GMT Per

GMT Per

Uploaded by

Rajiv GandhiCopyright:

Available Formats

GMT Per

GMT Per

Uploaded by

Rajiv GandhiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

GMT Per

GMT Per

Uploaded by

Rajiv GandhiCopyright:

Available Formats

GMT

GMT Eccentric Compensating Chuck with Retractable jaws. The gripped portion can now be finished with fine

Jaws and face drive (PER) is used for machining forgings depth of cut. This ensures that the component is

and black bars between centres in single setup, (i.e.) no machined right upto the chuck face and the centre to

second operation necessary. centre machining of component is completed. The chuck

body is made from forged medium carbon steel and

This Chuck is designed to machine components centre to toughened. The levers and hinge pins are made from

centre with great accuracy. nickel chrome steel, case hardened and ground in all

working surfaces. The hard jaws are made from low

The retractable jaws are actuated by a hydraulic cylinder carbon steel, case hardened and ground.

or an also centre to centre, since the jaws have an

eccentric clamping drive. After various machining The special jaws are designed to clamp the component

operations are done on the component, without stopping as close to the centre to avoid distortion of the

the machine the clamping jaws are retracted. The torque component and provide inconsistent gripping.

is then transmitted through the face driver for driving the

All dimensions in mm

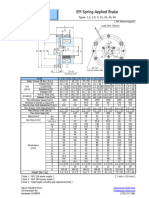

Hx K K1

Model Size Ø A Ø B Ø B1 Ø C D E Ø H6 F G (PCD) H1 J J1

3 Nos. Min. Max. Min. Max.

28-21 160 160 125 38 131 29 115 6 92 M 10 M 16 15 55 13.5 43.5 1 21

28-22 200 200 160 48 164 36 150 6 125 M 12 M 20 18 70 16.5 54.5 1 21

28-23 250 250 200 60 205 45 185 6 160 M 16 M 24 30 70 20.5 68 1.5 33

28-24 315 315 250 90 205 55 220 6 171.4 M 16 M 24 25 70 20.5 68 1.5 33

28-25 400 400 335 135 205 55 300 6 235 M 20 M 24 30 70 20.5 68 1.5 33

Compen Min. Drawbar Gripping

Jaw Wedge Body Speed Weight

Model N O Ø 01 Ø P -sation Clamping pull in Force

Movement Stroke Stroke in rpm in Kg

on dia dia. Kg in kgf

28-21 22.5 31.5 19 25 5.5 10 20 2 25 2600 2500 2500 23

28-22 28 35 24 30 6.5 13 25 3 32 2400 3100 3100 39

28-23 35 40 30 30 8 16 31.5 4 38 2400 4000 4000 74

28-24 35 40 30 30 8 16 31.5 4 38 1900 4000 4000 105

28-25 35 40 30 30 9 16 31.5 4 38 1500 4000 4000 170

Pallikkaranai, Chennai – 601302, INDIA

Ph: +91-44-2460627 to 629, Fax: +91-44-2460112 Email: gmt@gmt.co.in Web: www.gmt.co.in

Due to constant development work we reserve the right to depart from catalogue specifications.

You might also like

- Jeep 1995 YJ FSM Wiring DiagramsDocument190 pagesJeep 1995 YJ FSM Wiring DiagramsRonald Moore83% (6)

- Kuv Owner ManualDocument212 pagesKuv Owner ManualsajanpklNo ratings yet

- PHNCDocument6 pagesPHNCAmit MangaonkarNo ratings yet

- Angular Contact Bearing SwivelsDocument1 pageAngular Contact Bearing SwivelsmeromikhaNo ratings yet

- Housing & CouplingDocument12 pagesHousing & Couplingmajid fardniaNo ratings yet

- 546 DatasheetDocument11 pages546 Datasheetwilfredo mercedesNo ratings yet

- Monninghoff 546 - DatasheetDocument11 pagesMonninghoff 546 - DatasheetirfannadineNo ratings yet

- Design of Reinforced Concrete Elements: UsingDocument62 pagesDesign of Reinforced Concrete Elements: UsingISsa Qafa'itiNo ratings yet

- Data Perhitungan SambunganDocument42 pagesData Perhitungan SambunganBimo BaskoroNo ratings yet

- Alpha Series - Front End Cylinder With Single EyeDocument2 pagesAlpha Series - Front End Cylinder With Single EyeAji Aryandie100% (1)

- Tool MẫuDocument31 pagesTool MẫuPhước TânNo ratings yet

- Flyer Robot ES165D E 11.2012 05 PDFDocument2 pagesFlyer Robot ES165D E 11.2012 05 PDFJulio Vega AngelesNo ratings yet

- PAK AMIN PARAMETRIkDocument525 pagesPAK AMIN PARAMETRIkandratheshithandNo ratings yet

- EN5616 PT-ZubehoerDocument12 pagesEN5616 PT-Zubehoerhangmann169No ratings yet

- Correction To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsDocument2 pagesCorrection To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsTimNo ratings yet

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.0.0 License # 1TYYZ6WT9WKC6EXDocument8 pagesETABS 2015 Concrete Frame Design: ETABS 2015 15.0.0 License # 1TYYZ6WT9WKC6EXTeomnerCabreraNo ratings yet

- Magnetic Coupling Torque Vs Air GapDocument4 pagesMagnetic Coupling Torque Vs Air GapDallie KurniawanNo ratings yet

- Din 69002Document3 pagesDin 69002Dule JovanovicNo ratings yet

- Hibon NX Serisi Blover Katalogu - IngilizceDocument8 pagesHibon NX Serisi Blover Katalogu - IngilizceDocu CenterNo ratings yet

- Gls 150 SeriesDocument20 pagesGls 150 SeriesHâlid ŞenNo ratings yet

- Hibon NX Serisi Blover Kafa Katalogu - IngilizceDocument8 pagesHibon NX Serisi Blover Kafa Katalogu - IngilizceDocu Center100% (1)

- Macalloy-tension-bars-and-compression-strutsDocument16 pagesMacalloy-tension-bars-and-compression-strutsromanvoltar12No ratings yet

- 6 Conical Spring WashersDocument4 pages6 Conical Spring Washersbcsf01No ratings yet

- m3cb Sellsheet EngDocument2 pagesm3cb Sellsheet EngsalesNo ratings yet

- Strongwell Gridform Design GuideDocument352 pagesStrongwell Gridform Design GuideBintee PanchalNo ratings yet

- Jaw Crusher Eng 20141031 PDFDocument12 pagesJaw Crusher Eng 20141031 PDFBkiri AbderrahimNo ratings yet

- Desch KB 16 GB Lutex LKBDocument6 pagesDesch KB 16 GB Lutex LKBchodgemNo ratings yet

- MNB 2Document1 pageMNB 2Phan Thanh BảoNo ratings yet

- U Bolt STD LS 545-11 1Document4 pagesU Bolt STD LS 545-11 1Sayan SanyalNo ratings yet

- Inova Ball Joints JBDocument2 pagesInova Ball Joints JBSympatyagaNo ratings yet

- SKF Internal Bearing Puller Kits TMIP and TMIC SeriesDocument2 pagesSKF Internal Bearing Puller Kits TMIP and TMIC Seriesjaved samaaNo ratings yet

- Bevel CT & Abm-SeriesDocument17 pagesBevel CT & Abm-SeriesanrsrinivasanNo ratings yet

- Drilling Jar: General FeaturesDocument2 pagesDrilling Jar: General FeaturesPatou PatriceNo ratings yet

- Icp Electric Tooth Clutch M Series Etcm: DesignDocument4 pagesIcp Electric Tooth Clutch M Series Etcm: DesignsandraNo ratings yet

- Rexnord-Viva Vs enDocument2 pagesRexnord-Viva Vs enDenis AugustoNo ratings yet

- Fee A 05625 HivaDocument2 pagesFee A 05625 HivaSemirremolques Adrian GomezNo ratings yet

- Kinex. Special Bearings For Water PumpsDocument40 pagesKinex. Special Bearings For Water Pumpsa04205100% (1)

- Concrete Column DesignDocument2 pagesConcrete Column DesignJohn Aries SarzaNo ratings yet

- SteelDocument68 pagesSteelriyadhNo ratings yet

- Akn Series: Metal Bellows CouplingDocument1 pageAkn Series: Metal Bellows CouplingSueli ZaniNo ratings yet

- Tightening Torques For Screw JointsDocument6 pagesTightening Torques For Screw JointsTháiSơnTrầnNo ratings yet

- Datasheet KPPDocument1 pageDatasheet KPPRogelio LiceaNo ratings yet

- Pro 787426Document5 pagesPro 787426Mohamed ElmakkyNo ratings yet

- Hydraulic Tool Catalog 2021Document20 pagesHydraulic Tool Catalog 2021sebastián BohórquezNo ratings yet

- KDK MnE 2018 2 English - Part37Document1 pageKDK MnE 2018 2 English - Part37TYNo ratings yet

- Sheet Piles PT ANDALAN GLOBALINDODocument28 pagesSheet Piles PT ANDALAN GLOBALINDOqdod_waffi100% (1)

- PDF文档 2Document1 pagePDF文档 2Cuan HappyNo ratings yet

- Beacon Planetary Drive CatalogueDocument8 pagesBeacon Planetary Drive CatalogueMahesh100% (1)

- CPT Clampel 03Document16 pagesCPT Clampel 03trevorwoestNo ratings yet

- Cone Ring CouplingsDocument2 pagesCone Ring CouplingsnguyenhuanNo ratings yet

- Centrifugal PumpDocument32 pagesCentrifugal PumpAhmadMoaazNo ratings yet

- WCB Excavator Spare Parts Slewing Bearing Slewing Circle Slewing RingDocument24 pagesWCB Excavator Spare Parts Slewing Bearing Slewing Circle Slewing RingWCB BEARING0% (1)

- Datasheet KMDocument1 pageDatasheet KMFrancisco SanchezNo ratings yet

- FLURO Motor Sport Cataloque EnglishDocument16 pagesFLURO Motor Sport Cataloque EnglishRMCsportNo ratings yet

- Rectangular Column CalculationsDocument2 pagesRectangular Column CalculationsMopao JojoNo ratings yet

- RC Design Aci318m 19 v4.3Document72 pagesRC Design Aci318m 19 v4.3mohammed alebiedNo ratings yet

- CDA - Elecon Flexible CouplingDocument5 pagesCDA - Elecon Flexible CouplingMohit GuptaNo ratings yet

- SB D15-011 GMK Turntable Bearings Update PDFDocument5 pagesSB D15-011 GMK Turntable Bearings Update PDFDeepak MishraNo ratings yet

- Three Phase Squirrel Cage Induction Motors: Maa Series 63 - 160 SIZESDocument6 pagesThree Phase Squirrel Cage Induction Motors: Maa Series 63 - 160 SIZESsugirinNo ratings yet

- Sleeve Anchor Data Sheet - For SubmittalDocument3 pagesSleeve Anchor Data Sheet - For SubmittalvtalexNo ratings yet

- Rigging Hardware & Lifting EquipmentDocument6 pagesRigging Hardware & Lifting EquipmentJaycee PagadorNo ratings yet

- KX Large Series - English - 2019 12Document12 pagesKX Large Series - English - 2019 12Rajiv GandhiNo ratings yet

- HELLER - 5 Axis Machining Centres F - ENDocument8 pagesHELLER - 5 Axis Machining Centres F - ENRajiv GandhiNo ratings yet

- ENG Donovan Brochure DIBv4201510Document4 pagesENG Donovan Brochure DIBv4201510Rajiv GandhiNo ratings yet

- Curvic Coupling.Document11 pagesCurvic Coupling.Rajiv GandhiNo ratings yet

- WFT 11Document2 pagesWFT 11Rajiv GandhiNo ratings yet

- Thread Check Catalog 2021Document186 pagesThread Check Catalog 2021Rajiv GandhiNo ratings yet

- TEDISA - Standard SeriesDocument1 pageTEDISA - Standard SeriesRajiv GandhiNo ratings yet

- #50 2,500 f90 Grease Hexagon Socket Head Bolt Manual Helical Bevel Gear Lubricating Oil 373 X 250 X 486.8 80Document1 page#50 2,500 f90 Grease Hexagon Socket Head Bolt Manual Helical Bevel Gear Lubricating Oil 373 X 250 X 486.8 80Rajiv GandhiNo ratings yet

- The Hytorc Nut Replaces Fasteners, Minimizes Stresses, and Covers A Wide Range of Sizes and Applications Tn-Series Hytorc NutDocument4 pagesThe Hytorc Nut Replaces Fasteners, Minimizes Stresses, and Covers A Wide Range of Sizes and Applications Tn-Series Hytorc NutRajiv GandhiNo ratings yet

- PMH-H Series Gantry Style Mold HandlersDocument1 pagePMH-H Series Gantry Style Mold HandlersRajiv GandhiNo ratings yet

- Gear Errors Due To HOB MisalignmentDocument5 pagesGear Errors Due To HOB MisalignmentRajiv GandhiNo ratings yet

- PartList Helico PDFDocument1 pagePartList Helico PDFRajiv GandhiNo ratings yet

- Global S: The Coordinate Measuring Machine Pushing Productivity FurtherDocument20 pagesGlobal S: The Coordinate Measuring Machine Pushing Productivity FurtherRajiv GandhiNo ratings yet

- KAfo DCMC AdvantagesDocument14 pagesKAfo DCMC AdvantagesRajiv GandhiNo ratings yet

- GLOBAL S: Pushing Productivity Further: Configurable Messaging Lights Speed and StabilityDocument2 pagesGLOBAL S: Pushing Productivity Further: Configurable Messaging Lights Speed and StabilityRajiv GandhiNo ratings yet

- TCF 160 / TCF 200 / TCF 224 / TCF 250 TCF 275 / TCF 300: Heavy Centre LathesDocument8 pagesTCF 160 / TCF 200 / TCF 224 / TCF 250 TCF 275 / TCF 300: Heavy Centre LathesRajiv GandhiNo ratings yet

- Savage Hydraulic Presses Are Application-Specific and Job-EngineeredDocument1 pageSavage Hydraulic Presses Are Application-Specific and Job-EngineeredRajiv GandhiNo ratings yet

- For Round Bars and Tubes - TFS Presses: Lift / Rotation Stand V-Block AnvilDocument1 pageFor Round Bars and Tubes - TFS Presses: Lift / Rotation Stand V-Block AnvilRajiv GandhiNo ratings yet

- Induerf - Induction Refining Laddle PDFDocument6 pagesInduerf - Induction Refining Laddle PDFRajiv GandhiNo ratings yet

- Future Controlview BrochureDocument24 pagesFuture Controlview Brochuresamir kadiwala100% (1)

- Manual de Partes Cfb110mDocument122 pagesManual de Partes Cfb110mRobinson GuanemeNo ratings yet

- Pst/Sl-E Pst/Es-E: Product BrochureDocument9 pagesPst/Sl-E Pst/Es-E: Product BrochureJose DiazNo ratings yet

- Kodiak Cone Crusher k200 Spec Sheet EnglishDocument2 pagesKodiak Cone Crusher k200 Spec Sheet EnglishKevin GuoNo ratings yet

- ELCoCatalog WebDocument56 pagesELCoCatalog WebrschwarkNo ratings yet

- Sewa Equipment PricelistDocument9 pagesSewa Equipment PricelistSuzanaShafiiNo ratings yet

- 196 - GEA32677 - MV3000 Delta Module Retrofit Factsheet PDFDocument2 pages196 - GEA32677 - MV3000 Delta Module Retrofit Factsheet PDFAdson GomesNo ratings yet

- Bendix M-32 - (QR)Document8 pagesBendix M-32 - (QR)Hernando MontenegroNo ratings yet

- JLA Safety Valve Test BenchDocument4 pagesJLA Safety Valve Test Benchjromero_rpgNo ratings yet

- To Match Tie-Ins LocationDocument1 pageTo Match Tie-Ins LocationABDERRAZZAKNo ratings yet

- 714 and 715 Zone Expander Modules: Installation GuideDocument4 pages714 and 715 Zone Expander Modules: Installation GuideOrlando BarretoNo ratings yet

- Iveco - Stralis Euro 3 - Repair Manual-1-1 - 1Document144 pagesIveco - Stralis Euro 3 - Repair Manual-1-1 - 1smhadinkedir092No ratings yet

- Timers in Intel 8051 Micro Controller: Unit IVDocument5 pagesTimers in Intel 8051 Micro Controller: Unit IVChanchal RawatNo ratings yet

- 614-00024-05 LW, LWS LCD User ManulDocument8 pages614-00024-05 LW, LWS LCD User ManulAbdelwhab ElsaftyNo ratings yet

- 12 Inch Two-Way Stage Monitor Loudspeaker SystemDocument2 pages12 Inch Two-Way Stage Monitor Loudspeaker SystemAriyadi NagaraNo ratings yet

- 5200030-02B - Salwico MCP-A SCI (GB) - M - EN - 2023 - HDocument4 pages5200030-02B - Salwico MCP-A SCI (GB) - M - EN - 2023 - Hcgabe68No ratings yet

- 22-DS-R-008 Rev 0 P 2460 A-B Utility Water PumpDocument3 pages22-DS-R-008 Rev 0 P 2460 A-B Utility Water PumpChike NwachukwuNo ratings yet

- Analog VLSI Design: Technology TrendsDocument25 pagesAnalog VLSI Design: Technology TrendsSathyaNarasimmanTiagarajNo ratings yet

- Notice Thomson ROC 6306Document54 pagesNotice Thomson ROC 6306Julien Noblet0% (2)

- K-ML-D5-KV2 K-TRON Product Specification Loss-in-Weight Vibratory FeederDocument2 pagesK-ML-D5-KV2 K-TRON Product Specification Loss-in-Weight Vibratory FeederHpnoteNo ratings yet

- Post Pyro Ip01Document56 pagesPost Pyro Ip01Durga PrasadNo ratings yet

- Us Earth Rite Plus Exd DatasheetDocument7 pagesUs Earth Rite Plus Exd DatasheetwlyskrdiNo ratings yet

- Daikin RXYMQ36 48PVJU Service ManualDocument264 pagesDaikin RXYMQ36 48PVJU Service ManualserbanicNo ratings yet

- Class 8Document45 pagesClass 8ASHFAQNo ratings yet

- Model K-P3 China Models: (Machine Code: G091-69, - 21, - 20)Document118 pagesModel K-P3 China Models: (Machine Code: G091-69, - 21, - 20)william lozadaNo ratings yet

- Control Valves (Manual / Pilot Operation) : Products InformationDocument1 pageControl Valves (Manual / Pilot Operation) : Products InformationNarasimha DNo ratings yet

- Machines General Requirements - Safety Checklist Program For Schools - NIOSH - CDCDocument2 pagesMachines General Requirements - Safety Checklist Program For Schools - NIOSH - CDCarroyave.auNo ratings yet

- Blind Spot Control System (BLIS)Document21 pagesBlind Spot Control System (BLIS)Ramanan MageswaranNo ratings yet