Previous Page Table of Contents Next Page

Previous Page Table of Contents Next Page

Uploaded by

angelo marraCopyright:

Available Formats

Previous Page Table of Contents Next Page

Previous Page Table of Contents Next Page

Uploaded by

angelo marraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Previous Page Table of Contents Next Page

Previous Page Table of Contents Next Page

Uploaded by

angelo marraCopyright:

Available Formats

Previous Page Table of Contents Next Page

Vol. 2, No. 1, January - March 1975

A SERVICE PUBLICATION OF

LOCKHEED-GEORGIA COMPANY

CONTENTS

A DIVISION OF 3 Flight Line Obstacle Course

LOCKHEED AIRCRAFT CORPORATION

4 How To Move An incomplete Hercules

Editor

Jay V. Roy 9 Polytetrafluoroethylene (Teflon)

Associate Editors Lining For Oxygen Servicing Hoses

James W. Buttram

James A. Loftin 10 Hercules High Energy Brakes

Art Direction & Production 12 New Alloy

Anne G. Anderson For JetStar Landing Gear Shock Struts

14 New Filter Elements

For Hercules Hydraulic Systems

StarTips

13 Hercules Crew Entrance DOOR OPEN

Warning Light Switch Adjustment

Product Support

Director T. J. Cleland

COVER: Italian Air Force C-130 Customer Service Division

Hercules of the 46th Aero Brigade, Pisa

Italy. Manager D. L. Braund

Field Service & Inventory Mgmt A. H. McCrum

JetStar Support & Customer Training J. L. Thurmond

Spares Stores & Shipping A. R. Love

Published by Lockheed-Georgia Company, a Division of

Lockheed Aircraft Corporatmn. Information contained in

this issue is considered by Lockheed-Georgia Company to

be accurate and authoritative it should not be assumed,

Customer Supply Division

however, that this material has received approval from any Manager M. M. Hodnett, Jr.

governmental agency or military service unless it is

specifically noted. This publication is for planning and Supply Procurement R. C. Weihe

information purposes only, and it is not to be construed

as authority for making changes on aircraft or equipment Supply System & Inventory Control C. K. Allen

or as superseding any established operational or

maintenance procedures or policies The following marks Supply Sales & Contracts H. T. Nissley

are registered and owned by Lockheed Aircraft

Supply Technical Support H. L. Burnette

Corporation: “Lockheed”, “Hercules”, and

"JetStar". Written permission must be obtained f r o m

Lockheed-Georgia Company before republishing any

material in this periodical Address all communications to

Editor, Service News, Department 64-22 Zone 278,

Lockheed-Georgia Company, Marietta, Georgia, 30063

CopyrIght 1975 Lockheed Aircraft Corporation.

Previous Page Table of Contents Next Page

the safety precautions that can be found in your Hercules

Maintenance Manuals. For instance, remember that the

nose landing gear is not to be turned beyond its limits

when towing the airplane in a turn. Also, never turn the

nose gear with the towbar when the wheels are not

rotating.

Here is another important thing to remember about

towing (or taxiing) an airplane in a turn. Be considerate

of the wing tip observers. If other airplanes or

obstructions are around the towing area, these two men,

one at each wing tip, are required to walk below the tips

to warn the crew if there is a possibility of a collision.

It is surprising how fast the wing tip travels on the outside

of a sharp turn. It may be more than the wing tip

Towing or taxiing the Hercules requires the same general observer can do to keep up with the tip, even if he runs.

precautions as does any other airplane in motion. A shortcut is not the answer because he will lose

perspective of the tip and the objects he is to warn

Characteristics peculiar to the Hercules which relate to against. This factor has been overlooked several times in

ground handling will be found in your Hercules the past resulting in expensive repairs.

Maintenance Manuals covering these activities. We do

want to point out how to avoid some unfortunate The tractor driver (or pilot in taxi operations) must be

situations which can occur when details are overlooked considerate enough of the wing man and concerned

while moving airplanes on the flight line. enough for safety to slow down to a reasonable speed

when approaching a turn.

Preparation for towing a Hercules airplane fully equipped

is not confined to just attaching a tractor of adequate On the following pages we continue this discussion with

power by means of a towbar with fittings that match another aspect of ground handling - that of towing and/or

3

those provided on the Hercules. It is necessary that you jacking the Hercules with certain major components

know the maneuvering limitations for this airplane and removed.

Previous Page Table of Contents Next Page

How to Move an

b y Karl Porter, Commercial Hercules Engineer, Senior

The occasion sometimes arises when it is necessary to Center of gravity limits found in the maintenance manual

move a Hercules while major components are removed. for jacking the Hercules should also be used for towing.

Observe and stay within the maximum towing speeds and

Every situation must be evaluated individually; however, the minimum turning radius given in the maintenance

the following offers some general guidelines for movement manual.

of the Hercules with certain major components removed.

These examples are applicable only to the standard size Balance must be maintained whether the airplane is in

(97 foot) airplane in its cargo configuration. Your aircraft motion or standing with components removed. A simple

may be a “stretched” model or modified in such a manner formula for balance is employed to compute the amount

that the following would not apply; therefore, it is of weight that must be used to compensate for major

recommended that you review the aircraft records. components when they are removed.

Please note that extreme caution should be exercised (W) - (A)=M; Where: W=Weight

when moving an incomplete Hercules. Stop the action A=Arm

immediately if there is any indication that the airplane M=Moment

may be unbalanced. Other than that, our

recommendation is to use your handbooks and good A MOMENT is a numerical value representing the effect

judgment as factors in limiting things like - how fast, how of a force at a given distance (ARM) from a specific

far, and how much incline can be allowed and still remain reference point. An ARM always represents the location

within safe limits. of the center of gravity of the weight in question. Any

OUTER WING STATION 0

CENTER WING STATION 220

r

(A RM 4 4 4 )

576 (A R M 400) 196 84.3 ,

OWS 82

I ARM 0 I

(A RM 3 0 2 )

ARM 85.6 ARM 85.6

Previous Page Table of Contents Next Page

Hercules While weighing the Hercules is not your objective, and is

not the subject of our article, a large part of the data

found in manuals on this subject will be essential to your

calculations for the amount of ballast necessary and where

it should be placed.

CENTER OF GRAVITY (cg) location must be controlled

units of measure for weights and distances could be used,

within limits in two directions fore-to-aft and

providing the same units were used consistently to

side-to-side. (remember that a reference to an ARM is a

complete a calculation.

cg location.) First, let’s take a look at fore-to-aft center

However, the known data provided for the Lockheed of gravity.

Hercules is in POUNDS for WEIGHT and in INCHES for

ARM, or distance, denoting fuselage stations and wing FORE-TO-AFT BALANCE

stations. The Weight and Balance Manual for your aircraft

includes charts showing “stations” layouts and Removal of the four main power plants will create an

instructions about their use. unsafe towing condition as well as a condition that would

leave the airplane subject to damage from the wind if

A working knowledge of the Hercules station locations is parked out in the open.

necessary to avoid the necessity of actually measuring

ARM distances. All four engines, inboard and outboard, on the Hercules

have the same fore-to-aft ARM. The reason for this is that

You probably have recognized the importance of the the four engines are lined up evenly along the almost

Station Location concept used in the Hercules. This straight leading edge of the Hercules wing.

concept not only identifies the location of things but

simplifies the calculations necessary for weight and POUND FOR POUND - If it is easy to load the ballast at

balance, whether for loading cargo or for distributing the same ARM location as that of the components

ballast to compensate for components removed. removed, the weight of the ballast should be the same as

Previous Page Table of Contents Next Page

the total weight of the components. For example, if all

four engines and propellers are removed, ballast weighing

15,612 pounds can be evenly distributed over the cargo

floor centering around fuselage station (FS) 43.5 which is

the same as the ARM of the four engines collectively.

A situation where things balance - Removal of all of the

empennage group components and the four power plants

will create an unsafe condition unless the proper removal

sequence is followed. Remove all the empennage group

components first; then remove the four power plants,

after which no ballast will be required.

The Pound-for-Pound approach is not often the most Weights are suspended from jack fittings on the Hercules nose

practical and so it may be necessary to calculate the section to stabilize balance during assembly at Lockheed-Georgia.

moment for the components to be removed, (M=WA).

fittings, P/N 372447-1, may be installed and 1,255

When removing components and adding compensating pounds of ballast (weighted oil drums or other suitable

ballast, the ARM is not a Fuselage Station but it is the weights) may be added to each fitting for a total of 2,510

distance from the original aircraft cg to the removed pounds. To prevent damage, be sure the suspension of the

component or the distance from the original aircraft cg to ballast will clear the fuselage.

the ballast added cg.

Please note that load limits of these jack fittings and

Select the Fuselage Station of a suitable ballast location. fuselage structure must not be exceeded. Each jack pad

Use the station layout chart to determine the ARM. fitting and structure is good for 2,000 pounds.

Divide the ARM into MOMENT to get the necessary

ballast WEIGHT, (W= SIDE-TO-SIDE BALANCE

6 For example, let’s say you had an aircraft that weighed During towing operations, preventing dislocation of the

70,000 lb. with a center of gravity at FS 535. You want center of gravity to either side is extremely important

to remove one propeller assembly and then ballast the since the main landing gear is located at the fuselage near

aircraft back to the original center of gravity (i.e., the basic airplane center of gravity.

FS 535). Suppose the only location for ballast is at FS

300. The propeller cg is at FS 380 which is 155 inches FUEL BY THE POUND - One of the easiest ways to

forward of the aircraft cg. The MOMENT effect felt by compensate for removed weight where engines and/or

the aircraft is -166,780 in. lb. The ballast location of FS propellers are removed from only one side is to transfer

300 is 235 inches forward of the aircraft cg. So we want fuel from the opposite wing to the side needing ballast.

to overcome -166,780 in. lb. at a distance of 235 inches. Ah, but you say the handbook has a restriction limiting

Divide 166,780 in. lb. by 235 inches and get 710 lb. of you to 1,000 pounds difference between opposite fuel

ballast. This will return the aircraft to the original cg of tanks and no more than 1,500 pounds difference between

FS 535. See chart below. wings. That restriction is not a structural one, but a flight

restriction to prevent “running out of roll (aileron)

Divide the ARM into MOMENT to get the necessary control” during landing at low speeds and low gross

ballast WEIGHT, If the WEIGHT is in weights. Further, it is to keep the aircraft from tilting too

predetermined increments you should adjust the ARM by far while on the ground - so, why not transfer fuel to

dividing the MOMENT by the WEIGHT maintain side-to-side balance.

Here is another way to achieve the same basic center of Just remember to transfer the fuel back when the engines

gravity with engines removed. The forward fuselage jack and/or propellers are reinstalled.

Inch - Pounds

Previous Page Table of Contents Next Page

A typical fuel control panel, accessible from the ground, for fuel One end of a torque strut is shown connected to the bottom of a

transfer between tanks, as well as for fueling and defueling t h e MLG shock strut. Similar connections at each end hold the two

Hercules. wheels, on either side, in alignment.

Another way to achieve balance side-to-side is to remove Therefore, special attention should be given to the center

an object on one side of the airplane, such as an outboard of gravity location when one or more rear main landing

power plant or wing, when it is necessary to remove a like gear parts are removed.

item on the other side.

The torque strut is vital to prevent the lower portion of

For example - removal of the left or right outer wing will the main landing gear shock strut (axle and wheel) from

produce an unbalanced condition which will be unsafe for 7

twisting - or turning out of alignment. Therefore, the

towing. Prevent this unsafe condition by also removing loose end of the torque strut (that is the end where the

the opposite outer wing. strut is removed) must be secured in some manner within

the wheel well to prevent the installed wheel from

Other examples - Removal of the left or right outboard twisting.

power plant will produce an unbalanced condition which

will be unsafe for towing. Prevent this unsafe condition Here are two methods that have been employed in the

by removing the opposite outboard power plant. past:

Both outboard power plants should be removed before Where the main landing gear strut has been removed for

removing either inboard power plant when all four of maintenance and no structural damage exists within the

them are to be removed. Why? To maintain side-to-side wheel well, the torque strut may be secured to the main

cg, close to the center line, within limits specified in your landing gear “shelf bracket” or other structure with a

maintenance manual. cargo tie-down chain or heavy rope.

As pointed out previously, not all factors in unusual Where structural damage exists in the wheel well, it may

circumstances are predictable so we include alternate be necessary to fabricate some bracketry to secure the

approaches to accomplish the same results, leaving the loose end of the torque strut.

choice to be made on site. Whether you choose to achieve

balance by transferring fuel, using sandbag type ballast, or Keeping in mind that it makes a difference as to whether

by removing an equal and opposite major assembly, can the forward or aft strut is removed, be sure to adjust the

depend on the fuel situation, availability of ballast, the center of gravity as necessary. The same thing applies if

surface of the flight line or parking area, etc. you have removed two main landing gear struts (one on

each side of the airplane).

What about moving a three-legged bird (one MLG strut

removed)? STRUCTURAL COMPONENTS

Normally, the completely assembled airplane’s center of Questions also arise from time to time concerning towing

gravity is just aft of the forward main landing gear. the airplane with fuselage and wing components removed

Previous Page Table of Contents Next Page

which carry structural loads in normal operations, such as Note that it is generally much easier to remove or install

floorboards, wing access panels or leading edges. As wing leading edges and access panels if the airplane has

anyone who has removed any of these components been de-fueled.

knows, they are difficult to remove and even more

It is structurally safe to tow the aircraft with either or

difficult to install, especially if the aircraft has shifted or

both the cargo ramp and aft cargo door removed. As

has been moved. A good rule is to place the item back

could be determined earlier by checking fore-to-aft center

into position and secure it with an appropriate number of

of gravity, no ballast is required when the cargo ramp and

the corner fasteners prior to towing the aircraft. Also,

aft cargo door are removed.

floor boards the full length of the cargo compartment

should be secured with enough fasteners to hold. There should be no damage to the airplane if you have

Generally, the center floor boards are preferable; however, exercised good judgment along with the proper

treadway floor boards are adequate. Floor boards procedures consistent with the Maintenance Manuals

through the main landing gear area must be installed. applicable to your Hercules.

WEIGHT ARM WEIGHT ARM

COMPONENT (Pounds) COMPONENT (Pounds)

(Inches) (Inches)

1. Propeller (with spinner) 1,076 380 12. Tail Cone 43 1,158

2. Power Plant (dry engine) 2,827 455 13. Aft Cargo Door 731 956

3. Wing Leading Edges LH or RH 14. cargo Ramp 1,135 508

A. Center Wing 71 496 15. Main Gear Wheel (Complete 392 Fwd 523

B. Inboard-outer wing 104 496 with tire and tube) 392 Aft 583

C. Outboard-outer wing 162 501 16. Main Landing Gear (one gear

4. Outer wing (dry) 4,112 557 complete with wheel, tire, and

5. Aileron 205 583 brake) 1.073 Fwd 523

6. Outer Wing Flap & Carriages 276 620 1,073 A f t 583

7. Center Section Flap & Carriages 147 630 17. Nose Landing Gear 573 167

8. Horizontal Stabilizer Assembly 2,104 1,079 18. Radome 218 67

9. Elevator (inboard counterweight 19. Wing Pylon Tank (dry and less

removed) 270 1,116 pylon Attachment bolts) 627 561

10. Vertical Stabilizer 976 1,052 20. Wing Pylon Tank Installation 791 561

11. Rudder (not including balance 21. Wing Pylon Support (less wing

weight) 172 1,139 attachment bolts) 143 556

18 17

EDITOR’S NOTES moments for a variety of loads at different Locations.

The Weight and Balance Data handbook is regularly

used while loading the Hercules, in checking weight and T.O. 1-1 B-40 and AN 01-1 B-40 for Hercules follows a

balance, and in weighing the airplane when required. For standard outline for all airplanes except that the data in

example, SMP521 is for Lockheed Model 382B Hercules. this edition is specifically tailored for a Hercules

Included in this manual are charts giving calculated configuration.

Previous Page Table of Contents Next Page

POLYTETRAFLUOROETHYLENE

We have some additional information to be used in When servicing the oxygen system, all the service cart

conjunction with “Oxygen safety” which appeared in the equipment must be kept a safe distance (8 to 10 ft.) from

Vol. 1, No. 1, January - March 1974 issue of the Service the aircraft - except the service hose. In some cases the

News magazine. This information concerns oxygen hose is pulled inside the airplane to reach the connectors.

servicing hoses and there is an important detail that we In other cases, the bottles are removed for servicing or an

feel should be emphasized because it has been overlooked external oxygen service connector is utilized. There is

at times. Apparently, because so many high quality hoses some degree of hazard associated with each of these

look alike, some industrial type hoses have been methods. Therefore, the service hose should not be a

erroneously used for servicing airplanes with oxygen. weak link in the safety precautions.

Some of these create a hazard because of their

composition. We welcome subjects on safety and will include short

items as well as full length articles when the need comes 9

It has been pointed out that the kindling temperature of to our attention. If you have any suggestions, please let

many materials, considered safe and noninflammable, us know.

becomes much lower as the percent of oxygen increases.

In other words, a small amount of heat can start a fire or

explosion in 100% oxygen. Fire can start inside an

ordinary hose from elevated temperatures produced by

resistance to high pressure flow, or from sudden

compression.

A fire may be created by the inadvertent contamination

of the oxygen servicing equipment and system. This can

occur through the use of servicing hoses that are not

compatible with high pressure oxygen. For example, the

inner liners of certain hydraulic or pneumatic hoses are

constructed of nitrile or neoprene rubber. These rubbers

use plasticizers that, with time, age, or heat, tend to

“bloom” and surface an oily substance on the inner liner.

The presence of this oily flammable plasticizer in the

inner liner of the servicing hose can create a serious fire

hazard. For this reason, a hose with an inner liner of pure

polytetrafluoroethylene (Teflon) should be used that

conforms to specification MIL-H-26633B, Hose Assembly,

Polytetrafluoroethylene, Oxygen. This specification

includes a requirement for a teflon-lined hose assembly

that is banded with a metal band showing this

specification number and other specific information.

Previous Page Table of Contents Next Page

by CHARLES R. BUSH Design Engineer Specialist

AS MOST PEOPLE in the industry know, airplanes tend The extra disks, with their greater torque, give faster

to grow in size and weight through the years. It’s as deceleration stops with less brake fade; and the chance of

inevitable as progress itself and the bigger airplanes get, checking in at the parking ramp with hot brakes is

the harder they are to brake to a stop when landing. lessened. With this added stopping power, the Hercules

can land in even shorter distances an easy achievement for

The Lockheed Hercules is no exception. From 124,000 a bird already known and respected for its short field

pounds on the original C-130A model, the Hercules’ gross performance.

takeoff weight has increased to 155,000 pounds on the E

and H models now flying, with an over gross takeoff Check these other tri-metallic (as it is also called) brake

weight of 175,000 lbs. Naturally, this added weight put system advantages:

extra stress on the commonly-used single disk brake

system which was never designed to stop up to 77 1/2 tons LOWER OPERATING COSTS - the direct result of

of airplane. longer brake life due to a much lower wear rate of the

sintered metallic lining, and to the fact that many of the

So it was time for a change. Accordingly, Lockheed heat sink components have wear pads that can be

current production Hercules are equipped with a new replaced. With the new brakes, Operators are reporting

Goodyear high-energy, multi-disk brake system. Earlier ten times as many landings between wear parts

C-130E and HC-130H airplanes have been retrofitted by replacements.

10 T.O. 1 C-130-778 to incorporate the new brakes and LESS MAINTENANCE - required simply because the

associated wheels. brake doesn’t call for overhaul as often. And the

multi-disk tri-metallic brake has housing cylinder sleeves

What’s better about the multi-disk brake system? Plenty. which do away with the need to discard the housing

First of all, you get substantially more, 60 percent, kinetic because of damaged cylinder walls.

energy capacity - stopping power - at a weight increase

of only 30 percent over the single disk brake. GREATER RELIABILITY - thanks to the tri-metallic

si ngle Disk

Brake Provided

o n E a r l y

Hercules

Models

Tri-Metallic

Multi-Disk

Brake with

Greater Stop-

ping Power

Previous Page Table of Contents Next Page

brake’s greater stopping power and its better high The rotating disks have a bonded lining of bronze based

temperature performance. Its operating temperature limit friction material, while the non-rotating friction parts

is 60 percent higher than that of the single disk brake. have replaceable rivited-on wear pads. Note the 12

pistons instead of four (all 12 brake returns are separate

In general, maintenance procedures for the two brake from the pistons). The tri-metallic brake has piston

systems are similar. There are, however, certain basic cylinder sleeves sealed by static O-rings as well as by the

design differences you’ll want to bear in mind. For dynamic piston seals. A synthetic rubber piston boot

instance, the tri-metallic brake has four rotating disks, keeps dirt out of the area.

three stationary disks, a back plate, and a pressure plate;

the older system has only one rotating disk (see Now, we’ll show you the difference in maintenance tasks

illustrations). for the two brake systems and. describe the tasks for each.

TASK TRI-METALLIC (MULTI-DISK) ORGANIC (SINGLE DISK)

Apply brake pressure. Return pins on back of pistons

to be or 3/8 inch below the surface of the adjust-

Apply brake pressure. Base of nuts on two wear indi-

Inspection of ing nut (depending on brake P/N) when brake wear

cators diametrically opposite on housing to be flush

brake ““ear. has reached recommended removal limit. Distance

with housing when brake wear has reached recom-

b e t w e e n h o u s i n g a n d d i s k t o b e l e s s t h a n 15/16 or

mended removal limit.

l-l/B inch minimum for removal (depending on brake

P/N). Distance between end of piston and brake to be

1 / 8 inch or less for removal.

Remove brake bolts. Remove return pin nuts to allow

Remove disk stack. removal of grip and tube sub-assembly and to free the Remove brake bolts.

pressure plate.

Remove insulator screw and insulator, Screw return

Remove pistons. pin in the insulator screw hole in the piston and pull Push piston from housing using Arbor press.

piston from housing.

Remove cylinder Carefully remove the cylinder sleeve using a good 11

sleeve. 2 1 / 8 inch hex socket or an open-end wrench.

Replace rotating disk when worn to a thickness of

0.270” or less. Inspect wear pads on pressure plate, Inspect rotating disk for wear shrinkage and dishing

stationary disks and back plate for (1) attaching rivet Minimum disk thickness is 0.925”.

tightness, (2) cracks or damage, and (3) curling.

Inspection o f Replace wear pads as required. Minimum disk diameter is 21.060”.

disk stack.

Cold straighten the base plate after ““ear pads have

Maximum disk key slot width is 0.938”.

been removed, if required.

Minimum pressure plate thickness is 0.345”.

Minimum stationary disk thickness is 0.355”. Minimum lining thickness at outer edge is 0.125”.

Minimum back plate, and pad, thickness is 0.610”.

Coat all bearing surfaces of bolts, washers and nuts Coat all bearing surfaces of bolts, washers and nuts

Assembly of brake. with anti-seize compound. Torque cylinder sleeves to with anti-seize compound. Torque brake bolts to:

55 foot-pounds. Torque brake bolts to 50 150 foot-pounds small bolts. 300 foot-pounds - large

foot-pounds. bolts.

Apply 3000 psi several times and release. Minimum

Testing. clearance between pressure plate and rotating disk Functional testing using 1792 psi.

should be 0.090” minimum with 75 psi back

pressure.

A striking difference in the performance of the two brake tri-metallic brakes. As with any brake system, use the

systems is the way the tri-metallic brake keeps working brakes sparingly - and be sure your Hercules will stop

and working in spite of abuse and over-use. But, when and where you want it to.

remember that the new system gives no warning signal

when it’s being abused, while the single disk brake will

show brake fade. So, to ensure maximum performance

and life, guard against unknowingly overworking the

Previous Page Table of Contents Next Page

JetStar landing gear shock, struts are now being manu- Your JetStar Handbook of Operating and Maintenance

factured from a new aluminum alloy, 7049-T73, which Instructions and JetStar Illustrated Parts Breakdown pro-

was specifically developed to resist stress corrosion. It is vide the basic instructions necessary to accomplish re-

only recently that such aluminum alloys with suitable placement of the struts. The new information is in the

strength for use in landing gear struts have become Service Bulletin 329-266 and on Lockheed-Georgia

available, Company Drawing JLK27. These two documents are

included in each kit. A separate kit is available for each of

You probably have already learned about the use of this the three landing gears. Reference to the strut kits are A

new alloy from JetStar Service Bulletin 329-266 and from for the left MLG, B for the right MLG and C for the NLG.

JetStar Operators Maintenance Reports, OMR A12 and ,

OMRA31. For more information or to place an order contact:

The new cylinder assemblies a n d related parts have been Lockheed-Georgia Company

available from Lockheed as preferred spares for about a JetStar Support

year. Many operators have replaced original struts with Dept. 64-22, Zone 287

these of the new alloy when stress corrosion cracking was Marietta, Georgia 30063

discovered or when replacements were necessary for other

reasons, Inspections required by JetStar Service Bulletin or calI (404) 424-3281

329-267 are cancelled on the replacement gear cylinder

assemblies because of the resistance of the new alloy to

corrosion.

Previous Page Table of Contents Next Page

HERCULES CREW ENTRANCE DOOR OPEN (4) Now open the door so you can fit the second

WARNING LIGHT SWITCH ADJUSTMENT step of the tool against the switch bracket

(same place on bracket as previously used).

by F. A. Hehmeyer, Service Representative

(5) Adjust the switch to actuate when the roller

is even with the rod end. Any convenient

The following procedure has proven beneficial to straight edge across the roller and rod end can

Hercules maintenance personnel around the verify evenness.

world.

All of your adjustments on the switch are out in

It involves adjustment of the crew entrance the “open” so that accuracy is easy to

DOOR OPEN warning light switch with the aid of accomplish.

an easy-to-make tool described in our illustration.

After you tighten the bracket mounting screws,

Use this tool in the following steps. close the door for a check.

(1) With the door closed securely, place the first THE OTHER SWITCH - You know that the

step of the tool against the aft, inboard side crew entrance DOOR OPEN light can receive

of the switch mounting bracket. current through another microswitch which is

turned off by the latch mechanism when it is in

(2) With the door in the closed position, adjust the latched (over center) position. Presently,

the tool rod so it will touch the striker plate, Service News doesn’t have a special tool for this

on the door, adjacent to the contact point of switch, but we did not want to ignore the

the switch actuating arm roller. possibility of its being out of adjustment, also.

Your Hercules maintenance manual is our

(3) Tighten the thumb screw so the rod will stay recommended reference if the simple approaches

at this specific length. are not effective. 13

FIRST

SECON

STEP

HUMB

CREW

THIS END OF ROD

T O U C H E S STRICKER PLATE

MATERIAL:

Bar, Tool Steel

3/32 Drill Rod

Thumb Screw

Previous Page Table of Contents Next Page

Beginning with Lockheed Serial Number LAC 4499, a

new type of filter element is being installed in production

airplanes (Commercial, Foreign Direct, and Military) at

five locations in the Hercules hydraulic systems. Four of

these are three-micron absolute elements and one is a five-

micron absolute element. This element change does not

require a change to the filter bowls since the new elements

are directly interchangeable with the old elements which

they replace.

Since the new elements are interchangeable with the old

elements, Lockheed Engineering stongly recommends that

all commercial and foreign direct operators, and military

operators (C-130B and up), replace their existing filter

FOR HERCULES elements with these new FAA and military approved

elements on an attrition basis.

HYDRAULIC SYSTEMS

Four of the old elements were disposable, with the utility

system main return element being the only cleanable

type. All five of the new elements are disposable.

by John Walters, For the time being, the schedule currently stipulated in

Design Engineer, Senior the handbook for replacement of the old elements should

be followed for the new elements. A service test is

currently being conducted that will furnish data which

hopefully will show increased service life for the new

elements.

14 Testing at Lockheed reveals that the new elements result

in the contamination count level of the hydraulic system

being lowered several classes within a very short opera-

tional period. These tests further reveal that silt particles

Filter element at right is typical of the ones previously used in the The new elements are for existing hydraulic filters located near the

subject hydraulic systems. The element at left is a new one. The reservoirs for the systems they serve. The filters in the Booster

outer protective wire screen is a distinguishing feature. Part Hydraulic System are typical, as shown in the photograph above.

numbers are stamped into the bottom of each element. Consult your Maintenance Manuals for servicing instructions.

Previous Page Table of Contents Next Page

(smaller than 10 microns), which are not counted during decrease in pump failures with the advent of fine

the contamination count process, are drastically reduced filtration.

in number. Theoretically, these silt particles cause most

of the wear in hydraulic pumps, motors, and spool-and- The following chart identifies the filter elements by their

sleeve type valves. A Navy program, which was closely location and old part numbers, with new replacement part

monitored on the A-6 and F-4 aircraft, showed a 17% numbers in the last column.

The new elements can be procured from:

Lockheed-Georgia Company

Department 65-11, Zone 287

86 South Cobb Drive 15

Marietta, Georgia 30063

PROJECTED PRODUCT IMPROVEMENT

The single point fill system allows servicing of all of the

Lockheed is preparing a service bulletin for foreign direct three Hercules reservoirs from one position, with fluid

operators which directs installation of a single point being pumped through a three-micron filter prior to

hydraulic reservoir fill system and sampling valves. If entering each respective reservoir. The sampling valves

sufficient interest is expressed by commercial operators, a provide an easy means of drawing a representative sample

service bulletin could also be published to cover com- of hydraulic fluid from each system for contamination

mercial Hercules aircraft. count analysis.

Previous Page Table of Contents Next Page

CUSTOMER SERVICE DIVISION

LOCKHEED-GEORGIA COMPANY

A DIVISION OF LOCKHEED AIRCRAFT CORPORATION

MARIETTA, GEORGIA, 30063

Thirty-six countries, not counting the United nations outside the U.S. currently have plant

States, have bought nearly 400 Lockheed representatives stationed in Marietta to monitor

Hercules propjet airplanes. Total Hercules sales manufacture of their Lockheed-Georgia aircraft.

have exceeded 1,400 airplanes.

The success of the Hercules is due, in part, to our

Lockheed-Georgia has hosted more than 2,000 emphasis on continuing Product Support,

visitors from 77 different countries in the past including deployment of Lockheed Field Service

year. Students from 11 nations have trained in Representatives under contract to Hercules’

1974 at the company’s Marietta plant; and 10 operators anywhere in the world.

Previous Page Table of Contents Next Page

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5945)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1109)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (888)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (926)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (598)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (545)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (354)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (476)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (831)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (274)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (419)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2272)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (99)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (270)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (235)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (232)

- Robert Proctor, Londa Schiebinger Agnotology The Making and Unmaking of Ignorance 2008Document64 pagesRobert Proctor, Londa Schiebinger Agnotology The Making and Unmaking of Ignorance 2008carlos arias galindoNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (75)

- Well Control PRESENTATION ModifiedDocument25 pagesWell Control PRESENTATION ModifiedCandra Wae Lah83% (6)

- c-130 Service New Vol. 1 Nr. 3 1974Document24 pagesc-130 Service New Vol. 1 Nr. 3 1974angelo marraNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Subcontracting 1610Document16 pagesSubcontracting 1610Sivakumar LakshminarayananNo ratings yet

- Service New V21N4Document20 pagesService New V21N4angelo marraNo ratings yet

- Service New V22N01Document16 pagesService New V22N01angelo marraNo ratings yet

- Service New V22N02Document16 pagesService New V22N02angelo marraNo ratings yet

- Service New V24N02Document16 pagesService New V24N02angelo marraNo ratings yet

- E-Bill: (See Bill Detail Section For More Information)Document2 pagesE-Bill: (See Bill Detail Section For More Information)David Parias DiazNo ratings yet

- Fundamental Electrical Measurements: Experiment # 1Document8 pagesFundamental Electrical Measurements: Experiment # 1Erwin CabangalNo ratings yet

- PIM130B1 - Daihatsu DT Series Archived JUN PDFDocument5 pagesPIM130B1 - Daihatsu DT Series Archived JUN PDFAnonymous XGsiY6rNo ratings yet

- Hilsen, A., & Olsen, D. (2021) - The Importance and Value of Older EmployeesDocument104 pagesHilsen, A., & Olsen, D. (2021) - The Importance and Value of Older Employeesnadine.galinoNo ratings yet

- The Suntory and Toyota International Centres For Economics and Related DisciplinesDocument21 pagesThe Suntory and Toyota International Centres For Economics and Related DisciplinesScott LeonNo ratings yet

- HS-2000 EngDocument4 pagesHS-2000 Engdody100% (1)

- A Saw I I Series Operating ManualDocument34 pagesA Saw I I Series Operating ManualPascu AurelNo ratings yet

- Resume - SHARATH - 2023-Updated NissanDocument5 pagesResume - SHARATH - 2023-Updated NissanCRUZZ Sharath.vNo ratings yet

- IECEx TOTAL Standards AngolaDocument31 pagesIECEx TOTAL Standards AngolaIso macnamareNo ratings yet

- Background of The StoryDocument6 pagesBackground of The StoryJohn Carlo ChinchonticNo ratings yet

- Quality AssuranceDocument30 pagesQuality Assurancedavid oj100% (1)

- Utilities FA4Document2 pagesUtilities FA4FewisNo ratings yet

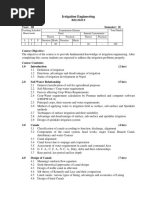

- BEG363CI Year: III Semester: II: Irrigation EngineeringDocument3 pagesBEG363CI Year: III Semester: II: Irrigation EngineeringAnil MarsaniNo ratings yet

- CFD of Exahust Valve 5Document52 pagesCFD of Exahust Valve 5Muhammad Imran KhanNo ratings yet

- Chapter 15 - SI - Final SolutionsDocument14 pagesChapter 15 - SI - Final SolutionsDouglas FernandesNo ratings yet

- Sanitaryware AER (Offline)Document11 pagesSanitaryware AER (Offline)Tri Setia BudiNo ratings yet

- Proposal PE-2Document5 pagesProposal PE-2Vikramp ParameswaranNo ratings yet

- Web PEER2010 111 ATCDocument245 pagesWeb PEER2010 111 ATCLuu Quang Hieu100% (1)

- SUN2000MA-12-15-20KTL-M0 Datasheet 01 Brazil - (20190326)Document2 pagesSUN2000MA-12-15-20KTL-M0 Datasheet 01 Brazil - (20190326)Fernando Augusto Campanharo CostaNo ratings yet

- Time Team - Bedford PurlieusDocument49 pagesTime Team - Bedford PurlieusWessex ArchaeologyNo ratings yet

- MetacognitionDocument11 pagesMetacognitionRenell FriasNo ratings yet

- Bariw Nhs Individual Daily Log and Accomplishment Report - Senior High SchoolDocument2 pagesBariw Nhs Individual Daily Log and Accomplishment Report - Senior High SchoolAnnalie Delera CeladiñaNo ratings yet

- Chapter 1.2 The Marketing System, Its Nature and The ElementsDocument3 pagesChapter 1.2 The Marketing System, Its Nature and The ElementsJisoo StarNo ratings yet

- Catalog Slim LineDocument16 pagesCatalog Slim LineAlina SecrețeanuNo ratings yet

- Angular 2 Mental Model PDFDocument11 pagesAngular 2 Mental Model PDFGregory Tec-infoNo ratings yet

- PLC Connection Guide PDFDocument1,508 pagesPLC Connection Guide PDFEvandro Amaral RodriguesNo ratings yet