Hard Chromium Plated Th.0.03: Skl01-Deflector - Roll - Assy

Hard Chromium Plated Th.0.03: Skl01-Deflector - Roll - Assy

Uploaded by

hawyegOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hard Chromium Plated Th.0.03: Skl01-Deflector - Roll - Assy

Hard Chromium Plated Th.0.03: Skl01-Deflector - Roll - Assy

Uploaded by

hawyegCopyright:

Available Formats

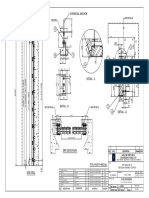

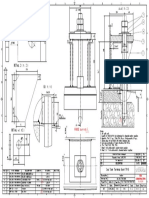

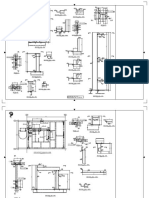

8 7 6 5 4 3 2 1

1881

F F

175 1576 130

JUST CLEAN

g 0.01 47 1440 89

B 265 910 265

28 237

0.8

12 12

0,01)

)

)

0,01)

(-+ 0,01

)

)

16 2

(-+ 0,04

0,01)

0,01)

(-+ 0,04

(-+ 0,01

(-+ 0,04

(-+ 0,04

(-+ 0,01

(-+ 0,01

0

0

0

0

n106 j6

n106 H7

n106 H7

n106 j6

n106 H7

n106 H7

E E

n106 j6

n106 j6

A

C 1.6 3.2 C1 3.2 3.2 3.2 1.6

)

1

0,13)

(470,06

(++ 0,17

R2

470

B 3.2

3.2 3.2 3.2

n460

A

n470 H7

n470 r6

R2

0,07)

(-- 0,04

0,07)

(-- 0,04

n500

n100 f7

n100 f7

16

D D

105

238 235

28 225 117 130

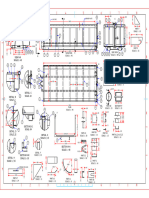

HARD CHROMIUM PLATED th.0.03 500

175 75 225 25

500

r 0.02 A B

C C

NOTES:

ALL WELDS ARE 8 MM THICKNESS CONTINUES FILLET WELD

° STRESS RELIEVE BEFORE MACHINED

60

STATIC AND DYNAMIC BALANCE

EDGES SHOULD BE CHAMFER AT 0.5X45°

53

n3

HRU

6xn70 T

50

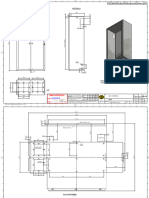

39 5 1 SKL01-DEFLECTOR_ROLL_SHAFT2 EN S355JR-ST-52 36.200 kg

B 13,5 4 4 SKL01-DEFLECTOR_ROLL_PLT1 EN S235JR-ST.37 13.297 kg B

3 1 SKL01-DEFLECTOR_ROLL_SHAFT1 EN S355JR-ST-52 35.856 kg

M20x2.5

1 1 SKL01-DEFLECTOR_ROLL_DRUM EN S355JR-ST-52 310.880 kg

n34

n29

n21

ITEM QTY PART NUMBER MATERIAL MASS

3.6 3.2 1.6 0.8 PARTS LIST

( ) FILE NAME SKL01-DEFLECTOR_ROLL_ASSY

1,5

SIZE A2 1 DWG NO 523951

WELDING N°.3 WELDING N°.2 WELDING N°.1

SHAFT END HOLE DRAWN mmgied 8/29/2022

A A A

VIEW A DETAIL (B) APPR.

A ISSUED A

EXCEPTION NOTED

SURFACE ROUGHNESS EXCEPT AS NOTED

FROM 0 TO 10 ` 0.2

ALLOWANCES ON THREADS 6H-6g

> 10 : Js13 REV

BREAK SHARP CORNERS AND EDGES

~ Angles from 0 to 90~ :`0.5~

WEIGHT:

0.025 0.05 0.1 0.2 0.4 0.8 1.6 3.2 6.3 12.5 25 50 436.124 kg QTY: Email: engineering@kandil.com

8 7 6 5 4 3 2 1

You might also like

- API1104 Code Clinic Study Guide 22 ND Edition PVDocument7 pagesAPI1104 Code Clinic Study Guide 22 ND Edition PVAgüero Vale33% (3)

- WaveSurfer 454 SchematicsDocument43 pagesWaveSurfer 454 SchematicsTom MillerNo ratings yet

- Northwest Minnesota Regional Construction and Demolition Waste Management Feasibility Assessment - Update PDFDocument21 pagesNorthwest Minnesota Regional Construction and Demolition Waste Management Feasibility Assessment - Update PDFShannon GeisenNo ratings yet

- TM-HBI-00030-H0-VOESAL: Approved: Checked: Drawn: Date: DesignedDocument3 pagesTM-HBI-00030-H0-VOESAL: Approved: Checked: Drawn: Date: DesignedMarko's Brazon'No ratings yet

- 428 05634 O DRW en - 1 BallDocument1 page428 05634 O DRW en - 1 BallJose Maria HernandezNo ratings yet

- KORD3 19-414 Dimensions For V1505Document2 pagesKORD3 19-414 Dimensions For V1505liyuping200809No ratings yet

- Mkes P&R Laxmanjhula Cg18 4 Rev 0Document1 pageMkes P&R Laxmanjhula Cg18 4 Rev 0sidhaksinghbhattiNo ratings yet

- V100-2MW T220 95m Tower DrawingDocument1 pageV100-2MW T220 95m Tower DrawingDat TienNo ratings yet

- (1-2) SIDE SEAL Dock Gate (ASSEMBLY) - ModelDocument1 page(1-2) SIDE SEAL Dock Gate (ASSEMBLY) - Modelsunengineers711No ratings yet

- Mkes P&R Laxmanjhula Cg18 3 Rev 0Document1 pageMkes P&R Laxmanjhula Cg18 3 Rev 0sidhaksinghbhattiNo ratings yet

- Part Drawing Sheet2Document1 pagePart Drawing Sheet2Shrikrushna MaliNo ratings yet

- ELEV. +814.12: Moa EngenhariaDocument1 pageELEV. +814.12: Moa EngenhariaLeonardo AmaralNo ratings yet

- SRE BNC V 202 0 - BkkNoiPierSeg PDFDocument1 pageSRE BNC V 202 0 - BkkNoiPierSeg PDFkeaoreNo ratings yet

- 2B-25-002 Pnid D-400-25-50-0004 - Rev - F1Document1 page2B-25-002 Pnid D-400-25-50-0004 - Rev - F1jk.jackycheokNo ratings yet

- CCT 400m3 No.2.4.6.8Document1 pageCCT 400m3 No.2.4.6.8Kiên ĐăngNo ratings yet

- Mohammed Asras ARDocument1 pageMohammed Asras AReman65178No ratings yet

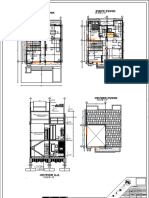

- Ground Floor Plan: Scale 1:100Document2 pagesGround Floor Plan: Scale 1:100CSEC Uganda Ltd.No ratings yet

- ITEM #05 Section R-R: Document StatusDocument1 pageITEM #05 Section R-R: Document StatusNitinNo ratings yet

- 50 00250 (Bowl Cone) Rev.4Document1 page50 00250 (Bowl Cone) Rev.4서정윤No ratings yet

- 7.629194.V 002 02aDocument1 page7.629194.V 002 02arajitkumar.3005No ratings yet

- 7.629194.V 002 02aDocument1 page7.629194.V 002 02arajitkumar.3005No ratings yet

- Support Bracket S Tube Akva Feeding: Rev. Description Date AprDocument1 pageSupport Bracket S Tube Akva Feeding: Rev. Description Date AprClaudio Vera diazNo ratings yet

- Agcc01 11718a CRD VDC CV STR 33585 R5Document1 pageAgcc01 11718a CRD VDC CV STR 33585 R5sunilarunaNo ratings yet

- Connection Detail Steel Beam To Wall: A B C A B CDocument1 pageConnection Detail Steel Beam To Wall: A B C A B CMark Roger Huberit IINo ratings yet

- Mid STA.2+342.91Document1 pageMid STA.2+342.91Julian SandovalNo ratings yet

- Designed Sgd. PS Drawing Verified Aproved Sgd. PS: 1st Angle Projection Dimensions in Mm. 6/24/2019 11/19/2018Document1 pageDesigned Sgd. PS Drawing Verified Aproved Sgd. PS: 1st Angle Projection Dimensions in Mm. 6/24/2019 11/19/2018Birlan AdrianNo ratings yet

- Ems e 0066 001 01 01Document2 pagesEms e 0066 001 01 01Luong LeNo ratings yet

- Location: Crusher PlantDocument1 pageLocation: Crusher PlantNaeem LalloNo ratings yet

- Assad Palace Pavilion 07062021 PDFDocument7 pagesAssad Palace Pavilion 07062021 PDFOmar AmirNo ratings yet

- B PlateDocument1 pageB Plateluca.laniNo ratings yet

- BAH053-KJB-DWG-ME-BW-03 Sheet 2 of 2Document1 pageBAH053-KJB-DWG-ME-BW-03 Sheet 2 of 2Gopa KumarNo ratings yet

- Parts and Assemblies Model of Diesel Hydraulic Shunter of The Bulgarian Narrow Gauge Railways (BDZ)Document1 pageParts and Assemblies Model of Diesel Hydraulic Shunter of The Bulgarian Narrow Gauge Railways (BDZ)M Ardan Budi PrasetyaNo ratings yet

- RR Container-FabDocument1 pageRR Container-FabProjetos NicolettiNo ratings yet

- Villa ProjectDocument1 pageVilla Projectimene lemitiNo ratings yet

- Asa-Bagc-971arch-Sd-Cv-Pt-Ga-310-Concrete LayoutDocument1 pageAsa-Bagc-971arch-Sd-Cv-Pt-Ga-310-Concrete LayoutvipinvnairNo ratings yet

- 402 08 TY01 000.rev2Document1 page402 08 TY01 000.rev2Miro CiglenečkiNo ratings yet

- Lus CP10J Ajp Le 2099 - Z00Document1 pageLus CP10J Ajp Le 2099 - Z00Mohammed NadeemNo ratings yet

- Copia Controlada: ESP: 03101.T144/146Document1 pageCopia Controlada: ESP: 03101.T144/146Samuel MuñozNo ratings yet

- Ceiling Layout 34 Sds LTC 015-23-004 34Document1 pageCeiling Layout 34 Sds LTC 015-23-004 34almamoura.eaNo ratings yet

- 01 ParterDocument1 page01 ParterJaravete Sebastian DamianNo ratings yet

- BL90-30 - 951784Document1 pageBL90-30 - 951784Bps PSNo ratings yet

- Crank Ver 2.4Document1 pageCrank Ver 2.4Cao Đào NamNo ratings yet

- Anchor - Bolt 12 MKD' NO. 1642001ABD-0002: Grid LocationDocument1 pageAnchor - Bolt 12 MKD' NO. 1642001ABD-0002: Grid LocationGHULAM NABINo ratings yet

- Rab03 Dde Sidm PFZ 234 0011Document1 pageRab03 Dde Sidm PFZ 234 0011renjithyesodharanNo ratings yet

- Typical Floor PlanDocument1 pageTypical Floor PlandihirdigitalNo ratings yet

- 2000kva 11KV Ip23 DrawingsDocument3 pages2000kva 11KV Ip23 Drawingsabdalla el-saadaneyNo ratings yet

- 3 - Ga Drawing 3 of 3Document1 page3 - Ga Drawing 3 of 3nimish.aquamarineNo ratings yet

- QGBT_HTB_R001-Layout1Document1 pageQGBT_HTB_R001-Layout1João Victor Oliveira dos santosNo ratings yet

- 3945 18-Me20831a-00345 00001 C (64-X8736)Document6 pages3945 18-Me20831a-00345 00001 C (64-X8736)SathiyaseelanNo ratings yet

- Canzone Arrabbiata-BatteriaDocument3 pagesCanzone Arrabbiata-BatteriamannafrancescopaoloNo ratings yet

- Diagrams TDS820Document42 pagesDiagrams TDS820Waldemar JęczewskiNo ratings yet

- Addc BB STL Co2 Lev4-004 (00) Addc BB STL Co Ge Lev-04 c02Document1 pageAddc BB STL Co2 Lev4-004 (00) Addc BB STL Co Ge Lev-04 c02wrkrvlgNo ratings yet

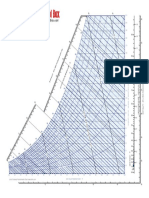

- Psychrometric Chart 29inhgDocument1 pagePsychrometric Chart 29inhgDickcy BenedictNo ratings yet

- Denah Lantai 3Document1 pageDenah Lantai 320 142 kadek surya praska dinataNo ratings yet

- Psychrometric Chart 29inhgDocument1 pagePsychrometric Chart 29inhgGunnar Leonardo Gutiérrez QuisbertNo ratings yet

- Psychrometric ChartDocument1 pagePsychrometric ChartJawBone YtNo ratings yet

- CD 330+ Dimension DrawingDocument1 pageCD 330+ Dimension DrawingJOSUE FERNANDO FERNANDEZNo ratings yet

- Sample - Pipe Support - 4Document5 pagesSample - Pipe Support - 4sridharNo ratings yet

- SCALE 1:50 SCALE 1:50: Ground Floor First FloorDocument1 pageSCALE 1:50 SCALE 1:50: Ground Floor First Floortesfayeseid7No ratings yet

- SKALA 1:2: Perancangan Compact Automatic TransmissionDocument1 pageSKALA 1:2: Perancangan Compact Automatic TransmissionYosa MelodyNo ratings yet

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- UntitledDocument1 pageUntitledhawyegNo ratings yet

- How Does Redex Differential Drive WorkDocument26 pagesHow Does Redex Differential Drive WorkhawyegNo ratings yet

- Submission Confirmation: Entry Received: v12.01.00 Applicant Entry SystemDocument1 pageSubmission Confirmation: Entry Received: v12.01.00 Applicant Entry SystemhawyegNo ratings yet

- Split Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard Seals - SNL 524-62Document2 pagesSplit Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard Seals - SNL 524-62hawyegNo ratings yet

- NICRO Company Presentation 2015Document27 pagesNICRO Company Presentation 2015hawyegNo ratings yet

- Pipe Flow Design 1: Results DataDocument7 pagesPipe Flow Design 1: Results DatahawyegNo ratings yet

- HK 40Document2 pagesHK 40hawyegNo ratings yet

- Airmotor CatalogDocument33 pagesAirmotor CataloghawyegNo ratings yet

- ErodeDocument465 pagesErodedeva nesanNo ratings yet

- Defects of The Steel Billet in Continuous CastingDocument7 pagesDefects of The Steel Billet in Continuous CastingJorge MadiasNo ratings yet

- (Original) Super Glue X2000 Multi Purpose Adhesive Adhesive Super Strong Liquid - Stick All Materials 50g - Lazada PHDocument9 pages(Original) Super Glue X2000 Multi Purpose Adhesive Adhesive Super Strong Liquid - Stick All Materials 50g - Lazada PHRene BesanaNo ratings yet

- S. No Pg. No: I List of Figures IDocument15 pagesS. No Pg. No: I List of Figures Iyuvaraj shankarNo ratings yet

- Kemppi MinarcMig Auto en USDocument11 pagesKemppi MinarcMig Auto en USAlexandre RodriguesNo ratings yet

- Application of ResinsDocument2 pagesApplication of Resinsjonesmuta769No ratings yet

- Pyrometallurgy 2Document14 pagesPyrometallurgy 2Athlur Sai KiranNo ratings yet

- Data Sheet FZP II SODocument1 pageData Sheet FZP II SOJuan PalomoNo ratings yet

- Chapter 4 Exercises 1-8Document9 pagesChapter 4 Exercises 1-8deniz turkbayragiNo ratings yet

- Factory Profile FlossyDocument17 pagesFactory Profile FlossyK.M. Abedur Rahman ShuvroNo ratings yet

- Saw Blades: Product OverviewDocument34 pagesSaw Blades: Product Overviewhumberto cerda gonzalezNo ratings yet

- Self Improving CNC Milling Machine by Torjus SpillingDocument125 pagesSelf Improving CNC Milling Machine by Torjus SpillingMihaela Ileni100% (1)

- Chemical Reactions and Equations: Case Study Based Questions 10th ScienceDocument8 pagesChemical Reactions and Equations: Case Study Based Questions 10th ScienceSath-HyaNo ratings yet

- Cleaning and Inspection of Condenser TubesDocument2 pagesCleaning and Inspection of Condenser TubesMuhammad Hasbi AsidiqiNo ratings yet

- Profile 45 250 Sandwich Panel Techincal DatasheetDocument2 pagesProfile 45 250 Sandwich Panel Techincal DatasheetEle SultanaNo ratings yet

- Acceptable Weld ProfilesDocument14 pagesAcceptable Weld ProfilesMark Miano100% (1)

- 91, RW 3001 Emi GND Corrosion Resistant Gaskets 1cfcdDocument14 pages91, RW 3001 Emi GND Corrosion Resistant Gaskets 1cfcdOzan BegdeNo ratings yet

- Importance of Spindle Speed in Ring Frame: Research Article ISSN: 2637-4595Document3 pagesImportance of Spindle Speed in Ring Frame: Research Article ISSN: 2637-4595Arif HasanNo ratings yet

- M58 M68 K Resin InstructionDocument3 pagesM58 M68 K Resin InstructionAllen HardingNo ratings yet

- Worksheet - 6 - Unit VDocument9 pagesWorksheet - 6 - Unit Vtax.amit1988No ratings yet

- 04 Metal and Glass-Wood PolicyDocument1 page04 Metal and Glass-Wood Policykitek100% (1)

- 3 AS AMP SyllabusDocument3 pages3 AS AMP SyllabusBrute ForceNo ratings yet

- Posterbook Tubing 23447199 202202 enDocument4 pagesPosterbook Tubing 23447199 202202 enbadrul hisyamNo ratings yet

- BW30HR 440Document2 pagesBW30HR 440Alejandro OdioNo ratings yet

- Manpower Reduction PlanDocument3 pagesManpower Reduction PlanakshayNo ratings yet

- ReactorDocument16 pagesReactorkhansartaj19995No ratings yet

- Flygt 2102 LDocument11 pagesFlygt 2102 LAlexandreNo ratings yet

- 10.1016@b0 12 227055 x@00772 0Document8 pages10.1016@b0 12 227055 x@00772 0import.xenoninterNo ratings yet