PM 372 E - The ROTO-PACKER

PM 372 E - The ROTO-PACKER

Uploaded by

AliCopyright:

Available Formats

PM 372 E - The ROTO-PACKER

PM 372 E - The ROTO-PACKER

Uploaded by

AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

PM 372 E - The ROTO-PACKER

PM 372 E - The ROTO-PACKER

Uploaded by

AliCopyright:

Available Formats

HAVER & BOECKER

DIE MASCHINENFABRIK

THE ROTO-PACKER® RVT

REDEFINING AN ICON

HAVER & BOECKER

CONTENT

Inspiration 4–5

Motivation 6–7

Modular 8–9

Intelligence 10 – 11

Profitable 12 – 13

Clean 14 – 15

Prosperous 16 – 17

HAVER & BOECKER 18 – 19

2 3 HAVER & BOECKER

INSPIRATION

“Our products are not an end in themselves,

but a means by which our customers can

accomplish something useful and profitable.”

Washington Samuel Tyler

While HAVER & BOECKER was founded in 1887, our subsidiary W.S. TYLER is even older and was established

in 1872. Washington Samuel Tyler captured in words the philosophy that has been the driving factor to every

WASHINGTON SAMUEL TYLER

product we have ever designed. The foundation of the ROTO-PACKER® worldwide success story is the realization * 1835 in Ohio City, † unknown

that it is not an end in itself, but a tool for its owner to create something useful and profitable. This is the mantra At 37 years of age, Washington S. Tyler

started a wire weaving mill in Cleveland

which inspired us to redesign the RVT version of our ROTO-PACKER® which stands for Rotating packing system

in 1872 and began operations with

for Valve bags using Turbine (impeller) technology. eleven workers.

4 5 HAVER & BOECKER

MOTIVATION

“The ROTO-PACKER® is an icon. It is the original that

not only sets the bar for our customers, but also our

competitors. The RVT needs to be designed to break

barriers when it comes to performance, intelligence,

profitability and cleanliness.”

Christian Bähner, RVT Project Manager

ROTO-PACKER® represents more than just HAVER & BOECKER’s product designation for the biggest selling bulk

packaging system in the world. Our ROTO-PACKER® machines are known among our customers, engineering

companies and even our competitors as guarantor for high-performance rotating packing technology.

In order to live up to its name, the ROTO-PACKER® needs to push the envelope. It needs to set new standards

and break current technological barriers. Developed by a designated mechatronic team, the RVT generation is

focused on reaching new heights when it comes to performance, intelligence, profitability and cleanliness.

6 7 HAVER & BOECKER

MODULAR

“Whatever we do, we must design a machine

that can be adapted to any performance

requirement our customers may have.

The machine must be configurable in

every way that is important to the client.

He should not pay for anything that he does

not need, but at the same time have the

option to upgrade the machine to

everything he wants.”

Bernhard Pagenkemper, Chief Sales Officer

The RVT version of the ROTO-PACKER® is designed to fulfill any and every performance

requirement you may have. Similarly to an automobile you can configure your RVT in any

way you want. Even if you are not sure about your performance requirements for the future,

you can choose to configure your RVT in a manner that it can be upgraded at a later point in time.

The key to optimum performance is proper weight. The heart of the ROTO-PACKER® RVT is its

MEC® 4.0 weighing system, which not only serves as a scale but a configurable control system for your

complete packing system. It provides ideal weights and ensures that you never waste your product.

In summary, there are no limits to the configuration of your machine. You tell us what you need, and we

will help you to configure the RVT in way that is perfect for you.

8 9 HAVER & BOECKER

INTELLIGENCE

“Build me a machine that makes it easy for us to

operate. It has to be simple. It has to talk to us.

It has to let us know what we should do.” – YOU

Prior to developing the ROTO-PACKER® RVT we spoke to many of you. Your message to us was clear. You

wanted a packing system which made it easy for you and your team to operate. You told us that the experience

of your team is becoming a more and more important issue. With less time for training and a much increased rate

of job rotation and added process complexity, you require a packaging system that can be operated intuitively.

It should be easy to understand, quick to learn and, most importantly, it must communicate with you. The RVT

accomplishes the goals you gave us. Using LED mood lighting, the ROTO-PACKER® RVT talks to you. A blue light

indicates it is running fine. The red light tells you it has a fault and a white light helps you to see clearly when BLUE = Operation Mode WHITE = Maintenance Mode RED = Fault Mode

maintaining the machine. The large touch-screen panel offers you all features at a click of a button. It can be set

to different user interfaces such as operator, maintenance or service technician. The optional HAVER QUATTRO

technology allows you to document and adapt the RVT operational settings according to your team’s desires.

It also enables you to remotely monitor the machine’s conditions.

10 11 HAVER & BOECKER

PROFITABLE

“The key to making money in this business is time.

It cannot be wasted. The process to make my product

is too expensive to be sitting idle. The product must

flow continuously and the process should not be

interrupted.” – YOU

We understood. In response to your determination to generate constant flow, we designed the ROTO-PACKER®

RVT modularly. Each filling spout is a complete filling system in itself. It encompasses everything required to fill,

weigh, optionally seal and deliver your bag to the subsequent process step. As a result you can maintain or, if

necessary, repair each filling module individually without stopping the machine for an extended period of time.

You can both remove the filling module and continue to operate your machine at slightly reduced capacity, or

use an interchangeable spare filling module and run your ROTO-PACKER® at full capacity all the time. Either

way your maintenance crew can roll the filling module requiring work into your maintenance shop, thus allowing

your team to properly work on your machine under ideal conditions without the associated time crunch.

12 13 HAVER & BOECKER

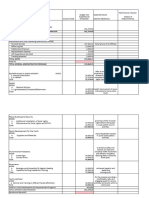

THE PERFECT FILLING MODULE

The high-performance ROTO-LOCK® dosing unit

ROTO-LOCK® is a new, patented rotating dosing unit for ideal filling of valve bags.

n maintenance-free dosing unit Your benefits

n no adjustments or readjustments necessary n Profit increase due to cleaner

n fully closed filling canal filling and reduced product loss

n clean filling n Higher production yield due to

n long operating lifetime due to improved material less downtime

selection and optimized design n Cost reduction from less cleaning

and lower spare parts costs

The intelligent aeration

n automatic regulation of the

various aeration positions

n optimum air amount adjustment

according to the product

n no manual pressure adjustment

necessary

Your benefits

n reduction of operating costs,

especially for compressed air,

less air inside the product

= less air in the bag

= cleaner filling

= less wear and tear

n less machine downtime

n reduction of spare parts costs

The ideal modularity

n can be expanded to the

SEAL technology

n exchangeable dosing units

(pinch, slider, or rotary valve)

n filling module can be used with

The maintenance-friendly ROTO-PACKER®, INTEGRA®

design and ELEMENTRA®

n good accessibility to all components from the front n exchangeable impeller box

n easy replacement of complete filling modules of the R130 and R180 size

Your benefits Your benefits

n reduction in maintenance works n reduction in stocking costs

n longer machine operating times n higher flexibility when operating

longer machine operating times filling systems

n reduction in maintenance and

training costs

HAVER & BOECKER

PROFITABLE

“The key to making money in this business is time.

It cannot be wasted. The process to make my product

is too expensive to be sitting idle. The product must

flow continuously and the process should not be

interrupted.” – YOU

We understood. In response to your determination to generate constant flow, we designed the ROTO-PACKER®

RVT modularly. Each filling spout is a complete filling system in itself. It encompasses everything required to fill,

weigh, optionally seal and deliver your bag to the subsequent process step. As a result you can maintain or, if

necessary, repair each filling module individually without stopping the machine for an extended period of time.

You can both remove the filling module and continue to operate your machine at slightly reduced capacity, or

use an interchangeable spare filling module and run your ROTO-PACKER® at full capacity all the time. Either

way your maintenance crew can roll the filling module requiring work into your maintenance shop, thus allowing

your team to properly work on your machine under ideal conditions without the associated time crunch.

12 13 HAVER & BOECKER

THE NEW DOSING UNIT

ROTO-LOCK®

CLEAN

The new

designed filling

box even for

high blaine

cements.

"The health and safety of our staff is our top priority. YOUR ADVANTAGES

n Maximize performance even with higher blain

Therefore, any machine designed for today's require-

n Less wear and tear

ments must ensure a clean working environment by The patented high- n Maintenance-free dosing unit

performance ROTO-LOCK® n No adjustments or readjustments necessary

minimizing product spillage." – YOU dosing unit for clean filling

n Fully closed filling channel

of valve bags.

n Clean filling process

n Long operating lifetime of the filling spout

due to improved material selection

YOUR BENEFITS

n Higher performance, higher output, higher profit

n Profit increase due to clean filling and reduced

product loss

n Higher production due to less downtime

n Cost reduction due to less cleaning and lower

spare part costs

The existing pneumatic

operation cylinder can

If not maintained properly, one primary source of spillage in high-performance rotating packing systems has be used.

always been the sliding plates, which link the impeller box and filling spout. The ROTO-PACKER® RVT is the

world’s only packing system that allows you to replace the sliding plates with ROTO-LOCK® dosing unit as an

option. The ROTO-LOCK® is a rotating flow gate. It completely eliminates spillage during the dosing process

and requires almost no maintenance. The ROTO-LOCK® is designed in a manner that allows you to retrofit your

ROTO-PACKER® RVT at any time. It can even be retrofitted on all ROTO-PACKER® built since the year 2000.

14 15 HAVER & BOECKER

PROSPEROUS

“My bag is my business card. The quality of my package

reflects on the quality of my product. My bag must be

compact, clean and sharp looking.” – YOU

We understand how important your package is to you. Having a clean bag radiates your image to your market,

customers, competitors and even your own employees. In response to your demand we want to create a new

standard when it comes to traditional valve bag filling technology as well as integrate a completely clean system

for those who want to go that extra mile.

For exceptional bag appearance, you can configure your ROTO-PACKER® RVT to be equipped with SEAL

technology. The SEAL eliminates spillage by inflating a rubber sleeve on a specially designed filling spout during

the filling process. After filling, the bag is carefully pulled off the spout and welded shut using an ultrasound

sealing device. The result is an absolutely compact and clean bag, which will make your product stand out in

any form of presentation. Additionally, the SEAL system avoids spillage during transport and prevents any kind

of contamination or product extraction. This allows you to increase your weight accuracy without the need to

overfill the bag. The resulting additional product profit to your operation far outweighs the extra expense to

installing the SEAL system. Similar to the ROTO-LOCK®, the SEAL system can be retrofitted to your RVT or any

ROTO-PACKER® built after 2000.

HAVER & BOECKER 16 17 HAVER & BOECKER

Since the inception of business as we know it, the measurement of success for a company has always been the

profit it generates. The dictionary defines profit as “the ratio of pecuniary gain compared to the amount of

capital invested.” At HAVER & BOECKER we believe that the key to maximizing this ratio for any company lies

in perfecting the quality of its flow in terms of product and process. We are convinced that a single perfect flow

HAVER & BOECKER applicable to any and every product or process does not exist. Instead we are driven to identify the ideal flow

for each product, customer and operation. In essence, at HAVER & BOECKER we are a family of flow designers

TECHNOLOGY and engineers focused on finding your perfect flow. The foundation for our endeavors is our range of premium

technologies, which can be combined to form complete systems of flow. From processing and materials handling

over mixing, packaging and filling to palletizing, loading and automating, HAVER & BOECKER can partner with

you in all aspects of your business. With W.S. TYLER, IBAU HAMBURG, SOMMER, Feige FILLING, BEHN + BATES,

NEWTEC BAG PALLETIZING and of course HAVER & BOECKER itself, we have assembled over time nothing but

the best and strongest brands in our industry to ensure that we will not make any compromises when designing

the perfect flow for you. Maximize your success by allowing our family of flow specialists and professionals to be

a part of yours.

18 19 HAVER & BOECKER

HAVER & BOECKER OHG

Internet: www.haverboecker.com

E-mail: haver@haverboecker.com

Carl-Haver-Platz 3 • 59302 Oelde • Germany

Phone: +49 2522 30-0 • Fax: +49 2522 30-403

PM 372 E 4062 0517 1 Fe

The machines and equipment shown in this brochure as well as the technical parameters represent only examples of customer-specific technical solutions. We reserve the right to make changes at any time without notice!

The ® symbol indicates a registered trademark of HAVER & BOECKER oHG in Germany. Some of the trademarks are also registered in other countries.

You might also like

- 02.01 - SEPOL LM High-Efficiency SeparatorDocument103 pages02.01 - SEPOL LM High-Efficiency Separatorsrinivasarao nerellaNo ratings yet

- Project Plan Template 0Document5 pagesProject Plan Template 0anshNo ratings yet

- Belt Weigher MaintenanceDocument3 pagesBelt Weigher MaintenanceJong JavaNo ratings yet

- Cement Bag Loading SysDocument56 pagesCement Bag Loading SysomercomsatNo ratings yet

- Altamina Chronology UpdateDocument5 pagesAltamina Chronology UpdateLouis Santos100% (1)

- Section 1 The Entrepreneurial Perspective Section 1 The Entrepreneurial PerspectiveDocument12 pagesSection 1 The Entrepreneurial Perspective Section 1 The Entrepreneurial PerspectiveJAYANT MAHAJANNo ratings yet

- Jaypee Cement Plant Grinding Uniit-3Document27 pagesJaypee Cement Plant Grinding Uniit-3sunil kumar patelNo ratings yet

- Method Study For Process Flow of Cement PackingDocument37 pagesMethod Study For Process Flow of Cement Packingrameshkrk3835254100% (4)

- Lucie MillDocument50 pagesLucie Millrudye kardunNo ratings yet

- Binani Cement Limited, SirohiDocument47 pagesBinani Cement Limited, SirohivikassspaceNo ratings yet

- Per Banding An Desain Fls Pfister FeederDocument5 pagesPer Banding An Desain Fls Pfister Feederde_chemenx2540No ratings yet

- Energy Efficient Turbo BlowersDocument11 pagesEnergy Efficient Turbo BlowersnishanandNo ratings yet

- Performance of Fans After at Various Plants: RetrofittingDocument19 pagesPerformance of Fans After at Various Plants: RetrofittingmkpqNo ratings yet

- Avinash MechwellDocument33 pagesAvinash Mechwell1977julNo ratings yet

- Weigh Feeder ManufacturersDocument5 pagesWeigh Feeder ManufacturersinduscontrolsNo ratings yet

- Instruction For Filling Up The Form-Sb & Keeping Records and Information For Verification ProcessDocument57 pagesInstruction For Filling Up The Form-Sb & Keeping Records and Information For Verification ProcessBùi Hắc HảiNo ratings yet

- Performance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement PlantDocument8 pagesPerformance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement PlantSohail AhmedNo ratings yet

- I-P-1.01-W-5 (Solid Flow Meter)Document2 pagesI-P-1.01-W-5 (Solid Flow Meter)Mechanical ShauryaNo ratings yet

- Improving Weigh Feeder Control Using Scale Location CompensationDocument7 pagesImproving Weigh Feeder Control Using Scale Location CompensationabcNo ratings yet

- RCA Kiln Nar2 Due To AnalyzerDocument31 pagesRCA Kiln Nar2 Due To AnalyzerSafrin SangiaNo ratings yet

- Distributing Flap, Motor ActuatedDocument29 pagesDistributing Flap, Motor ActuatedRahmat HidayatNo ratings yet

- Procon Engineering LTD: Loss in Weight SystemsDocument8 pagesProcon Engineering LTD: Loss in Weight SystemsSaurav DasNo ratings yet

- Cement Mill Note BookDocument4 pagesCement Mill Note BookK.SRINIVAS RAONo ratings yet

- Ims Afr User GuideDocument9 pagesIms Afr User GuideSafrin SangiaNo ratings yet

- Global Cement ArticleDocument3 pagesGlobal Cement Articleskb25No ratings yet

- Verderflex: Industrial Peristaltic Hose PumpsDocument20 pagesVerderflex: Industrial Peristaltic Hose PumpsWilmerNo ratings yet

- Table 2 Factors To Consider When Selecting Fits Factors Situation Guideline RulesDocument2 pagesTable 2 Factors To Consider When Selecting Fits Factors Situation Guideline Ruleskuruvillaj2217No ratings yet

- Unit8.2 Cement MillDocument30 pagesUnit8.2 Cement MillRevati MotagiNo ratings yet

- Intensiv Filter 15th Arab 08Document25 pagesIntensiv Filter 15th Arab 08Zahir KhiraNo ratings yet

- Kiln Shell ScanningDocument3 pagesKiln Shell ScanningMarey Morsy100% (1)

- Cement Maintenance Ms WordDocument6 pagesCement Maintenance Ms Wordsharif339No ratings yet

- Inventory Manament - Zuari CementDocument82 pagesInventory Manament - Zuari CementSwathi ManthenaNo ratings yet

- Weighfeeder DetailsDocument4 pagesWeighfeeder DetailsAnonymous p4GdtQpNo ratings yet

- Assiut Cement PlantDocument17 pagesAssiut Cement PlantMahmoud RashadNo ratings yet

- Belt ScaleDocument9 pagesBelt ScaleMuhammad ChabibiNo ratings yet

- 4.1 Best Practices Tata SpongeDocument28 pages4.1 Best Practices Tata SpongeSameer BagalkotNo ratings yet

- ShreddingDocument10 pagesShreddingFlora MaeNo ratings yet

- KIMA Smart Fill + Mill MasterDocument1 pageKIMA Smart Fill + Mill MasterJunaid MazharNo ratings yet

- Kilnloq Datasheet 270910 PDFDocument40 pagesKilnloq Datasheet 270910 PDFFranz Alegria50% (2)

- VSK SeparatorDocument3 pagesVSK Separatorm_verma21No ratings yet

- Fls FHT Proj MGT Presentation 26aug13Document19 pagesFls FHT Proj MGT Presentation 26aug13Marquis HowardNo ratings yet

- Comp - Roll Crusher & SizerDocument2 pagesComp - Roll Crusher & Sizerrajeevup2004100% (1)

- Process Roadmap 2016Document10 pagesProcess Roadmap 2016Safrin SangiaNo ratings yet

- Cement Plant ControlDocument17 pagesCement Plant ControlAhmad NilNo ratings yet

- 2.4 Solid Fuel Handling SystemDocument29 pages2.4 Solid Fuel Handling SystemNind's Chef100% (1)

- Operation Manual: HRM1700M Vertical Roller Coal MillDocument30 pagesOperation Manual: HRM1700M Vertical Roller Coal MillAhmed ElhusseinyNo ratings yet

- 1366 - Volume-2B - Vibrating Feeder PDFDocument16 pages1366 - Volume-2B - Vibrating Feeder PDFkumarNo ratings yet

- AFR Data SheetDocument6 pagesAFR Data SheetAnthony SolanoNo ratings yet

- Loss-In-weight Feeder - Intecont TersusDocument220 pagesLoss-In-weight Feeder - Intecont TersusneelakanteswarbNo ratings yet

- ResumeDocument3 pagesResumeHari Prathap ReddyNo ratings yet

- V6 EngineeringDocument252 pagesV6 Engineeringcrengifo1726No ratings yet

- FLS, Eng RequirementsDocument9 pagesFLS, Eng RequirementsDeepak DasNo ratings yet

- KHD Pyrofloor PDFDocument2 pagesKHD Pyrofloor PDFNhaca100% (1)

- Quality Plan TemplateDocument2 pagesQuality Plan Templateapi-3850616100% (3)

- Belt Weighing WT10 - en - Kap04 PDFDocument60 pagesBelt Weighing WT10 - en - Kap04 PDFomarNo ratings yet

- 15th NCB Technical PaperDocument10 pages15th NCB Technical PaperSalah RomdaniNo ratings yet

- SCL Corporate PresentationDocument60 pagesSCL Corporate Presentationgangadhar_reddybNo ratings yet

- End To End Supply Chain Management A Complete Guide - 2021 EditionFrom EverandEnd To End Supply Chain Management A Complete Guide - 2021 EditionNo ratings yet

- Effective Implementation of an ISO 50001 Energy Management System (EnMS)From EverandEffective Implementation of an ISO 50001 Energy Management System (EnMS)Rating: 4 out of 5 stars4/5 (1)

- PM 372 Roto Packer RVTDocument20 pagesPM 372 Roto Packer RVTLiuel GirmaNo ratings yet

- Quicke Light LeafletDocument8 pagesQuicke Light Leafletinfo4826No ratings yet

- Sage Oil Vac - Lube Truck Literature - September 2019Document7 pagesSage Oil Vac - Lube Truck Literature - September 2019winexonlineNo ratings yet

- List Chemtech 2015 Exhibitors DirectoryDocument410 pagesList Chemtech 2015 Exhibitors Directoryindusexposium100% (1)

- 8 GWDC16K企业画册设计0219-英文版Document13 pages8 GWDC16K企业画册设计0219-英文版AliNo ratings yet

- XL ClassDocument8 pagesXL ClassAliNo ratings yet

- Haver BoeckerDocument5 pagesHaver BoeckerAliNo ratings yet

- DQS ISO 9001 - enDocument2 pagesDQS ISO 9001 - enAliNo ratings yet

- Akash ReportDocument24 pagesAkash ReportDark PrinceNo ratings yet

- Anti-Money Laundering / Counter-Terrorism Financing Policy (AML/CTF-Policy)Document4 pagesAnti-Money Laundering / Counter-Terrorism Financing Policy (AML/CTF-Policy)Georgio RomaniNo ratings yet

- Art of Solving Business Problems The Data Science Way Shweta Doshi DileepDocument75 pagesArt of Solving Business Problems The Data Science Way Shweta Doshi DileepSreekanth AkulaNo ratings yet

- Prajakta Shewale: ObjectiveDocument2 pagesPrajakta Shewale: ObjectiveKiranNo ratings yet

- PPPPPPPPDocument9 pagesPPPPPPPPAndhika HardiansyahNo ratings yet

- Principles of Marketing Ch-2Document5 pagesPrinciples of Marketing Ch-2Nelson B. Porcioncula Jr.No ratings yet

- BSM 230 AssignmentDocument10 pagesBSM 230 Assignmentnchimunyaclement5No ratings yet

- Solved Madison and Tilson Agree To Form A Limited Partnership WithDocument1 pageSolved Madison and Tilson Agree To Form A Limited Partnership WithAnbu jaromiaNo ratings yet

- BJJ9862 Agentcvnote96.jspDocument2 pagesBJJ9862 Agentcvnote96.jspmurray1986No ratings yet

- Archean Chemical Industries LTD - Initiating Coverage - 19122023 - FinalDocument30 pagesArchean Chemical Industries LTD - Initiating Coverage - 19122023 - FinalaccountsNo ratings yet

- ReChain WhitepaperDocument43 pagesReChain WhitepaperJalaluddin Rumi PrasadNo ratings yet

- WP Final 20.06Document154 pagesWP Final 20.06Navroz SinghNo ratings yet

- Kun Motoren PVT LTD: Proforma InvoiceDocument1 pageKun Motoren PVT LTD: Proforma Invoicevijayarama rajuNo ratings yet

- Textiles Market Situation Report 2019 PDFDocument28 pagesTextiles Market Situation Report 2019 PDFsalman sheikhNo ratings yet

- SS1 Economics Third Term Note2022Document56 pagesSS1 Economics Third Term Note2022Emmanuel EyoNo ratings yet

- Kuliah 12-13 Chap017 - 18 PDFDocument66 pagesKuliah 12-13 Chap017 - 18 PDFSajidah PutriNo ratings yet

- Engineering Economy and AccountingDocument143 pagesEngineering Economy and AccountingDan Mitchelle CanoNo ratings yet

- Human Resouse Accounting Nature and Its ApplicationsDocument12 pagesHuman Resouse Accounting Nature and Its ApplicationsParas JainNo ratings yet

- Rate Confirmation 425164Document2 pagesRate Confirmation 425164info.ras7No ratings yet

- Staffing Models and StrategyDocument31 pagesStaffing Models and StrategyNiranjan SinghNo ratings yet

- Disclosure Template - FullDocument15 pagesDisclosure Template - FullMarvin CeledioNo ratings yet

- MRSLConformanceGuidanceV2 1april2024Document24 pagesMRSLConformanceGuidanceV2 1april2024ParsonNo ratings yet

- Ratio Analysis Uttara Bank VS City BankDocument70 pagesRatio Analysis Uttara Bank VS City BankTaznina Nur MuntahaNo ratings yet

- Chap 8Document5 pagesChap 8Sinthya Chakma RaisaNo ratings yet

- T NG H P QuizzDocument4 pagesT NG H P Quizzyen saubiNo ratings yet

- Abyip 2024Document2 pagesAbyip 2024Marc SantosNo ratings yet

- Trading Journal From APRIL 2024 NEW Financial YearDocument11 pagesTrading Journal From APRIL 2024 NEW Financial YearSARVESH SINGHNo ratings yet