Audit Reprot - MK Lide - 2019

Audit Reprot - MK Lide - 2019

Uploaded by

Abhishek SharmaCopyright:

Available Formats

Audit Reprot - MK Lide - 2019

Audit Reprot - MK Lide - 2019

Uploaded by

Abhishek SharmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Audit Reprot - MK Lide - 2019

Audit Reprot - MK Lide - 2019

Uploaded by

Abhishek SharmaCopyright:

Available Formats

01 111 1637105

Ist Surveillance Audit report as per

IATF 16949:2016

MK Lide Auto Clutch Industries (P) Ltd.

12/1, Delhi-Mathura Road, Faridabad -121005, Haryana, India

Issued by: Ashutosh Sharma Date:21.02.2019

Name and signature of the lead auditor

Acknowledged by: Mr Anil Kumar

Name and signature of the client Date:21.02.2019

D_IATF_3_E Audit report 20170328 Page 1 of 9

Audit report

Client Certification number Audit End Date

MK Lide Auto Clutch Industries (P) 01 111 1637105 21-02-2019

Ltd

Type of audit Standard Accreditation

SA1 IATF 16949:2016 VDA-QMC / TIS

Table of contents

1 BASIC INFORMATION........................................................................................................................................ 3

2 AUDIT CONCLUSIONS....................................................................................................................................... 3

3 AUDIT SCOPE.................................................................................................................................................... 4

3.1 INFORMATION ABOUT COMPANY......................................................................................................................................4

3.2 SCOPE......................................................................................................................................................................... 4

4 CHANGES ABOUT QUALITY MANAGEMENT SYSTEM / REVIEW OF THE CONTRACT AGREEMENT.......4

4.1 VALIDATION OF AUDIT DAY REDUCTION FOR APPLYING RULE 5.2 H..........................................................................................5

4.2 JUSTIFICATION FOR THE SINGLE SITE WITH EXTENDED SITE CERTIFICATION STRUCTURE AND VALIDATION OF CURRENT CONDITIONS ACC.

ANNEX 4 („ANNEX 4 - ELIGIBILITY CRITERIA FOR CERTIFICATE STRUCTURE“)........................................................................................5

5 AUDIT FINDINGS................................................................................................................................................ 6

5.1 CUSTOMER SPECIFIC REQUIREMENTS.................................................................................................................................6

5.2 QUALITY PERFORMANCE TO THE AUTOMOTIVE CUSTOMERS...................................................................................................6

5.3 QUALITY PERFORMANCE OF AUDITED PROCESSES................................................................................................................6

5.4 SUMMARY OF SUPPORTING FUNCTIONS (RL).......................................................................................................................6

5.5 NONCONFORMITIES....................................................................................................................................................... 7

5.6 OPPORTUNITIES / POSITIVE ASPECTS.................................................................................................................................7

5.7 INFORMATION FOR NEXT AUDIT........................................................................................................................................7

5.8 DATE OF NEXT AUDIT......................................................................................................................................................7

6 ATTACHMENT.................................................................................................................................................... 9

D_IATF_3_E Audit report 20170328 Page 2/9

Audit report

Client Certification number Audit End Date

MK Lide Auto Clutch Industries (P) 01 111 1637105 21-02-2019

Ltd

Type of audit Standard Accreditation

SA1 IATF 16949:2016 VDA-QMC / TIS

1 Basic information

Management system representative: Mr. Anil Kumar

Lead Auditor: Ashutosh Sharma

Auditor Team Members: NA

Technical expert: NA

Translator: NA

Audit start and end dates: 20-21.02.2019

2 Audit conclusions

Management system effectiveness was verified on site by means of random sampling by an appropriately

selected audit team / auditor. This applies in particular to the compliance of workflows with standard

requirements and the descriptions in management system documentation. The special features of the business

activities of the organization, the applicable statutory and regulatory requirements and the requirements set forth

in other generally applicable documents were also taken into account. This was done by means of a sampling

approach, by conducting interviews and reviewing the appropriate documentation.

☒ The last audit revealed nonconformities which have been demonstrably corrected. The corrections and

corrective actions taken in this respect have been verified. ( Last audit was a special audit and all ncr’s

closure verification done)

☐ A stage 1 audit was performed and the organization found ready for certification. Identified

weaknesses, if any, have been eliminated and the corrective action associated therewith verified.

☒ Number of nonconformities:

Major: Nil Minor: 4

☒ Needed on site verification of nonconformities via special audit.

(Proposed due date): 04.04.2018

Therefore the audit team / the auditor recommend:

☐ The organization has established and maintains an effective system to ensure compliance with its

policy and objectives. The audit team confirms in line with the audit targets that the management

system of the organization complies with. The organization adequately maintains and implements the

requirements of the standard(s).

☐ Inclusion of the changes (see section 4) in the scope of application of existing certification.

☒ The organization failed to demonstrate within the course of the certification procedure that it has

established a quality management system in compliance with the above standard. The

nonconformities identified in the certification procedure must be closed and verified within 90 days of

the last day of the audit. By correcting the nonconformities, the current status of “open” can be

transformed into the status of “closed“. This will be documented in an appropriate supplementary

report and / or in the non-conformity report.

Maintenance or issue of certificates after successful verification of the corrective actions.

D_IATF_3_E Audit report 20170328 Page 3/9

Audit report

Client Certification number Audit End Date

MK Lide Auto Clutch Industries (P) 01 111 1637105 21-02-2019

Ltd

Type of audit Standard Accreditation

SA1 IATF 16949:2016 VDA-QMC / TIS

3Audit scope

3.1 Information about company

MK Lide Auto Clutch Industries is a Private limited firm and engaged in the Design and Manufacture of Clutch

assemblies. The company has proper infrastructure like Assembly section and design testing machines like Life

rigs, etc. and inspection facilities like Vernier caliper, micrometer, Pressure Gauges, weighing machine, digital

temperature controllers, Dial gauges, surface plate etc. and skilled manpower to perform the above said

activities.

3.2 Scope

Scope of the certification:

Design and Manufacture of Clutch assemblies

Standard chapters

Nil

excluded for IATF 16949:

Reason for exclusion: N.A

Certification covers the following sites and their scope (production site), Extended Site and supporting functions

(RL) resp.:

Site No. Sites included in the Number of scope (production Standard(s) Reported in the

(CN suffix) certification employees site) and present tool y/n?

Name/address of site: (relevant) supporting (if "no" please

functions (RL) indicate the

resp.: respective CN

where the

documentation is

filed)

01 111 MK Lide Auto Clutch 25 Design and IATF16949:20 Yes

1637105 Industries (P) Ltd. Manufacture of 16

12/1 , Delhi- Mathura Clutch Assemblies

Road , Faridabad-

121005

Haryana , India

4 Changes about quality management system / Review of the contract agreement

☒ No significant changes have been implemented in the management system and the management

system documentation since the last audit. The order details which form the basis of the audit

(including number of employees, scope of application and sites) correspond to the organization’s

actual situation.

☐ Some changes of quality management system related since last audit are either communicated during

readiness evaluation or observed on site audit. These changes are verified during the audit, which

include:

D_IATF_3_E Audit report 20170328 Page 4/9

Audit report

Client Certification number Audit End Date

MK Lide Auto Clutch Industries (P) 01 111 1637105 21-02-2019

Ltd

Type of audit Standard Accreditation

SA1 IATF 16949:2016 VDA-QMC / TIS

4.1 Validation of audit day reduction for applying rule 5.2 h

Not Applicable

4.2 Justification for the single site with extended site certification structure and validation

of current conditions acc. Annex 4 („Annex 4 - Eligibility Criteria for Certificate

Structure“)

Not applicable

5 Audit findings

5.1 Customer specific requirements – of all automotive customers

Customer specific

Customer Version Used internet-portals Supplier code

requirements

Atul Auto Final Inspection ---------------

NIL NA

Report -

5.2 Quality performance of all automotive customers

Special

Customer Quality of product Quality of delivery Implemented actions

status

Atul Auto Zero Complaint and 100%

NIL NIL

Zero PPM ( satisfactory)

5.3 Quality performance of all audited processes

Process key

QM-system process Target Status Implemented actions

indicators

Strategic Planning/ Reviewed Refer NCR#2

Management Review/ Continual On time MRM 100%

Improvement

100%

Sales 1.8 Crores

1.61 Crore

Marketing and Production On time Delivery 100% Reviewed and found

planning and Control 100% Satisfactory

D_IATF_3_E Audit report 20170328 Page 5/9

Audit report

Client Certification number Audit End Date

MK Lide Auto Clutch Industries (P) 01 111 1637105 21-02-2019

Ltd

Type of audit Standard Accreditation

SA1 IATF 16949:2016 VDA-QMC / TIS

CSI`

95% 95% for Atul

Auto

New Product Development/ On time Development 100% Reviewed Refer NCR#3

No new

Engg. Change Control developmen

Ist time Sample t

100%

approval

Purchase Reviewed and found

100% Satisfactory

98%

Supplier Rating

Prod. Loss due to n/A

Nil

raw material Nil

Supplier Rejection

Nil

Nil

Stores FIFO 100% 100% Reviewed and found

Satisfactory

Deterioration Nil Nil

Production and NC product handling Prod. Plan. Vs actual Reviewed and found

100% 100% Satisfactory

OEE

100% 100%

Quality Assurance 0.5% of Sales 0.35% of Reviewed Refer NCR#4

COPQ Sales

Rejection/Rework Nil

Nil

On time Cal

100% 100%

Despatch Customer Rejection Nil Nil Reviewed and found

Satisfactory

Schedule vs

Despatch 100% 100%

Control of Documents and Records Reviewed Refer NCR#1

and Internal audits( Process and On time iQA 100% 100%

Product audit)

Maintenance and Tool MTTR Nil Nil Reviewed and found

Maintenance

Nil Satisfactory

MTBF

D_IATF_3_E Audit report 20170328 Page 6/9

Audit report

Client Certification number Audit End Date

MK Lide Auto Clutch Industries (P) 01 111 1637105 21-02-2019

Ltd

Type of audit Standard Accreditation

SA1 IATF 16949:2016 VDA-QMC / TIS

Nil

PM Plan vs Actual

100%

Breakdown hrs 100%

Nil Nil

Human Resource Absenteeism 5% 4% Reviewed and found

management Satisfactory

Accidents Nil Nil

Trg. Plan adhernece 100% 100%

Corrective and Preventive Actions Repeated complaints Nil Nil Reviewed and found

(Customer Complaint handling)

Satisfactory

Automotive complaint

Nil Nil

5.4 Summary of supporting functions (RL)

Address-RL1 RL1-Function Interface with PS Result

NA NA NA NA

Address-RL2 RL2-Function Interface with PS Result

5.5 Nonconformities

All information gained during the audit will be treated strictly confidentially by the audit team /

auditor and the certification body. In view of the sampling approach applied to the audit, it must

be pointed out that weaknesses and nonconformities may exist which have not been

determined during the audit.

The audit findings / nonconformities related to the audited standard are documented in the enclosed

nonconformity report.

The detailed nonconformity report is attached (attachment 1).

5.6 Opportunities / Positive aspects

Opportunities for improvement and positive aspects have been documented in the draft report included. The draft

report was handed over to the representatives of the organization in the closing meeting. The opportunities for

improvement expressed in the form of recommendations and information are aimed at contributing to the

continuous improvement of management systems.

D_IATF_3_E Audit report 20170328 Page 7/9

Audit report

Client Certification number Audit End Date

MK Lide Auto Clutch Industries (P) 01 111 1637105 21-02-2019

Ltd

Type of audit Standard Accreditation

SA1 IATF 16949:2016 VDA-QMC / TIS

They also serve to eliminate any weaknesses still available in the organization, ensure management system

effectiveness and prevent nonconformities.

The acceptance and, if necessary, implementation of the suggested actions are reviewed and questioned by the

auditor within the scope of the next audit.

Positive aspects

Process control,

No customer return and Delivery performance

5.7 Information for next audit

Next audit will be IInd Surveillance audit, due date for next audit is 21.02.2020.

5.8 Date of next audit

Due Date of the next audit: 21-02-2020

Agreed date of the next audit: 10-02-2020

Lead Auditor: Ashutosh Sharma

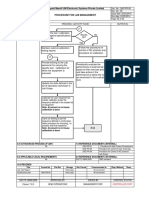

Table 1 for verification of the completeness of the process-oriented auditing according to IATF 16949

requirements (incl. all processes of extended site)

10.2

10.3

10.1

4.1

4.2

4.3

4.4

5.1

5.2

5.3

6.1

6.2

6.3

7.1

7.2

7.3

7.4

7.5

8.1

8.2

8.3

8.4

8.5

8.6

8.7

9.1

9.2

9.3

Process

Strategic Planning/

ManagementReview/ Continual X X X X X X X X X X X X X X X

Improvement

Marketing and Production

plannign and Control X X X X X X X X X X X

New Product

Development/ Engg.

X X X X X X X X X X X

Change Control

Purchase X X X X X X X X X X

Stores X X X X X X X X X X X

Production and NC product

handling

X X X X X X X X X X X X X

Quality Assurance X X X X X X X X X X

Despatch X X X X X X X X X X

D_IATF_3_E Audit report 20170328 Page 8/9

Audit report

Client Certification number Audit End Date

MK Lide Auto Clutch Industries (P) 01 111 1637105 21-02-2019

Ltd

Type of audit Standard Accreditation

SA1 IATF 16949:2016 VDA-QMC / TIS

10.2

10.3

10.1

4.1

4.2

4.3

4.4

5.1

5.2

5.3

6.1

6.2

6.3

7.1

7.2

7.3

7.4

7.5

8.1

8.2

8.3

8.4

8.5

8.6

8.7

9.1

9.2

9.3

Process

Control of Documents and Records

and Internal audits( Process and X X X X X X X X X X X

Product audit)

Maintenance and Tool

Maintenance X X X X X X x X X X X X

Human Resource

management x X X X x x x x X X X X

Corrective and Preventive Actions

(Customer Complaint handling)

x x x x x

Table 2 to verify the completeness of the production processes and shifts (incl. all production processes and

shifts of extended site)

CA 1st Surveillance audit 2nd Surveillance audit

Process Shifts

Assembly 1 1 1

Table 3 to verify customer-specific requirements of all customers in the automotive supply chain

1st Surveillance 2nd Surveillance

Customer-specific CA

Customer audit audit

requirements

Atul Auto Final Inspection x

x

report

6 Attachment

Attachment 1: Table 1+2+3

Attachment 2: Nonconformity Report (Supplement Report)

Attachment 3: Audit Plan

Attachment 4: Readiness Evaluation

Attachment 5: Audit Notes

Attachment 6: Verification Report of the nonconformities of last audit

D_IATF_3_E Audit report 20170328 Page 9/9

You might also like

- A Sample Go Kart Business Plan TemplateDocument15 pagesA Sample Go Kart Business Plan TemplateMahirezqiNo ratings yet

- In Their Words: History and Society in Gilbertese Oral TraditionDocument226 pagesIn Their Words: History and Society in Gilbertese Oral TraditionkemalNo ratings yet

- (Ver21.00) ISO 9001 QMS Internal Audit Training (New)Document177 pages(Ver21.00) ISO 9001 QMS Internal Audit Training (New)RSA Channel100% (1)

- IQA Report Summary Sheet - Bolt & Zest Front Strut: 1 Mounting of PartDocument33 pagesIQA Report Summary Sheet - Bolt & Zest Front Strut: 1 Mounting of PartJetesh DevgunNo ratings yet

- Business Plan AyamasDocument9 pagesBusiness Plan AyamasMazurah Mohamad Ikhwan100% (2)

- DocxDocument48 pagesDocxLorraine Mae Robrido100% (1)

- Special Audit Report - MK Lide - 2018 SPADocument5 pagesSpecial Audit Report - MK Lide - 2018 SPAAbhishek SharmaNo ratings yet

- NCR VDA 6.3 Process Audit 02.04.2020Document11 pagesNCR VDA 6.3 Process Audit 02.04.2020r arumugamNo ratings yet

- Iatf 16949:2016 Qms Audit ChecklistDocument5 pagesIatf 16949:2016 Qms Audit ChecklistAddinda ZurainieNo ratings yet

- MSA StudyDocument22 pagesMSA StudySandip PandeNo ratings yet

- PFD and Pqcs of Can Rear BreakDocument16 pagesPFD and Pqcs of Can Rear BreakVikas KashyapNo ratings yet

- MSA DecDocument45 pagesMSA DecpsathishthevanNo ratings yet

- IATF16949+Chapter+1 +QMS+Documentation+OverviewDocument10 pagesIATF16949+Chapter+1 +QMS+Documentation+Overviewalex hokcNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument36 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Internal Auditor AssesmentDocument8 pagesInternal Auditor AssesmentdocumentsNo ratings yet

- PDI Quality Manual Rev 4 - 2.0 Revision Register and Distribution ListDocument1 pagePDI Quality Manual Rev 4 - 2.0 Revision Register and Distribution ListlouieNo ratings yet

- Maintatnance Process ProcedureDocument16 pagesMaintatnance Process Proceduresharif1974No ratings yet

- Iatf Cara ToolDocument10 pagesIatf Cara ToolJohn OoNo ratings yet

- 06100-FO1-Application Form - v5.1Document4 pages06100-FO1-Application Form - v5.1nego linksNo ratings yet

- Clauses IATF16949 2016Document2 pagesClauses IATF16949 2016Javier BustamanteNo ratings yet

- RP2-ISO9001 2015 ADocument50 pagesRP2-ISO9001 2015 AMasrawana Mohd Masran100% (1)

- (Click Here) : Instruction/Guideline For Applying For Vendor ApprovalDocument2 pages(Click Here) : Instruction/Guideline For Applying For Vendor Approvalchandan kumarNo ratings yet

- F-HR-13 - Skill MatrixDocument1 pageF-HR-13 - Skill MatrixAnand PrakashNo ratings yet

- Team FeasibilityDocument3 pagesTeam FeasibilityChethan Nagaraju KumbarNo ratings yet

- IATF - International Automotive Task ForceDocument25 pagesIATF - International Automotive Task ForceAtul SharmaNo ratings yet

- Bgl-Pm-Qa-12 Control of Non Conforming OutputsDocument4 pagesBgl-Pm-Qa-12 Control of Non Conforming OutputsMohit SinghNo ratings yet

- IA Audit Observation ReportDocument12 pagesIA Audit Observation ReportKeval ShethNo ratings yet

- IQCS-QMSLA-01A Presentation Slides Apr2020 R23 (Protected)Document260 pagesIQCS-QMSLA-01A Presentation Slides Apr2020 R23 (Protected)sharkawyenppaNo ratings yet

- Requirements Comparison TS16949 VDA61Document22 pagesRequirements Comparison TS16949 VDA61TarunaiNo ratings yet

- Team Feasibility CommitmentDocument1 pageTeam Feasibility Commitmentmurali4095No ratings yet

- ISO 9001 LA-Workshop ManualDocument54 pagesISO 9001 LA-Workshop Manualمختار حنفىNo ratings yet

- Process Audit Checklist: What To Look For: Materials ControlDocument12 pagesProcess Audit Checklist: What To Look For: Materials ControlLeslie VazquezNo ratings yet

- Work Instruction Manual: Document ControlDocument10 pagesWork Instruction Manual: Document ControlAriel OrtizNo ratings yet

- Supplier Management V4 PDFDocument13 pagesSupplier Management V4 PDFRx DentviewNo ratings yet

- 02 04 15 T 001 - PpapDocument36 pages02 04 15 T 001 - Ppapgocohov660No ratings yet

- Att#11 - A - Painting ProcedureDocument14 pagesAtt#11 - A - Painting ProcedureClémentNo ratings yet

- Iatf Sanctioned Interpretations Nov 2023 Applicable From December 2023Document31 pagesIatf Sanctioned Interpretations Nov 2023 Applicable From December 2023AnkurNo ratings yet

- Effective Management Review Training (For Sharing)Document11 pagesEffective Management Review Training (For Sharing)limkeanjinNo ratings yet

- Materi Learner Guide - Iso 9001-2015 Qms A-La Vilt LG - 16!02!2021Document254 pagesMateri Learner Guide - Iso 9001-2015 Qms A-La Vilt LG - 16!02!2021Rizqi Aprial100% (1)

- IRCA and CQI Webinar SlidesDocument40 pagesIRCA and CQI Webinar SlidesabdelmutalabNo ratings yet

- NcManagement Ra - Ha 50253631 Adinath Forging P LTD 50253631 - IATF16 26.jun.2021 27.jun.2021Document8 pagesNcManagement Ra - Ha 50253631 Adinath Forging P LTD 50253631 - IATF16 26.jun.2021 27.jun.2021Abhishek DahiyaNo ratings yet

- Ipp Training Question Paper.Document3 pagesIpp Training Question Paper.Atul Sharma100% (1)

- 5S CQI GQA ChecklistDocument4 pages5S CQI GQA ChecklistMostafa Abd ElalemNo ratings yet

- Resume. ShyamDocument3 pagesResume. Shyamsunder2006No ratings yet

- Vrutti Annual ReportDocument40 pagesVrutti Annual ReportAtish100% (1)

- IATF 16949 2016 Transition Overview October 2016 UpdateDocument3 pagesIATF 16949 2016 Transition Overview October 2016 UpdateVaspeoNo ratings yet

- IATF16949,2016Document28 pagesIATF16949,2016Vinni WadeNo ratings yet

- Product Audit Procedure Example, Plan, Report and ChecklistDocument17 pagesProduct Audit Procedure Example, Plan, Report and Checklistdr.anasasa275No ratings yet

- F 8.4 PU 03 - PRF Supplier Audit Check Sheet - EMFDocument13 pagesF 8.4 PU 03 - PRF Supplier Audit Check Sheet - EMFkumar QANo ratings yet

- Control Plan m6 Flange NutDocument8 pagesControl Plan m6 Flange NutRANANo ratings yet

- Management Procedure For The: Management of New Works, Modifications and RepairsDocument55 pagesManagement Procedure For The: Management of New Works, Modifications and RepairsigorNo ratings yet

- Case Study - PPAPDocument45 pagesCase Study - PPAPrc2834338No ratings yet

- Fmea 39 PDF FreeDocument5 pagesFmea 39 PDF Freeahya azizahNo ratings yet

- Audit PeparationDocument1 pageAudit PeparationPravin Balasaheb GunjalNo ratings yet

- 02 Slides - QMS04101ENGX - v6 (AD05) - Oct2021Document115 pages02 Slides - QMS04101ENGX - v6 (AD05) - Oct2021Nopan SulistyoNo ratings yet

- Section 8.5 - Production and Service ProvisionDocument3 pagesSection 8.5 - Production and Service Provisionturkih_1988100% (1)

- JLR Customer Specific Requirements For Ppap: ScopeDocument10 pagesJLR Customer Specific Requirements For Ppap: ScopeVladimir Radulović100% (1)

- Stores - QMP-ST-01Document5 pagesStores - QMP-ST-01Rohit VishwakarmaNo ratings yet

- Audit Plan 审核计划: To be completed by theDocument3 pagesAudit Plan 审核计划: To be completed by thegeorge liuNo ratings yet

- Inspection Report FormatDocument1 pageInspection Report Formatkgkganesh8116No ratings yet

- Project Checklist for ISO 13485 Implementation EnDocument3 pagesProject Checklist for ISO 13485 Implementation EnLokeshNo ratings yet

- Iso 13485 Medical Devices 2016 PDFDocument12 pagesIso 13485 Medical Devices 2016 PDFsercalsaNo ratings yet

- QAD Procedure - Lab Management P2Document1 pageQAD Procedure - Lab Management P2sumanNo ratings yet

- PART A-Commercial Proposal-IATF 16949Document5 pagesPART A-Commercial Proposal-IATF 16949Rakesh SNo ratings yet

- 9002109B008 (Workshop Report) - 20221008 - 0001 PDFDocument1 page9002109B008 (Workshop Report) - 20221008 - 0001 PDFAbhishek SharmaNo ratings yet

- Lide Auto LTD.: Clutch Industries PVTDocument1 pageLide Auto LTD.: Clutch Industries PVTAbhishek SharmaNo ratings yet

- 293subs SIAMCommodityPrice-MonthlyMonitorReportJuly2022Document44 pages293subs SIAMCommodityPrice-MonthlyMonitorReportJuly2022Abhishek SharmaNo ratings yet

- ACMA - Commodity Prices - June2021Document42 pagesACMA - Commodity Prices - June2021Abhishek SharmaNo ratings yet

- Caliber 2 PDFDocument80 pagesCaliber 2 PDFDinesh WikramasingheNo ratings yet

- Indian Institute of Banking & Finance: Certificate Course in Digital BankingDocument6 pagesIndian Institute of Banking & Finance: Certificate Course in Digital BankingKay Aar Vee RajaNo ratings yet

- Freehand Drawing Week2Document29 pagesFreehand Drawing Week2John TinaNo ratings yet

- Partnership Case To Be DigestDocument4 pagesPartnership Case To Be DigestCrystal KateNo ratings yet

- deviation methodDocument25 pagesdeviation methoddebapriyayogaNo ratings yet

- Sap GRC Risk Analysis and RemediationDocument38 pagesSap GRC Risk Analysis and RemediationShiva Kumar0% (1)

- Consolidated FsDocument7 pagesConsolidated FsfreyawonderlandNo ratings yet

- Preperation Safety CaseDocument38 pagesPreperation Safety Casezhangjie100% (2)

- IIFL - Awfis - Initiating Coverage - 20241125Document40 pagesIIFL - Awfis - Initiating Coverage - 20241125Kshitij SarafNo ratings yet

- An Internship ReportDocument59 pagesAn Internship ReportFahad chowdhury100% (3)

- Formulation of Plan Implementation StrategiesDocument8 pagesFormulation of Plan Implementation Strategiesemman quistNo ratings yet

- Grade 8 - Forms of Ownership Term 3Document29 pagesGrade 8 - Forms of Ownership Term 3mocheche.tertia100% (1)

- Strategic Management & Business Policy: Thomas L. Wheelen J. David HungerDocument186 pagesStrategic Management & Business Policy: Thomas L. Wheelen J. David Hungerchemist_tmaNo ratings yet

- Complaint Form finq-FILLEDDocument4 pagesComplaint Form finq-FILLEDhamza najamNo ratings yet

- Videoscript Business PartnerDocument35 pagesVideoscript Business PartnerNô Lệ Tư BảnNo ratings yet

- Attendance EgmDocument39 pagesAttendance EgmPuspa NicholasNo ratings yet

- Member'S Contribution Remittance Form (MCRF) : Anas Lemleo ADocument4 pagesMember'S Contribution Remittance Form (MCRF) : Anas Lemleo AGRETCHENNo ratings yet

- NVQ SVQ Diploma in Beauty Therapy Level 3 Sample Unit G8 Draft Sample MaterialDocument6 pagesNVQ SVQ Diploma in Beauty Therapy Level 3 Sample Unit G8 Draft Sample MaterialJowie SooNo ratings yet

- Living in SeoulDocument248 pagesLiving in SeoulaphroditeuraniaNo ratings yet

- Tesco PaperfDocument15 pagesTesco PaperfsunflowerNo ratings yet

- TCCDocument106 pagesTCCsavitha satheesanNo ratings yet

- De Guzman vs. Court of AppealsDocument4 pagesDe Guzman vs. Court of Appealsmamp05No ratings yet

- General Journal Page Number 01 Descriptions PR Debit CreditDocument12 pagesGeneral Journal Page Number 01 Descriptions PR Debit CreditKurt SoriaoNo ratings yet

- BA5014-Entrepreneurship Development PDFDocument12 pagesBA5014-Entrepreneurship Development PDFJanakakumariNo ratings yet

- No Boston Olympics Presentation To Calgary Bid Exploration CommitteeDocument74 pagesNo Boston Olympics Presentation To Calgary Bid Exploration CommitteeCalgary Herald75% (4)

- Cost Output Relationship in ShortrunDocument4 pagesCost Output Relationship in ShortrunNagaraj BeeduNo ratings yet

- Office of The Inland Revenue and Customs (South), Karachi: Director General AuditDocument14 pagesOffice of The Inland Revenue and Customs (South), Karachi: Director General AuditHamid AliNo ratings yet