CBE Approved ROB-55 Launching 8.06.21

CBE Approved ROB-55 Launching 8.06.21

Uploaded by

Ravikant YadavCopyright:

Available Formats

CBE Approved ROB-55 Launching 8.06.21

CBE Approved ROB-55 Launching 8.06.21

Uploaded by

Ravikant YadavOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

CBE Approved ROB-55 Launching 8.06.21

CBE Approved ROB-55 Launching 8.06.21

Uploaded by

Ravikant YadavCopyright:

Available Formats

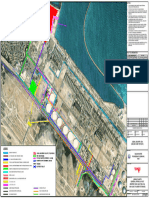

STAGE - I

NOTES

(1) ALL THE DIMENSION & LEVEL ARE IN METER UNLESS OTHERWISE SPECIFIED.

(2) DIMENSIONS ARE NOT TO BE SCALED & ONLY WRITTENDIMENSION SHALL BE FOLLOWED.

31280 c/c of exapansion joint

(3) THE ARRANGEMENT OF CRANE ITS CAPACITY AS PER OPERATING RADIUS AS PER SITE CONDITION TO

0

37280 c/c of exapansion joint BE DECIDED BY SITE ENGG. SITE ENGG SHALL ENSURE AVAILABILITY OF STAND - BY CRANE OF SAME

70

37280 c/c of exapansion joint 30000 c/c of bearing

31

36000 c/c of bearing

36000 c/c of bearing OR HIGHER CAPACITY.

26380

(4). THE RAILWAY TRACK IS BG LINE.

31700

(5) SPAN - 1 STEEL GIRDER ERECTION SHALL BE CARRIED OUT UNDER POWER & TRAFFIC BLOCK

C/L UP TRK

C/L UP TRK

(6) SIGNAL MAN TO BE ENGAGED AT THE BOTH THE SIDE OF TRACK AT PROPER DISTANCE AS DIRECTED

C/L DN TRK

C/L UP TRK

P5 P4 P3 P2 BY RAILWAY AUTHORITY TO PROTECT THE TRACK.

CRANE

CRANE (7) SAFETY NET TO BE PROVIDED DURING ALL CONSTRUCTION OPERATION TILL REMOVAL OF DECK

SHUTTERING DURING THE TRAFFIC BLOCK. TRACK WILL BE PROTECTED BY RAILWAY STAFF AS PER G

37280 & S RULES AND IRPWM

2700 6560 4470 31.28 37.28

31280 6560 4470 26250 (8) ALL THE WORK ON RAILWAY PORTION SHALL BE CARRIED OUT UNDER CLOSE SUPERVISION OF

P5

RAILWAY ENGG.

P4 P3

P5 P4 P3 (9) CGM/ENGG/DFCCIL TO ENSURE THE FEASIBILITY OF ERECTION SCHEME BEFORE COMMENCING THE WORK.

9.55 6.56 4.91 25.82

5 (10) CGM/ENGG./DFCCIL TO TAKE ALL THE PRECAUTION AND TAKE NECESSARY TEMPORARY SIGNALING

3 ARRANGEMENT DURING LINE BLOCK AND DURING CASTING OF DECK SLAB.

(11) THE SPECIFIED CRANE SHOULD BE TESTED AND CERTIFIED AFTER REASSEMBLING AT SITE BEFORE

4.86

COMMENCEMENT OF LAUNCHING WORK

STAGE - II 6.57 4.93 25.78

STAGE - II (12) THE POSITION OF CRANE FOR LIFTING OF GIRDER SHALL BE PLANNED IN SUCH MANNER THAT IT IS NOT

TO TARAPUR INFRINGING EXISTING TRACK

C/L OF PROP. DFC TRACK-1

C/L OF PROP. DFC TRACK-2

31280 c/c of exapansion joint TO KHAMBALE (13) TEMPORARY BARRICATING IF NECESSARY SHALL BE PROVIDED AT 3.5M FROM TRACK

0

37280 c/c of exapansion joint

70

37280 c/c of exapansion joint 30000 c/c of bearing

31

36000 c/c of bearing

36000 c/c of bearing (14) INCHARGE WILL ENSURE AVAILABLE OF CRANE HAVING MIN. CAPACITY AS PER THE BELOW REQUIREMENT A

WESTERN RAILW

C/L OF EXIST. TRACK-1

STAND BY CRANE WILL ALSO BE ENSURE OF SIMILAR CAPACITY . ALL SLINGS, SHACKLES & LIFTING HOOKS

C/L OF EXIST. TRACK-2

C/L OF PROP. FUTURE TRACK-2

26380

C/L OF PROP.FUTURE TRACK-1

31700

USED TO BE PRE TESTED AND CERTIFIED FOR THE LOAD REQUIRED TO BE HANDLED.

(15) THE SPECIFIED CRANE SHOULD BE TESTED AND CERTIFIED AFTER REASSEMBLING AT SITE BEFORE

C/L UP TRK

C/L UP TRK

C/L DN TRK

C/L UP TRK

COMMENCEMENT OF LAUNCHING WORK

DFCC BOUNDARY

(16) PRIOR TO LAUNCHING OF ACTUAL GIRDER IT MUST BE ENSURED TO DEMONSTRATE THE CAPACITY OF THE

AY BOU

CRANE

CRANE

CRANE TO LIFT THE REQUIRED WEIGHT CORRESPONDING TO REQUIRED RADII & BOOM LENGTH AT MOCK

LOCATION IN PRESENCE OF RAILWAY/DFCCIL ENGINEER IN-CHARGE

NDARY

37280 (17) ANY GIRDER SHOULD NOT BE LEFT UN BRACED AFTER ERECTION . INCLINED SUPPORTS SHOULD BE FIXED AS

2700 6560 4470 SHOWN TILL END DIAPHRAGMS ARE FIXED PROPERLY.

31280 6560 4470 26250

(18) SITE INCHARGE SHALL ENSURE THAT ACTUAL WEIGHT OF GIRDER TO BE LIFTED BY CRANE DOES NOT

P5 P4 P3 EXCEED THE VALUE GIVEN IN CRANE EFFICIENCY CHART.

P5 P4 P3 (19) PATHWAY FOR CRANE MOVEMENT CROSSING THE EXISING TRACK SHALL BE PREPARED WITH GUNNY BAGS

TO FACE AN EMERGENCY WHICH SHALL BE CLEARED OFF THE TRACK AFTER LAUNCHING OPERATION

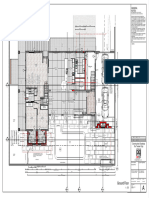

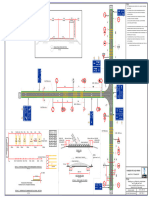

GIRDER DETAILS CRANE DETAILS = LTM 1500

ELEVATION OF SPAN -1 ELEVATION OF SPAN -2

(1) WEIGHT OF STEEL GIRDER (SINGLE) FOR SPAN 1 - 37.00 MT CAPACITY = 500 MT.

(2) WEIGHT OF STEEL GIRDER (SINGLE) FOR SPAN 2 - 25.00 MT MAXIMUM RADIUS OPERATION= (20 MTR) - 58 MT

ELEVATION (3) LENGTH OF GIRDER FOR SPAN 1 - 36.90 MTR STAND BY CRANE : 500 MT

ACTIVITY / LAUNCHING SCHEDULE (4) LENGTH OF GIRDER FOR SPAN 2 - 30.90 MTR

WORK TO BE DONE AFETER

DAY TYPE AND DURATION

REQUIREMENT

WORK TO BE DONE IN BLOCK

OF BLOCK

BLOCK PERIOD EXCLUDING PRE BLOCK ACTIVITIES -

TRACK PORTION (1) SHIFT STEEL GIRDER TO SITE USING CRANE

ROAD LAUNCH GIRDER G1 AND PROVIDE COMPLETE BRACING BETWEEN G1

AND G 2 GIRDER. (2) FIX THE SLING TO ALL GIRDERS ON LIFTING HOOK ARRANGEMENT ATTACHED IN THE GIRDER AT L/4 FROM THE

TEMPORARY SUPPORT TO G1

ROAD END

LAUNCH GIRDER G2 AND PROVIDE END COMPLETE BRACING BETWEEN G2 (3) GIRDER WILL BE KEPT READY FOR ERECTION OVER BEARINGS FIXED ON PEDESTAL AS PER DWG

DIAPHRAGM BETWEEN G1 & G2 AND G 3 GIRDER.START SHUTTERING (4) ROAD TRAFFIC DIVERSION ARRANGEMENT SHALL BE DONE BEFORE STARTING OF ERECTION ( IF NECESSARY)

PROVIDE REMAINING BRACING BETWEEN ACTIVITY OF SLAB

GIRDER G1 & G2 OVER TRACK PORTION

TO KHAMBALE P5

P4 P3 TO TARAPUR

TO KHAMBALE P4 P3 LAUNCH GIRDER G3 AND PROVIDE END COMPLETE BRACING BETWEEN G 3

DURING BLOCK ACTIVITIES (SPAN 1)-

P5 TO TARAPUR DIAPHRAGM BETWEEN G 2 & G3 4 HOURS - AND G 4 IN PORTION OF GIRDER (1) LIFT THE GIRDER G 1 KEEPING SPECIFIED OR LESSER OPERATING RADIUS OF CRANE UP TO HEIGHT JUST

POWER & NOT AFFECTED BY TRACK PIER CAP. FORWARD MOVEMENT OF GIRDER BE RESORTED THROUGH ROTATING AND EXTENDING THE

ABOVE PILE

TRAFFIC CRANE BOOM TOWARDS PIER.

PROVIDE REMAINING BRACING BETWEEN BLOCK ON UP COMPLETE BRACING BETWEEN G3 AND

SPAN - 1 GIRDER G2 & G3 OVER TRACK PORTION (2) LOWER THE GIRDER OVER THE BEARING AND MINOR ADJUSTMENT BE DONE FOR ALLOWING GIRDERS TO SIT

0

AND DOWN G 4 GIRDER.START SHUTTERING IN THEIR CORRECTED POSITION.

88 ACTIVITY OF SLAB

19 LAUNCH GIRDER G 4 AND PROVIDE END TRACK

DIAPHRAGM BETWEEN G3 & G4 (3) FIX THE INCLINED SUPPORTING PROPS ON BOTH SIDES AT EACH END OF THE GIRDER AT SHOWN IN DRG.

0

38

19 00

(4) REMOVE THE CRANES SLING FROM LIFTING HOOKS OF STEEL GIRDER.

15530

18030

187 0

18030

PROVIDE REMAINING BRACING BETWEEN COMPLETE BRACING BETWEEN G4

1820

17800 GIRDER G3 & G4 OVER TRACK PORTION AND G5 IN PORTION OF GIRDER (5) REPEAT STEPS ABOVE TO LAUNCH GIRDER G2. PROVIDE END & CENTRAL BRACINGS, DIAPHRAGM

13030

10530

NOT AFFECTED BY TRACK START BETWEEN G1 & G2 AS SHOWN.

C/L DN TRK

C/L UP TRK

LAUNCH GIRDER G 5 AND PROVIDE END

8040

SHUTTERING ACTIVITY OF SLAB (6) REPEAT STEPS 1 TO 5 ABOVE FOR REMAINING GIRDERS G3,G4,G5

DIAPHRAGM & CENTRAL BRACING BRACING

0 BETWEEN G4 & G5 REQUIREMENTS

36900

75

16

2700

30000 (1) SHORT DURATION TRAFFIC AND POWER BLOCK SHALL BE REQUIRED AT LEAST 12 HRS. PRIOR TO

36900

24000

MAJOR BLOCK FOR ENTRANCE OF CRANE INTO WORKING AREA

LAUNCH GIRDER G1,G2,G3,G4 & G5 AND NOT REQUIRED

PROVIDE END & CENTRAL BRACING AND POWER & TRAFFIC (2) SHORT DURATION TRAFFIC AND POWER BLOCK SHALL BE REQUIRED AS FEASIBLE AFTER MAJOR BLOCK

SPAN - 2

15000

DIAPHRAGMS BETWEEN GIRDER BLOCK FOR FIXING OF BRACING OF GIRDER ALREADY LAUNCHING

45000 (3) THE NECESSARY NUMBER OF TRAFFIC WARDEN TO BE DEPLOYED TO GUIDE PEDESTRIANS.

C/L DN TRK

C/L UP TRK

SLING DETAILS :- (4) FLAG MAN AND LAMP MAN TO BE DEPLOYED ON THE TRACK PROTECTION

4000 (5) SINCE THE ERECTION WILL BE DONE IN TRAFFIC BLOCK ALL THE AREA WILL BE ILLUMINATED BY

TOTAL WEIGHT TO BE LIFTED :- 37MT.

30000 LOAD ON CRANE :- 37 MT. FLOOD LIGHT FOR WHICH GENERATOR WILL BE KEPT AS STAND BY ARRANGEMENT FOR LIGHTING.

SAFE CAPACITY OF ONE SLING :- (6) THE TOTAL HOUR OF MAJOR (TRAFFIC / POWER ) BLOCK IN A DAY CAN NOT BE SPLIT IN TO SEPARATE BLOCK

NO.OF SLING USED :- 2 NO. (7) DURING CASTING OF DECK SLAB SPEED RESTRICTION OF 20 KMPLON THE RAILWAY TRACK IS REQUIRED

STAND BY CRANE

6340 MAXIMUM FORCE IN ONE SLING :-

STAND BY CRANE

DIA OF SLING :- 60 MM IMPORTANT NOTES :

TYPE OF SLING TO BE USED :- 6 x 37 M (18/12/6-1) 1570 GRADE STEEL

DETAILS OF SITE PLAN OF LAUNCHING OF SPAN -1 DETAILS OF SITE PLAN OF LAUNCHING OF SPAN-2 CORE AS PER TABLE 3 OF IS 2266:2002 (1) AS PER RAILWAY BOARD LETTER NO. 2015/CE-IV/RUB/206 DATED - 15.02.2016 & 11.08.2016, BASED ON SITE

CONDITION i.e. FOR MAXIMUM BOOM LENGTH AND OPERATING RADIUS, SAFE WORKING LOAD OF CRANE

SHALL BE ASSESSED WHICH SHALL BE MORE THAN 1.5 TIME FOR LOAD TO BE HANDLED

PLAN (2) PATHWAY FOR CRANE MOVEMENT CROSSING EXISTING TRACK SHALL BE TEMPORARILY PREPARED

ADDITIONAL STIFFENERS TO BE PROVIDED AT 1 NO OF 6 x 37 M (18/12/6-1) GIRDER WITH GUNNY BAGS TO FACE AN EMERGENCY WHICH SHALL BE CLEARED OFF THE TRACK AFTER THE

BOTH ENDS TO FIX TEMPORARY SUPPORTING 25 @ BOLT 25 @ BOLT

ISMC - 100 1570 GRADE STEEL CORE OPERATION OF LAUNCHING

(600 x 600 x 20) ARRANGEMENT TO GIRDER (TYP.) ISMC - 250 400 ISMC - 250

PLATE (TYP.) ISMC - 100 CAPACITY = MT BACK TO BACK

50

BACK TO BACK (3) FOR LAUNCHING OF STEEL GIRDER USING ROAD CRANE ALL THE NECESSARY PRECAUTION AS

ISMC - 250

BACK TO BACK (600 x 600 x 20) STIPULATED VIDE HQ LETTER NO. W65/0/BRIDGE (W3) DATED 25.02.2016 SHOULD BE OBSERVED IT

WOODEN PLATE 25 @ BOLT

SLEEPER WOODEN SHOULD BE ENSURE THAT NO CRANE OPERATION IN UNDER TAKEN UNLESS A STAND BY CRANE OF

12 MM THK .PLATE SLEEPER GIRDER ADEQUATE CAPACITY IS AVAILABLE WHICH CAN HANDEL THE JOB IN CASE OF FAILURE OF DESIGNATED

2000

(600 x 600 x 20) 60MM DIA 6 x 37 M (18/12/6-1) 1570

WOODEN WOODEN

PLATE BEARING (TYP) GRADE STEEL CORE AS PER TABLE CRANE TEST CERTIFICATE OF THE CRANE FOR IT MAINTENANCE CAPACITY & PROPER LICENCE OF THE

BLOCK BLOCK

PEDESTAL WOODEN

12 MM THK 3 OF IS 2266:2002 DRIVER SHALL BE ENSURED & MAINTAINED AT SITE.

BLOCK PEDESTAL PEDESTAL

PEDESTAL BEARING PEDESTAL PEDESTAL PEDESTAL

PIER CAP PLATE (4) REFER HQ LETTER NO.W65/0/POLICY (W3) DATED 04.02.2019 FOR SAFETY PRECAUTIONS TO BE TAKEN

(TYP)

PIER CAP

°

>45

DURING LAUNCHING OPERATION.

>45

PIER CAP

45

850

SIDE SUPPORTS ARRANGEMENT WHEN

°

SINGLE GARDER IS PLACED IN POSITION SIDE SUPPORTS ARRANGEMENT WHEN CROSS SECTION OF GIRDER (5) REFER HQ LETTER NO. W65/11/SAFETY DATED 18.06.2019 FOR GUIDELINES FOR TAKING TRAFFIC & POWER

TWO GIRDERS PLACED IN POSITION FIX END DIPHARAMGM BETWEEN FIRST AND SECOND GIRDER BEFORE REMOVING THE SIDE (36.90 M ) BLOCK.

SUPPORT OF 1st & 2nd GIRDER AND PROVIDE SEPARATE SIDE SUPPORTS TO THE NEXT GIRDER

CONTINUE IN SIMILAR WAY FOR NEXT GIRDER.

REFERENCE DRAWINGS :

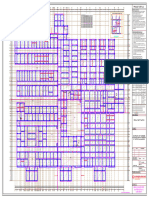

L/4 L/4

30900 1. GENERAL ARRANGEMENT DRAWING : DRM (B) 24853/14-F, PCE NO.24078-DRM/1-D

4 NOS. RIB PLATE

65Ø HOLE 80 80

220 X 80 X 16 60MM DIA 6 x 37 M (18/12/6-1) 1570

400 GRADE STEEL CORE AS PER TABLE

3 OF IS 2266:2002

PCE NO. e-29255-DRM / 1-D

°

>45

>45

32 65Ø HOLE

°

4 NOS. RIB PLATE

TOP FLANGE OF

80 140 80

220

220 X 80 X 16

DRM(B) 26817/14-F LAUNCHING SCHEME OF ROB IN

GIRDER

32

10 MM THICK PLATE 220 X 300 X 32

LIEU OF LC 55 AT KM 110/14-16

350

PLATE 220 X 300 X 32 L/4 L/4

WELD

36900 (L)

PLATE 400 X 350 X 20 16 16

10 MM THICK WELD

ELEVATION

WESTERN RAILWAY BETWEEN BOISAR-VANGAON OF

400 300 PLATE 400 X 350 X 20 ARRANGEMENT FOR LIFTING WITHOUT LIFTING FRAME

Signature block

VR-ST SECTION

SPAN-1 (P3 TO P4)

BLOCK/ACTIVITY SHEDULE & CRANE EFFICENCY CHART CBE-CCG MANJUL MATHUR Digitally signed by MANJUL MATHUR

(SPAN 1X30 M) + (SPAN 1X36 M)

Date: 2021.06.08 16:11:41 +05'30'

TOOLS & PLANTS WEIGHT OF MAXIMUM RADIUS RQD

AS PER CRANE LOAD CHART %CRANE CAPACITY

Digitally signed by HIMANSHU MMCT DIVISION

NO BLOCK PERIOD ACTIVITY BOOM LENGTH IN LIFTING CAPACITY IN USED

PLAN Sr.No PERTICULARS NOS

GIRDER IN MTR RADIUS IN MTR

MTR MT

DYCE-DESIGN-CCG SHARMA

SIDE VIEW

Date: 2021.06.07 16:37:15 +05'30'

G1

LIFTING & PLACING

OF GIRDER 1

37.0 MT 19.98 20 31.7 58 63.79 %

AXEN-DESIGN-CCG N K Chaudhary Digitally signed by N K Chaudhary VR-ST SECTION

Date: 2021.06.07 13:11:44 +05'30'

4 NOS. RIB PLATE 1. HYDRAULIC CRANE (500T) 1 NOS G2 4 HRS TRAFFIC

LIFTING & PLACING

OF GIRDER 2

37.0 MT 19.38 20 31.7 58 63.79 % G V L SATYA KUMAR Digitally signed by G

&POWER

65Ø HOLE 300

220 X 80 X 16 2. STAND BY CRANE (500T) 1 NOS G3 BLOCK LIFTING & PLACING

37.0 MT 18.70 31.7 58 63.79 %

DRM-MMCT V L SATYA KUMAR

Date:2021.05.17 03:28:36 +05'30'

OF GIRDER 3 20

80 140 80 GURU PRAKASH Digitally signed by GURU

3. HYDRA/ FRAHANA 2 NOS G4

LIFTING & PLACING

37.0 MT 18.20 20 31.7 58 63.79 % ADRM-I-MMCT PRAKASH CLIENT:- DFCCIL

OF GIRDER 4 Date:2021.05.13 04:29:00 +05'30'

16 4. SLING S /DECYCLE 2 +2 NOS G5

LIFTING & PLACING

37.0 MT 17.80 18 31.7 67 55.22 % KAILASH MEENA Digitally signed by

OF GIRDER 5

PLATE 220 X 300 X 32 5. WOODEN BLOCKS AS REQUIRED

SRDEN-NORTH-MMCT KAILASH MEENA

Date:2021.05.13 01:11:39 +05'30'

220 SPAN-2 (P4 TO P5)

6. SAFETY ARRANGEMENT AS REQUIRED BLOCK/ACTIVITY SHEDULE & CRANE EFFICENCY CHART JE-DESIGN-I-CCG Harshal Patil Digitally signed by Harshal Patil

10 MM THICK 110 16 110

Date: 2021.06.07 10:00:27 +05'30'

CONTRACTOR:- M/S A B INFRABUILD .LTD

7. MAN POWER AS REQUIRED WEIGHT OF

AS PER CRANE LOAD CHART %CRANE CAPACITY

WELD NO BLOCK PERIOD ACTIVITY GIRDER

MAXIMUM RADIUS RQD

IN MTR RADIUS IN MTR

BOOM LENGTH IN LIFTING CAPACITY IN USED

PLATE 400 X 350 X 20 8. WELDING MACHINE 2 NOS LIFTING & PLACING

MTR MT

G1 25 MT 18.03 20 31.7 58 43.10 %

9. GAS CUTTER SET 2 NOS OF GIRDER 1

G2

LIFTING & PLACING WORK :- LAUNCHING SCHEME OF LC-55 OF

ELEVATION 10. LPG CYLINDER 2 NOS

G3 NOT REQUIRED

OF GIRDER 2

LIFTING & PLACING

25 MT 15.530 16 31.7 78

92

32.05 %

VANGAON

11. ERECTION TOOLS AS REQUIRED OF GIRDER 3

25 MT 13.03 14 31.7 27.17 %

LIFTING & PLACING

LIFTING HOOK ARRANGEMENT 12. CHAIN PULLEY 2 NOS G4

OF GIRDER 4

LIFTING & PLACING

25 MT 10.53 12 31.7 110 22.73 %

DRG. NO. CCG/N/MUM/LC-55 LAUNCHING SCHEME/BOR-VGN/2021/008

13. DG SET 2 NOS G5

OF GIRDER 5

25 MT 8.04 10 31.7 130 19.23 %

You might also like

- P1-Sanitary, Waterline, Storm Drainage Layout, General NotesDocument1 pageP1-Sanitary, Waterline, Storm Drainage Layout, General NotesRonnel John CruzNo ratings yet

- RN 02 00001 06 11 El WBG DG 000754Document1 pageRN 02 00001 06 11 El WBG DG 000754eiohatNo ratings yet

- Tbpp-Con-02-Ww-Sdr-5006-0 Section ST U-Channel (9052184.908,317490.350) To M13-1F (Sheet 1 of 2)Document1 pageTbpp-Con-02-Ww-Sdr-5006-0 Section ST U-Channel (9052184.908,317490.350) To M13-1F (Sheet 1 of 2)jenorico soaresNo ratings yet

- For Continuation of Services Refer To Drawing No. 39488-6000-Xx-01-Dr-M-31011Document1 pageFor Continuation of Services Refer To Drawing No. 39488-6000-Xx-01-Dr-M-31011Mohammed MonisNo ratings yet

- Bxxxx-200-E-Cv-Dg-013 - RC - Drain Layout (SH-1 of 2) - 2024-05-15Document1 pageBxxxx-200-E-Cv-Dg-013 - RC - Drain Layout (SH-1 of 2) - 2024-05-15Er Rizwan AhmedNo ratings yet

- SLRB_Krishnunipalem_10-09-2020Document1 pageSLRB_Krishnunipalem_10-09-2020Anand BabuNo ratings yet

- GIANT-DOC-ALFE-DRAWING-L110-SK-K10.1U.R1-Giant TemplateDocument1 pageGIANT-DOC-ALFE-DRAWING-L110-SK-K10.1U.R1-Giant TemplateJhun VelascoNo ratings yet

- GIANT-DOC-ALFE-DRAWING-L105-SK-E01-A-Giant TemplateDocument1 pageGIANT-DOC-ALFE-DRAWING-L105-SK-E01-A-Giant TemplateJhun VelascoNo ratings yet

- GIANT-DOC-ALFE-DRAWING-L109-SK-K10.1L.R1-Giant TemplateDocument1 pageGIANT-DOC-ALFE-DRAWING-L109-SK-K10.1L.R1-Giant TemplateJhun VelascoNo ratings yet

- GIANT-DOC-ALFE-DRAWING-L109-SK-K10.1L-Giant TemplateDocument1 pageGIANT-DOC-ALFE-DRAWING-L109-SK-K10.1L-Giant TemplateJhun VelascoNo ratings yet

- GIANT-DOC-ALFE-DRAWING-L105-SK-E01-A.R1-Giant TemplateDocument1 pageGIANT-DOC-ALFE-DRAWING-L105-SK-E01-A.R1-Giant TemplateJhun VelascoNo ratings yet

- L (63) 09 Layout1Document1 pageL (63) 09 Layout1Shreekant KeraiNo ratings yet

- Kafd A1 111 Comn BF1 XXXXX SHP Arc Asb 00023Document1 pageKafd A1 111 Comn BF1 XXXXX SHP Arc Asb 00023YazNo ratings yet

- A-A0-0904-2 - Lift Details-5bDocument1 pageA-A0-0904-2 - Lift Details-5bNilan GamageNo ratings yet

- P-DRG-117 - 11TH Floor Plan - Drainage LayoutDocument1 pageP-DRG-117 - 11TH Floor Plan - Drainage LayoutengmaramalsaidiNo ratings yet

- Stage 4: For Continuation of Services Refer To Drawing No. 39488-6000-Xx-01-Dr-M-31014Document1 pageStage 4: For Continuation of Services Refer To Drawing No. 39488-6000-Xx-01-Dr-M-31014Mohammed MonisNo ratings yet

- Structural DrawingsDocument3 pagesStructural Drawingssydney augustNo ratings yet

- Notes: A-ACN-120409Document1 pageNotes: A-ACN-120409Hakim BukenyaNo ratings yet

- Msar Sab Pa Ic Zn1 Bs02 b03 SPD Arc 1102b 00Document1 pageMsar Sab Pa Ic Zn1 Bs02 b03 SPD Arc 1102b 00Mahmoud Abou El NagaNo ratings yet

- 112-E-00056 - 1 Electrical One Line Diagram - 1Document1 page112-E-00056 - 1 Electrical One Line Diagram - 1winmyintzawNo ratings yet

- MP-01 (Cornice-1 D08)Document1 pageMP-01 (Cornice-1 D08)Ibrahim MohamedNo ratings yet

- NAS-6-RA04-EE030-0004-SD-01-01-R02-Code BDocument1 pageNAS-6-RA04-EE030-0004-SD-01-01-R02-Code BVijayan Thekke VeeduNo ratings yet

- Storm Water PDFDocument1 pageStorm Water PDFthushanmadusankaNo ratings yet

- t76-R-pp-476561-001 - Rev B Utility Ome Building PlanDocument1 paget76-R-pp-476561-001 - Rev B Utility Ome Building PlanTayyab AchakzaiNo ratings yet

- Merge Drawings 1 6Document1 pageMerge Drawings 1 6BenNo ratings yet

- Stage 4: For High Level Services Refer To Drawing No. 39488-6000-XX-01-DR-M-31011Document1 pageStage 4: For High Level Services Refer To Drawing No. 39488-6000-XX-01-DR-M-31011Mohammed MonisNo ratings yet

- A-1803d - Landscape Sections & Details - 05Document1 pageA-1803d - Landscape Sections & Details - 05karthikeyan dhanasekaranNo ratings yet

- Approved Plan 1Document1 pageApproved Plan 1sibusiso.chisi9No ratings yet

- Water & Air PipelineDocument2 pagesWater & Air Pipelinereza.rahardjoNo ratings yet

- Jubail 4&6 OverallDocument1 pageJubail 4&6 Overallnazih sedrakNo ratings yet

- 20-001-A-10-A1 PlansElevSecDocument4 pages20-001-A-10-A1 PlansElevSecDanie CoetzerNo ratings yet

- Msar MHT Pa Ic Zn1 Bs02 Det DWG STR 0608 02Document1 pageMsar MHT Pa Ic Zn1 Bs02 Det DWG STR 0608 02柔道—Ibn MasudNo ratings yet

- FFDocument1 pageFFHassan RazaNo ratings yet

- Typical T Intersection On Rural Local Road With Left Turn LanesDocument1 pageTypical T Intersection On Rural Local Road With Left Turn Lanesahmed.almakawyNo ratings yet

- Typical T Intersection On Rural Local Road With Left Turn LanesDocument1 pageTypical T Intersection On Rural Local Road With Left Turn Lanesahmed.almakawyNo ratings yet

- Geotechnical DrawingsDocument21 pagesGeotechnical DrawingsWaleed FayezNo ratings yet

- Typical T-Intersection Details Between Branch Road and Divided Highways - 1Document1 pageTypical T-Intersection Details Between Branch Road and Divided Highways - 1ahmed.almakawyNo ratings yet

- 8320 Poi DRG Civ 200011 P01Document1 page8320 Poi DRG Civ 200011 P01Suhas VNo ratings yet

- 150 TO 200 BEDED - GROUND FLOOR ROOF BEAM SHUTTERING PLAN, SLAB & BEAM DESIGN - 23-08-2023-ModelDocument1 page150 TO 200 BEDED - GROUND FLOOR ROOF BEAM SHUTTERING PLAN, SLAB & BEAM DESIGN - 23-08-2023-ModelMUKESH RAJENDRANo ratings yet

- A61 Q FDN Va 046778 001 Pile Cap DetailsDocument1 pageA61 Q FDN Va 046778 001 Pile Cap DetailsadnanNo ratings yet

- Somaa Bay Pool Reef Town - Emw 3 (1) - Pool PlanDocument1 pageSomaa Bay Pool Reef Town - Emw 3 (1) - Pool PlanAhmed NaserNo ratings yet

- Merge Drawings 1 13Document1 pageMerge Drawings 1 13BenNo ratings yet

- Rpipl K Oa Amp Ce DWG MCR 008Document2 pagesRpipl K Oa Amp Ce DWG MCR 008aaaaNo ratings yet

- Pump Foundation Plan Pump Foundation Plan: NotesDocument1 pagePump Foundation Plan Pump Foundation Plan: NotesamitNo ratings yet

- Saudi Arabian Oil Company: H75 P HA-162461 004 00Document1 pageSaudi Arabian Oil Company: H75 P HA-162461 004 00cherif yahyaouiNo ratings yet

- A12PR01Document3 pagesA12PR01aatifmumtazNo ratings yet

- WC Layout Level 6: SCALE:1/350Document13 pagesWC Layout Level 6: SCALE:1/350lengchhanun893No ratings yet

- Construction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesDocument1 pageConstruction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesrajavelNo ratings yet

- Structural DrawingsDocument3 pagesStructural Drawingskwoshaba pidson100% (1)

- Merge Drawings 1 9Document1 pageMerge Drawings 1 9BenNo ratings yet

- DA216513 003生水、消防水泵进口管路系统Document1 pageDA216513 003生水、消防水泵进口管路系统hasni sheikhNo ratings yet

- Slab 2355Document1 pageSlab 2355kevoroyalprinzNo ratings yet

- NotesDocument1 pageNotesassis alihNo ratings yet

- Subdivision Storm Sewers Sample AnnotatedDocument1 pageSubdivision Storm Sewers Sample Annotatedaggrey noahNo ratings yet

- Subdivision Storm Sewers SampleDocument1 pageSubdivision Storm Sewers Sampleaggrey noahNo ratings yet

- A12PR06Document2 pagesA12PR06aatifmumtazNo ratings yet

- Madac SD El Fa BF 504Document1 pageMadac SD El Fa BF 504shoaibNo ratings yet

- NotesDocument1 pageNotes김대환No ratings yet

- Paul Cafe@Marassi Galleria Bahrain SD Mep Emergency Lighting System Layout R 00Document1 pagePaul Cafe@Marassi Galleria Bahrain SD Mep Emergency Lighting System Layout R 00arulselvan22No ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Beosound 4 v2.PhpDocument32 pagesBeosound 4 v2.PhpwudixiaoxingyaNo ratings yet

- Herald MPMC Course PlanDocument11 pagesHerald MPMC Course PlanheraldNo ratings yet

- Shodan - Io Cheat Sheet: by ViaDocument1 pageShodan - Io Cheat Sheet: by ViaCarlos MirandaNo ratings yet

- Mastering Digital Dropshipping - Your ComprehensivDocument4 pagesMastering Digital Dropshipping - Your ComprehensivtalesnapsNo ratings yet

- Ba Rf18xc-Rf18xci 76 En-UsDocument184 pagesBa Rf18xc-Rf18xci 76 En-UsKatya ButterflieNo ratings yet

- IGC 2 - Element 5 - Electrical SafetyDocument33 pagesIGC 2 - Element 5 - Electrical SafetyHim SiwakotiNo ratings yet

- NAT SimulationDocument3 pagesNAT SimulationdarkfirexNo ratings yet

- RPSC Programmer MCQ 2Document15 pagesRPSC Programmer MCQ 2Vikas SinghalNo ratings yet

- Fm/Am Compact Disc Player: CDX-GT540UIDocument52 pagesFm/Am Compact Disc Player: CDX-GT540UIYail Martinez LorenzoNo ratings yet

- 1 FIELD STUDY Episode 11 16Document75 pages1 FIELD STUDY Episode 11 16Kenith RagonNo ratings yet

- Instrument Selection, Installation ProceduresDocument38 pagesInstrument Selection, Installation ProceduresHalouani IsmailNo ratings yet

- WINRM (Windows Remote Management)Document8 pagesWINRM (Windows Remote Management)ZzaY .ANo ratings yet

- CS8493 Operating Systems - Unit IDocument24 pagesCS8493 Operating Systems - Unit ILokesh Srm100% (2)

- SOC Analyst SeriesDocument26 pagesSOC Analyst SeriesRuchirNo ratings yet

- SaaS ArchitectureDocument20 pagesSaaS ArchitectureFirdausNo ratings yet

- Petronas Syntium 5000 CP 5w-30 70606e18eu 70606m12euDocument2 pagesPetronas Syntium 5000 CP 5w-30 70606e18eu 70606m12eusergsxrNo ratings yet

- User Manual: HGM9510 Genset Parallel (With Genset) UnitDocument64 pagesUser Manual: HGM9510 Genset Parallel (With Genset) UnitZia ur RehmanNo ratings yet

- 2021 Field Sales Benchmark ReportDocument19 pages2021 Field Sales Benchmark ReportFarosNo ratings yet

- Hardware: ArchitecturesDocument33 pagesHardware: Architecturesaliha ghaffarNo ratings yet

- The Basics of Intrinsic SafetyDocument4 pagesThe Basics of Intrinsic SafetyMahesh DivakarNo ratings yet

- GCL Installation Manual 2020Document26 pagesGCL Installation Manual 2020Javad NaserbakhtNo ratings yet

- Syllabus 2Document2 pagesSyllabus 2satyam rajNo ratings yet

- 550-560-570 User Guide en-EN PDFDocument274 pages550-560-570 User Guide en-EN PDFjanam_sweetNo ratings yet

- Otrs Itsm BookDocument86 pagesOtrs Itsm BooklimesmartNo ratings yet

- Operation Qualification Protocol For Air Handling Unit & Air Distribution System - Pharmaceutical GuidanceDocument13 pagesOperation Qualification Protocol For Air Handling Unit & Air Distribution System - Pharmaceutical GuidanceMohamad IsmailNo ratings yet

- Reil ReportDocument55 pagesReil ReportTajinder SinghNo ratings yet

- Whip ChecksDocument1 pageWhip ChecksARULSELVAN MURUGESANNo ratings yet

- 3.1.12 Lab - Explore Python Development ToolsDocument8 pages3.1.12 Lab - Explore Python Development ToolsEduardo Manuel Sandoval SalazarNo ratings yet

- Globetech 2023Document4 pagesGlobetech 2023pradip.adsare82No ratings yet

- LESSON 2 Q1 Oral Com G11Document2 pagesLESSON 2 Q1 Oral Com G11Joshua Lander Soquita CadayonaNo ratings yet