Exapmle 2-Gas Well PDF

Exapmle 2-Gas Well PDF

Uploaded by

Sazzadul HossainCopyright:

Available Formats

Exapmle 2-Gas Well PDF

Exapmle 2-Gas Well PDF

Uploaded by

Sazzadul HossainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Exapmle 2-Gas Well PDF

Exapmle 2-Gas Well PDF

Uploaded by

Sazzadul HossainCopyright:

Available Formats

Example 2

After successful drilling of a gas well-Bhola-3 in a remote area of the country,

the authority has decided to complete the well to put it on production. The first

step of this well completion procedure is to identify the optimum tubing size.

Necessary reservoir data (for IPR) and down hole equipment description (for

VLP) are available.

You are required to:

- Build a PROSPER well model for a gas producing well. Write down your name

and roll number in the description box.

1. Use the model to estimate the minimum flow rate at Turner velocity

against a well head flowing pressure of 1000 psig (First node pressure)

and your proposed tubing dia, because the local market only can

consume 5-8 MMcfd of gas.

2. A third party service company suggested that the well could be

completed with a 5” liner (from 4000 ft-5000 ft) instead of using any

tubing string to minimize cost. Explain why it would not be a suitable

option for this gas well.

3. Estimate the suitable tubing dia for the well.

The basic available PVT data are:

Parameter Value

Oil Gravity: 50 API

Gas gravity: 0.65 (Air =1)

Water salinity: 10000 ppm

Impurities (CO , N , H S): None

2 2 2

Deviation survey

Measured Depth in ft True Vertical Depth in ft

0 0

5000 5000

Down hole equipment

The down hole equipment includes the tubings and casings,.

Equipment type Measured depth in ft Internal diameter in Roughness in Rate

(down to) inches inches multiplier

Xmas Tree (Well 0 N/A N/A N/A

Head)

Tubing 4800 Assume any 0.0018 1

Casing 5000 6.2 0.0018 1

The geothermal gradient

Measured Depth in ft Static temperature in deg F

0 120

5000 200

The overall heat transfer coefficient is 3btu/h/ft2/F.

Reservoir Data

IPR model: C and N

Static Reservoir Pressure: 3000 psig

Reservoir Temperature: 220 degF

WGR 20 stb /scf

CGR: 15 stb /scf

Compaction Permeability Reduction model: No

Relative Permeability: No

C 100 mcf/day/psi2 +last two digit of your roll number

N 0.5

You might also like

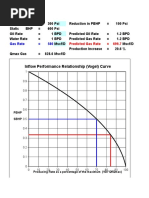

- Inflow Performance Relationship (Vogel) Curve: Gas Rate 580No ratings yetInflow Performance Relationship (Vogel) Curve: Gas Rate 5802 pages

- Gasteiger-2003-Handbook of Chemoinformatics - F PDFNo ratings yetGasteiger-2003-Handbook of Chemoinformatics - F PDF1,915 pages

- Comparison - Choke Equation Schlumberger vs. Texas A & I ModelsNo ratings yetComparison - Choke Equation Schlumberger vs. Texas A & I Models16 pages

- University of Tripoli Faculty of Engineering Petroleum EngineeringNo ratings yetUniversity of Tripoli Faculty of Engineering Petroleum Engineering8 pages

- Application For Revised Bypass: Form MMS l23A/t23S - ElectronicNo ratings yetApplication For Revised Bypass: Form MMS l23A/t23S - Electronic10 pages

- 1ntroduction To Petroleum Production SystemNo ratings yet1ntroduction To Petroleum Production System12 pages

- AL Selection - Draft of Document - 2d12 - Continuous Gas-LiftNo ratings yetAL Selection - Draft of Document - 2d12 - Continuous Gas-Lift23 pages

- Advanced Production Engineering Chapter # 2 Choke PerformanceNo ratings yetAdvanced Production Engineering Chapter # 2 Choke Performance50 pages

- MB Petroleum Standard Well Test Layout: Production Wing ValveNo ratings yetMB Petroleum Standard Well Test Layout: Production Wing Valve1 page

- HW - 3 - PEQ 202 - Dr. Adel Salem - Fall 2020 - AnswerNo ratings yetHW - 3 - PEQ 202 - Dr. Adel Salem - Fall 2020 - Answer7 pages

- Lecture 5 - Reservoir-Fluid PVT PropertiesNo ratings yetLecture 5 - Reservoir-Fluid PVT Properties44 pages

- Blann Presentation - Continuous Flow Gas Lift Design100% (1)Blann Presentation - Continuous Flow Gas Lift Design59 pages

- Schlumberger Pipesim Manual Pipesim Manual Schlumberger Official Site SchlumbergerNo ratings yetSchlumberger Pipesim Manual Pipesim Manual Schlumberger Official Site Schlumberger3 pages

- API Example 100 1000 0.650 78 178 8000 2.441 2125 2125 1941 200 0.40 1.00 400 50 ENo ratings yetAPI Example 100 1000 0.650 78 178 8000 2.441 2125 2125 1941 200 0.40 1.00 400 50 E2 pages

- Numerical Simulation in Reservoir ModelingNo ratings yetNumerical Simulation in Reservoir Modeling9 pages

- Cyclonic Desander: Sand and Solids Handling For All ApplicationsNo ratings yetCyclonic Desander: Sand and Solids Handling For All Applications2 pages

- ABC Guide To Gas Hydrates Awareness: Revision: 1.0 Oct 2002100% (1)ABC Guide To Gas Hydrates Awareness: Revision: 1.0 Oct 200232 pages

- Well-Test Horizontal Well, Student PresentationNo ratings yetWell-Test Horizontal Well, Student Presentation13 pages

- The Freeze Desalination of Mine Waters : J. S. At,. Inst. Min. Metal/., Vol. 87, No. 4No ratings yetThe Freeze Desalination of Mine Waters : J. S. At,. Inst. Min. Metal/., Vol. 87, No. 46 pages

- Lesson 02 - Inverse - Functions - Inverse - Triginometric - Functions-1-1No ratings yetLesson 02 - Inverse - Functions - Inverse - Triginometric - Functions-1-17 pages