,100 Drift Size (in) 2.3125

Tool Joint/Drill Pipe Torsional Ratio (New Pipe) 1.34

Balance OD (in) 4.992

Note: Minimum make-up is based on shoulder separation caused by bending

The technical information contained herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy

and suitability of use of the technical information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall

thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end

user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box ID’s, tool joint ID refers to the pin ID. Per

Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

JCT 03-21-2011

You might also like

- HWDPDocument15 pagesHWDPjinyuan74No ratings yet

- Drill Collar, 6.625 API Reg (8.000 X 2.813) 100,000 (Psi PDFDocument1 pageDrill Collar, 6.625 API Reg (8.000 X 2.813) 100,000 (Psi PDFИнженер Луис А. ГарсиаNo ratings yet

- Problems On Reheat CycleDocument8 pagesProblems On Reheat CycleMurvin VillarosaNo ratings yet

- Chemsheets A2 1001 Kinetics BookletDocument20 pagesChemsheets A2 1001 Kinetics BookletMarc WilfordNo ratings yet

- 3.500 HWDP With HT38 (4.875 X 2.250 TJ) Tri-SpiralDocument1 page3.500 HWDP With HT38 (4.875 X 2.250 TJ) Tri-SpiralLuis A G. C.No ratings yet

- 5.875 HWDP With XT57 (7.000 X 4.000 TJ) Tri-SpiralDocument1 page5.875 HWDP With XT57 (7.000 X 4.000 TJ) Tri-SpiralRonaldNo ratings yet

- 5.000 HWDP With NC50 (4.5IF) (6.500 X 3.000 TJ) Integral SpiralDocument1 page5.000 HWDP With NC50 (4.5IF) (6.500 X 3.000 TJ) Integral SpiraljosephbenettonNo ratings yet

- Especificaciones de Tuberia Pesada HW 5 1/2 F.HDocument1 pageEspecificaciones de Tuberia Pesada HW 5 1/2 F.HAlberto Cárdenas100% (1)

- 5.000 HWDP With NC50 (4.5IF) (6.625 X 3.0625 TJ) SpiralDocument1 page5.000 HWDP With NC50 (4.5IF) (6.625 X 3.0625 TJ) Spiralfaishal hafizhNo ratings yet

- Geometry and Performance: Pipe Data (In)Document1 pageGeometry and Performance: Pipe Data (In)Diego Fabian Ruiz VacaflorNo ratings yet

- 5 5PDSDocument1 page5 5PDSMAICOLNo ratings yet

- 4in DP 14# IU S135T XTF39 (5.00 x2.5625)Document7 pages4in DP 14# IU S135T XTF39 (5.00 x2.5625)Pavin PiromNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection Classalekz89No ratings yet

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetJeremias UtreraNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection Classalekz89No ratings yet

- 4Inch DP SpecsDocument3 pages4Inch DP SpecsDhrubajyoti BoraNo ratings yet

- 6.625 HWDPDocument23 pages6.625 HWDPözgüncNo ratings yet

- For Reference Only: Drill Pipe Performance Characteristics ©Document3 pagesFor Reference Only: Drill Pipe Performance Characteristics ©alekz89100% (1)

- Datasheet 312 EU-x-1330-x-S135-x-R2-31.5-ft - 478-x-2916-x-TSDS38-x-135-ksi-SMYS - 1412-Box-12-Pin - HB-Box - 60-70-MUT - 1.0-FF-and-1.15-FF - TSC-DP-Web-Site-1Document2 pagesDatasheet 312 EU-x-1330-x-S135-x-R2-31.5-ft - 478-x-2916-x-TSDS38-x-135-ksi-SMYS - 1412-Box-12-Pin - HB-Box - 60-70-MUT - 1.0-FF-and-1.15-FF - TSC-DP-Web-Site-1oscarNo ratings yet

- 3.5 In. 15.50# EU X-95 R2 XT39 (5.0 X 2.6875) - 10P.15BDocument3 pages3.5 In. 15.50# EU X-95 R2 XT39 (5.0 X 2.6875) - 10P.15BIng. Luis A. García CórdovaNo ratings yet

- 中原150根 5 12 FH加重钻杆合格证资料Document33 pages中原150根 5 12 FH加重钻杆合格证资料MAICOLNo ratings yet

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetGaona industrial PetroleroNo ratings yet

- HeavyWeight 3.5 25.58lbs NC-38 PDFDocument3 pagesHeavyWeight 3.5 25.58lbs NC-38 PDFHomero NavarroNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Luis Alberto García CórdovaNo ratings yet

- No. 27Document3 pagesNo. 27UPGM Ingenieria petroleraNo ratings yet

- Drill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)Document1 pageDrill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)juan moralesNo ratings yet

- Archer DP 5.875 Inch XT 57 SpecsDocument3 pagesArcher DP 5.875 Inch XT 57 SpecsMamani Vargas Wiljho100% (1)

- Drill Pipe Configuration: 80 % Inspection ClassDocument7 pagesDrill Pipe Configuration: 80 % Inspection ClassWaleedm MariaNo ratings yet

- Drillpipe 3.500 G 105 2.438 ID 15.5ppf NC38Document1 pageDrillpipe 3.500 G 105 2.438 ID 15.5ppf NC38german131418No ratings yet

- 5.5in Hwdp Ht55质量文件包裹模板Document20 pages5.5in Hwdp Ht55质量文件包裹模板zhaibo666No ratings yet

- 3.5 Eue 9.3 L80 TubingDocument1 page3.5 Eue 9.3 L80 TubingGeorge IkpeNo ratings yet

- 4英寸短钻杆 HT40质量文件包裹模板Document17 pages4英寸短钻杆 HT40质量文件包裹模板zhaibo666No ratings yet

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetDheeraj KapoorNo ratings yet

- DrillPipe, 80%, 2.875 OD, 0.362 Wall, EU, G-105.. XT26 (3.375 X 1.750)Document3 pagesDrillPipe, 80%, 2.875 OD, 0.362 Wall, EU, G-105.. XT26 (3.375 X 1.750)Luis Alberto García CórdovaNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection ClassLuis Manuel García GuillénNo ratings yet

- Datasheet - 5 IEU X 1950 X S135 X R2 31.5 FT - 658 X 312 X TSDS50 X 135 Ksi SMYS - 14 Box 11 Pin - HB Box - 60 70 MUT - 1.0 FF and 1.15 FF - TSC DP Web Site 1Document2 pagesDatasheet - 5 IEU X 1950 X S135 X R2 31.5 FT - 658 X 312 X TSDS50 X 135 Ksi SMYS - 14 Box 11 Pin - HB Box - 60 70 MUT - 1.0 FF and 1.15 FF - TSC DP Web Site 1oscar0% (1)

- Drill-Pipe Performance SheetDocument8 pagesDrill-Pipe Performance SheetrahulNo ratings yet

- 4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated PipeDocument3 pages4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated Pipeyatinbhat100% (2)

- Technical Data Sheet TMK UP FMT 3.5 X 9.2 N80Document1 pageTechnical Data Sheet TMK UP FMT 3.5 X 9.2 N80earlangga rmpNo ratings yet

- 4.0 Drill Pipe W XT39 ConnectionsDocument1 page4.0 Drill Pipe W XT39 ConnectionsDugas DeivyNo ratings yet

- PS PTECH55 - 6.625 X 4.250 - 5.500 - 24.70 S135 RG2 Rev3 - TSC Drill PipeDocument3 pagesPS PTECH55 - 6.625 X 4.250 - 5.500 - 24.70 S135 RG2 Rev3 - TSC Drill Pipe11tkt11No ratings yet

- METRIC - 5.500 HWDP With 5.5FH DSTJ (7.000 X 3.500 TJ) Integral ConventionalDocument1 pageMETRIC - 5.500 HWDP With 5.5FH DSTJ (7.000 X 3.500 TJ) Integral Conventionalarun sidhuNo ratings yet

- 5.5 HWDPDocument3 pages5.5 HWDPözgüncNo ratings yet

- 3,5 in Drill Pipe Performance Data SS 105Document1 page3,5 in Drill Pipe Performance Data SS 105mustafaNo ratings yet

- PS PTECH55 - 6.625 X 4.250 - 5.500 - 21.90 S135 RG2 Rev5 - TSC Drill PipeDocument3 pagesPS PTECH55 - 6.625 X 4.250 - 5.500 - 21.90 S135 RG2 Rev5 - TSC Drill Pipe11tkt11No ratings yet

- 5.5 Drill Pipe W Cet54 ConnectionsDocument1 page5.5 Drill Pipe W Cet54 Connectionsfarhad iqbalNo ratings yet

- Drill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUDocument9 pagesDrill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUFernando Ruiz ArroyoNo ratings yet

- Drillpipe 3.500 110KSI 225 ID NC38Document1 pageDrillpipe 3.500 110KSI 225 ID NC38Lucas Paul Perez HernandezNo ratings yet

- 5.5in Dp 0.415wt Ht55质量文件包裹模板Document21 pages5.5in Dp 0.415wt Ht55质量文件包裹模板zhaibo666No ratings yet

- Diseño Correa 0.25LDocument5 pagesDiseño Correa 0.25Lusuario1.masconNo ratings yet

- 4.0 S-135 Drill Pipe W Xt39Document1 page4.0 S-135 Drill Pipe W Xt39rdos14No ratings yet

- 3.5 Drill Pipe W Nc38 ConnectionsDocument1 page3.5 Drill Pipe W Nc38 ConnectionsMohamed FikryNo ratings yet

- Ejemplo FichaDocument1 pageEjemplo FichaYesid Cruz Yesid CruzNo ratings yet

- 5-1/2" Ht-55 HWDP Performance Data SheetDocument1 page5-1/2" Ht-55 HWDP Performance Data SheetJanderson Sanchez CastañedaNo ratings yet

- 3 12 13.30 S NC38 DatasheetDocument4 pages3 12 13.30 S NC38 DatasheetDaniel NavarroNo ratings yet

- 5.5英寸短钻杆 HT55质量文件包裹模板Document17 pages5.5英寸短钻杆 HT55质量文件包裹模板zhaibo666No ratings yet

- 7.13.1.4 DP 2 7,8 10,4ppfDocument1 page7.13.1.4 DP 2 7,8 10,4ppfkbgwseNo ratings yet

- Drill Pipe PerformanceDocument3 pagesDrill Pipe PerformanceJohn Jairo Simanca CastilloNo ratings yet

- 2.875 Eue 6.50 L80 TubingDocument1 page2.875 Eue 6.50 L80 TubingALEX MAKANGANo ratings yet

- TBPSDocument1 pageTBPSElvis E Prado PNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Tools and Techniques in Failure Analysis: Scanning Electron MicrosDocument10 pagesTools and Techniques in Failure Analysis: Scanning Electron MicrosBaljit SinghNo ratings yet

- Ultrasonic Technique & Equipment For Residual Stress MeasurementDocument2 pagesUltrasonic Technique & Equipment For Residual Stress Measurementcal2_uniNo ratings yet

- Dayananda Sagar College of Engineering: (An Autonomous Institute Affiliated To VTU, Belagavi)Document2 pagesDayananda Sagar College of Engineering: (An Autonomous Institute Affiliated To VTU, Belagavi)Anusha ReddyNo ratings yet

- 2 Electrolytes and Nonelectrolytes: Chapter 4 SolutionsDocument10 pages2 Electrolytes and Nonelectrolytes: Chapter 4 SolutionsMohamed AlQallafNo ratings yet

- CHAPTER.1 of Minor ProjectDocument38 pagesCHAPTER.1 of Minor ProjectAadil AhmadNo ratings yet

- RTAF XSE CatalogueDocument8 pagesRTAF XSE Cataloguepraveen yadavNo ratings yet

- Rheology of A Non-Newtonian FluidDocument7 pagesRheology of A Non-Newtonian FluidKeisha Richards100% (1)

- Uniaxial Stress SystemDocument36 pagesUniaxial Stress SystemKhalid YousafNo ratings yet

- Centrifugal CompressorsDocument152 pagesCentrifugal Compressorsnmaciel123No ratings yet

- Free FallDocument2 pagesFree FallIvan De VeraNo ratings yet

- Catenation by Ali AfzalDocument10 pagesCatenation by Ali AfzalAli AfzalNo ratings yet

- MZ 9Document9 pagesMZ 9Anderson RamosNo ratings yet

- Fosroc Conbextra Epoxy Grouts Application GuideDocument3 pagesFosroc Conbextra Epoxy Grouts Application GuideChukwuma OgbonnaNo ratings yet

- Introduction To Geothermal Comfort SystemsDocument83 pagesIntroduction To Geothermal Comfort Systemsdelux grafNo ratings yet

- Impedance Analysis of Electrochemical Systems - VivierDocument38 pagesImpedance Analysis of Electrochemical Systems - VivierSureshBharadwajNo ratings yet

- A Case Study in Ow Assurance of A Pipeline-Riser System Using OLGADocument10 pagesA Case Study in Ow Assurance of A Pipeline-Riser System Using OLGAAhmed BedhiefNo ratings yet

- Module 3.1 Ppt3.1 PumpsDocument26 pagesModule 3.1 Ppt3.1 Pumpsjithin jacobNo ratings yet

- Curriculum-Vitae Gaurav Kumar SethDocument3 pagesCurriculum-Vitae Gaurav Kumar SethKrishna SwamyNo ratings yet

- Design Data Sheet For Box CulvertDocument131 pagesDesign Data Sheet For Box CulvertJaganraj Sesuraj100% (1)

- Gear Safety, Service and Application FactorsDocument3 pagesGear Safety, Service and Application Factorsluis_dominguezeNo ratings yet

- Introduction To The Physical and Biological Oceanography of Shelf Seas by John Simpson Jonathan SharplesDocument466 pagesIntroduction To The Physical and Biological Oceanography of Shelf Seas by John Simpson Jonathan SharplesJose Gabriel CordovaNo ratings yet

- Atlas Copco MD Dryer Brochure 2Document12 pagesAtlas Copco MD Dryer Brochure 2MistysParts100% (1)

- Activated Carbon From Orange Peels As Supercapacitor Electrode and Catalyst Support For Oxygen Reduction PDFDocument8 pagesActivated Carbon From Orange Peels As Supercapacitor Electrode and Catalyst Support For Oxygen Reduction PDFchandrikamaniNo ratings yet

- Fundamental University Physics. (Second Edition), Volume 2 (Fields and Waves) - Alonso, FinnDocument665 pagesFundamental University Physics. (Second Edition), Volume 2 (Fields and Waves) - Alonso, Finnphoneee100% (17)

- Thin Airfoil Theory Reviewed by UMMAY MIM 2027019Document3 pagesThin Airfoil Theory Reviewed by UMMAY MIM 2027019Balram MandalNo ratings yet

- The Ultimate Bearing Capacity of Foundation On SlopesDocument3 pagesThe Ultimate Bearing Capacity of Foundation On SlopesGutnar Gomez ChaconNo ratings yet

- ESE Prelims 17 EE SET A 4 PDFDocument68 pagesESE Prelims 17 EE SET A 4 PDFGanesh M SurangeNo ratings yet