Can Coating Formulations (Sheet 1 To 4)

Can Coating Formulations (Sheet 1 To 4)

Uploaded by

No NameCopyright:

Available Formats

Can Coating Formulations (Sheet 1 To 4)

Can Coating Formulations (Sheet 1 To 4)

Uploaded by

No NameOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Can Coating Formulations (Sheet 1 To 4)

Can Coating Formulations (Sheet 1 To 4)

Uploaded by

No NameCopyright:

Available Formats

Guideline Formula 13.

External Varnish for Bodies

PRODUCT WEIGHT PRODUCER

Acrylic resin (60% nvm, medium mole weigth, Ohv 110) 370

BE 659 45

Razeen LR 1100 60 JANA www.jana-ksa.net

PMA 285 DOW www.dow.com

PMA 139 DOW www.dow.com

Phosphoric Acid 1

And all items in turn to item 1.

Formulating Details

Film former type Acrylic

Crosslinker type Benzoguanamine

8.7/1 (acrylic +

Solis ratio

epoxy/amino)

Typical Stoving Schedule 15-45 secs @ 200-250˚C

Solids 0.31

45 seconds Ford Cup

Viscosity

4/25˚C

Testing

Mechanical Slip

Wedge bend Pasteurisation 80˚C/30 minutes in water

Box draw Process 115˚C/30 minutes in water

Adhesion (cross hatch to basecoat)

Abrasion resistance

Scratch

Slip

External Coating for Ends

Guideline Formula 6 is suitable

Internal Coating for Ends

Guideline Formula 5 is suitable

Guideline Formula 5 is suitable

Guideline Formula 12. External White Basecoat for bodies

Acrylic resin (60% nvm, medium mole weight, Ohv 110) 370

Titanium dioxide 250

Cymel 301 25

Razeen LR 1100 70

PMA 185

PM 99

Phosphoric Acid 1

Disperse item 2 in item 1 using HSD and keeping temperature

below 50˚C. Continue until off

Scale using a Hegman gauge. Add remaining items in turn.

Formulating Details

Film former type Acrylic

Crosslinker type HMMM

Solids ratio 11.7/1 (acrylic +epoxy/amino)

Typical Stiving Schedule 15-45 secs @ 200-250˚C

Solids 56%

65 seconds Ford Cup

Viscosity 4/25˚C

Testing

Mechanical

Wedge bend

Box draw

Adhesion (cross hatch)

Abrasion resistance

Scratch

Slip

2.3 Two Piece Aerosols

Guideline Formula 14. Internal Spray

Razeen SR 5099 140

Xylene 273

Butanol 205

Ethyl glycol 282

Phenolic (butylated resole 60% 70

BE 659 20

Lanco wax TF1780 10

Dissolve epoxy in items 2-4 by heating to 80˚C. Cool and add remaining items.

Formulating Details

Film former type Epoxy phenolic

Crosslinker type Benzoguanamine

Solids ratio 12.6/1 (epoxy +phenolic/amino)

Typical Stoving Schedule 6 -7 minutes at 230˚C

Solids Solids

Viscosity 25 seconds Ford Cup 4/25˚C

Testing

Mechanical Chemical

Buckle test Dichloromethane at 40˚C/24 hours

Box draw followed by wedge bend Diethy ether/water/ethanol 45/10/45 at 40 ˚C/24 hrs.

Cross hatch adhesion Cross hatch adhesion

Necking test Enamel rating

External White for bodies

Guideline Formulation 12 is suitable

Typical stoving schedule is 1-2 minutes at 160 -190˚C

External Varnish for bodies

Guideline Formulation 13 is suitable

Typical stoving schedule is 1-2 minutes at 160 -190˚C

External White for end (Cones)

Guidelines Formulation 8 is suitable

Typical stoving schedule is 10-12 minutes at 160 -180˚C

External Varnish for ends (Cones)

Guideline Formulation 6 is suitable and can be used without white basecoat if required

typical stoving schedule is 10-12 minutes at 160 -180˚C

The information and recommendations contained herein are based upon our data believed to be correct. However, since the conditions of use are beyond

our control, no guarantee or warranty of any kind expressed or implied is made with respect to the information contained herein. Furthermore, nothing

contained in this guide shall be interpreted as a recommendation for using the product in violation of any patents relating to the material and their uses.

You might also like

- Alkyd Resin CalculationsDocument2 pagesAlkyd Resin CalculationsAli Raza100% (2)

- 5 - Body Filler - Polyester Putty - 2019 EditionDocument2 pages5 - Body Filler - Polyester Putty - 2019 Editiondamax rec100% (1)

- Formulation Additives - Economic Solutions For Solventborne Tinting SystemsDocument24 pagesFormulation Additives - Economic Solutions For Solventborne Tinting SystemsSantos Garcia100% (1)

- Architectural CoatingDocument28 pagesArchitectural CoatingDuc Nguyen100% (4)

- "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Sewer PipeDocument9 pages"Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Sewer PipeRed RedNo ratings yet

- 21 - Resins For Road Marking PaintsDocument4 pages21 - Resins For Road Marking Paintsraj jangid100% (1)

- Dow Performance Solvents: - Your Choice of Coalescent in Waterborne CoatingsDocument4 pagesDow Performance Solvents: - Your Choice of Coalescent in Waterborne CoatingsAPEX SONNo ratings yet

- Multifunctional Additives: For Paints and CoatingsDocument2 pagesMultifunctional Additives: For Paints and Coatingspandep22No ratings yet

- 01 - 2K PU SB Auto Refinish & Ind Systems 08-10Document67 pages01 - 2K PU SB Auto Refinish & Ind Systems 08-10محمد عزت100% (1)

- Supreme: Premium Opacifying Mineral For Titanium Dioxide ExtensionDocument2 pagesSupreme: Premium Opacifying Mineral For Titanium Dioxide Extensionkensley oliveiraNo ratings yet

- Croda How To LoVOCoatDocument6 pagesCroda How To LoVOCoatkarla100% (1)

- LoVOCoat - For Low VOC High Performance Solvent Borne CoatingsDocument4 pagesLoVOCoat - For Low VOC High Performance Solvent Borne CoatingskarlaNo ratings yet

- Oxylink - Technical Product Information: Additive For Waterborne Resin SystemsDocument32 pagesOxylink - Technical Product Information: Additive For Waterborne Resin SystemsAPEX SONNo ratings yet

- Ucar Latex 379G: The Best Just Got BetterDocument12 pagesUcar Latex 379G: The Best Just Got BetterQuimicosgenericosgaffaro GaffaroNo ratings yet

- 03 WB 1K and 2K Furniture CoatingsDocument85 pages03 WB 1K and 2K Furniture CoatingsJavier Triana MendozaNo ratings yet

- RosinDocument42 pagesRosinVingiu Katre100% (1)

- ARKEMA COATEX Presentation COADIS 123 K Hidrophobic Dispersant PDFDocument22 pagesARKEMA COATEX Presentation COADIS 123 K Hidrophobic Dispersant PDFJose E BatistaNo ratings yet

- Nuosperse FA 196Document2 pagesNuosperse FA 196Sandra Rojas100% (3)

- Equivalent Weight: Technical Center Guide To Urethane CalculationsDocument4 pagesEquivalent Weight: Technical Center Guide To Urethane CalculationsAbdullah Sahly100% (1)

- Solvent Evap RateDocument2 pagesSolvent Evap RateBoro Terakol100% (1)

- Long Durability Exterior CoatingDocument1 pageLong Durability Exterior CoatingAmit BholaNo ratings yet

- Inz 2K Polyaspartics Topcoat White GuideDocument2 pagesInz 2K Polyaspartics Topcoat White GuideOswaldo Manuel Ramirez Marin100% (1)

- UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161Document4 pagesUCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161sriatul2006No ratings yet

- Cryol 912 60 - TDSDocument2 pagesCryol 912 60 - TDSShafiq LatifNo ratings yet

- Technical Presentation: Improve Water Resistance With Rheology AdditivesDocument30 pagesTechnical Presentation: Improve Water Resistance With Rheology AdditivesAPEX SON100% (1)

- 2K-PU Flooring, Flexible, Self-Leveling, Solvent-Free, 50-65-75 Shore A (V 44409 - 0)Document2 pages2K-PU Flooring, Flexible, Self-Leveling, Solvent-Free, 50-65-75 Shore A (V 44409 - 0)Oswaldo Manuel Ramirez Marin50% (2)

- Clariant Wetting-AgentsDocument7 pagesClariant Wetting-AgentsAPEX SON100% (1)

- Incozol 2 DataDocument2 pagesIncozol 2 DataJeffrey Bempong100% (1)

- ExtendersDocument33 pagesExtenderssbttbsNo ratings yet

- Omnova Coatings PresentationDocument12 pagesOmnova Coatings PresentationNatalia Rodriguez100% (1)

- How To Disperse A Matting AgentDocument2 pagesHow To Disperse A Matting Agenttessaro18230% (1)

- 07 Hungary Interior VINNAPAS VAE Dispersions 2018e KotschiDocument62 pages07 Hungary Interior VINNAPAS VAE Dispersions 2018e KotschiForeverNo ratings yet

- Jo GradeDocument40 pagesJo GradeEvonne TanNo ratings yet

- Duroftal VPE 7186 Coil - e PDFDocument24 pagesDuroftal VPE 7186 Coil - e PDFPratik MehtaNo ratings yet

- Industrial Coating Road Marking Paint, Yellow: Guide FormulationDocument1 pageIndustrial Coating Road Marking Paint, Yellow: Guide FormulationFabio Samir CuzinskyNo ratings yet

- Byk Ts-A5 Putties enDocument6 pagesByk Ts-A5 Putties enSebastian GonzalezNo ratings yet

- Stepan Formulation 1166Document2 pagesStepan Formulation 1166kus2002inNo ratings yet

- Formulation Formulation: Chromate Free 1K Epoxy Etch Primer Using HALOX CW-491Document1 pageFormulation Formulation: Chromate Free 1K Epoxy Etch Primer Using HALOX CW-491nanoNo ratings yet

- SpecialChem - Coalescing Agents in Coatings - Definition, Types & PropertiesDocument5 pagesSpecialChem - Coalescing Agents in Coatings - Definition, Types & Propertiesichsan hakim100% (1)

- Interior Paint FormulationDocument1 pageInterior Paint FormulationSrun Bunsroeun100% (1)

- Introduction To Waterborne Paints & Coatings Rheology: Technical DocumentDocument46 pagesIntroduction To Waterborne Paints & Coatings Rheology: Technical DocumentAPEX SON100% (1)

- How To Achieve Better Than Acrylic Performance Without Acrylics For Architectural and Masonry PaintsDocument45 pagesHow To Achieve Better Than Acrylic Performance Without Acrylics For Architectural and Masonry Paintssriatul2006No ratings yet

- SPC-24 Specialty Glow in The Dark TDSDocument2 pagesSPC-24 Specialty Glow in The Dark TDSnophiaNo ratings yet

- Cytec Cymel ResinsDocument9 pagesCytec Cymel ResinsHarshad PorwalNo ratings yet

- Woodcoatings PDFDocument22 pagesWoodcoatings PDFnano100% (1)

- Formulation Techniques Using Feve Resins in Waterborne and HighDocument10 pagesFormulation Techniques Using Feve Resins in Waterborne and HighManuel Chire100% (1)

- APAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFDocument10 pagesAPAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFraahul_nNo ratings yet

- Formula 152 Topcoat (MILDTL-24441)Document4 pagesFormula 152 Topcoat (MILDTL-24441)Trịnh Minh KhoaNo ratings yet

- 24 391 01 Coatings and Inks Additive Selection GuideDocument16 pages24 391 01 Coatings and Inks Additive Selection GuideLong An DoNo ratings yet

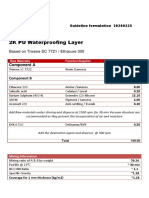

- 2K Solvent Free Waterproofing FormulationDocument2 pages2K Solvent Free Waterproofing FormulationM Idrees100% (2)

- EDM - 012 Additives For Wood and Furniture Coatings PDFDocument8 pagesEDM - 012 Additives For Wood and Furniture Coatings PDFEugene PaiNo ratings yet

- SC1918 PDFDocument3 pagesSC1918 PDFA MahmoodNo ratings yet

- Polishes, Coatings and SealersDocument30 pagesPolishes, Coatings and SealersIdkaNo ratings yet

- 20 - Alkyd Emulsifier - ES 4045 - 2019 EditionDocument4 pages20 - Alkyd Emulsifier - ES 4045 - 2019 Editionumar buttNo ratings yet

- MAINCOTE™ AEH-20 Acrylic-Epoxy Hybrid Resin: Regional Product Availability DescriptionDocument2 pagesMAINCOTE™ AEH-20 Acrylic-Epoxy Hybrid Resin: Regional Product Availability DescriptionXuxo XuxitoNo ratings yet

- Dokumen - Tips - Waterborne Silicates in Coatings and Construction Waterborne Silicates inDocument37 pagesDokumen - Tips - Waterborne Silicates in Coatings and Construction Waterborne Silicates inLong An Đỗ100% (2)

- Primal Ac 369sDocument20 pagesPrimal Ac 369shongducxxx100% (1)

- Talc For Wall Paint - WallpaintDocument9 pagesTalc For Wall Paint - Wallpaintboyo17meiNo ratings yet

- FP Pigments - Opacity Pigments, Cost Saving Opportunities in Architectural Coatings Paul DietzDocument22 pagesFP Pigments - Opacity Pigments, Cost Saving Opportunities in Architectural Coatings Paul DietzHiếu Mai Đức100% (1)

- Polyurethanes: Science, Technology, Markets, and TrendsFrom EverandPolyurethanes: Science, Technology, Markets, and TrendsRating: 1 out of 5 stars1/5 (1)

- Adhesion Promoters - Adhesion Basics & Material Selection Tips For AdhesivesDocument16 pagesAdhesion Promoters - Adhesion Basics & Material Selection Tips For AdhesivesNo NameNo ratings yet

- Environment Friendly Electrostatic Spraying Technology of Solvent Based Coatings 2165 784X.1000101Document3 pagesEnvironment Friendly Electrostatic Spraying Technology of Solvent Based Coatings 2165 784X.1000101No NameNo ratings yet

- Food Can Internal CoatingsDocument1 pageFood Can Internal CoatingsNo NameNo ratings yet

- Wood Coatings 101 Part 1Document26 pagesWood Coatings 101 Part 1No NameNo ratings yet

- DR Fixit General Repair Remedial Waterproofing Guide PDFDocument40 pagesDR Fixit General Repair Remedial Waterproofing Guide PDFandrealeger755774No ratings yet

- Scotchweld EC 2216BADocument8 pagesScotchweld EC 2216BAbenNo ratings yet

- Ficha GP3477 Epoxy Water EmulsionDocument2 pagesFicha GP3477 Epoxy Water EmulsionMarina AvNo ratings yet

- JSS 4210-18-2005Document25 pagesJSS 4210-18-2005Kaushik Sengupta100% (1)

- Interbond 808: Epoxy AnticorrosiveDocument4 pagesInterbond 808: Epoxy AnticorrosivedcsamaraweeraNo ratings yet

- Amercoat 400AL PDFDocument4 pagesAmercoat 400AL PDFLalit Bom MallaNo ratings yet

- Experimental Investigation of GFRP LaminatesDocument59 pagesExperimental Investigation of GFRP LaminatesKHALEEL PASHA SHAIKNo ratings yet

- 55194HMPPSplashzoneWhitepaper.5d8cbbf884bccDocument3 pages55194HMPPSplashzoneWhitepaper.5d8cbbf884bccWan Ah-LunNo ratings yet

- Simazinc EP Primer 1402-01Document2 pagesSimazinc EP Primer 1402-01Agung RiyantoNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical Dataウィリアムズ アンディNo ratings yet

- Fiberline Design Manual PDFDocument326 pagesFiberline Design Manual PDFJulian David Buitrago QuinteroNo ratings yet

- Surfboard Glassing Manual: Fiberglassing A Wood Surfboard With Epoxy ResinDocument50 pagesSurfboard Glassing Manual: Fiberglassing A Wood Surfboard With Epoxy ResinDiego ValenzuelaNo ratings yet

- Aero Supplies Catalogue MILSPECDocument7 pagesAero Supplies Catalogue MILSPECJeniffer BarriosNo ratings yet

- Painting Procedure For PPDocument14 pagesPainting Procedure For PPbehzad mohammadiNo ratings yet

- Efka PB 2744: Technical InformationDocument2 pagesEfka PB 2744: Technical InformationSebastian GonzalezNo ratings yet

- Monoseal EXDocument2 pagesMonoseal EXosama mohNo ratings yet

- EC TDS IN2 Infusion ResinDocument2 pagesEC TDS IN2 Infusion ResinDiego JimenezNo ratings yet

- Nitomortar 30Document2 pagesNitomortar 30PremNo ratings yet

- Carbomastic15BNX EngDocument2 pagesCarbomastic15BNX Engfazeel mohammedNo ratings yet

- Piezo FilmDocument89 pagesPiezo Filmmcu_power100% (1)

- Service Center Repairs We Buy Used Equipment: InstraDocument50 pagesService Center Repairs We Buy Used Equipment: InstraPaulo BerriosNo ratings yet

- Genosil GF 95Document3 pagesGenosil GF 95RAAX1No ratings yet

- Berger Protectomastic RPL CoatingDocument2 pagesBerger Protectomastic RPL CoatingRight Solutions Waterproofing ServicesNo ratings yet

- Getting Started With EpoxyDocument5 pagesGetting Started With EpoxyelmicakNo ratings yet

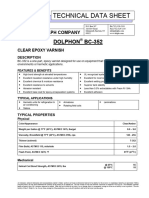

- Dol BC352Document2 pagesDol BC352Jerry Mar LucenaNo ratings yet

- Interseal 670HS+Br+EngDocument2 pagesInterseal 670HS+Br+Engrajauae2008100% (1)

- Grouting Soultions BrochureDocument4 pagesGrouting Soultions BrochureafrdhkNo ratings yet

- ProductCatalogue 2020 SouthAfricaDocument76 pagesProductCatalogue 2020 SouthAfricaBaraka LetaraNo ratings yet

- Construction of Cross Country PipelinesDocument40 pagesConstruction of Cross Country PipelinesGaurav100% (2)