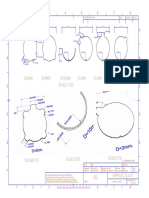

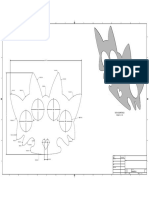

Baffle Support, Non Discharge Side

Baffle Support, Non Discharge Side

Uploaded by

Công NguyênCopyright:

Available Formats

Baffle Support, Non Discharge Side

Baffle Support, Non Discharge Side

Uploaded by

Công NguyênCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Baffle Support, Non Discharge Side

Baffle Support, Non Discharge Side

Uploaded by

Công NguyênCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

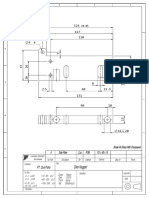

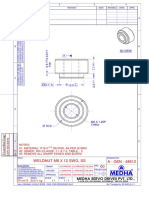

STANDARD TOLERANCE REV CHANGE DESCRIPTION ZONE ECN # DATE APV BY

GRADES

A

( ISO 286-1:1988 )

DIMENSION

RANGE

IT 12

PRELIMINARY A

0-3 ±0.05

3-6 ±0.06

6-10 ±0.08

10-18 ±0.09 R195.15 16

18-30 ±0.11 25.00

30-50 ±0.13

15

50-80 ±0.15

80-120 ±0.18

120-180 ±0.20

B 180-250 ±0.23 B

250-315 ±0.26

315-400 ±0.29

400-500 ±0.32

500-630 ±0.35 12.00 16.65 18

630-800 ±0.40 17

800-1000 ±0.45

C C

2.88 19

D D

64.33 8

R4.00

E E

5

167.33 14

147.81

F 4

F

G G

H H

30.00 13

J J

54.00 R4.00

6.00 22.00 10

12

6 7

6.00

11

K K

40.00

3

123.50

9

L L

M M

1

NOTES:

N N

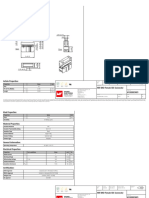

M 1. MATERIAL: Q235A, A36 WITH MATERIAL TEST REPORT, OR EQUIVALENT.

MATERIALS NOT EXPLICITLY LISTED MUST BE APPROVED BY TTI ENGINEERING.

MATERIAL SPECIFICATIONS:

A. MINIMUM YIELD STRENGTH OF 230 MPa

B. MINIMUM ULTIMATE TENSILE STRENGTH OF 370 MPa

C. MINIMUM HARDNESS OF 125HB OR 70HRB

P P

SURFACE FINISH: 12.5 MICRO-METER Ra OR BETTER

COATING: PARTS TO BE PROTECTED AGAINST RUST PRIOR TO WELDING/PAINTING

COLOR: N/A

PART NEEDS TO COMPLY WITH HSF REQUIREMENTS AND HS RISK ASSESSMENT

INSTRUCTION REFER TO DOCUMENT OIQSA0014.

2. UNLESS OTHERWISE SPECIFIED:

A. NO BURRS OR SHARP EDGES ALLOWED

B. SHARP CORNERS AND FILLETS TO BE BROKEN WITH A 0.38 TO 0.89 RADIUS

R R

C. PART MUST BE FREE OF CRACKS, CHIPS, SHAVINGS AND ANY OTHER DEBRIS

THAT MAY OCCUR DURING PROCESSING

D. USE TOLERANCE BLOCK ABOVE FOR LINEAR DIMENSION TOLERANCES

E. DEFAULT ANGLE TOLERANCE TO BE 0.5

3. FOR ALL UNDIMENSIONED GEOMETRY REFER TO 3-D CAD FILE

4. SEE QUALITY ASSURANCE FOR ADDRESSING CRITICAL AND MAJOR DIMENSIONS

PRELIMINARY

3.00 Techtronic Industries Co. Ltd. METRIC UNLESS OTHERWISE SPECIFIED 3RD ANGLE

DIMENSIONS ARE IN MILLIMETERS PROJECTION

TOTAL C THIS PAGE = 0

DIMENSION & TOLERANCE UNSPECIFIED DIMENSIONS CN ORA P/N PART NAME

BAFFLE SUPPORT, NON DISCHARGE SIDE

2

CONFIDENTIAL

M

TOTAL M THIS PAGE = 2 PER ASME Y14.5 - 2009 REFERENCE CAD MODEL

T 19

THIS DRAWING IN DESIGN AND PART & PROCESS MUST COMPLY WITH THE COMPANY SC SAP P/N

DETAIL IS THE PROPERTY OF REQUIREMENTS OF HAZARDOUS SUBSTANCE FREE - 42" DECK T

TOTAL INSPECTION =

TECHTRONIC INDUSTRIES WEIGHT DRAWN BY MODEL NO.

COMPANY LIMITED. WEIGHT & TOLERANCE JOSEPH AYDT

A

ALL RIGHTS OF DESIGN OR COLOR BU CAD TOOL SCALE SHEET SIZE PLM ID REV

INVENTION ARE RESERVED. COLOR NAME, COLOR CHIP # OP NX 2:1 1 OF 1 A0 SL00047023

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

You might also like

- Taig Lathe ManualDocument12 pagesTaig Lathe Manualspayt100% (1)

- Lenovo X1 Carbon LCFC YODA-2 NM-B48 6th Gen (EX480 NM-B481)Document88 pagesLenovo X1 Carbon LCFC YODA-2 NM-B48 6th Gen (EX480 NM-B481)rocky liuNo ratings yet

- Introduction To Well Intervention Model AnswerDocument4 pagesIntroduction To Well Intervention Model Answermissaoui50% (2)

- CF BraunDocument4 pagesCF BraunTito EcheverriaNo ratings yet

- Part Manual SK330-8 PDFDocument500 pagesPart Manual SK330-8 PDFReiman22100% (1)

- Exam03 Sol f12Document12 pagesExam03 Sol f12hasib_07No ratings yet

- Sigma: Industrial SolutionDocument1 pageSigma: Industrial Solutionpokharkarsunil00No ratings yet

- Sigma: Industrial SolutionDocument1 pageSigma: Industrial Solutionpokharkarsunil00No ratings yet

- If in Doubt Ask: Engineering SADocument1 pageIf in Doubt Ask: Engineering SAARAFANo ratings yet

- In/Mm 2:1: B-SIZE 172672Document2 pagesIn/Mm 2:1: B-SIZE 172672GeeNo ratings yet

- 144 03-0005099Document1 page144 03-0005099Gabriela CordovaNo ratings yet

- Functional Symbols Current Rev Desc:: Dimension Units ScaleDocument2 pagesFunctional Symbols Current Rev Desc:: Dimension Units ScaleCarlos ParapeNo ratings yet

- AJ Sai Clock Ver2-Layout1SketchyDocument1 pageAJ Sai Clock Ver2-Layout1Sketchynoonot126No ratings yet

- Molex Micro-Fit (3.0) Bmi Vertical ReceptacleDocument2 pagesMolex Micro-Fit (3.0) Bmi Vertical ReceptacleVijoy PaulNo ratings yet

- Side Plate Dies NuggetDocument1 pageSide Plate Dies NuggetArief FibonacciNo ratings yet

- Wurth WR-BHD 61202023021 IDC JTag Connecteur 2x10pinDocument6 pagesWurth WR-BHD 61202023021 IDC JTag Connecteur 2x10pinSupportNo ratings yet

- Tolba SuperiorDocument1 pageTolba SuperiorDaniela María Arizmendi BarónNo ratings yet

- Master Frame of HPPDocument1 pageMaster Frame of HPPYadi KusmayadiNo ratings yet

- E1340 05 PDFDocument1 pageE1340 05 PDFSunil Ranjan MohapatraNo ratings yet

- Inch/Mm NTS: Dimension Units ScaleDocument1 pageInch/Mm NTS: Dimension Units ScaleQazi JunaidNo ratings yet

- MANOPLADocument1 pageMANOPLAJuan José HernándezNo ratings yet

- Pa000006-Guide Rod - Dia12x215Document1 pagePa000006-Guide Rod - Dia12x215YAGNA V YAGNA VNo ratings yet

- RedactedDocument1 pageRedactedJose PerezNo ratings yet

- Fatima Khalid - Assignment 1Document5 pagesFatima Khalid - Assignment 1fatimakmuhammad97No ratings yet

- DCMOTOR - Transmotec Datasheet J - 5 SeriesDocument1 pageDCMOTOR - Transmotec Datasheet J - 5 Seriestanaya.rpsNo ratings yet

- Released RPS Standard ACS XS/XSC Heatsink CDocument1 pageReleased RPS Standard ACS XS/XSC Heatsink CAmc Forklift ElektrikNo ratings yet

- Connector RJ45 Jack SMT Vertical Plastic 8P8C 634108149621 DatasheetDocument7 pagesConnector RJ45 Jack SMT Vertical Plastic 8P8C 634108149621 DatasheetSérgio MartinsNo ratings yet

- 106211001-SD18 AbridgedDocument15 pages106211001-SD18 AbridgedvivsNo ratings yet

- FC-280SC: Output: 0.1W 4.0W (Approx)Document1 pageFC-280SC: Output: 0.1W 4.0W (Approx)Jordi MarsàNo ratings yet

- CROSSOVER 11 1 2 OTIS X 8 1 4 OTIS - IdwDocument1 pageCROSSOVER 11 1 2 OTIS X 8 1 4 OTIS - IdwNhoj AicragNo ratings yet

- Machine Capability - SPOT Welding - Platform Width (+ - 1.2)Document2 pagesMachine Capability - SPOT Welding - Platform Width (+ - 1.2)Jagadesh PNo ratings yet

- SJ117219Document1 pageSJ117219sheecheong01No ratings yet

- MC Spool 250X144X100X36X182Document1 pageMC Spool 250X144X100X36X182rajiv jainNo ratings yet

- Cover Housing: All Sharp Edges C0.3-0.5Document1 pageCover Housing: All Sharp Edges C0.3-0.5Arief FibonacciNo ratings yet

- 22 Hussein - Tuyan - Mangrove PDFDocument1 page22 Hussein - Tuyan - Mangrove PDFCirilo Jr. LagnasonNo ratings yet

- Model 4Document1 pageModel 4karpagavalli NNo ratings yet

- Rhi MBS Center of Mass Dwg.Document1 pageRhi MBS Center of Mass Dwg.AWNISH PRASAD SINGHNo ratings yet

- Joint Bolt DrumDocument1 pageJoint Bolt DrumFranciscus Dwi PrasetyoNo ratings yet

- AnguloDocument1 pageAnguloEdwin Ancota AcoticonaNo ratings yet

- Ocr-2688-069-01 Simplex 19.05P 40T SprocketDocument1 pageOcr-2688-069-01 Simplex 19.05P 40T SprocketUTTAM CHANDRA VIDYARTHINo ratings yet

- Die 1Document1 pageDie 1Muhamad HafidzNo ratings yet

- Released CEM Standard ACS M/L/XL Heatsink FDocument1 pageReleased CEM Standard ACS M/L/XL Heatsink FAmc Forklift ElektrikNo ratings yet

- Cnx4 (PX4) 1: 72CPU-000 - (BLK 20ga) 72CPU-001 - (BLK 18ga)Document1 pageCnx4 (PX4) 1: 72CPU-000 - (BLK 20ga) 72CPU-001 - (BLK 18ga)Jose ZorrillaNo ratings yet

- Ctagon O: Title: REV HRC Qty: 1 Pc/1 PCDocument1 pageCtagon O: Title: REV HRC Qty: 1 Pc/1 PCandhikabpNo ratings yet

- Revisions C: REVISED PER ECO-11-005150 RK HMR New Creo Drawing BV GBDocument1 pageRevisions C: REVISED PER ECO-11-005150 RK HMR New Creo Drawing BV GBhulaneNo ratings yet

- Detail A Scale 7: 1: Corner Should Be C0.2 or R0.2 Except As Note !. DIN ISO 2768Document1 pageDetail A Scale 7: 1: Corner Should Be C0.2 or R0.2 Except As Note !. DIN ISO 2768syaikulNo ratings yet

- Prop En1065 C-D35Document1 pageProp En1065 C-D35alessandroNo ratings yet

- 2SC2922Document1 page2SC2922zeckNo ratings yet

- Rakitan 103541Document1 pageRakitan 103541eko apriliantoNo ratings yet

- Acx3574730 2 AfsDocument1 pageAcx3574730 2 AfsBRUNO MONTECHIESINo ratings yet

- ConnectorDocument1 pageConnectorSuriyachai NiamsornNo ratings yet

- Blade+1Document1 pageBlade+1MJ DuNo ratings yet

- Pad Eye For Crystal Simec Global Services LimitedDocument1 pagePad Eye For Crystal Simec Global Services LimitedLast Son of AbrahamNo ratings yet

- 2-3 Turk'S Head Roll SM120A - 75x75 - L75: 33047 REMANZACCO (UD)Document2 pages2-3 Turk'S Head Roll SM120A - 75x75 - L75: 33047 REMANZACCO (UD)Alejandra ChocueNo ratings yet

- Mccsemi: 182KD10JX Thru 180LD10JXDocument6 pagesMccsemi: 182KD10JX Thru 180LD10JXbajarlibroselectroNo ratings yet

- EERAL A Rev00Document1 pageEERAL A Rev00er_paramjeetgillNo ratings yet

- 2 SC 4131Document1 page2 SC 4131Cosmin CodrescuNo ratings yet

- Sol11 Economics SP 02Document10 pagesSol11 Economics SP 02ak1gphotosNo ratings yet

- Hw8 PDFDocument6 pagesHw8 PDFDisanee SuphawatdisakulNo ratings yet

- 05 Parafuso Fenda Rev. 02Document1 page05 Parafuso Fenda Rev. 02fernandoincesaNo ratings yet

- Enclosure - 03 Technical SpecificationDocument10 pagesEnclosure - 03 Technical SpecificationHasibullah MirzadNo ratings yet

- Lami Upper Cutter and Under Cutter (2 Type) - REV1.0-ModelDocument1 pageLami Upper Cutter and Under Cutter (2 Type) - REV1.0-Modelciptasuryamulia.engNo ratings yet

- Kartesisk Distans Taktil 1: Characteristic Value Pattern Control Chart Histogram +tol - Tol Correction Value Nominal ValueDocument1 pageKartesisk Distans Taktil 1: Characteristic Value Pattern Control Chart Histogram +tol - Tol Correction Value Nominal ValueRobin PetterssonNo ratings yet

- DWG No. A4 SQ 12/3/2018 Plate / Section: Next ProcessDocument1 pageDWG No. A4 SQ 12/3/2018 Plate / Section: Next ProcesshadeNo ratings yet

- Air WasherDocument2 pagesAir WasherAryo BayuNo ratings yet

- Telehandler ChecklistDocument1 pageTelehandler Checklistjapv_pasNo ratings yet

- Retrofit Solutions: Technical DatabookDocument42 pagesRetrofit Solutions: Technical DatabookSanjayNo ratings yet

- 2 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (086-165)Document80 pages2 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (086-165)Lala CéspedesNo ratings yet

- Expt Guide - F2 - Pressure DropDocument7 pagesExpt Guide - F2 - Pressure DropBabyyFaced100% (1)

- Fundamentals of Engine Design and Operation: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDocument62 pagesFundamentals of Engine Design and Operation: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia Coralie100% (2)

- FluidandThermodynamics Vol1Document20 pagesFluidandThermodynamics Vol1Vaibhav JhanwarNo ratings yet

- List of Machineries and Machine Related Spare Parts, (Regular and Irregular (IR) ) KCLDocument10 pagesList of Machineries and Machine Related Spare Parts, (Regular and Irregular (IR) ) KCLMd HossainNo ratings yet

- Alwasy Step Ahead in TechnologyDocument6 pagesAlwasy Step Ahead in TechnologyDxFx100% (1)

- 12 Specification TS A C Machines R0 Oct 07 PDFDocument3 pages12 Specification TS A C Machines R0 Oct 07 PDFxchannel28No ratings yet

- Transition PlanDocument14 pagesTransition Planapi-572616954No ratings yet

- CBSE Class 11 Chemistry MCQs - Chemical ThermodynamicsDocument4 pagesCBSE Class 11 Chemistry MCQs - Chemical Thermodynamicsamar lalNo ratings yet

- Turbine ErectionDocument130 pagesTurbine Erectionkarthikgoldenrock100% (1)

- Cross-Sectional Optimization of Cold-Formed Steel Channels To Eurocode 3Document12 pagesCross-Sectional Optimization of Cold-Formed Steel Channels To Eurocode 3dineshNo ratings yet

- Apcy H 2018 PDFDocument72 pagesApcy H 2018 PDFEmad Elnoo PyNo ratings yet

- Kymco Service Manual: MXU 150 MX'er 150/125Document41 pagesKymco Service Manual: MXU 150 MX'er 150/125testiNo ratings yet

- Seismic Strengthening and Repair of RC Shear Walls PDFDocument8 pagesSeismic Strengthening and Repair of RC Shear Walls PDFSri LathaNo ratings yet

- AC Hotels by Marriott Design Standards Module 15 HVACDocument12 pagesAC Hotels by Marriott Design Standards Module 15 HVACIan OsorioNo ratings yet

- Building CollapseDocument22 pagesBuilding CollapseManishSharmaNo ratings yet

- Ae 104Document96 pagesAe 104wNo ratings yet

- Computational/Experimental Analysis of Hydrokinetic TurbineDocument18 pagesComputational/Experimental Analysis of Hydrokinetic TurbineFozanNo ratings yet

- ResearchDocument139 pagesResearchMohamed Bin IerousNo ratings yet

- Fire Protection BOQ - ToolDocument1 pageFire Protection BOQ - ToolReymarion MorataNo ratings yet

- ME140 Cantera Function GuideDocument2 pagesME140 Cantera Function GuideBen WolkNo ratings yet

- MESB 150.8 - ISSELNORD - FINALE Rev 3Document124 pagesMESB 150.8 - ISSELNORD - FINALE Rev 3FHDNo ratings yet