C2 Lab Manual Final

Uploaded by

Rafiah JobC2 Lab Manual Final

Uploaded by

Rafiah JobCHNG 2009 CHEMICAL ENGINEERING LABORATORY II

C2 TERNARY LIQUID-LIQUID EQUILIBRIUM II

Objective: To construct a ternary diagram for a liquid-liquid extraction process consisting of

a water-acetic acid-butyl acetate system.

THEORY

Liquid-liquid extraction is a process whereby a solute is transferred from a solution

representing the raffinate phase into the extracting solvent representing the extract phase. The

two phases are chemically different, which leads to the separation of the components depending

on their distribution or partition between the two phases. The distribution coefficient represents

the ratio of the concentrations of the solute in the extract phase to the raffinate phase.

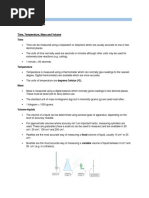

Data obtained for liquid-liquid extraction can be plotted on a ternary diagram as shown in

Figure 1 below.

Figure 1: Ternary Diagram

The three apexes represent pure components A, B and C. The point M represents a mixture.

The perpendicular distance from point M to any base line is the mass fraction of the component

at the corner opposite to the respective baseline.

Prepared by: R.B.B 2022

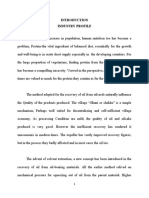

Figure 2: Aspects of a ternary diagram for a Type II system.

Figure 2 above represents some useful characteristics of a ternary diagram. In this diagram, A

represents the diluent, B represents the extract solvent and C represents the solute. The feed in

a liquid-liquid extraction contains the two components to be separated, i.e. components A and

C. The key component in the feed is A whilst the transferred substance is C. An extracting

solvent has to be added in order to separate C from A and usually, this solvent is pure. Upon

mixing and then separation, the solvent phase contains mainly B and the extracted component

C, with a minute amount of A. The raffinate phase is that which is left from the feed after being

mixed with the extract solvent. It is composed mainly of A and very small amounts of both B

and C.

Under the solubility curve, there exists the two phase region whilst anywhere above the curve

will be a homogeneous mixture of one liquid phase. The dotted line RE represents a tie line

which are straight lines drawn across the immiscible region to connect points on the solubility

curve. These two points represent the equilibrium-phase compositions. The operating line,

which connects the point B (pure solvent) to RF (the feed composition of the raffinate), can be

used to determine the mixing point, M. The point at which the operating line and tie line

intersects is the point M.

Alternatively, the mixing point, M can be determined using the lever arm rule which is

represented in the formula below.

̅̅̅̅̅

𝑅𝑀 𝐸

= (1)

̅̅̅̅̅

𝑀𝐸 𝑅

Where E = Extract phase

R = Raffinate phase

Prepared by: R.B.B 2022

̅̅̅̅̅ = Length between the raffinate phase and the mixing point

𝑅𝑀

̅̅̅̅̅

𝑀𝐸 = Length between the mixing point and the extract phase

The formula for standard deviation is expressed below.

∑𝑁

1 (𝑉 − 𝜇)

2

𝑆𝑡𝑎𝑛𝑑𝑎𝑟𝑑 𝐷𝑒𝑣𝑖𝑎𝑡𝑖𝑜𝑛, 𝑆𝐷 = √ (2)

𝑁−1

Where V = sample

μ = average

N = number in sample

APPARATUS/REAGENTS

Apparatus

• Analytical balance • 1 – 50 ml burette

• Mixer • Retort stand with clamp

• Magnetic stirrer • Funnel

• Magnetic rod • Separating funnel

• 6 – 250 ml beakers • Retort stand with separating funnel

• 1 – 500 ml beaker (for waste) holder

• 3 – 100 ml conical flasks • Dropper

• 1 – 5 ml digital pipette and tips

Reagents

• Acetic acid (glacial)

• Butyl Acetate

• Distilled Water

• 1 M NaOH

• Phenolphthalein

Prepared by: R.B.B 2022

PROCEDURE

1. Pour approximately 50 ml of acetic acid and 200 ml of butyl acetate into two separate

and well labelled beakers. These will be used as the samples for each run.

2. Fill the burette with the 1 M NaOH solution provided.

3. For a total mass of 35 grams, weigh approximately 5% (by mass) acetic acid in a beaker

using the analytical balance. Use distilled water to make up the mass to 35 grams.

Carefully drop the magnetic stirrer into this beaker and place the beaker onto the mixer.

4. Use another beaker to measure approximately 35 grams of butyl acetate. Once weighed,

pour the butyl acetate into the beaker containing the acetic acid-water mixture and

simultaneously turn the dial on the mixer to a setting of “6” to allow the contents to mix

for five (5) minutes. (Note: Stirrer should be put on a setting to avoid splashing)

5. Once mixing has finished, use the magnetic rod to retrieve the stirrer and then pour the

mixture into the separating funnel. Allow the mixture to separate for five (5) minutes.

6. When the time has elapsed, run the aqueous phase from the separating funnel into a

beaker.

7. Pipette 5 ml of the aqueous phase into a conical flask and note the mass. Add

phenolphthalein indicator to the conical flask.

8. Titrate the sample against the NaOH in the burette until a faint pink colour is obtained.

Note the initial and final volumes on the burette. (The endpoint is critical of the faint

pink colour. Note that an intense pink colour is erroneous.)

9. Repeat steps 7 and 8 twice to obtain data in triplicate.

10. Run the solvent phase from the separating funnel into a beaker and note the mass.

11. Repeat procedure for 10%, 15%, 25% and 45% by mass of acetic acid.

RESULTS/CALCULATIONS

Notes: Include the standard deviation where appropriate.

State all assumptions.

1. Complete the solubility data table for the water phase and plot this data on a ternary

diagram.

2. State the uncertainties in the analytical balance and burette readings.

Prepared by: R.B.B 2022

3. Compute the standard deviation for the titre values.

4. Using the titration values tabulated, calculate the number of moles of acetic acid in the

aqueous phase.

5. Using the number of moles estimated, calculate the mass of acetic acid in the aqueous

phase.

6. Taking a component balance, find the mass of acetic acid in the solvent phase.

7. Calculate the composition of acetic acid in both the aqueous and solvent phases for each

run.

8. Using the acetic acid compositions, plot the tie lines on the ternary diagram for each

run and state the equilibrium compositions of each tie line for both the raffinate and

extract phases.

9. Determine the composition of the mixing point graphically on each tie line. Use this

point to determine the mass of both phases as well as the percentage of the mass of each

phase to the total mass. (Note: The percentage of the mass for each phase obtained

experimentally should also be calculated for comparison purposes)

10. Determine the maximum concentration of the solvent free extract graphically.

11. Determine the maximum concentration in an extract graphically.

NB: Tabulate data where necessary.

For graphical estimations, one ternary diagram is appropriate.

DISCUSSION OF RESULTS

1. Discuss how the tie lines were plotted from experimental data.

2. Discuss how the mixing point can be determined graphically on the ternary diagram.

3. With reference to the distribution coefficient, discuss the trends observed for the

experimental masses obtained for both the aqueous and solvent phases across the five

runs. Were these trends expected?

4. Compare the experimental masses of both phases to that obtained from the tie lines.

Comment on any major discrepancies observed.

Prepared by: R.B.B 2022

Discovery Section

1. Compare the extraction efficiency between a partially miscible system and a totally

immiscible system, commenting on the availability of the solute and the distribution

coefficients where applicable.

2. How does temperature affect solubility of this system?

REFERENCES

Harker, J. H., J. R. Backhurst, and J. F, Richardson. Chemical Engineering Volume 2:

Particle Technology and Separation Processes. Burlington: Elsevier Science, 2002.

Prepared by: R.B.B 2022

You might also like

- Experiment 3: Ternary Phase Diagram (Liquid-Liquid Extraction)100% (1)Experiment 3: Ternary Phase Diagram (Liquid-Liquid Extraction)15 pages

- Calculate Distribution Coefficient: I. AimNo ratings yetCalculate Distribution Coefficient: I. Aim2 pages

- Liquid-Liquid Extraction (Effect of Phase Ratio)No ratings yetLiquid-Liquid Extraction (Effect of Phase Ratio)21 pages

- Chapter 4 - Liquid - Liquid Extraction PDFNo ratings yetChapter 4 - Liquid - Liquid Extraction PDF80 pages

- Bliquid-Liquid Ternary Equilibrium in Water (A) - Butyl Acetate (B) - Acetic Acid (C) System Mow Wei Keat Kil160043No ratings yetBliquid-Liquid Ternary Equilibrium in Water (A) - Butyl Acetate (B) - Acetic Acid (C) System Mow Wei Keat Kil16004311 pages

- Chapter 5 Liquid-Liquid Extraction: Subject: 1304 332 Unit Operation in Heat TransferNo ratings yetChapter 5 Liquid-Liquid Extraction: Subject: 1304 332 Unit Operation in Heat Transfer52 pages

- ERT 313 Bioseparation Engineering Extraction: Prepared By: Miss Hairul Nazirah Abdul HalimNo ratings yetERT 313 Bioseparation Engineering Extraction: Prepared By: Miss Hairul Nazirah Abdul Halim34 pages

- Che 249 - Chapter 3 (Liquid-Liquid Extraction)No ratings yetChe 249 - Chapter 3 (Liquid-Liquid Extraction)34 pages

- Design of Liquid-Liquid Extraction ColumnsNo ratings yetDesign of Liquid-Liquid Extraction Columns36 pages

- 2019 Spring Che338 - Homework #6 Save Your Solution As A PDF File (Maximum Size 10 MB) and Submit On Moodle by Midnight 4/5 (Friday) Problem 1No ratings yet2019 Spring Che338 - Homework #6 Save Your Solution As A PDF File (Maximum Size 10 MB) and Submit On Moodle by Midnight 4/5 (Friday) Problem 113 pages

- Mass Transfer 02: Instructor: Zafar ShakoorNo ratings yetMass Transfer 02: Instructor: Zafar Shakoor29 pages

- Separation Chapter+8+Principles+of+Liquid Liquid+Extraction+14032024No ratings yetSeparation Chapter+8+Principles+of+Liquid Liquid+Extraction+1403202433 pages

- Chapter_8_Liquid_Liquid_Extraction-Final VersionNo ratings yetChapter_8_Liquid_Liquid_Extraction-Final Version104 pages

- 8-Liquid-Liquid-Equilibrium-and-Extraction-Using-MathematicaNo ratings yet8-Liquid-Liquid-Equilibrium-and-Extraction-Using-Mathematica4 pages

- Chapter 2 Elements, Compounds and Mixtures (Notes)No ratings yetChapter 2 Elements, Compounds and Mixtures (Notes)11 pages

- Full Paper Liquid Liquid Equilibrium For The DesignNo ratings yetFull Paper Liquid Liquid Equilibrium For The Design19 pages

- Corkford Brewing Excel With Sensitivity Analysis 1No ratings yetCorkford Brewing Excel With Sensitivity Analysis 110 pages

- CHNG1002 - Manufacturing A Plastic Product Project-DESKTOP-C6NEOIPNo ratings yetCHNG1002 - Manufacturing A Plastic Product Project-DESKTOP-C6NEOIP19 pages

- Handbook of Elastomers Second Edition Plastics Engineering PDFPDF 3 PDF FreeNo ratings yetHandbook of Elastomers Second Edition Plastics Engineering PDFPDF 3 PDF Free937 pages

- Liquid-Liquid Extraction With Ternary Systems: 8.0 Instructional ObjectivesNo ratings yetLiquid-Liquid Extraction With Ternary Systems: 8.0 Instructional Objectives22 pages

- Solvents Used in Liquid-Liquid ExtractionNo ratings yetSolvents Used in Liquid-Liquid Extraction3 pages

- CHM 102 Purification & Structural Determination of Organic CompoundsNo ratings yetCHM 102 Purification & Structural Determination of Organic Compounds49 pages

- Computational Strategies For Sizing Liquid-Liquid ExtractorsNo ratings yetComputational Strategies For Sizing Liquid-Liquid Extractors17 pages

- System and Process For Direct Lithium Extraction and Production of Low Carbon Intensity Lithium Chemicals From Geothermal BrinesNo ratings yetSystem and Process For Direct Lithium Extraction and Production of Low Carbon Intensity Lithium Chemicals From Geothermal Brines19 pages

- "Soil Purification" Analysis of Pesticide Residues in The SoilNo ratings yet"Soil Purification" Analysis of Pesticide Residues in The Soil9 pages

- Synthesis of Natural Food Colour From Carotenoid Using Flower Petals100% (1)Synthesis of Natural Food Colour From Carotenoid Using Flower Petals10 pages

- Column Leach Test Procedure - Copper Ores: Ore Sample RequirementsNo ratings yetColumn Leach Test Procedure - Copper Ores: Ore Sample Requirements3 pages

- Solid-Liquid Separations: Two Classes Solid and Liquid in Equilibrium Solid and Liquid Not in EquilibriumNo ratings yetSolid-Liquid Separations: Two Classes Solid and Liquid in Equilibrium Solid and Liquid Not in Equilibrium16 pages

- Technical Report 1 - Liquid-Liquid ExtractionNo ratings yetTechnical Report 1 - Liquid-Liquid Extraction14 pages

- Extraction of Date Palm Seed Oil (Phoenix Dactylifera) by Soxhlet ApparatusNo ratings yetExtraction of Date Palm Seed Oil (Phoenix Dactylifera) by Soxhlet Apparatus12 pages

- Experiment 3: Ternary Phase Diagram (Liquid-Liquid Extraction)Experiment 3: Ternary Phase Diagram (Liquid-Liquid Extraction)

- O Level Biology Practice Questions And Answers EnzymesFrom EverandO Level Biology Practice Questions And Answers Enzymes

- Bliquid-Liquid Ternary Equilibrium in Water (A) - Butyl Acetate (B) - Acetic Acid (C) System Mow Wei Keat Kil160043Bliquid-Liquid Ternary Equilibrium in Water (A) - Butyl Acetate (B) - Acetic Acid (C) System Mow Wei Keat Kil160043

- Chapter 5 Liquid-Liquid Extraction: Subject: 1304 332 Unit Operation in Heat TransferChapter 5 Liquid-Liquid Extraction: Subject: 1304 332 Unit Operation in Heat Transfer

- ERT 313 Bioseparation Engineering Extraction: Prepared By: Miss Hairul Nazirah Abdul HalimERT 313 Bioseparation Engineering Extraction: Prepared By: Miss Hairul Nazirah Abdul Halim

- 2019 Spring Che338 - Homework #6 Save Your Solution As A PDF File (Maximum Size 10 MB) and Submit On Moodle by Midnight 4/5 (Friday) Problem 12019 Spring Che338 - Homework #6 Save Your Solution As A PDF File (Maximum Size 10 MB) and Submit On Moodle by Midnight 4/5 (Friday) Problem 1

- Separation Chapter+8+Principles+of+Liquid Liquid+Extraction+14032024Separation Chapter+8+Principles+of+Liquid Liquid+Extraction+14032024

- 8-Liquid-Liquid-Equilibrium-and-Extraction-Using-Mathematica8-Liquid-Liquid-Equilibrium-and-Extraction-Using-Mathematica

- Chapter 2 Elements, Compounds and Mixtures (Notes)Chapter 2 Elements, Compounds and Mixtures (Notes)

- Full Paper Liquid Liquid Equilibrium For The DesignFull Paper Liquid Liquid Equilibrium For The Design

- Corkford Brewing Excel With Sensitivity Analysis 1Corkford Brewing Excel With Sensitivity Analysis 1

- CHNG1002 - Manufacturing A Plastic Product Project-DESKTOP-C6NEOIPCHNG1002 - Manufacturing A Plastic Product Project-DESKTOP-C6NEOIP

- Handbook of Elastomers Second Edition Plastics Engineering PDFPDF 3 PDF FreeHandbook of Elastomers Second Edition Plastics Engineering PDFPDF 3 PDF Free

- Liquid-Liquid Extraction With Ternary Systems: 8.0 Instructional ObjectivesLiquid-Liquid Extraction With Ternary Systems: 8.0 Instructional Objectives

- CHM 102 Purification & Structural Determination of Organic CompoundsCHM 102 Purification & Structural Determination of Organic Compounds

- Computational Strategies For Sizing Liquid-Liquid ExtractorsComputational Strategies For Sizing Liquid-Liquid Extractors

- System and Process For Direct Lithium Extraction and Production of Low Carbon Intensity Lithium Chemicals From Geothermal BrinesSystem and Process For Direct Lithium Extraction and Production of Low Carbon Intensity Lithium Chemicals From Geothermal Brines

- "Soil Purification" Analysis of Pesticide Residues in The Soil"Soil Purification" Analysis of Pesticide Residues in The Soil

- Synthesis of Natural Food Colour From Carotenoid Using Flower PetalsSynthesis of Natural Food Colour From Carotenoid Using Flower Petals

- Column Leach Test Procedure - Copper Ores: Ore Sample RequirementsColumn Leach Test Procedure - Copper Ores: Ore Sample Requirements

- Solid-Liquid Separations: Two Classes Solid and Liquid in Equilibrium Solid and Liquid Not in EquilibriumSolid-Liquid Separations: Two Classes Solid and Liquid in Equilibrium Solid and Liquid Not in Equilibrium

- Extraction of Date Palm Seed Oil (Phoenix Dactylifera) by Soxhlet ApparatusExtraction of Date Palm Seed Oil (Phoenix Dactylifera) by Soxhlet Apparatus