Core Report for Superpave فبراير

Core Report for Superpave فبراير

Uploaded by

Mohamed NagiCopyright:

Available Formats

Core Report for Superpave فبراير

Core Report for Superpave فبراير

Uploaded by

Mohamed NagiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Core Report for Superpave فبراير

Core Report for Superpave فبراير

Uploaded by

Mohamed NagiCopyright:

Available Formats

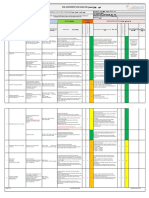

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3784

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE-I 1ST ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SULAIBIYA PLANT TESTED DATE : 12/2/2022

SAMPEL LOCATION: ST . 6+650 TO 6+800 R/S TESTED BY :

Quantity in tons = 1284.5 TON

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 6+650 1/2/2022 91.0 2019.0 3308.0 3298.0 1289 2.559 2551 0.8 2.730 6.3 93.7

6.4 93.6

1.B 6+650 1/2/2022 90.0 2027.0 3317.0 3295.0 1290 2.554 2547 1.7 2.730 6.4 93.6

2.A 6+675 1/2/2022 93.0 2078.0 3439.0 3425.0 1361 2.517 2509 1.0 2.730 7.8 92.2

7.6 92.4

2.B 6+675 1/2/2022 94.0 2051.0 3379.0 3357.0 1328 2.528 2520 1.7 2.730 7.4 92.6

3.A 6+700 1/2/2022 92.0 2014.0 3294.0 3276.0 1280 2.559 2552 1.4 2.730 6.3 93.8

6.8 93.2

3.B 6+700 1/2/2022 91.0 2079.0 3431.0 3422.0 1352 2.531 2523 0.7 2.730 7.3 92.7

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3784

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE-I 1ST ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SULAIBIYA PLANT TESTED DATE : 12/2/2022

SAMPEL LOCATION: ST . 6+650 TO 6+800 R/S TESTED BY :

Quantity in tons = 1284.5 TON

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

4.A 6+725 1/2/2022 92.0 2256.0 3730.0 3715.0 1474 2.520 2513 1.0 2.730 7.7 92.3

6.9 93.1

4.B 6+725 1/2/2022 93.0 2164.0 3540.0 3525.0 1376 2.562 2554 1.1 2.730 6.2 93.8

5.A 6+750 1/2/2022 92.0 2138.0 3505.0 3496.0 1367 2.557 2550 0.7 2.730 6.3 93.7

7.1 92.9

5.B 6+750 1/2/2022 91.0 2124.0 3519.0 3510.0 1395 2.516 2509 0.6 2.730 7.8 92.2

6.A 6+800 1/2/2022 92.0 2088.0 3449.0 3436.0 1361 2.525 2517 1.0 2.730 7.5 92.5

6.9 93.1

6.B 6+800 1/2/2022 91.0 2028.0 3325.0 3320.0 1297 2.560 2552 0.4 2.730 6.2 93.8

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3784

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE-I 1ST ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SULAIBIYA PLANT TESTED DATE : 12/2/2022

SAMPEL LOCATION: ST . 6+800 TO 7+000 R/S TESTED BY :

Quantity in tons = 962.2 TON

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 6+800 2/2/2022 93.0 2169.0 3581.0 3572.0 1412 2.530 2522 0.6 2.730 7.3 92.7

6.9 93.1

1.B 6+800 2/2/2022 91.0 2127.0 3491.0 3485.0 1364 2.555 2547 0.4 2.730 6.4 93.6

2.A 6+850 2/2/2022 91.0 2166.0 3574.0 3566.0 1408 2.533 2525 0.6 2.730 7.2 92.8

7.4 92.6

2.B 6+850 2/2/2022 90.0 2155.0 3564.0 3552.0 1409 2.521 2513 0.9 2.730 7.7 92.3

3.A 6+900 2/2/2022 92.0 2110.0 3486.0 3475.0 1376 2.525 2518 0.8 2.730 7.5 92.5

7.4 92.6

3.B 6+900 2/2/2022 90.0 2102.0 3465.0 3448.0 1363 2.530 2522 1.2 2.730 7.3 92.7

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

eGmm

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3784

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE-I 1ST ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SULAIBIYA PLANT TESTED DATE : 12/2/2022

SAMPEL LOCATION: ST . 6+800 TO 7+000 R/S TESTED BY :

Quantity in tons = 962.2 TON

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

4.A 6+950 2/2/2022 93.0 2110.0 3459.0 3446.0 1349 2.554 2547 1.0 2.730 6.4 93.6

6.5 93.5

4.B 6+950 2/2/2022 92.0 2127.0 3491.0 3480.0 1364 2.551 2544 0.8 2.730 6.5 93.5

5.A 7+000 2/2/2022 91.0 2074.0 3408.0 3395.0 1334 2.545 2537 1.0 2.730 6.8 93.2

6.7 93.3

5.B 7+000 2/2/2022 92.0 2143.0 3519.0 3508.0 1376 2.549 2542 0.8 2.730 6.6 93.4

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3792

/

Consultant : MPW REQ.COMP : 80 mm

N

Sample Description : TYPE-I ( SHOULDER ) ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SULAIBIYA PLANT TESTED DATE : 12/2/2022

SAMPEL LOCATION: ST . 6+650 TO 6+800 R/S TESTED BY :

Quantity in tons = 375 TON

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1A 6+700 3/2/2022 81.0 1647.0 2721.0 2714.0 1074 2.527 2519 0.7 2.730 7.4 92.6

7.0 93.0

1.B 6+700 3/2/2022 80.0 1608.0 2640.0 2633.0 1032 2.551 2544 0.7 2.730 6.5 93.5

2.A 6+800 3/2/2022 82.0 1678.0 2776.0 2765.0 1098 2.518 2511 1.0 2.730 7.8 92.2

7.3 92.7

2B 6+800 3/2/2022 80.0 1619.0 2662.0 2655.0 1043 2.546 2538 0.7 2.730 6.8 93.2

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3792

/

Consultant : MPW REQ.COMP : 80 mm

N

Sample Description : TYPE-I ( SHOULDER ) ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SULAIBIYA PLANT TESTED DATE : 12/2/2022

SAMPEL LOCATION: ST . 6+800 TO 7+000 R/S TESTED BY :

Quantity in tons = 200 TON

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1A 6+900 5/2/2022 83.0 1602.0 2625.0 2618.0 1023 2.559 2551 0.7 2.730 6.3 93.7

6.7 93.3

1.B 6+900 5/2/2022 82.0 1615.0 2661.0 2649.0 1046 2.533 2525 1.1 2.730 7.2 92.8

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3889

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE-I 1ST ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SULAIBIYA PLANT TESTED DATE : 23/02/2022

SAMPEL LOCATION: ST . 7+000 TO 7+375 R/S TESTED BY :

Quantity in tons = 1870 TON

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 7+000 8/2/2022 93.0 2074.0 3410.0 3395.0 1336 2.541 2534 1.1 2.723 6.7 93.3

6.8 93.2

1.B 7+000 8/2/2022 92.0 2238.0 3681.0 3655.0 1443 2.533 2525 1.8 2.723 7.0 93.0

2.A 7+050 8/2/2022 91.0 2175.0 3600.0 3590.0 1425 2.519 2512 0.7 2.723 7.5 92.5

7.3 92.7

2.B 7+050 8/2/2022 93.0 2110.0 3480.0 3465.0 1370 2.529 2522 1.1 2.723 7.1 92.9

3.A 7+100 8/2/2022 93.0 2147.0 3556.0 3546.0 1409 2.517 2509 0.7 2.723 7.6 92.4

7.2 92.8

3.B 7+100 8/2/2022 92.0 2066.0 3398.0 3382.0 1332 2.539 2531 1.2 2.723 6.8 93.2

4.A 7+150 8/2/2022 91.0 2101.0 3476.0 3467.0 1375 2.521 2514 0.7 2.723 7.4 92.6

7.3 92.7

4.B 7+150 8/2/2022 92.0 2179.0 3595.0 3580.0 1416 2.528 2521 1.1 2.723 7.2 92.8

5.A 7+200 8/2/2022 90.0 2260.0 3707.0 3697.0 1447 2.555 2547 0.7 2.723 6.2 93.8

6.3 93.7

5.B 7+200 8/2/2022 91.0 2167.0 3550.0 3527.0 1383 2.550 2543 1.7 2.723 6.3 93.7

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3889

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE-I 1ST ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SULAIBIYA PLANT TESTED DATE : 23/02/2022

SAMPEL LOCATION: ST . 7+000 TO 7+375 R/S TESTED BY :

Quantity in tons = 1870 TON

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

6.A 7+250 8/2/2022 91.0 2106.0 3483.0 3470.0 1377 2.520 2512 0.9 2.723 7.5 92.5

7.0 93.0

6.B 7+250 8/2/2022 90.0 2070.0 3404.0 3397.0 1334 2.546 2539 0.5 2.723 6.5 93.5

7.A 7+275 8/2/2022 93.0 2077.0 3439.0 3427.0 1362 2.516 2509 0.9 2.723 7.6 92.4

6.9 93.1

7.B 7+275 8/2/2022 93.0 2174.0 3567.0 3558.0 1393 2.554 2547 0.6 2.723 6.2 93.8

8.A 7+300 8/2/2022 91.0 2147.0 3556.0 3488.0 1409 2.476 2468 4.8 2.723 9.1 90.9

8.4 91.6

8..B 7+300 8/2/2022 92.0 2066.0 3398.0 3345.0 1332 2.511 2504 4.0 2.723 7.8 92.2

9.A 7+325 8/2/2022 90.0 2101.0 3476.0 3476.0 1375 2.528 2520 0.0 2.723 7.2 92.8

7.5 92.5

9.B 7+325 8/2/2022 91.0 2179.0 3595.0 3550.0 1416 2.507 2500 3.2 2.723 7.9 92.1

10.A 7+375 8/2/2022 92.0 2260.0 3707.0 3640.0 1447 2.516 2508 4.6 2.723 7.6 92.4

6.4 93.6

10.B 7+375 8/2/2022 91.0 2167.0 3550.0 3568.0 1383 2.580 2572 -1.3 2.723 5.3 94.7

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

eGmm

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/2925

/

Consultant : MPW REQ.COMP : 90mm

N

Sample Description : TYPE- I 1ST LAYER SP SOUTHER EAST LINK ROAD (L/S) THICKNESS . REQ 92-94 o

.

Supplier/Source: SULIBIYA PLANT TESTED DATE : 5/12/2021

SAMPEL LOCATION: ST .9+700 TO 9+900 TESTED BY : MAHMOUD

Quantity in tons = 400 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 9+700 7/10/2021 91.0 2352.0 3880.0 3867.0 1528 2.531 2523 0.9 2.726 7.2 92.8

7.2 92.8

1.B 9+700 7/10/2021 92.0 2330.0 3844.0 3832.0 1514 2.531 2523 0.8 2.726 7.2 92.8

2.A 9+850 7/10/2021 97.0 2360.0 3877.0 3866.0 1517 2.548 2541 0.7 2.726 6.5 93.5

6.9 93.1

2.B 9+850 7/10/2021 92.0 2331.0 3849.0 3837.0 1518 2.528 2520 0.8 2.726 7.3 92.7

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

eGmm

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/2929

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE- I 1ST LAYER SP SOUTHER EAST LINK ROAD (L/S) THICKNESS . REQ 92-94 o

.

Supplier/Source: SULIBIYA PLANET TESTED DATE : 5/12/2021

SAMPEL LOCATION: ST . 9+500 TO 9+800 L/S SHOULDER TESTED BY : MAHMOUD

Quantity in tons = 450 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 9+600 7/10/2021 91.0 2055.0 3384.0 3375.0 1329 2.540 2532 0.7 2.732 7.0 93.0

7.3 92.7

1.B 9+600 7/10/2021 93.0 2031.0 3360.0 3355.0 1329 2.524 2517 0.4 2.732 7.6 92.4

2.A 9+800 7/10/2021 92.0 2049.0 3384.0 3370.0 1335 2.524 2517 1.0 2.732 7.6 92.4

7.3 92.7

2.B 9+800 7/10/2021 93.0 2038.0 3355.0 3349.0 1317 2.543 2535 0.5 2.732 6.9 93.1

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/2876

/

Consultant : MPW REQ.COMP : 60mm

N

Sample Description : TYPE- I 2ND RAMP3 IC#1 THICKNESS . REQ 92-94 o

.

Supplier/Source: SULIBIYA PLANT TESTED DATE : 5/12/2021

SAMPEL LOCATION: ST . 0+000 TO 0+250 TESTED BY : MAHMOUD

Quantity in tons = 300 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 2+662.5 9/10/2021 62.0 1696.0 2800.0 2787.0 1104 2.524 2517 1.2 2.733 7.6 92.4

7.8 92.2

1.B 2+662.5 9/10/2021 63.0 1671.0 2764.0 2750.0 1093 2.516 2508 1.3 2.733 7.9 92.1

2.A 2+900 9/10/2021 64.0 1687.0 2777.0 2763.0 1090 2.535 2527 1.3 2.733 7.2 92.8

7.3 92.7

2.B 2+900 9/10/2021 65.0 1714.0 2822.0 2807.0 1108 2.533 2526 1.4 2.733 7.3 92.7

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

eGmm

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/2941

/

Consultant : MPW REQ.COMP : 70mm

N

Sample Description : TYPE- I 1ST LAYER SP RAMP 4 IC#1 THICKNESS . REQ 92-94 o

.

Supplier/Source: SULIBIYA PLANT TESTED DATE : 5/12/2021

SAMPEL LOCATION: ST . 0+175 TO 0+500 TESTED BY : MAHMOUD

Quantity in tons = 600 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

6.A 3+750 12/10/21 75.0 2365.0 3911.0 3900.0 1546 2.523 2515 0.7 2.739 7.9 92.1

7.0 93.0

6.B 3+750 12/10/21 74.0 2455.0 4003.0 3985.0 1548 2.574 2567 1.2 2.739 6.0 94.0

7.A 3+800 12/10/21 76.0 2433.0 3986.0 3972.0 1553 2.558 2550 0.9 2.739 6.6 93.4

7.4 92.6

7.B 3+800 12/10/21 76.0 2422.0 4009.0 3991.0 1587 2.515 2507 1.1 2.739 8.2 91.8

8.A 3+950 12/10/21 75.0 2350.0 3863.0 3850.0 1513 2.545 2537 0.9 2.739 7.1 92.9

7.3 92.7

8.B 3+950 12/10/21 75.0 2295.0 3784.0 3770.0 1489 2.532 2524 0.9 2.739 7.6 92.4

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

eGmm

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/2943

/

Consultant : MPW REQ.COMP : 70 mm

N

Sample Description : TYPE- I 1ST LAYER SP RAMP 4 IC#1 THICKNESS . REQ 92-94 o

.

Supplier/Source: SULIBIYA PLANET TESTED DATE : 5/12/2021

SAMPEL LOCATION: ST . 0+125 TO 0+462.5 TESTED BY : MAHMOUD

Quantity in tons = 400 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 0+200 13/10/2021 69.0 1662.0 2738.0 2732.0 1076 2.539 2531 0.6 2.736 7.2 92.8

6.9 93.1

1.B 0+200 13/10/2021 69.0 1605.0 2634.0 2627.0 1029 2.553 2545 0.7 2.736 6.7 93.3

2.A 0+400 13/10/2021 68.0 1462.6 2412.0 2407.0 949 2.535 2528 0.5 2.736 7.3 92.7

7.5 92.5

2.B 0+400 13/10/2021 69.0 1648.0 2723.0 2716.0 1075 2.527 2519 0.7 2.736 7.7 92.3

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/2963

/

Consultant : MPW REQ.COMP : 60 mm

N

Sample Description : TYPE-I 2ND LAYER SP RAMP 1 IC#1 THICKNESS . REQ 92-94 o

.

Supplier/Source: SULIBIYA PLANT TESTED DATE : 5/12/2021

SAMPEL LOCATION: ST . 0+600 TO 1+100 TESTED BY : MAHMOUD

Quantity in tons = 450 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 9+200 16/10/2021 65.0 1710.0 2809.0 2804.0 1099 2.551 2544 0.5 2.733 6.6 93.4

7.2 92.8

1.B 9+200 16/10/2021 65.0 1400.0 2311.0 2298.0 911 2.523 2515 1.4 2.733 7.7 92.3

2.A 9+250 16/10/2021 64.0 1444.0 2373.0 2362.0 929 2.543 2535 1.2 2.733 7.0 93.0

7.3 92.7

2.B 9+250 16/10/2021 64.0 1310.0 2163.0 2155.0 853 2.526 2519 0.9 2.733 7.6 92.4

3.A 9+400 16/10/2021 65.0 1800.0 2946.0 2938.0 1146 2.564 2556 0.7 2.733 6.2 93.8

6.2 93.8

3.B 9+400 16/10/2021 63.0 1755.0 2870.0 2859.0 1115 2.564 2556 1.0 2.733 6.2 93.8

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

eGmm

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/2961

/

Consultant : MPW REQ.COMP : 70 mm

N

Sample Description : TYPE- I 1ST LAYER SP RAMP 1 IC 1 THICKNESS . REQ 92-94 o

.

Supplier/Source: SULIBIYA PLANT TESTED DATE : 5/12/2021

SAMPEL LOCATION: ST .0+600 TO 1+1+100 TESTED BY : MAHMOUD

Quantity in tons = 600 TON

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 3+200 16/10/2021 78.0 2621.0 4286.0 4270.0 1665 2.565 2557 1.0 2.734 6.2 93.8

6.5 93.5

1.B 3+200 16/10/2021 75.0 2693.0 4425.0 4412.0 1732 2.547 2540 0.8 2.734 6.8 93.2

2.A 3+250 16/10/2021 79.0 2521.0 4145.0 4133.0 1624 2.545 2537 0.7 2.734 6.9 93.1

7.1 92.9

2.B 3+250 16/10/2021 77.0 1721.0 2837.0 2826.0 1116 2.532 2525 1.0 2.734 7.4 92.6

3.A 3+450 16/10/2021 75.0 1792.0 2952.0 2940.0 1160 2.534 2527 1.0 2.734 7.3 92.7

7.3 92.7

3.B 3+450 16/10/2021 75.0 1708.0 2812.0 2800.0 1104 2.536 2529 1.1 2.734 7.2 92.8

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

eGmm

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/2973

/

Consultant : MPW REQ.COMP : 70 mm

N

Sample Description : TYPE- I 1ST LAYER SP ST.1+400 TO 1+642 RAMP 6 IC-1 THICKNESS . REQ 92-94 o

.

Supplier/Source: Sulibiya PLANET TESTED DATE : 5/12/2021

SAMPEL LOCATION: ST . 1+400 TO 1+642 TESTED BY : MAHMOUD

Quantity in tons = 300

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 1+450 17/10/2021 70.0 2325.0 3811.9 3800.4 1487 2.556 2548 0.8 2.733 6.5 93.5

6.4 93.6

1.B 1+450 17/10/2021 72.0 2207.0 3616.0 3610.8 1409 2.563 2555 0.4 2.733 6.2 93.8

2.A 1+600 17/10/2021 70.0 1453.0 2395.0 2385.0 942 2.532 2524 1.1 2.733 7.4 92.6

7.1 92.9

2.B 1+600 17/10/2021 72.0 1322.0 2168.0 2156.0 846 2.548 2541 1.4 2.733 6.8 93.2

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/2975

/

Consultant : MPW REQ.COMP : 70 mm

N

Sample Description : TYPE- I 1ST LAYER SP 1+400 TO 1+642 RAMP 6 IC -1 THICKNESS . REQ 92-94 o

.

Supplier/Source: SULIBIYA PLANT TESTED DATE : 5/12/2021

SAMPEL LOCATION: ST .1+400 TO 1+642 TESTED BY : MAHMOUD

Quantity in tons = 550TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 1+450 17/10/2021 70.0 2076.0 3420.0 3409.0 1344 2.536 2529 0.8 2.734 7.2 92.8

7.1 92.9

1.B 1+450 17/10/2021 71.0 2044.0 3362.0 3350.0 1318 2.542 2534 0.9 2.734 7.0 93.0

2.A 1+550 17/10/2021 72.0 2094.0 3468.0 3456.0 1374 2.515 2508 0.9 2.734 8.0 92.0

7.6 92.4

2.B 1+550 17/10/2021 74.0 2057.0 3388.0 3375.0 1331 2.536 2528 1.0 2.734 7.3 92.7

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/2991

/

Consultant : MPW REQ.COMP : 70mm

N

Sample Description : TYPE- 1ST LAYER SP RAMP 3 IC-21 THICKNESS . REQ 92-94 o

.

Supplier/Source: SULIBIYA PLANT TESTED DATE : 5/12/2021

SAMPEL LOCATION: ST .0+709TO 1+175 TESTED BY : MAHMOUD

Quantity in tons = 550 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 0+750 18/10/2021 72.0 1641.0 2710.0 2694.0 1069 2.520 2513 1.5 2.739 8.0 92.0

7.9 92.1

1.B 0+750 18/10/2021 78.0 1693.0 2792.0 2778.0 1099 2.528 2520 1.3 2.739 7.7 92.3

2.A 1+150 18/10/2021 76.0 1711.0 2810.0 2796.0 1099 2.544 2536 1.3 2.739 7.1 92.9

7.3 92.7

2.B 1+150 18/10/2021 77.0 1640.0 2699.0 2686.0 1059 2.536 2529 1.2 2.739 7.4 92.6

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/3545

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE-I 2nd/L Abdaly Road R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SULIBIYA PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST . 9+750 TO 9+900 R/S TESTED BY : MAHMOUD

Quantity in tons = 880 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 9+750 1/1/2022 93.0 2585.0 4230.0 4216.0 1645 2.563 2555 0.9 2.733 6.2 93.8

6.4 93.6

1.B 9+750 1/1/2022 92.0 2614.0 4288.0 4273.0 1674 2.553 2545 0.9 2.733 6.6 93.4

2.A 9+800 1/1/2022 92.0 2572.0 4253.0 4240.0 1681 2.522 2515 0.8 2.733 7.7 92.3

7.8 92.2

2.B 9+800 1/1/2022 90.0 2589.0 4286.0 4273.0 1697 2.518 2510 0.8 2.733 7.9 92.1

3.A 9+850 1/1/2022 91.0 2575.0 4253.0 4243.0 1678 2.529 2521 0.6 2.733 7.5 92.5

7.6 92.4

3.B 9+850 1/1/2022 92.0 2590.0 4284.0 4275.0 1694 2.524 2516 0.5 2.733 7.7 92.3

4.A 9+900 1/1/2022 93.0 2595.0 4300.0 4295.0 1705 2.519 2512 0.3 2.733 7.8 92.2

7.4 92.6

4.B 9+900 1/1/2022 92.0 2665.0 4388.0 4377.0 1723 2.540 2533 0.6 2.733 7.0 93.0

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

eGmm

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3657

/

Consultant : MPW REQ.COMP : 80 mm

N

Sample Description : TYPE- I ( Shoulder ) SP Abdaly Road R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SULIBYA PLANT TESTED DATE : 25/1/2022

SAMPEL LOCATION: ST .9+650 TO 9+900 TESTED BY : MAHMOUD

Quantity in tons = 250

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 9+800 6/1/2022 83.0 2058.0 3384.0 3376.0 1326 2.546 2538 0.6 2.734 6.9 93.1

7.0 93.0

1.B 9+800 6/1/2022 82.0 2040.0 3360.0 3354.0 1320 2.541 2533 0.5 2.734 7.1 92.9

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

eGm

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3545

/

Consultant : MPW REQ.COMP : 90 MM

N

Sample Description : TYPE- I 2ND LAYER ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST . 9+650 TO 9+750 TESTED BY : MAHMOUD

Quantity in tons = 428.5 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 9+700 8/1/2022 92.0 2311.0 3806.0 3800.0 1495 2.542 2534 0.4 2.739 7.2 92.8

7.1 92.9

1.B 9+700 8/1/2022 91.0 2304.0 3785.0 3776.0 1481 2.550 2542 0.6 2.739 6.9 93.1

2.A 9+750 8/1/2022 93.0 2315.0 3821.0 3812.0 1506 2.531 2524 0.6 2.739 7.6 92.4

7.7 92.3

2.B 9+750 8/1/2022 92.0 2402.0 3972.0 3966.0 1570 2.526 2519 0.4 2.739 7.8 92.2

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3543

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE- I 1ST/L LAYER SP ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: 9+650 TO 9+750 TESTED BY : MAHMOUD

Quantity in tons = 385 Ton

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) Compaction COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C % AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 9+650 8/1/2022 94.0 1428.0 2347.0 2338.7 919 2.545 2537 0.9 2.739 7.1 92.9

6.7 93.3

1.B 9+650 8/1/2022 95.0 1890.5 3089.4 3078.6 1199 2.568 2560 0.9 2.739 6.2 93.8

2.A 9+750 8/1/2022 93.0 1738.0 2850.3 2841.0 1112 2.554 2547 0.8 2.739 6.7 93.3

7.3 92.7

2.B 9+750 8/1/2022 92.0 1505.4 2490.0 2484.6 985 2.523 2516 0.5 2.739 7.9 92.1

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3576

/

Consultant : MPW REQ.COMP : 90mm

N

Sample Description : TYPE- I 1ST/L LAYER SP ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST 10+250 TO 10+375 R/S TESTED BY : MAHMOUD

Quantity in tons = 774.1 Ton

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 10+250 8/1/2022 93.0 2944.0 4855.0 4842.0 1911 2.534 2526 0.7 2.733 7.3 92.7

6.9 93.1

1.B 10+250 8/1/2022 94.0 2890.0 4742.0 4730.0 1852 2.554 2546 0.6 2.733 6.5 93.5

2.A 10+300 8/1/2022 95.0 2855.0 4708.0 4697.0 1853 2.535 2527 0.6 2.733 7.3 92.7

7.6 92.4

2.B 10+300 8/1/2022 93.0 2951.0 4887.0 4874.0 1936 2.518 2510 0.7 2.733 7.9 92.1

3.A 10+350 8/1/2022 93.0 3060.0 5022.0 5006.0 1962 2.551 2544 0.8 2.733 6.6 93.4

7.2 92.8

3.B 10+350 8/1/2022 94.0 3052.0 5050.0 5037.0 1998 2.521 2513 0.7 2.733 7.8 92.2

4.A 10+375 8/1/2022 95.0 3064.0 5076.0 5060.0 2012 2.515 2507 0.8 2.733 8.0 92.0

7.8 92.2

4.B 10+375 8/1/2022 94.0 3051.0 5042.0 5030.0 1991 2.526 2519 0.6 2.733 7.6 92.4

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3578

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE- I 2ND LAYER SP ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST 10+250 TO 10+350 TESTED BY : MAHMOUD

Quantity in tons = 737.2 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 10+250 8/1/2022 91.0 2231.0 3677.0 3668.0 1446 2.537 2529 0.6 2.739 7.4 92.6

7.5 92.5

1.B 10+250 8/1/2022 92.0 1933.0 3181.0 3157.0 1248 2.530 2522 1.9 2.739 7.6 92.4

2.A 10+300 8/1/2022 92.0 2419.0 3975.0 3968.0 1556 2.550 2542 0.4 2.739 6.9 93.1

7.3 92.7

2.B 10+300 8/1/2022 90.0 2830.0 4674.0 4662.0 1844 2.528 2521 0.7 2.739 7.7 92.3

3.A 10+350 8/1/2022 93.0 2641.0 4349.0 4341.0 1708 2.542 2534 0.5 2.739 7.2 92.8

6.9 93.1

3.B 10+350 8/1/2022 92.0 2208.0 3616.0 3600.0 1408 2.557 2549 1.1 2.739 6.7 93.3

4.A 10+375 8/1/2022 90.0 2538.0 4193.0 4179.0 1655 2.525 2518 0.8 2.739 7.8 92.2

7.6 92.4

4.B 10+375 8/1/2022 91.0 2599.0 4272.0 4246.0 1673 2.538 2530 1.6 2.739 7.3 92.7

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

eGmm

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3586

/

Consultant : MPW REQ.COMP : 80 mm

N

Sample Description : TYPE- I ( Shoulder ) SP Abdaly Road R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/1/2022

SAMPEL LOCATION: ST .10+250 TO 10+375 TESTED BY : MAHMOUD

Quantity in tons = 102.5 Ton

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 10+300 9/1/2022 83.0 2052.0 3384.0 3376.0 1332 2.535 2527 0.6 2.734 7.3 92.7

7.2 92.8

1.B 10+300 9/1/2022 83.0 2040.0 3360.0 3354.0 1320 2.541 2533 0.5 2.734 7.1 92.9

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3608

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE- I 1ST LAYER SP ABDALY ROAD THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST .6+100 TO 6+400 R/S TESTED BY : MAHMOUD

Quantity in tons = 1255.9 TON

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 6+100 10/1/2022 91.0 2075.0 3422.0 3410.0 1347 2.532 2524 0.9 2.736 7.5 92.5

7.3 92.7

1.B 6+100 10/1/2022 93.0 2064.0 3394.0 3381.0 1330 2.542 2534 1.0 2.736 7.1 92.9

2.A 6+150 10/1/2022 92.0 2033.0 3343.0 3331.0 1310 2.543 2535 0.9 2.736 7.1 92.9

7.4 92.6

2.B 6+150 10/1/2022 92.0 2021.0 3338.0 3325.0 1317 2.525 2517 1.0 2.736 7.7 92.3

3.A 6+200 10/1/2022 93.0 2110.0 3479.0 3467.0 1369 2.533 2525 0.9 2.736 7.4 92.6

7.7 92.3

3.B 6+200 10/1/2022 94.0 2098.0 3472.0 3460.0 1374 2.518 2511 0.9 2.736 8.0 92.0

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3608

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE- I 1ST LAYER SP ABDALY ROAD THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST .6+100 TO 6+400 R/S TESTED BY : MAHMOUD

Quantity in tons = 1255.9 TON

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

4.A 6+250 10/1/2022 93.0 2075.0 3422.0 3410.0 1347 2.532 2524 0.9 2.736 7.5 92.5

7.3 92.7

4.B 6+250 10/1/2022 95.0 2064.0 3394.0 3381.0 1330 2.542 2534 1.0 2.736 7.1 92.9

5.A 6+300 10/1/2022 92.0 2033.0 3343.0 3331.0 1310 2.543 2535 0.9 2.736 7.1 92.9

7.4 92.6

5.B 6+300 10/1/2022 93.0 2021.0 3338.0 3325.0 1317 2.525 2517 1.0 2.736 7.7 92.3

6.A 6+400 10/1/2022 93.0 2110.0 3479.0 3467.0 1369 2.533 2525 0.9 2.736 7.4 92.6

7.7 92.3

6.B 6+400 10/1/2022 93.0 2098.0 3472.0 3460.0 1374 2.518 2511 0.9 2.736 8.0 92.0

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

eGmm

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3610

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE- I 2ND LAYER SP ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST 6+100 TO 6+400 TESTED BY : MAHMOUD

Quantity in tons = 1344.7 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 6+100 10/1/2022 92.0 2231.0 3677.0 3668.0 1446 2.537 2529 0.6 2.739 7.4 92.6

7.2 92.8

1.B 6+100 10/1/2022 90.0 1940.0 3181.0 3164.0 1241 2.550 2542 1.4 2.739 6.9 93.1

2.A 6+150 10/1/2022 91.0 2419.0 3975.0 3968.0 1556 2.550 2542 0.4 2.739 6.9 93.1

7.3 92.7

2.B 6+150 10/1/2022 92.0 2830.0 4674.0 4662.0 1844 2.528 2521 0.7 2.739 7.7 92.3

3.A 6+200 10/1/2022 91.0 2641.0 4349.0 4341.0 1708 2.542 2534 0.5 2.739 7.2 92.8

6.9 93.1

3.B 6+200 10/1/2022 92.0 2208.0 3616.0 3600.0 1408 2.557 2549 1.1 2.739 6.7 93.3

4.A 6+250 10/1/2022 91.0 2538.0 4193.0 4179.0 1655 2.525 2518 0.8 2.739 7.8 92.2

7.6 92.4

4.B 6+250 10/1/2022 93.0 2599.0 4272.0 4246.0 1673 2.538 2530 1.6 2.739 7.3 92.7

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3610

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE- I 2ND LAYER SP ABDALY ROAD R/S THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST 6+100 TO 6+400 TESTED BY : MAHMOUD

Quantity in tons = 1344.7 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

5.A 6+300 10/1/2022 93.0 2231.0 3677.0 3668.0 1446 2.537 2529 0.6 2.739 7.4 92.6

7.2 92.8

5.B 6+300 10/1/2022 90.0 1940.0 3181.0 3164.0 1241 2.550 2542 1.4 2.739 6.9 93.1

6.A 6+350 10/1/2022 93.0 2419.0 3975.0 3968.0 1556 2.550 2542 0.4 2.739 6.9 93.1

7.3 92.7

6.B 6+350 10/1/2022 92.0 2830.0 4674.0 4662.0 1844 2.528 2521 0.7 2.739 7.7 92.3

7.A 6+400 10/1/2022 92.0 2641.0 4349.0 4341.0 1708 2.542 2534 0.5 2.739 7.2 92.8

6.9 93.1

7.B 6+400 10/1/2022 90.0 2208.0 3616.0 3600.0 1408 2.557 2549 1.1 2.739 6.7 93.3

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3626

/

Consultant : MPW REQ.COMP : 80 mm

N

Sample Description : TYPE-I SP ABDALY ROAD ( SHOULDER ) THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST . 6+100 TO 6+250 R/S TESTED BY : MAHMOUD

Quantity in tons = 208.2 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 6+150 11/1/2022 92.0 2209.0 3650.0 3637.0 1441 2.524 2516 0.9 2.733 7.6 92.4

7.6 92.4

1.B 6+150 11/1/2022 95.0 2293.0 3786.0 3772.0 1493 2.526 2519 0.9 2.733 7.6 92.4

2.A 6+250 11/1/2022 93.0 2295.0 3770.0 3754.0 1475 2.545 2537 1.1 2.733 6.9 93.1

7.4 92.6

2.B 6+250 11/1/2022 93.0 2320.0 3842.0 3830.0 1522 2.516 2509 0.8 2.733 7.9 92.1

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

eGm

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3626

/

Consultant : MPW REQ.COMP : 80 mm

N

Sample Description : TYPE-I SP ABDALY ROAD ( SHOULDER ) THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST . 6+250 TO 6+400 R/S TESTED BY : MAHMOUD

Quantity in tons = 70 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 6+300 11/1/2022 91.0 2209.0 3650.0 3637.0 1441 2.524 2516 0.9 2.733 7.6 92.4

7.7 92.3

1.B 6+300 11/1/2022 92.0 2293.0 3786.0 3768.0 1493 2.524 2516 1.2 2.733 7.7 92.3

2.A 6+350 11/1/2022 92.0 2295.0 3770.0 3754.0 1475 2.545 2537 1.1 2.733 6.9 93.1

7.4 92.6

2.B 6+350 11/1/2022 93.0 2320.0 3842.0 3830.0 1522 2.516 2509 0.8 2.733 7.9 92.1

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3617

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE- I 2ND/L ABDALY ROAD THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI / SULAIBIYA PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST .6+300 TO 6+550 L/S TESTED BY : MAHMOUD

Quantity in tons = 969.7 TON

: ###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 6+300 11/1/2022 92.0 2299.0 3769.4 3752.5 1470 2.552 2544 1.1 2.733 6.6 93.4

6.6 93.4

1.B 6+300 11/1/2022 93.0 2368.2 3886.1 3872.2 1518 2.551 2543 0.9 2.733 6.7 93.3

2.A 6+350 11/1/2022 93.0 2299.3 3811.2 3800.0 1512 2.513 2506 0.7 2.733 8.0 92.0

7.7 92.3

2.B 6+350 11/1/2022 91.0 2182.3 3598.0 3581.9 1416 2.530 2523 1.1 2.733 7.4 92.6

3.A 6+400 11/1/2022 90.0 1977.0 3249.0 3226.5 1272 2.537 2529 1.8 2.733 7.2 92.8

7.6 92.4

3.B 6+400 11/1/2022 92.0 2176.0 3606.0 3596.1 1430 2.515 2507 0.7 2.733 8.0 92.0

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3617

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE- I 2ND/L ABDALY ROAD THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI / SULAIBIYA PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST .6+300 TO 6+550 L/S TESTED BY : MAHMOUD

Quantity in tons = 969.7 TON

: ###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

4.A 6+450 11/1/2022 92.0 2299.0 3769.4 3752.5 1470 2.552 2544 1.1 2.733 6.6 93.4

6.6 93.4

4.B 6+450 11/1/2022 90.0 2368.2 3886.1 3872.2 1518 2.551 2543 0.9 2.733 6.7 93.3

5.A 6+550 11/1/2022 90.0 2299.3 3811.2 3800.0 1512 2.513 2506 0.7 2.733 8.0 92.0

7.7 92.3

5.B 6+550 11/1/2022 91.0 2182.3 3598.0 3581.9 1416 2.530 2523 1.1 2.733 7.4 92.6

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3615

/

Consultant : MPW REQ.COMP : 90 mm

N

Sample Description : TYPE-I 1ST/L Abdaly Road THICKNESS . REQ 92-94 o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST . 6+300 TO6+550 L/S TESTED BY : MAHMOUD

Quantity in tons = 872.1 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 6+300 11/1/2022 92.0 2585.0 4230.0 4216.0 1645 2.563 2555 0.9 2.733 6.2 93.8

6.4 93.6

1.B 6+300 11/1/2022 90.0 2614.0 4288.0 4273.0 1674 2.553 2545 0.9 2.733 6.6 93.4

2.A 6+400 11/1/2022 90.0 2572.0 4253.0 4240.0 1681 2.522 2515 0.8 2.733 7.7 92.3

7.8 92.2

2.B 6+400 11/1/2022 91.0 2589.0 4286.0 4273.0 1697 2.518 2510 0.8 2.733 7.9 92.1

3.A 6+450 11/1/2022 93.0 2575.0 4253.0 4243.0 1678 2.529 2521 0.6 2.733 7.5 92.5

7.6 92.4

3.B 6+450 11/1/2022 91.0 2590.0 4284.0 4275.0 1694 2.524 2516 0.5 2.733 7.7 92.3

4.A 6+550 11/1/2022 92.0 2595.0 4300.0 4295.0 1705 2.519 2512 0.3 2.733 7.8 92.2

7.4 92.6

4.B 6+550 11/1/2022 90.0 2665.0 4388.0 4377.0 1723 2.540 2533 0.6 2.733 7.0 93.0

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3631

/

Consultant : MPW REQ.COMP : 92-94

N

Sample Description : TYPE-I 1ST ABDALY ROAD (SHOULDER) THICKNESS . REQ 80 mm o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST . 6+300 TO 6+550 L/S TESTED BY : MAHMOUD

Quantity in tons = 305 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 6+350 12/1/2022 84.0 2540.0 4198.0 4185.0 1658 2.524 2517 0.8 2.721 7.2 92.8

7.4 92.6

1.B 6+350 12/1/2022 82.0 2515.0 4165.0 4154.0 1650 2.518 2510 0.7 2.721 7.5 92.5

2.A 6+500 12/1/2022 81.0 2520.0 4180.0 4179.0 1660 2.517 2510 0.1 2.721 7.5 92.5

7.4 92.6

2.B 6+500 12/1/2022 80.0 2510.0 4155.0 4148.0 1645 2.522 2514 0.4 2.721 7.3 92.7

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3640

/

Consultant : MPW REQ.COMP : 92-94

N

Sample Description : TYPE-I 1ST ABDALY ROAD THICKNESS . REQ 90 mm o

.

Supplier/Source: SALMI / SULAIBIYA PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST . 6+550 TO 6+900 L/S TESTED BY : MAHMOUD

Quantity in tons = 2047.9 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 6+580 13/1/2022 90.0 2334.0 3819.0 3806.0 1485 2.563 2555 0.9 2.729 6.1 93.9

7.0 93.0

1.B 6+580 13/1/222 93.0 2586.0 4285.0 4274.0 1699 2.516 2508 0.6 2.729 7.8 92.2

2.A 6+600 13/1/222 91.0 2342.0 3840.0 3834.0 1498 2.559 2552 0.4 2.729 6.2 93.8

6.8 93.2

2.B 6+600 13/1/2022 92.0 2472.0 4085.0 4073.0 1613 2.525 2518 0.7 2.729 7.5 92.5

3.A 6+630 13/1/222 90.0 2410.0 3958.0 3942.0 1548 2.547 2539 1.0 2.729 6.7 93.3

6.5 93.5

3.B 6+630 13/1/2022 91.0 2365.0 3875.0 3861.0 1510 2.557 2549 0.9 2.729 6.3 93.7

4.A 6+660 13/1/222 90.0 2295.0 3783.0 3770.0 1488 2.534 2526 0.9 2.729 7.2 92.8

6.7 93.3

4.B 6+660 13/1/2022 90.0 2298.0 3762.0 3748.0 1464 2.560 2552 1.0 2.729 6.2 93.8

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3640

/

Consultant : MPW REQ.COMP : 92-94

N

Sample Description : TYPE-I 1ST ABDALY ROAD THICKNESS . REQ 90 mm o

.

Supplier/Source: SALMI / SULAIBIYA PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST . 6+550 TO 6+900 L/S TESTED BY : MAHMOUD

Quantity in tons = 2047.9 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

5.A 6+690 13/1/2022 92.0 2582.0 4262.0 4249.0 1680 2.529 2522 0.8 2.726 7.2 92.8

6.7 93.3

5.B 6+690 13/1/2022 93.0 2645.0 4335.0 4322.0 1690 2.557 2550 0.8 2.726 6.2 93.8

6.A 6+720 13/1/2022 91.0 2562.0 4210.0 4196.0 1648 2.546 2538 0.8 2.726 6.6 93.4

7.0 93.0

6.B 6+720 13/2/2022 90.0 2498.0 4128.0 4114.0 1630 2.524 2516 0.9 2.726 7.4 92.6

7.A 6+750 13/1/2022 94.0 2679.0 4388.0 4372.0 1709 2.558 2551 0.9 2.726 6.2 93.8

6.3 93.7

7.B 6+750 13/2/2022 90.0 2564.0 4208.0 4194.0 1644 2.551 2543 0.9 2.726 6.4 93.6

8.A 6+800 13/1/2022 91.0 2601.0 4256.0 4240.0 1655 2.562 2554 1.0 2.734 6.3 93.7

6.6 93.4

8.B 6+800 13/2/2022 92.0 2622.0 4312.0 4301.0 1690 2.545 2537 0.7 2.734 6.9 93.1

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3640

/

Consultant : MPW REQ.COMP : 92-94

N

Sample Description : TYPE-I 1ST ABDALY ROAD THICKNESS . REQ 90 mm o

.

Supplier/Source: SALMI / SULAIBIYA PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST . 6+550 TO 6+900 L/S TESTED BY : MAHMOUD

Quantity in tons = 2047.9 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

9.A 6+840 13/1/2022 92.0 2586.0 4241.0 4228.0 1655 2.555 2547 0.8 2.734 6.6 93.4

6.9 93.1

9.B 6+840 13/1/2022 91.0 2548.0 4201.0 4189.0 1653 2.534 2527 0.7 2.734 7.3 92.7

10.A 6+880 13/1/2022 93.0 2635.0 4321.0 4315.0 1686 2.559 2552 0.4 2.734 6.4 93.6

7.2 92.8

10.B 6+880 13/1/2022 90.0 2484.0 4115.0 4105.0 1631 2.517 2509 0.6 2.734 7.9 92.1

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3640

/

Consultant : MPW REQ.COMP : 92-94

N

Sample Description : TYPE-I 1ST ABDALY ROAD THICKNESS . REQ 90 mm o

.

Supplier/Source: SALMI PLANT TESTED DATE : 25/01/2022

SAMPEL LOCATION: ST . 6+900 TO 7+000 L/S TESTED BY : MAHMOUD

Quantity in tons = 618.2 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 6+920 15/1/2022 91.0 2594.0 4254.0 4243.0 1660 2.556 2548 0.7 2.726 6.2 93.8

7.1 92.9

1.B 6+920 15/1/2022 90.0 2536.0 4206.0 4192.0 1670 2.510 2503 0.8 2.726 7.9 92.1

2.A 6+960 15/1/2022 92.0 2640.0 4331.0 4315.0 1691 2.552 2544 0.9 2.726 6.4 93.6

7.0 93.0

2.B 6+960 15/1/2022 91.0 2605.0 4310.0 4295.0 1705 2.519 2512 0.9 2.726 7.6 92.4

3.A 6+990 15/1/2022 93.0 2675.0 4386.0 4372.0 1711 2.555 2548 0.8 2.726 6.3 93.7

6.5 93.5

3.B 6+990 15/1/2022 92.0 2612.0 4298.0 4286.0 1686 2.542 2534 0.7 2.726 6.7 93.3

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3652

/

Consultant : MPW REQ.COMP : 92-94

N

Sample Description : TYPE-I 2ND ABDALY ROAD THICKNESS . REQ 90 mm o

.

Supplier/Source: SALMI / SULAIBIYA PLANT TESTED DATE : 26/01/2022

SAMPEL LOCATION: ST . 6+550 TO 6+700 L/S TESTED BY : MAHMOUD

Quantity in tons = 1349.2 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific

Core Specimen Specimen absorbed by Theoretical Air Voids % = AIR

25 °C gravity (Gmb) COMPACTION

Ref. STATION laying date Thickness (kg/m³) at 25 ◦C volume maximum spg, 100*(Gmm- VOIDS Compaction %

Mass. in Water ( Mass of SSD in Dry mass in Air = at 25 ◦C AVER

No. (mm) = Bulk sp = (B-A)/(B- Gmm Gmb)/Gmm AVER

C) Air ( B ) (A) ( B-C ) = A/(B-C)

gr(Gmb) x 997.0 C)x100

1.A 6+520 15/1/2022 93.0 2610.0 4284.0 4272.0 1674 2.552 2544 0.7 2.724 6.3 93.7

6.4 93.6

1.B 6+520 15/1/2022 92.0 2586.0 4248.0 4231.0 1662 2.546 2538 1.0 2.724 6.5 93.5

2.A 6+550 15/1/2022 91.0 2552.0 4230.0 4219.0 1678 2.514 2507 0.7 2.724 7.7 92.3

7.8 92.2

2.B 6+550 15/1/2022 90.0 2540.0 4220.0 4211.0 1680 2.507 2499 0.5 2.724 8.0 92.0

3.A 6+570 15/1/2022 93.0 2643.0 4345.0 4332.0 1702 2.545 2538 0.8 2.724 6.6 93.4

6.5 93.5

3.B 6+570 15/1/2022 94.0 2667.0 4378.0 4362.0 1711 2.549 2542 0.9 2.724 6.4 93.6

4.A 6+610 15/1/2022 92.0 2635.0 4321.0 4308.0 1686 2.555 2547 0.8 2.724 6.2 93.8

7.0 93.0

4.B 6+610 15/1/2022 91.0 2595.0 4302.0 4289.0 1707 2.513 2505 0.8 2.724 7.8 92.2

QCS 2014SECTION 6 PART 5 LIMITE AIR VOID (6-8) % WATER ABSORBED ( MAX 2%)

Note : All Specification as per QCS 2014

CONTRACTOR CONSULTANT

Lab Technician Material Engineer Lab Technician Material Engineer

TEST REPORT ON DETERMINATION OF THICKNESS, BULK SPECIFIC GRAVITY, DENSITY , PERCENT OF COMPACTED BITUMINOUS MIXTURE

C

o

SUPERPAVE ASPHALT MIX DESIGN r

e

ASTM D3549/D3549M-11, ASTM D2726/D2726M-13, ASTM D3203/D3203M-11 Gmm

s

Project : RA/245 CONTRACTOR: UGCC / MAKYOL r

.

Contract owner : MPW RFI REF NO: RFI/RO/ 3652

/

Consultant : MPW REQ.COMP : 92-94

N

Sample Description : TYPE-I 2ND ABDALY ROAD THICKNESS . REQ 90 mm o

.

Supplier/Source: SALMI / SULAIBIYA PLANT TESTED DATE : 26/01/2022

SAMPEL LOCATION: ST . 6+550 TO 6+700 L/S TESTED BY : MAHMOUD

Quantity in tons = 1349.2 TON

###

###

Specimen mass. in (g)

Density of the % Water

Bulk Volume at Bulk Specific