Vibrating Wire Strain Gauge ELB0007H

Vibrating Wire Strain Gauge ELB0007H

Uploaded by

Wempy WiryaatmajaCopyright:

Available Formats

Vibrating Wire Strain Gauge ELB0007H

Vibrating Wire Strain Gauge ELB0007H

Uploaded by

Wempy WiryaatmajaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Vibrating Wire Strain Gauge ELB0007H

Vibrating Wire Strain Gauge ELB0007H

Uploaded by

Wempy WiryaatmajaCopyright:

Available Formats

TEL 604 540 1100 RST Instruments Ltd.

info@rstinstruments.com 11545 Kingston St.,

www.rstinstruments.com Maple Ridge, BC V2X 0Z5 Canada

PRODUCT CATEGORY:

LOAD CELLS + PRESSURE SENSORS + STRESS METERS

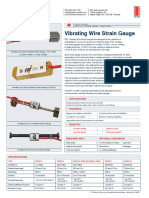

Vibrating Wire Strain Gauge

RST Vibrating Wire Strain Gauges are designed to be welded to or

embedded in various structures for monitoring strain. RST vibrating

wire strain gauges are available in 3 models: VWSG-A, for arc welding

to steel structures; VWSG-S, for spot welding to steel structures;

VWSG-E and VWSG-EL, for embedment in concrete.

Vibrating Wire Spot Weldable Strain Gauge - Low Profile

Each strain gauge consists of two end blocks (designed specifically for each

application) with a tensioned steel wire between them. As the steel or concrete

surface that encompasses the strain gauge undergoes strain, the end blocks

will move relative to each other. The tension in the wire between the blocks

will change accordingly, thus altering the resonant frequency of the wire. A

vibrating wire readout is utilized to generate voltage pulses in the magnet/coil

assembly located at the center of the strain gauge. The magnet/coil assembly

plucks the wire and measures the resulting resonant frequency of vibration.

The advantages of vibrating wire strain gauges are that the frequency

output is immune to electrical noise, able to tolerate wet wiring

common to geotechnical applications, and capable of signal

transmission of several kilometers without loss of signal.

Vibrating Wire Spot Weldable Strain Gauge

The RST VW2106 Vibrating Wire Readout (see separate brochure)

can be used to read the vibrating wire strain gauges.

> APPLICATIONS

Measuring strain in steel members and concrete

structures including bridges, piles, dams, tunnels, and buildings.

> FEATURES

Rugged and reliable construction. Pre tensioned for ease of installation.

Accurate to 1 microstrain. Remote monitoring capability.

Integral thermistor for temperature compensation.

Vibrating Wire Arc Weldable Strain Gauge

> BENEFITS

Increase Safety High Accuracy

High Reliability Technical Support

ORDERING INFO OPTIONAL EQUIPMENT

Model number. VW2106 vibrating wire readout. Spot welder.

Length of cable required. Terminal boxes. Data loggers.

Vibrating Wire Embedment Strain Gauge Accessories required. Arc welding installation jig.

SPECIFICATIONS

ITEM VWSG-A VWSG-S VWSG-S-LP VWSG-E VWSG-EL

Installation by Arc welding Spot Welding Spot Welding Embedment Embedment

Standard Gauge Length 150 mm (5.88 in.) 50.8 mm (2 in.) 50.8 mm (2 in.) 153 mm (6 in.) 250 mm (10 in.)

Strain Range 3000 με 3000 με 3000 με 3000 με 3000 με

Sensitivity 1.0 microstrain 0.5 to 1 microstrain 0.5 to 1 microstrain 1.0 microstrain 0.5 microstrain

-4 to 176°F -4 to 176°F -4 to 176°F -4 to 176°F

Operating Temperature -4 to 176°F (-20°C to 80°C)

(-20°C to 80°C) (-20°C to 80°C) (-20°C to 80°C) (-20°C to 80°C)

Thermal Coefficient of Expansion 12.0 ppm/°C 12.0 ppm/°C 12.0 ppm/°C 12.0 ppm/°C 12.0 ppm/°C

Thermistor Accuracy 0.9°F (0.5°C) 0.9°F (0.5°C) 0.9°F (0.5°C) 0.9°F (0.5°C) 0.9°F (0.5°C)

RST Instruments Ltd. reserves the right to change specifications without notice. ELB0007H

You might also like

- FXO Parts List (3-524) 1st EditionDocument32 pagesFXO Parts List (3-524) 1st EditionLibardo Alfonso Cadena Rodriguez100% (1)

- Type 123 Class II 1.2m Ku Band Offset Antenna - REV 3 PDFDocument2 pagesType 123 Class II 1.2m Ku Band Offset Antenna - REV 3 PDFWesley JordãoNo ratings yet

- HE Mini-Pak 6 ManualDocument100 pagesHE Mini-Pak 6 ManualJavier Alejandro QuingaNo ratings yet

- B 62443en 2 - 03 FanucDocument166 pagesB 62443en 2 - 03 FanucDanisimo Simona100% (1)

- Kaeser m17 Compresor PDFDocument5 pagesKaeser m17 Compresor PDFEduardo RazerNo ratings yet

- Vibrating Wire Strain Gauge ELB0007IDocument1 pageVibrating Wire Strain Gauge ELB0007IAnji AndreiNo ratings yet

- Strain Gauges: Vibrating WireDocument7 pagesStrain Gauges: Vibrating WirePiulitza88No ratings yet

- Vibrating Wire Strain GaugesDocument9 pagesVibrating Wire Strain Gaugessannan azizNo ratings yet

- Vibrating Wire PiezometerDocument2 pagesVibrating Wire Piezometerelisio_fonsecaNo ratings yet

- RST Instruments - Vibrating Wire Piezometer ELB0055P - 2024Document2 pagesRST Instruments - Vibrating Wire Piezometer ELB0055P - 2024Jorge Armando Ysuiza RomeroNo ratings yet

- Vibrating Wire Piezometer: TEL 604 540 1100 RST Instruments Ltd. 11545 Kingston ST., Maple Ridge, BC V2X 0Z5 CanadaDocument2 pagesVibrating Wire Piezometer: TEL 604 540 1100 RST Instruments Ltd. 11545 Kingston ST., Maple Ridge, BC V2X 0Z5 CanadaLikinStoriesNo ratings yet

- Vibrating Wire Soil Extensometer EXB0011KDocument1 pageVibrating Wire Soil Extensometer EXB0011KDanang Adi KuncaraNo ratings yet

- VW Strain Gauge 2017 1Document4 pagesVW Strain Gauge 2017 1BuiDucVinhNo ratings yet

- Gas Tube Surge Arrestor Type N Male Female, Bulkhead: Product Data Sheet N-UC230-01Document2 pagesGas Tube Surge Arrestor Type N Male Female, Bulkhead: Product Data Sheet N-UC230-01João Carlos OliveiraNo ratings yet

- Vibrating Wire Strain Gauges: I N S T R U C T I O NDocument44 pagesVibrating Wire Strain Gauges: I N S T R U C T I O NWandyy GonçalvesNo ratings yet

- Interpreting Strain Measurements From Load Tests in Bored PilesDocument7 pagesInterpreting Strain Measurements From Load Tests in Bored PilesMustafa SütcüoğluNo ratings yet

- Sondex Casing Collar Locator CCL SpecDocument1 pageSondex Casing Collar Locator CCL SpecAditya KarhanaNo ratings yet

- Vw2106-Vibrating Wire Readout Mib0033kDocument1 pageVw2106-Vibrating Wire Readout Mib0033kShafiq ZakariahNo ratings yet

- Strain Gauges: By: Pinank ShahDocument31 pagesStrain Gauges: By: Pinank ShahAnas EkramNo ratings yet

- Strain Gauge Load Cells LPB0005IDocument2 pagesStrain Gauge Load Cells LPB0005ILordbyron230% (1)

- Transducer CatalogDocument7 pagesTransducer CatalogJ. Rodrigo Rizatti Rodrigo RizattiNo ratings yet

- 4400 Series Displacement TransducersDocument4 pages4400 Series Displacement TransducersLord Lee CablingNo ratings yet

- Installation, Maintenance and Observations of Pore Pressure Measuring Devices in Concrete and Masonry Dams - Code of PracticeDocument9 pagesInstallation, Maintenance and Observations of Pore Pressure Measuring Devices in Concrete and Masonry Dams - Code of PracticeFaisal RizwanNo ratings yet

- Fire Rated CablesDocument3 pagesFire Rated CablesRoy MonroyNo ratings yet

- CWT 1110Document2 pagesCWT 1110carlos burgosNo ratings yet

- Vibrating Wire Piezometer RSTDocument2 pagesVibrating Wire Piezometer RSTjoeldlrosa0No ratings yet

- Effect of Grading Ring On Voltage Distribution of ArrestorsDocument7 pagesEffect of Grading Ring On Voltage Distribution of ArrestorsTravis WoodNo ratings yet

- ManualDocument12 pagesManualAndar ApriadiNo ratings yet

- Spec Sheet - Handler 187Document4 pagesSpec Sheet - Handler 187Hobart Welding ProductsNo ratings yet

- GV4200 CatalogueDocument1 pageGV4200 Cataloguemathi vijayNo ratings yet

- 3 1 8 Transmission LinesDocument2 pages3 1 8 Transmission LinesAdrianItseruNo ratings yet

- 4100 Series Strain GagesDocument2 pages4100 Series Strain GagesCristianNo ratings yet

- 7hx21en - Hawkeyehx May 2022Document4 pages7hx21en - Hawkeyehx May 2022Alberto DzibNo ratings yet

- 0 3ts 4 Pole CatalogueDocument12 pages0 3ts 4 Pole Cataloguesaurabh yadavNo ratings yet

- Borehole Extensometers LetterSize EXB0029ADocument4 pagesBorehole Extensometers LetterSize EXB0029AMark EdowaiNo ratings yet

- Busbar Supports - Catalogue - Pages - 2022 11 - DCG00502 - enDocument4 pagesBusbar Supports - Catalogue - Pages - 2022 11 - DCG00502 - enHardy Nagy BalázsNo ratings yet

- Raychem Screened Elbow/Straight Separable Connectors Rses/RsssDocument2 pagesRaychem Screened Elbow/Straight Separable Connectors Rses/RsssGiovany Vargas QuirozNo ratings yet

- Am3k Spec 2014-07-23Document2 pagesAm3k Spec 2014-07-23Diego CorderoNo ratings yet

- Resistive Transducer DesignDocument20 pagesResistive Transducer DesignSai Kumar LaghumavarapuNo ratings yet

- JST VHDocument5 pagesJST VHIojan AndreiNo ratings yet

- Dual Directional Coupler Design Duroid 5880Document5 pagesDual Directional Coupler Design Duroid 5880PaulNo ratings yet

- VW2106 Vibrating Wire Readout MIB0033LDocument1 pageVW2106 Vibrating Wire Readout MIB0033LcschwartzNo ratings yet

- CatalougeDocument15 pagesCatalougeBarbara OrtigozaNo ratings yet

- Amortiguador de Vibraciones Tipo SVDDocument3 pagesAmortiguador de Vibraciones Tipo SVDivan chavezNo ratings yet

- Mitutoyo - Sondy Indukcyjne I Wskaźniki Mu-Checker - E13003 (2) - 2016 ENDocument24 pagesMitutoyo - Sondy Indukcyjne I Wskaźniki Mu-Checker - E13003 (2) - 2016 END.T.No ratings yet

- VSL CT Stress Bar Systems Updated Aug 2023Document20 pagesVSL CT Stress Bar Systems Updated Aug 2023ian.ropeworksNo ratings yet

- Littelfuse Varistor ULTRAMOV Datasheet PDFDocument11 pagesLittelfuse Varistor ULTRAMOV Datasheet PDFRafonixscribdNo ratings yet

- 20 Series Wire Feeders PDFDocument4 pages20 Series Wire Feeders PDFmarcos.f.cNo ratings yet

- Vs-Vskt320Pbf Series: Vishay SemiconductorsDocument7 pagesVs-Vskt320Pbf Series: Vishay SemiconductorsRyu DanNo ratings yet

- Series LWG: Position Transducers Pivot Head Mounting Potentiometric Up To 750 MM, IP65Document4 pagesSeries LWG: Position Transducers Pivot Head Mounting Potentiometric Up To 750 MM, IP65Rodica PuscauNo ratings yet

- Mi 3242 Microohm 2A: Continuity TestersDocument2 pagesMi 3242 Microohm 2A: Continuity TestersMarco CornelioNo ratings yet

- RST Portable MEMS Tilt Meter With Tilt PlateDocument1 pageRST Portable MEMS Tilt Meter With Tilt PlateJorge OchoaNo ratings yet

- PGCILDocument50 pagesPGCILsataveerNo ratings yet

- Super Trex VFD Shielded Cable 1Document1 pageSuper Trex VFD Shielded Cable 1Juan Carlos Lopez TrejoNo ratings yet

- 2.4m Type 243 C CP RT Class III SpecDocument2 pages2.4m Type 243 C CP RT Class III SpecTran Duy TrongNo ratings yet

- License Saudi Services For Electro Mechanic Works Co., Ltd. (SSEM) /SA-894-t Not For Resale, 8/8/2019 10:03:26 AM Saudi TimeDocument17 pagesLicense Saudi Services For Electro Mechanic Works Co., Ltd. (SSEM) /SA-894-t Not For Resale, 8/8/2019 10:03:26 AM Saudi TimeAlessandro Bozzo100% (1)

- Magnetic Settlement Systems LetterSize SSB0001ODocument4 pagesMagnetic Settlement Systems LetterSize SSB0001OLordbyron23No ratings yet

- Sfu SiemensDocument32 pagesSfu Siemenswtstender2No ratings yet

- M110 20 Series EnglishDocument4 pagesM110 20 Series EnglishAldo QoduckNo ratings yet

- ST4 Vibrating Wire Embedment Strain GaugeDocument4 pagesST4 Vibrating Wire Embedment Strain GaugeNurul BaizuraNo ratings yet

- Eaton 281233 NZMN1 A32 en - GBDocument4 pagesEaton 281233 NZMN1 A32 en - GBFuzzzyLogNo ratings yet

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- Danfoss - Pressure Control KP1, KP5Document8 pagesDanfoss - Pressure Control KP1, KP5Parinpa Ketar100% (1)

- Product Specifications: FSJ4-50BDocument4 pagesProduct Specifications: FSJ4-50BManuel AlejandroNo ratings yet

- 300+ TOP D.C. GENERATORS Multiple Choice Questions and AnswersDocument32 pages300+ TOP D.C. GENERATORS Multiple Choice Questions and Answershem singhNo ratings yet

- DEC50113-Chapter 1 - 6 Display DevicesDocument52 pagesDEC50113-Chapter 1 - 6 Display DevicesFaiz ZakariaNo ratings yet

- Setup Sheet Report: Generic MillDocument10 pagesSetup Sheet Report: Generic MillaliNo ratings yet

- Advanced Microprocessors: Intel 80186Document13 pagesAdvanced Microprocessors: Intel 80186Rehana Karim Toma100% (1)

- 4 L 60 EgroundDocument2 pages4 L 60 EgroundDavid RosadoNo ratings yet

- Service Training Malaga 365B Ii & 385B Hydraulic Excavators: Smart BoomDocument6 pagesService Training Malaga 365B Ii & 385B Hydraulic Excavators: Smart BoomSamit JorgeNo ratings yet

- ITW - Dynabolt Sleeve AnchorDocument3 pagesITW - Dynabolt Sleeve AnchorBai AdiNo ratings yet

- Image For Illustrative Purposes Only..: Generating Set Model (Pm165)Document2 pagesImage For Illustrative Purposes Only..: Generating Set Model (Pm165)Anamta KhanNo ratings yet

- Ramos DLP Lesson1Document10 pagesRamos DLP Lesson1Irah kabilingNo ratings yet

- Commodity Codes (Class and Subclass List) : 005 - AbrasivesDocument7 pagesCommodity Codes (Class and Subclass List) : 005 - AbrasivesJohn Wilson MalonesNo ratings yet

- Ruelco 4222Document6 pagesRuelco 4222khasim15No ratings yet

- Solenoid Valve Namur Fig 33580 AluminiumDocument1 pageSolenoid Valve Namur Fig 33580 AluminiumNam Nguyễn ĐứcNo ratings yet

- Fuses: CAMTECH/2000/S/FUSEDocument11 pagesFuses: CAMTECH/2000/S/FUSEPankaj PalawatNo ratings yet

- Hard Mount Washer ExtractorDocument2 pagesHard Mount Washer ExtractorC.H. WEE0% (1)

- (LJ46B) 32LB580B-SBDocument79 pages(LJ46B) 32LB580B-SBMárcio FerreiraNo ratings yet

- Key Information of Rooftop Solar Phase-II Under MPMKVVCL: I) For Residential ConsumerDocument4 pagesKey Information of Rooftop Solar Phase-II Under MPMKVVCL: I) For Residential Consumermahendra haritNo ratings yet

- BATERIA ULTRACELL Opzv1000-2Document2 pagesBATERIA ULTRACELL Opzv1000-2Oscar Pardo PardoNo ratings yet

- Machine Load - KCLDocument3 pagesMachine Load - KCLMd HossainNo ratings yet

- Restraint PDFDocument119 pagesRestraint PDFErkki IsokangasNo ratings yet

- User Manual of 2 Stroke Petrol Bike Engine Kit: Start Term: Pedal Start (ZEDA-48CC/ZEDA-60CC/ZEDA-80CC)Document16 pagesUser Manual of 2 Stroke Petrol Bike Engine Kit: Start Term: Pedal Start (ZEDA-48CC/ZEDA-60CC/ZEDA-80CC)Pawan NabiyalNo ratings yet

- Silicon N-Channel Power F-MOS FETDocument3 pagesSilicon N-Channel Power F-MOS FETANDREASBOULNo ratings yet

- Christie Spyder X20Document4 pagesChristie Spyder X20Gui_llemNo ratings yet

- Carairpurifier ManualDocument11 pagesCarairpurifier ManualvhkprasadNo ratings yet

- Juni Now2022Document479 pagesJuni Now2022Hello yusiNo ratings yet