ASTM Glass Standards

ASTM Glass Standards

Uploaded by

Contracts E RiversideCopyright:

Available Formats

ASTM Glass Standards

ASTM Glass Standards

Uploaded by

Contracts E RiversideCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

ASTM Glass Standards

ASTM Glass Standards

Uploaded by

Contracts E RiversideCopyright:

Available Formats

470 Satellite Blvd NE Suite A Suwanee, GA 30024

Phone: 770-614-4121

Fax: (770) 614-4180

ASTM Glass Standards for General

Contractors

The purpose of this document is to manage the expectations of glass defects according to

ASTM (American Society for Testing & Materials).

Within the luxury market, expectations are high, and this document will help inform parties

on tolerances of error in terms of glass defects.

When Is A Defect Not A Defect?

In short, if facing the glass at 90 degrees in daylight, but not direct sunlight, at 10 feet, inspect

the central 80% of the glass panel. If defects are not visible to the naked eye, then, according

to ASTM, the glass is defect free.

Visual Inspection Visual Aid

Inspire Invision Design Build

470 Satellite Blvd NE Suite A Suwanee, GA 30024

Phone: 770-614-4121

Fax: (770) 614-4180

ASTM Official Standards for Imperfections in Glass

ASTM International is the basis for understanding glass and coating quality, allowable

defects, and visual inspection criteria. ASTM has many different specifications and

classifications depending on the type of glass being analyzed or quality controlled.

ASTM C 1036-16 (Standard specification for flat glass) Q3 / Glazing select specifications

Understanding ASTM inspection criteria is very important as it outlines inspection distance,

lighting requirements, inspection times, etc.

We’ve included a brief summary in this article of key parts of the ASTM. Keep in mind there

are different types of defects with different inspection rules.

The previously mentioned 10-foot rule is a general guideline but isn’t definitive. For example,

on sealed units of 35 sq. ft., the glass can have three 1” scratches and still be considered

within standards. Even if the scratches are visible.

Examples of Visual Inspection Criteria

• Glass shall be inspected in the central area in transmission at a distance of 5 feet from

the observer, and in reflection at a distance of 10 feet from the observer.

• Glass shall be inspected in the border area in transmission and reflection at a distance

of 10 feet from the observer.

• Glass must be inspected using a viewing angle of 90 degrees from the glass with

suitable background light (daylight without direct sunlight or a range of 500 – 1000

foot lamberts.) If a lighting box is used as a light source, the diffusing plate shall be

parallel to and at a distance of 10 ft from the glass.

• Inspection should not exceed viewing of more than 5 seconds for lites up to 6 square

feet, 10 seconds for lites up to 35 sq ft, and 20 seconds for lites larger than 35 square

feet, either in transmission or reflection.

• If defects are visible beyond what is allowable as listed by sizes (square feet) below

using the inspection criteria, the glass may be rejected.

Inspire Invision Design Build

470 Satellite Blvd NE Suite A Suwanee, GA 30024

Phone: 770-614-4121

Fax: (770) 614-4180

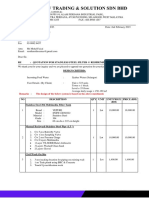

Allowable Defects

a) Single lites up to 6 square feet

• Scratches – Viewable as stated above must be 1” or less. No more than 1 is allowed

per lite.

• Debris, Dirt, Spots – Viewable as stated above, must be 1/16” or less. No more than 1 is

allowed per lite.

• Seeds, Bubbles, Knots, Stones – Viewable as stated above, must be 1/16” or less. No

more than 1 is allowed per lite.

• No more than 1 total viewable defect as described above is allowed per lite.

• Shells – No more than ¼” from edge less than ½ the thickness of the lite. No more

than 1 per side.

• Chips – No more than 1/8” from the edge. No more than 1 per side. (see illustration for

chips on page x.)

• Coating – Must be uniform on the lite inspected when viewed in transmission using

the inspection criteria previously stated above.

• The border area is comprised of 2 inches plus ½” from each edge of the lite. All other

area is the central area.

b) Single lites 6 to 35 square feet

• Scratches – Viewable as stated above must be 1” or less. No more than 2 are allowed

per lite and must be separated by a minimum of 24 inches.

• Debris, Dirt, Spots – Viewable as stated above, must be 1/16” or less. No more than 2

are allowed per lite and must be separated by a minimum of 24 inches.

• Seeds, Bubbles, Knots, Stones – Viewable as stated above, must be 1/16” or less. No

more than 2 are allowed per lite and must be separated by a minimum of 24 inches.

• No more than 2 total viewable defects as described above are allowed per lite.

• Shells – No more than ¼” from edge less than ½ the thickness of the lite. No more

than 1 per side.

• Chips – No more than 1/8” from the edge. No more than 1 per side. (see illustration for

chips.)

Inspire Invision Design Build

470 Satellite Blvd NE Suite A Suwanee, GA 30024

Phone: 770-614-4121

Fax: (770) 614-4180

• Coating – Must be uniform on the lite inspected when viewed in transmission using

the inspection criteria previously stated above.

• The border area is comprised of 4 inches plus ½” from each edge of the lite. All other

area is the central area (see illustration.)

c) Single lites over 35 square feet

• Scratches – Viewable as stated above, must be 1” or less. No more than 3 are allowed

per lite and must be separated by a minimum of 24 inches.

• Debris, Dirt, Spots – Viewable as stated above, must be 1/16” or less. No more than 3

are allowed per lite and must be separated by a minimum of 24 inches.

• Seeds, Bubbles, Knots, Stones – Viewable as stated above, must be 1/16” or less. No

more than 3 are allowed per lite and must be separated by a minimum of 24 inches.

• No more than 3 total viewable defects as described above are allowed per lite.

• Shells – No more than ¼” from edge less than ½ the thickness of the lite. No more

than 1 per side.

• Chips – No more than 1/8” from the edge. No more than 1 per side. (see illustration for

chips.)

• Coating – Must be uniform on the lite inspected when viewed in transmission using

the inspection criteria previously stated above.

• The border area is comprised of 6 inches plus ½” from each edge of the lite. All other

area is the central area (see illustration)

Allowable Defects Visual Aid

Inspire Invision Design Build

470 Satellite Blvd NE Suite A Suwanee, GA 30024

Phone: 770-614-4121

Fax: (770) 614-4180

Understanding Glass Chips and Shells

LED Edge Lit Glass Visual Aid

Inspire Invision Design Build

470 Satellite Blvd NE Suite A Suwanee, GA 30024

Phone: 770-614-4121

Fax: (770) 614-4180

Inspire Invision Design Build

You might also like

- Glass Inspection Standards For Filmed GlassDocument1 pageGlass Inspection Standards For Filmed GlassKhurshed Alam IndiaNo ratings yet

- 58 TD 117 Cutting Wheel Selection r1 1Document4 pages58 TD 117 Cutting Wheel Selection r1 1Admir HalilovicNo ratings yet

- PF 5188 GDocument10 pagesPF 5188 G林坤緯No ratings yet

- Ib305 Cross Hatch Ink Adhesion Tape TestDocument5 pagesIb305 Cross Hatch Ink Adhesion Tape TestPuneet SharmaNo ratings yet

- The Principles of Glass Cutting: A Comprehensive Technical Guide To Successful Glass Scoring and Cutting TechniquesDocument15 pagesThe Principles of Glass Cutting: A Comprehensive Technical Guide To Successful Glass Scoring and Cutting TechniquesAmir BakhshiyanNo ratings yet

- SP7031M00D01 000 ADocument29 pagesSP7031M00D01 000 Ashanthini01011986No ratings yet

- Vitro TD 119Document9 pagesVitro TD 119Eslam NaseebNo ratings yet

- This Is Very Common in Tank ConstructionDocument11 pagesThis Is Very Common in Tank ConstructionsbmmlaNo ratings yet

- GW PDFDocument22 pagesGW PDFSiahBiancaNo ratings yet

- Tempered Glass Datasheet.2Document2 pagesTempered Glass Datasheet.2James Tampepe100% (1)

- Parthi Site HandrillDocument1 pageParthi Site HandrillVidya MuraliNo ratings yet

- Why Is There A Bubble On My Tire?Document1 pageWhy Is There A Bubble On My Tire?arthymanicNo ratings yet

- 01 - Field Inspection Procedure For Used uLTIMATE™ Extreme™ Torque Connections (uXT™) PC-17 PDFDocument5 pages01 - Field Inspection Procedure For Used uLTIMATE™ Extreme™ Torque Connections (uXT™) PC-17 PDFKarla HernandezNo ratings yet

- Molding Sec 7.Qxd - GE - Plastic - DesignDocument15 pagesMolding Sec 7.Qxd - GE - Plastic - Designharishkumar.ravichandranNo ratings yet

- Widearea Eye/Face Washes G1727: Guardian EquipmentDocument2 pagesWidearea Eye/Face Washes G1727: Guardian Equipmenteisenbarger5607No ratings yet

- 02 - FIP CT M PC 10.2 2009feb11 ExtDocument4 pages02 - FIP CT M PC 10.2 2009feb11 ExtKarla HernandezNo ratings yet

- SampleDocument13 pagesSampleVivek LathNo ratings yet

- Phase 1 Pre-Pour Inspection ReportDocument8 pagesPhase 1 Pre-Pour Inspection Reportdefe123No ratings yet

- Cross Cut Adhesion Test Basic Cutter m44Document4 pagesCross Cut Adhesion Test Basic Cutter m44Madidj_2014No ratings yet

- Surface Vehicle Recommended Practice: Wheel and Wheel Trim Weathering Testing For Paint CoatingsDocument4 pagesSurface Vehicle Recommended Practice: Wheel and Wheel Trim Weathering Testing For Paint CoatingsAdriana SukmanaputraNo ratings yet

- Chart Drives: Main FeaturesDocument4 pagesChart Drives: Main FeaturesJohn SuarezNo ratings yet

- DC2685 Operating Procedures Double Block and Bleed Isolation PlugDocument9 pagesDC2685 Operating Procedures Double Block and Bleed Isolation PlugFitri BukhriNo ratings yet

- 7510 Value Series Manual Slicer: Exacting Standards, Just Like Yours, Since 1948Document2 pages7510 Value Series Manual Slicer: Exacting Standards, Just Like Yours, Since 1948wsfc-ebayNo ratings yet

- SLATER ROTORY BROCHING-catalog-englishDocument44 pagesSLATER ROTORY BROCHING-catalog-englishParesh PatelNo ratings yet

- SAE J 673-1993 Automotive Safety Glasses PDFDocument9 pagesSAE J 673-1993 Automotive Safety Glasses PDFmonkey1929100% (1)

- PAI Standard O-Ring Dimensions PDFDocument48 pagesPAI Standard O-Ring Dimensions PDFsalam87No ratings yet

- GAME OF TRUSSES - Rules Book - CENNOVATION 2019Document6 pagesGAME OF TRUSSES - Rules Book - CENNOVATION 2019Fahim shuvroNo ratings yet

- NDT Inspection Mud PumpsDocument6 pagesNDT Inspection Mud PumpsCristian BoselliNo ratings yet

- f436 Hardened Washers CATALOGODocument3 pagesf436 Hardened Washers CATALOGOWilfredo Marin AndradeNo ratings yet

- Visual Examination ProcedureDocument10 pagesVisual Examination ProceduresantanuriniNo ratings yet

- Ispring Water Filter ManualDocument28 pagesIspring Water Filter Manualdthibode100% (1)

- DC2693 Operating Procedures Double Block and Bleed Isolation Plug 4in To 24inDocument13 pagesDC2693 Operating Procedures Double Block and Bleed Isolation Plug 4in To 24inFitri BukhriNo ratings yet

- Cause Effect and Result of InvestigationsDocument38 pagesCause Effect and Result of InvestigationsfieqaNo ratings yet

- (DHT) Core CriteriaDocument3 pages(DHT) Core CriteriaKeith McCannNo ratings yet

- Bore Gage: Inside Diameter MeasurementDocument0 pagesBore Gage: Inside Diameter MeasurementPrekelNo ratings yet

- ESSAR ONGC R-Series 5well B-050 Offer 04.07.2017 PDFDocument3 pagesESSAR ONGC R-Series 5well B-050 Offer 04.07.2017 PDFAJAY PatilNo ratings yet

- DSI Ground Support Mechanical RockboltsDocument14 pagesDSI Ground Support Mechanical RockboltscuteshivNo ratings yet

- GPDS Connections Field InspectionDocument4 pagesGPDS Connections Field InspectiontheinmoeNo ratings yet

- ENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - ADocument9 pagesENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - AyoeyNo ratings yet

- PDS Spindle Care 07Document11 pagesPDS Spindle Care 07Sanderlei NascimentoNo ratings yet

- Aerospace Material Specification: Steel Cleanliness, Aircraft Quality Magnetic Particle Inspection ProcedureDocument15 pagesAerospace Material Specification: Steel Cleanliness, Aircraft Quality Magnetic Particle Inspection ProcedureShankar PediredlaNo ratings yet

- Truing & Dressing Centerless Diamond Grinding Wheels: AT's Wheel Adapter Mounting ServiceDocument1 pageTruing & Dressing Centerless Diamond Grinding Wheels: AT's Wheel Adapter Mounting ServiceWNo ratings yet

- Visual Examination ProcedureDocument10 pagesVisual Examination Proceduresantanurini67% (3)

- Goodrich NDTDocument5 pagesGoodrich NDTchungndt0% (1)

- SOP - 06 - Visual and Dimensional ProcedureDocument22 pagesSOP - 06 - Visual and Dimensional ProcedureSuci YatiningtiyasNo ratings yet

- Noise, Vibration and Harshness - Noise, Vibration and Harshness (NVH)Document7 pagesNoise, Vibration and Harshness - Noise, Vibration and Harshness (NVH)bledmikifrNo ratings yet

- Tolerance Standards New 2020Document11 pagesTolerance Standards New 2020Ajay PrasadNo ratings yet

- Flare Identification Chart: Double/SAE 45 Degree FlareDocument2 pagesFlare Identification Chart: Double/SAE 45 Degree Flaredavelance01No ratings yet

- PIRMH Chain Inspection PIDocument4 pagesPIRMH Chain Inspection PIRicardoNo ratings yet

- 4 Noise, Vibration and HarshnessDocument21 pages4 Noise, Vibration and Harshnessarasiuss arasiuss arasiussNo ratings yet

- Popular Tools CatalogDocument24 pagesPopular Tools CatalogCarbide Processors IncNo ratings yet

- Scratch/Dig Samples - D-667Document2 pagesScratch/Dig Samples - D-667Samir BagalkoteNo ratings yet

- Prensa Kurt D688Document17 pagesPrensa Kurt D688Arnulfo Larragoitia Martinez100% (1)

- JMB Residensi Desamas - 3rd Feb 23Document4 pagesJMB Residensi Desamas - 3rd Feb 23Al Kauthar EduqidsNo ratings yet

- PTA Guidance Note GN01 - Post-Formed Holes Through PT SlabsDocument2 pagesPTA Guidance Note GN01 - Post-Formed Holes Through PT Slabsalan_jalil9365No ratings yet

- The Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerFrom EverandThe Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerRating: 4 out of 5 stars4/5 (1)

- Automated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionFrom EverandAutomated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionNo ratings yet

- Landscape Architecture Documentation Standards: Principles, Guidelines, and Best PracticesFrom EverandLandscape Architecture Documentation Standards: Principles, Guidelines, and Best PracticesNo ratings yet

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- LogDocument131 pagesLogDoncri1234No ratings yet

- Multicut 620Document31 pagesMulticut 620kamilNo ratings yet

- Ameema CVDocument6 pagesAmeema CVAreebaNo ratings yet

- Rifyva PDFDocument3 pagesRifyva PDFjaswantsignhNo ratings yet

- CNT Svx17c enDocument130 pagesCNT Svx17c enJoe ConnorsNo ratings yet

- Service Prelim 2Document97 pagesService Prelim 2Jared Lawrie100% (1)

- 3D PasswordDocument3 pages3D PasswordIzhar CheemaNo ratings yet

- List of Functional Locally Improvised Apparatus-1Document23 pagesList of Functional Locally Improvised Apparatus-1Denver GuillermoNo ratings yet

- Guide To Design of Seawalls and BreakwatersDocument72 pagesGuide To Design of Seawalls and BreakwatersAbdur RachmanNo ratings yet

- c4 - Long-Term Behaviour of Soils Stabilized With Lime Cement - Nancy University PDFDocument36 pagesc4 - Long-Term Behaviour of Soils Stabilized With Lime Cement - Nancy University PDFyaser666No ratings yet

- Gab AssignmentDocument7 pagesGab AssignmentChelsey AnongosNo ratings yet

- GT 100 Display Instruction English VersionDocument5 pagesGT 100 Display Instruction English VersionAndresGBrenesChNo ratings yet

- Pre-Qualification of CartecDocument33 pagesPre-Qualification of CartecTony KimNo ratings yet

- Contoh Soal MikrotikDocument24 pagesContoh Soal MikrotikSaputra NugrahaNo ratings yet

- Ferguson Te20 - Tef20 Parts ListDocument48 pagesFerguson Te20 - Tef20 Parts ListEcu318se100% (1)

- Building PressurizationDocument1 pageBuilding Pressurizationmarak_gNo ratings yet

- Reflex Plus: The Powder Solve ApproachDocument4 pagesReflex Plus: The Powder Solve Approachmetal2567No ratings yet

- EC2 Design CalculationsDocument81 pagesEC2 Design Calculationscollins unankaNo ratings yet

- MoocDocument51 pagesMoocapi-274357826No ratings yet

- Advt .MARINE ENG APO FGM 23610Document4 pagesAdvt .MARINE ENG APO FGM 23610Avnish PanchalNo ratings yet

- 2 Spe 96798 HPWBM - HodderDocument12 pages2 Spe 96798 HPWBM - HodderPT100% (1)

- Hindered Amine Light StabilizersDocument1 pageHindered Amine Light StabilizersAmit PatelNo ratings yet

- Helicopter Vibration Reduction TechniquesDocument37 pagesHelicopter Vibration Reduction TechniquesSubbu Suresh25% (4)

- Endpd PDFDocument29 pagesEndpd PDFNaveen AgrawalNo ratings yet

- CHEMISTRY Question Paper 2017 All India Download in PDF SetDocument15 pagesCHEMISTRY Question Paper 2017 All India Download in PDF SetAmit YadavNo ratings yet

- Ayvaz Fire Protection Products BookDocument103 pagesAyvaz Fire Protection Products BookAhmed El Sayed SalamaNo ratings yet

- Aspen InfoPlus.21 Mobile V7.3Document8 pagesAspen InfoPlus.21 Mobile V7.3jamestppNo ratings yet

- PAUTDocument7 pagesPAUTDeepakNo ratings yet

- Lab 7 MEC454 - Flow Through Venturi Tube and Orifice PlateDocument21 pagesLab 7 MEC454 - Flow Through Venturi Tube and Orifice PlateRaziq HaiqalNo ratings yet

- Portable Specs 750Document2 pagesPortable Specs 750Ismail AliNo ratings yet