Lower

Lower

Uploaded by

tahaelnourCopyright:

Available Formats

Lower

Lower

Uploaded by

tahaelnourCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Lower

Lower

Uploaded by

tahaelnourCopyright:

Available Formats

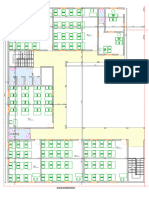

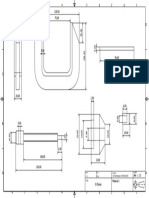

9 10 11 12 13 14 15

6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00

185

2,38 90 2,38 34 2,38 90 2,38 34 1,33 1,05 725 3,00 1,04 3,00 74 28,21 2,38 34 2,38 90 2,38 34 2,38 90 2,38 34 2,38 90 2,38 34 2,38 90 2,38 34 2,38 90 2,38 34 2,38 90 2,38 21,54

1,35 1,35 1,35 1,35 1,35 2,35 3,00 3,00 1,35 1,35 1,35 1,35 1,35 1,35 1,35 1,35 1,35 1,35 1,35 1,35

1.3.16.01

X 1.3.15.01 1.3.15.02 X

Separator

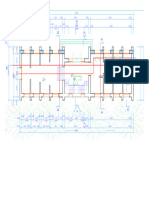

1.3.16. 200 kW @-38°C

DRIVER Separator

1.535 kW@-8°C

A: 21,41 m2

Cooling Compresor Freeze Compresor

H = 3.70 m 600 kW 100 kW

T = +20°C

7 8 1.3.16.02 16 17 18 19 20 21 22 23 24 25

1.3.16.03

1.3.16.04

Compresor Compresor

Cooling Compresor 395 kW 395 kW

Freeze Compresor

600 kW 100 kW

1.6.3.01 A

6%

1.3.15. 1.6.1

24

23

22

21

20

19

18

17

DISPATCH 1.6.2. REFRIGERATION Buffer Buffer

DOWN

A: 98,69 m2

CLEANING STATION vessel vessel

+20° +20° 16

H = 3.70 m A: 215,84 m2

EQUIPMENT

6%

6%

15

T = +20°C

A: 17,98 m2

H = 4,25 m 1.6.3. 14

H = 4,25 m Cooling Compresor STAIR CASE 13

Freeze Compresor GOODS LIFT 12

600 kW A: 33,96 m2

Pump skids

Pump skids

100 kW 11

H = 4,25 m 10

9

T = +20°C

24R x 16

UP

RECEIVING BIN 24G x 28

1.3.11.03 1.6.2.01 1.6.1.01 1.5.1.02

8

1.3.15.03 1.6.5.

EMERGENCY EMERGENCY

ELECTRICAL

B

DOOR

1.3.14. DOOR

ROOM

CORRIDOR 230 kg 230 kg

100 kg

100 kg

100 kg

70 kg

A: 8,36 m2 1.5.5.

DISPATCH

H = 4.15 m BLAST FREEZER I.

A: 153,70 m2

1.5.15.01

1.5.15.02

1.3.11.02

T = +20°C

H = 3.70 m A: 28,46 m2

751 kg

T = +20°C H = 5.80 m

6,00

1.5.5.01

T = -30°C

1.3.17.01

1.3.13.01 1.3.18.01 1.3.20.01 1.3.21.02 1.5.16.02

1.3.17. 1.3.18.

OFFICE 1.5.18. 130 kg 130 kg 130 kg 130 kg 130 kg 8 ton @ -30°C

CORRIDOR

DISPATCH WC MAN

56 kg

1.5.18.01

A: 8,29 m2

172 kg 172 kg 172 kg

1.3.12.01

A: 23,35 m2 A: 11,48 m2

1.3.12. H = 3.70 m

COOLING ROOM H = 3.70 m T = +20°C

H = 3.80 m 130 kg

T = +20°C T = +20°C

CASINGS

1.3.18.02 C

1.5.1.

DEBONING 1.5.6.

1.5.15. A: 453,17 m2 BLAST FREEZER II.

1.3.20.02

WASHING H = 3,70 m A: 29,88 m2 1.5.7.

1.5.7.01

130 kg

1.2.13. TROLEYS T = +12°C H = 5.80 m FREEZER

751 kg

STAIRCASE STORAGE I.

1.5.6.01

1.3.13. A: 97,08 m2 T = -30°C

93 kg

93 kg

13 13

12

16,04 m2

6,00

14

TRIPERY 11

14

H = 3.80 m A: 155,48 m2

1.2.11.03

H = 4.25 m 1.5.16. 8 ton @ -30°C

15 15

A: 217,44 m2 1.3.20. 1.3.21. 10

T = +20°C H = 5.80 m

1.3.19.

16 16

T = +20°C HYGIENE

9

17

H = 3.70 m COOLING ROOM BONES AND FAT 17

T = -20°C

RED ORGANS

130 kg 130 kg 130 kg 130 kg

8

RED ORGANS SCHLUISE 130 kg

18 18

A: 105,15 m2

T = +20°C 130 kg

7

24G x 28

24R x 16

19

AND HEAD 6

19

A: 113,98 m2 H = 3.60 m A: 35,32 m2

TREATMENT

20 20

5

H = 3.60 m T= +2° / +4°C H = 3.80 m

21 21

4

22

A: 115,63 m2 22

T= +2 / +4°C 3

T = +20°C

H = 3.70 m

23 23

130 kg

2

24 24

T = +12°C 1

D

1.5.19.

STAIRCASE 1.5.19.01

1.5.4.01

A: 20,87 m2

1.2.11. H = 3.80 m

HYGIENE SLUICE T = +20°C

1.3.20.03

A: 34,12 m2

230 kg 230 kg

93 kg

93 kg

1.5.1.01

6,00

H = 3.70 m

1.5.3.01

1.5.17.01

T = +20°C 172 kg 172 kg 172 kg 172 kg

130 kg

1.4.7.02

1.5.17.

WC LADIES

A: 11,91 m2

1.5.13.

1.2.14. 1.2.15. 1.2.16. H = 3.80 m

KNIFFE

1.2.16.01

VETERINARY FIRST AID OFFICE T = +20°C

SHARPENING

1.5.14.

120 kg

A: 18,96 m2 A: 9,13 m2 A: 12,55 m2 A: 12,03 m2

H = 3.70 m H = 3.70 m H = 3.70 m H = 3.80 m OFFICE

1.2.11.01 1.2.11.02 1.3.19.01 T = +20°C T = +20°C T = +20°C 1.5.16.01 T = +20°C A: 11,52 m2

E

H = 3.80 m

1.5.13.01

Vet. Inspection

1.5.12. T = +20°C 1.5.4.

Guts and Red Organs 1.3.14.01 1.3.21.01

CORRIDOR

1,00 1,00 1,00

1,00

1.2.14.01 1.2.15.01 1.5.14.01 PREPARATION

A: 56,16 m2

56 kg

56 kg

1.5.8.01

FREEZING

1.5.12.01

1.5.12.02

H = 3.80 m 120 kg

1.5.4.02

A: 109,40 m2

Remove Red T = +20°C 1.5.3.

6,00

Remove White Vet. Inspection H = 4,90 m

Saw Brisket Organs PACKED MEAT T = +2° / +4°C

1.5.8.

Organs Carcass FREEZER

STORAGE

120 kg

1.4.1. 1.4.6. 1.4.7. A: 279,85 m2 STORAGE II.

Trim Carcass

98 kg

QUATERING COOLING ROOM

98 kg

CORRIDOR

1.2.1.10

1.4.1.01

1.4.1.02

H = 4,90 m A: 150,83 m2

A: 164,72 m2 A: 80,34 m2 FRESH MEAT T = +2° / +4°C H = 5.80 m

Dehiding 130 kg 130 kg H = 5.65 m H = 4,90 m A: 85,86 m2 172 kg T = -20°C

1.2.6. T = +2° / +4°C T = +12°C 120 kg H = 4,90 m

SLAUGHTERHOUSE 98 kg 98 kg T = +2° / +4°C

CLEAN SIDE Split Carcass 1.5.9.01 F

A: 205,79 m2 404 kg 404 kg 404 kg 404 kg

1.4.2.02

H = 7.70 m

T = 20°C 1.5.9.

PREPARATION

Re-Trim Carcass DISPATCH

120 kg

120 kg

1.4.2. A: 32,42 m2

Vet. re-Inspection COOLING ROOM

6,00

H = 4,90 m

A: 149,48 m2 T = +2° / +4°C

Vet. Inspection 1.2.8.03 1.2.7.01

H = 5,65 m

1.5.2.

Transfer Red T = +2° / +4°C

PACKAGING

1.2.8.

Organs

1.5.3.03

CONDEMNED A: 139,90 m2

1.1.10. 130 kg

1.4.7.01

1.4.2.01

CARCASSES & H = 4,90 m

ACCEPTANCE

56 kg

56 kg

ORGANS T = +12°C

AREA

1.2.8.02

A: 23,80 m2 A: 45,93 m2

Transfer Carcass

H = 4.20 m 1.5.3.02 G

1.4.10.01

T = +12°C 404 kg 404 kg 404 kg 404 kg 1.4.9. 40 kg

1.4.9.01

1.4.3.02

1.4.10.

1.4.10.02

OFFICE

120 kg

DISPATCH CORRIDOR 1.5.9.02

A: 14,52 m2 1.5.11

A: 9,95 m2 1.5.10.

8

130 kg

130 kg

130 kg

H = 4,90 m STORAGE

1.2.8.01 1.4.3. H = 3.80 m DISPATCH II.

24R x 16

T = +12°C 1.4.8.

UP

PACKING

6,00

24G x 28

COOLING ROOM T = +20°C A: 21,05 m2

1.6.4. STAIR DISPATCH I. MATERIAL

9

A: 143,52 m2 1.4.11.01 H = 4,90 m

CASE A: 139,10 m2 2

A: 111,66 m2

T = +12°C

10

H = 5,65 m

11

A: 33,65 m2 1.4.11 H = 4,90 m H = 5.80 m

T = +2° / +4°C

1.5.11.01

1.5.2.02

1.5.2.01

DRIVER T = +12°C

12

H = 4,25 m

1.4.11.02

105 kg

13

14

T = +20°C A: 14,65 m2

2,38 90 2,38 34 2,38 90 2,38 3,62 2,38 34 2,38 21

1.4.3.01

H = 3.80 m

15

1,35 1,35 1,35 1,35 1,35 1,35 16

T = +20°C

DOWN

H 1.4.8.01 1.4.8.02 1.4.8.03 1.5.10.01

H

17

18

19

20

21

22

23

24

404 kg 404 kg 404 kg 404 kg

5

1.4.4.02

1.4.12.

COOL 1,23 3,00 3,075 3,00 1,95 2,38 34 2,38 1,95 3,00 1,95 2,38 34 2,38 2,255 3,00 1,645 2,38 34 2,38 6,82

1.4.12.01

45 kg

3,00 3,00 1,35 1,35 3,00 1,35 1,35 3,00 1,35 1,35

2,38

1,35

1.6.4.01 STORAGE

A: 13,54 m2

1.4.4. H = 3.80 m

COOLING ROOM

6,00

T = +2° / +4°C

7 8 9 10 A: 139,91 m2 1.4.13.02

6 2,30 18 H = 5,65 m

3,40

T = +2° / +4°C 18 19 20 21 22 23 24 25

6,00

5

3,35

STABLE

1.4.4.01

REVISION: DATE: NAME: REVISION INFO:

28 pcs.

a. 11.11.2019

1.4.5.01 1.4.5.02

I I b. 21.11.2019 AP Coolers | Measuring chain façade | Room number | 1.2.9. Cooling room heds & legs | 1.6.2. Refrigeration st. II.

404 kg 404 kg 404 kg 404 kg 1.4.13. c. 05.12.2019 AP 1.6.3 + 1.6.4 Staircase glazing & entrance portal | Floor height | Door number | Emergency doors

SHOP AP

d. 10.01.2020 Roof shape & size for "Manure container + Dispach area"

I1 A: 53,59 m2

H = 3.80 m e. 13.02.2020 SJ Air Coolers with loads complete | Room 1.5.19 Staircase, adjust size

T = +20°C f. 12.05.2020 SJ Room's 3.1.15 Dispatch & 1.6.1 Ref. Station I. enlarged, Room 1.6.2 Ref. Station II. disappeairs

1.4.5. COOLING

90 kg

ROOM

6,00

5,40

A: 166,24 m2

H = 5,65 m

T = +2° / +4°C 7 5 13 10

11.1

6,00

STABLE

07. WATER RESERVE 8

4

3

32 pcs.

6

2 12.1

1

12.2 12

1.4.13.01

5

J J

QIBLA

71

Sheryan Alshamal HighWay Road

1A 1B 14

12.3

15

J1

6

9

11.2

11 11.1 12 12.1 13 13.1 14 14.1 15 15.1 16 17 11.3

This drawing constitutes intellectual property rights of the involved planers and companies and may not be

copied or made available for whatever purpose to any third party without our prior written consent.

PROJECT | DESCRIPTION:

New Slaughterhouse & Meat processing Plant

6,00

STABLE 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00 6,00

Cattle slaughterline: 30 - 35 per hour

6,00 slaughterline : 100 - 150 per hour6,00

32 pcs. Sheep

Cutting & Deboning : 96 quaters per hour

BUILDER OWNER

Algunade For Multiactivities CO.Ltd.

Khartoum | Sudan

K1 PROJECT MANAGEMENT | ARCHITECT:

NAME:

SJ

6,00

STABLE DATE:

32 pcs. Gerster Joschika Architecture

21.05.2019

Marel Red Meat Slaughtering B.V.

P.O.Box 160 Goetheplatz 2

88214 Ravensburg SCALE:

7130 AD Lichtenvoorde

The Netherlands Germany

Fon: +49 751 3525965

M 1: 100

marel.com/meat stefan@gersterjoschika.de

L1 PHASE : DRAWING NR.:

MASTER PLAN 2017-185-001.02.A

DRAWING :

CATTLE / SHEEPS SLAUGHTERHOUSE REVISION:

- GROUND FLOOR RIGHT SIDE - F. | 12.05.2020

GSPublisherVersion 0.0.100.97

You might also like

- India Shedding Tears Over Onion Prices 1Document3 pagesIndia Shedding Tears Over Onion Prices 1Manjunath DvsNo ratings yet

- Plano Motor ElectricoDocument1 pagePlano Motor ElectricoRogger H-c0% (1)

- Chemistry Project Class 12Document17 pagesChemistry Project Class 12Abhishek46% (13)

- Plan EtajDocument1 pagePlan Etajdinu86689No ratings yet

- Planta 3 SamDocument1 pagePlanta 3 SamRedes UABNo ratings yet

- Planta Baja SamDocument1 pagePlanta Baja SamRedes UABNo ratings yet

- EX-10 Plan 2DDocument1 pageEX-10 Plan 2DFidy RazNo ratings yet

- A3 Nhom 16Document8 pagesA3 Nhom 16Trần Duy CảnhNo ratings yet

- 01 - Lay Out-Layout4Document1 page01 - Lay Out-Layout4Khaled AL-SayedNo ratings yet

- Ahmad Fadhillah Adli - 1955012003 - Studio Perancangan Arstitektur 6 - Denah 1Document2 pagesAhmad Fadhillah Adli - 1955012003 - Studio Perancangan Arstitektur 6 - Denah 1Ahmad FadhillahNo ratings yet

- Plano 2Document1 pagePlano 2segwrNo ratings yet

- Kapling Ngringin Towik-ModelDocument1 pageKapling Ngringin Towik-ModelDany AchmadNo ratings yet

- Instalatii Detectie Si Alarmare Incendiu - Plan EtajDocument1 pageInstalatii Detectie Si Alarmare Incendiu - Plan EtajCosmin MihaiNo ratings yet

- Plan Fundatii Si Detalii TribuneDocument1 pagePlan Fundatii Si Detalii TribuneGîlea ȘtefanNo ratings yet

- Válvula de BolaDocument1 pageVálvula de BolaJesús Los Arcos100% (1)

- Abril 4 PDFDocument1 pageAbril 4 PDFDavid Francisco Leva MesccoNo ratings yet

- Abril 4Document1 pageAbril 4David Francisco Leva MesccoNo ratings yet

- Denah Balok LT 2Document1 pageDenah Balok LT 2Mega LestariNo ratings yet

- Tierra GrataDocument1 pageTierra GratajefersontorogetialNo ratings yet

- Argyo 3/7/2018: Designed by Checked by Approved by Date DateDocument1 pageArgyo 3/7/2018: Designed by Checked by Approved by Date DateÁrgyó András-BotondNo ratings yet

- Argyo Andras Botond 6/5/2018: Designed by Checked by Approved by Date DateDocument1 pageArgyo Andras Botond 6/5/2018: Designed by Checked by Approved by Date DateÁrgyó András-BotondNo ratings yet

- Plan HangarDocument1 pagePlan HangarAouari issamNo ratings yet

- Planta de Dormitorio 4 Bloque de Bat. Sanitarias Cuarto de LavadoDocument1 pagePlanta de Dormitorio 4 Bloque de Bat. Sanitarias Cuarto de LavadoMarco GuzmanNo ratings yet

- Denah Hotel Lantai 3: SKALA 1:200Document1 pageDenah Hotel Lantai 3: SKALA 1:200Suryo SigitNo ratings yet

- FDBDFDocument1 pageFDBDFVictor RîndunicaNo ratings yet

- Mayo 5 PDFDocument1 pageMayo 5 PDFDavid Francisco Leva MesccoNo ratings yet

- Mayo 5 PDFDocument1 pageMayo 5 PDFDavid Francisco Leva MesccoNo ratings yet

- Gambar Denah Pelayanan 2Document1 pageGambar Denah Pelayanan 2Pemdes wonorejo KajenNo ratings yet

- Plano de A-02Document1 pagePlano de A-02Max LoboNo ratings yet

- Layout Pride 24Document1 pageLayout Pride 24ingcivilrodrigo68No ratings yet

- Proyecto Finca El Arbolito 01Document1 pageProyecto Finca El Arbolito 01Marnard DragutiNo ratings yet

- Digitalbaliraja ComDocument12 pagesDigitalbaliraja ComlesipNo ratings yet

- User 2/12/2020: Designed by Checked by Approved by Date DateDocument1 pageUser 2/12/2020: Designed by Checked by Approved by Date DatePoyaNo ratings yet

- Dimensi GurneysDocument2 pagesDimensi GurneysNurul FathiaNo ratings yet

- A C D E F B: Plan de Coffrage Etage 2Document1 pageA C D E F B: Plan de Coffrage Etage 2welakoNo ratings yet

- Drawing 12th ProjectDocument1 pageDrawing 12th ProjectOmar MetwallyNo ratings yet

- Hand Wheel, Valve, Valve Seat, Stud m16, Stud m10Document1 pageHand Wheel, Valve, Valve Seat, Stud m16, Stud m10ARI NURROHMAN TP1No ratings yet

- LABORATORIO PlanosDocument1 pageLABORATORIO PlanosJhon Edgar Alcala CastroNo ratings yet

- Rencana Penempatan Panel Lantai CiticonDocument1 pageRencana Penempatan Panel Lantai CiticonDio SaputraNo ratings yet

- Chery HeryandiDocument1 pageChery HeryandiagusNo ratings yet

- 2020.12.21 IslandDocument1 page2020.12.21 IslandProject DataNo ratings yet

- 1.-PROYECTO COMP - LAYANA PAREDES-Model PDFDocument1 page1.-PROYECTO COMP - LAYANA PAREDES-Model PDFJuanCarlosLayanaParedesNo ratings yet

- Abril 2 PDFDocument1 pageAbril 2 PDFDavid Francisco Leva MesccoNo ratings yet

- Abril 2 PDFDocument1 pageAbril 2 PDFDavid Francisco Leva MesccoNo ratings yet

- Abril 2Document1 pageAbril 2David Francisco Leva MesccoNo ratings yet

- PrintDocument1 pagePrintAnonymous 9T6VEqtttvNo ratings yet

- Cuadro de Columnas: C-1 C-2 C-3 C-4 CA-1 C-5 CA-0Document1 pageCuadro de Columnas: C-1 C-2 C-3 C-4 CA-1 C-5 CA-0Carlos MariscalNo ratings yet

- Trabajo 1 PDFDocument1 pageTrabajo 1 PDFAndres Espinoza ContrerasNo ratings yet

- Camera S 26.17mp Camera S 26.17mp Camera S 26.17mp: Baie S 3.59mp Baie S 3.59mp Baie S 3.59mp Baie S 3.59mpDocument1 pageCamera S 26.17mp Camera S 26.17mp Camera S 26.17mp: Baie S 3.59mp Baie S 3.59mp Baie S 3.59mp Baie S 3.59mpStefan IlieNo ratings yet

- Plan RDC 4Document1 pagePlan RDC 4will nanNo ratings yet

- Admin 19/06/2019: Designed by Checked by Approved by Date DateDocument1 pageAdmin 19/06/2019: Designed by Checked by Approved by Date DateSinggihPrabowoNo ratings yet

- Distribution 11Document1 pageDistribution 11Timothée Abéga BitaNo ratings yet

- PROYECTO COMP - LAYANA PAREDES-Model PDFDocument1 pagePROYECTO COMP - LAYANA PAREDES-Model PDFJuanCarlosLayanaParedesNo ratings yet

- Time Schedule - Jawaban TesDocument1 pageTime Schedule - Jawaban TesJOGI S. SILABAN 213 110No ratings yet

- 7H X 0,17 M 6F X 0,30 M: Gspublisherversion 0.81.100.38Document1 page7H X 0,17 M 6F X 0,30 M: Gspublisherversion 0.81.100.38snokigamesNo ratings yet

- CasaDocument1 pageCasaJuan IgnacioNo ratings yet

- Summary of Cash Out Flow For The ProjectDocument1 pageSummary of Cash Out Flow For The ProjectSisay chaneNo ratings yet

- San Blas PDF ActualizadoDocument2 pagesSan Blas PDF ActualizadoatuarmedNo ratings yet

- Usuario 4/12/2018: Dise o de Revisado Por Aprobado Por Fecha FechaDocument1 pageUsuario 4/12/2018: Dise o de Revisado Por Aprobado Por Fecha FechaRichardCaceresNo ratings yet

- Generales (4) - ModelDocument1 pageGenerales (4) - ModelCarlos InostrozaNo ratings yet

- 1: 2 MM Ari Nurhidayat (1405101020) Sheet: Title:: Scale: Unit: DesignerDocument1 page1: 2 MM Ari Nurhidayat (1405101020) Sheet: Title:: Scale: Unit: Designerpipit priyantoNo ratings yet

- Spelling, Grade 1: Strengthening Basic Skills with Jokes, Comics, and RiddlesFrom EverandSpelling, Grade 1: Strengthening Basic Skills with Jokes, Comics, and RiddlesNo ratings yet

- M. Abdelbagi Tower Skeleton Bill of Qty b+g+4 - Typical FloorsDocument6 pagesM. Abdelbagi Tower Skeleton Bill of Qty b+g+4 - Typical FloorstahaelnourNo ratings yet

- 1-Design of Structural Elements - (Intro)Document4 pages1-Design of Structural Elements - (Intro)tahaelnourNo ratings yet

- Paint SpecDocument11 pagesPaint SpectahaelnourNo ratings yet

- Mr. Saifeldeen Alsamani Report1Document69 pagesMr. Saifeldeen Alsamani Report1tahaelnourNo ratings yet

- 2-Design of Structural Elements - (Contents)Document7 pages2-Design of Structural Elements - (Contents)tahaelnourNo ratings yet

- 8Document1 page8tahaelnourNo ratings yet

- Flood Risk Management Research and Practice 2008Document334 pagesFlood Risk Management Research and Practice 2008tahaelnourNo ratings yet

- Feedlot Multiple Steel Sheds: Bilbaraka For Engineering and Consultancy ServicesDocument3 pagesFeedlot Multiple Steel Sheds: Bilbaraka For Engineering and Consultancy ServicestahaelnourNo ratings yet

- CoverDocument1 pageCovertahaelnourNo ratings yet

- Core Exa2Document14 pagesCore Exa2tahaelnourNo ratings yet

- Chapter ContentsDocument4 pagesChapter ContentstahaelnourNo ratings yet

- Floor: 1st & 2nd Floor Columns 3rd Floor Columns Foundation & Ground Floor Columns Roof Floor Columns 4th Floor ColumnsDocument1 pageFloor: 1st & 2nd Floor Columns 3rd Floor Columns Foundation & Ground Floor Columns Roof Floor Columns 4th Floor ColumnstahaelnourNo ratings yet

- Foundation DetailsDocument1 pageFoundation DetailstahaelnourNo ratings yet

- 01 - Trail Bridge Experience in Nepal PDFDocument54 pages01 - Trail Bridge Experience in Nepal PDFtahaelnourNo ratings yet

- MAGDY Final - BASEMENTDocument4 pagesMAGDY Final - BASEMENTtahaelnourNo ratings yet

- Foundation PlanDocument1 pageFoundation PlantahaelnourNo ratings yet

- Foundation Details PDFDocument1 pageFoundation Details PDFtahaelnourNo ratings yet

- Apartment Building: DR Abdel Rahim Hashim Kartum SudanDocument1 pageApartment Building: DR Abdel Rahim Hashim Kartum SudantahaelnourNo ratings yet

- Column LayoutDocument1 pageColumn LayouttahaelnourNo ratings yet

- LPG Loads SummaryDocument10 pagesLPG Loads SummarytahaelnourNo ratings yet

- Comparison On Wind Load Prediction of Transmission PDFDocument8 pagesComparison On Wind Load Prediction of Transmission PDFtahaelnourNo ratings yet

- Seismic Design Code of Japan PDFDocument175 pagesSeismic Design Code of Japan PDFtahaelnour0% (1)

- 2020 Dental-CertificateDocument3 pages2020 Dental-CertificateMc DLNo ratings yet

- First Year of LifeDocument13 pagesFirst Year of LifeIsak ShatikaNo ratings yet

- WEEK 5 LAB EXERCISE - Skeletal SystemDocument19 pagesWEEK 5 LAB EXERCISE - Skeletal SystemChristian GallardoNo ratings yet

- PE10 Q1 - Mod1 - Active Recreation Sports Lesson 1 7 - v3Document85 pagesPE10 Q1 - Mod1 - Active Recreation Sports Lesson 1 7 - v3Macquen BalucioNo ratings yet

- Paper 1: Year 9 Science TestDocument28 pagesPaper 1: Year 9 Science TestQH MusicNo ratings yet

- Physico-Chemical Quality and Metal Contamination of Well Water in The Sixthneighborhood of Cotonou, South BeninDocument13 pagesPhysico-Chemical Quality and Metal Contamination of Well Water in The Sixthneighborhood of Cotonou, South BeninIJAR JOURNALNo ratings yet

- (SACHMOI24H.COM) 500 CÂU TRẮC NGHIỆM NGỮ PHÁP NÂNG CAO - PHẠM LIỄUDocument39 pages(SACHMOI24H.COM) 500 CÂU TRẮC NGHIỆM NGỮ PHÁP NÂNG CAO - PHẠM LIỄUHieu NguyenNo ratings yet

- Basket BallDocument75 pagesBasket BallRaymond SantiagoNo ratings yet

- Vice President Operations VP in Dallas TX Resume Lisa HunterDocument3 pagesVice President Operations VP in Dallas TX Resume Lisa HunterLisaHunter2No ratings yet

- Beneficiality SpeechDocument3 pagesBeneficiality SpeechPaul Pabilico PorrasNo ratings yet

- White Blue Simple Full Stack Developer CV ResumeDocument1 pageWhite Blue Simple Full Stack Developer CV Resumehussymian06No ratings yet

- T22153 160 PDFDocument8 pagesT22153 160 PDFdanish moinNo ratings yet

- Ica Vmm-uh1-301-Garlick Tail Rotor Blade P - N 2042200-101Document8 pagesIca Vmm-uh1-301-Garlick Tail Rotor Blade P - N 2042200-101Eric ReyesNo ratings yet

- Pistonless PumpDocument21 pagesPistonless PumpDeepuDevarajanNo ratings yet

- Introduction To Heat Exchangers PDFDocument44 pagesIntroduction To Heat Exchangers PDFkamelNo ratings yet

- Dongmi Catalog 03.04.20Document29 pagesDongmi Catalog 03.04.20Adonis TabiosNo ratings yet

- General Biology 2Document21 pagesGeneral Biology 2gabrielNo ratings yet

- Fit 111 Contents and Assessments (2)Document60 pagesFit 111 Contents and Assessments (2)quentkarl8No ratings yet

- Suffix Prefix - Class 8Document13 pagesSuffix Prefix - Class 8Mohammad Abdul Motalib100% (2)

- LIMIT TEST-leadDocument3 pagesLIMIT TEST-leadfathimashajahan311No ratings yet

- FME OP BrochureDocument2 pagesFME OP BrochureMartin KratkyNo ratings yet

- Makalah Procedure TextDocument4 pagesMakalah Procedure TextReva Surya SyahputraNo ratings yet

- Electrical Engineering Most Important 770 MCQsDocument120 pagesElectrical Engineering Most Important 770 MCQsDarius Phuti100% (1)

- K Hotels Tian-Jin: (Example)Document3 pagesK Hotels Tian-Jin: (Example)WayneNo ratings yet

- Group 3 Kadayawa Festival PresentationDocument11 pagesGroup 3 Kadayawa Festival PresentationNaly YanoNo ratings yet

- California WinesDocument4 pagesCalifornia WinesYohanes Widi SonoNo ratings yet

- 926 IFE Level 3 Certificate in Fire Service Operations and Incident CommandDocument18 pages926 IFE Level 3 Certificate in Fire Service Operations and Incident CommandrajaNo ratings yet

- Develop WSH Culture 1Document22 pagesDevelop WSH Culture 1Ong Kian HongNo ratings yet