Cold Work Permit

Cold Work Permit

Uploaded by

herdianCopyright:

Available Formats

Cold Work Permit

Cold Work Permit

Uploaded by

herdianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Cold Work Permit

Cold Work Permit

Uploaded by

herdianCopyright:

Available Formats

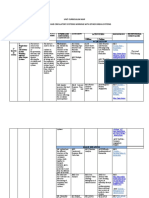

COLD WORK PERMIT Fire extinguisher N2 Purged / Steam Out System Mechanically Isolated

Erect signs and barriers Keep work site free of trip hazards Multi-Lock Isolated

Day Shoring Slope & Benching Eye Washer

Night

Permit Registry No.

Control the working hours Measure the temperature Comply with MSDS

NO WORK IS SO URGENT THAT WE CANNOT TAKE TIME TO DO IT SAFELY

Others : Water station

STOP WORK AND EVACUATE MUSTER POINT ON HEARING ANY EMERGENCY ALARM

5. PPE & SAFETY EQUIPMENT REQUIRED (by Performing Authority)

1. SPECIFICATION OF WORK (by Performing Authority)

Mandatory Fall Protection Eye & Face & Body Hand Protection Monitoring Equipment Respiratory Protector

Work Location : System (Item NO.) :

Safety Helmet Full Body Harness Face Shield Cotton Gloves H2S Badge Half Mask Respirator

Work Description :

Safety Shoes Fall Arrest Chemical Suit Leather Gloves Gas Monitor Full Face Respirator

Safety Glasses Hearing Protection Chemical Boot Lubber Gloves Film Badge/ Dosimeter Dust Mask

Equipment & Tools to be used :

Safety Gloves Ear Plug Rubber Boot Chemical Gloves Survey Meter Breathing Apparatus

Validity : This Permit is valid from DATE Hrs to DATE Hrs

Coverall Ear Muff Disposable Suit ETC. Life Jacket/ Vest

Company : Department : Apron Others :

6. GAS ANALYSIS OR INITIAL GAS TEST( by Authorized Gas Tester)

Requested by : Signed : ※ Task must be clearly described.

Not Required Inside Ouside Initial Result Authorized Gas Tester

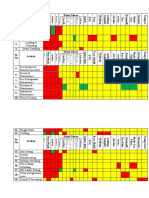

2. HAZARDOUS ACTIVITIES / HAZARDS IDENTIFIED (by Performing Authority)

Oxygen (%) 20.0% ≦O2≦ 20.9% 20.0% ≦O2≦ 20.9% Name

Excavation Work Confined Space Lifting operation Live Equipment Radiography Combustible(%) LEL ≦ 1 % LEL ≦ 10 % Signature

Toxic/H2S H2S ≦ 10 PPM H2S ≦ 10 PPM Date

Testing Maintenance Marine Work Diving Work High Voltage

CO CO ≦ 50 PPM CO ≦ 50 PPM Time

Low Voltage Welding sparks Electrical Spark Hot materials Eqpmt causing sparks ※ Initialled by Authorized Gas Tester as being within acceptable gas test limits. ※ Usable O2 CH4 H2S

※ Comments/Remarks : other sheet CO Other

Gases/fumes H2S Scaffolding Working at Height Severe/Adverse Weather

7. APPROVAL & ISSUE - This permit must be approved when the above precautions are implemented

Limited/poor lighting Moving machinery Pintch points Awkward Access/Egress Sharp edges

Step1. Reviewed by (Contractor Authorized representative)

Manual handling Vibration Electrocution Pressurized Hoses/Lines Unguarded Opening

Date : Time : Name : Signed :

Dust/ Powder Hazardous Substances Underground Utility Overhead Power Line Chemical

Step2. Reviewed by (HSE Authorized representative)

Extreme weather Flammable materials Explosives Noise Vehicle Traffic Date : Time : Name : Signed :

Danger of falling Dropped Object Tripping/Slipping Hazard MAN-BASKET OPERATION Handrail & Grating Removal Step3. Approved by (Approving Authority)

Date : Time : Name : Signed :

Others :

Step4. Accepted by (Subcontractor Task Supervisor / Site Manager)

3. SAFETY CHECK (by Performing Authority)

NA * - Not Applicable YES NO NA* I have read and understand the above conditions and precautions and declare that I accept responsibility for

A. Supplementary Requirements B. Site preparations carrying out work specified on this Permit, that no attempt will be made by myself or by the persons under my control to

carry out any other work, and that I will notify the Contractor engineer (HGU) upon completion/suspension of this work.

1 Risk Assessment is prepared

1 Excavation Certificate? Ref No.

2 Relevant workers are trained

2 Confined Space Entry Certificate? Ref No. - Safety Induction Date : Time : Name : Sgined :

- Adequate Safety Training

3 Lifting Certificate? Ref No.

3 Are all hazards clearly identified at site? 8. RE-VALIDATION (Complusory RE-VALIDATION of the work permit each shift - to continue work)

4 Radiography Certificate? Ref No. 4 All precaution in order to minimize risks

Subcontractor (Task

are taken at the site? Date Validity Time HSE Subcont In-charge HGU Site In-charge HSE HGU In-charge

5 Electrical Certificate? Ref No. Supervisor)

5 Hand tools & Power tools are inspected

Signature Signature Signature Signature

6 Electrical Isolation Certificate? Ref No. 6 Heay Equipment & Machinery are inspected

7 Process Isolation Certificate? Ref No. C. Adjacent work site precautions Signature Signature Signature Signature

1 Is notification given to safety about Signature Signature Signature Signature

8 Diving Certificate Ref No.

possible road blocks

Signature Signature Signature Signature

9 Grating Removal Certificate Ref No. 2 Has wind direction been considered

3 Is hazards from adjacent work taken into Signature Signature Signature Signature

10 Scaffolding Certificate Ref No.

consideration

Signature Signature Signature Signature

4 Is there any radio active hazard

5 Lock Out & Tag Out Signature Signature Signature Signature

4. PRECAUTION TO BE TAKEN (by Performing Authority) 9. PERMIT CLOSE-OUT ( CLOSURE ) - It must be registered by PTW Coordinator

Thoroughly ventilated Fire hose run out and pressurised Provided with suitable access and egress

Closed by(Subcontractor) Accepted by(HGU Authorized representative) Registered by(Permit Coordinator/HGU HSE)

Gas test required Fire resistance blanket/habitat erected Area free of flammable/combustible materials Date Time Date Time Date Time

Signed Signed Signed

Maintain radio contact Depressurised Grounding

Water flushed Secure loose objects Drained free of liquids

Cross-Referenced Documents : YES NO

Firewatcher present Containers for welding rods to be provided System Electrically Isolated ※ NOTE

Attached File : YES NO

You might also like

- GE Healthcare Aespire 7900 SmartVent BrochureDocument6 pagesGE Healthcare Aespire 7900 SmartVent BrochureVladimir OsunaNo ratings yet

- PTW Cold&hot All New YisuDocument4 pagesPTW Cold&hot All New YisuUD. Gunung JatiNo ratings yet

- PTW - Confined Space - ENDocument1 pagePTW - Confined Space - ENATSI HadjilaNo ratings yet

- Sop 04 Work Permit SystemDocument10 pagesSop 04 Work Permit Systemathul subashNo ratings yet

- 4.3 - B - 7 - Procedure For OHS Management ProgrammeDocument3 pages4.3 - B - 7 - Procedure For OHS Management ProgrammeSASIKUMAR SNo ratings yet

- HIRA AssessmentDocument25 pagesHIRA AssessmentPanchdev KumarNo ratings yet

- Job Safety Analysis FormDocument9 pagesJob Safety Analysis FormBhagat DeepakNo ratings yet

- PPM-FRM-GEN-079 Contractor Baseline Risk AssessmentDocument22 pagesPPM-FRM-GEN-079 Contractor Baseline Risk AssessmentbenitaNo ratings yet

- Risk Assessment: Kitchen - HomeDocument5 pagesRisk Assessment: Kitchen - HomesonofoddinNo ratings yet

- Appendix A Survey AnalysisDocument2 pagesAppendix A Survey Analysisahmed naveed100% (1)

- Vijay Kumar & Son'S: VENDOR CODE - 404168Document1 pageVijay Kumar & Son'S: VENDOR CODE - 404168Sean DasNo ratings yet

- (Your Business Name Here) - Safe Work Procedure Drill PressDocument2 pages(Your Business Name Here) - Safe Work Procedure Drill PressSafety DeptNo ratings yet

- Safety Meeting Agenda TemplateDocument1 pageSafety Meeting Agenda Templateashraf hafiziNo ratings yet

- Safety Inspection Checklist Band SawsDocument1 pageSafety Inspection Checklist Band Sawsallu arunNo ratings yet

- Accident Incident Report SampleDocument4 pagesAccident Incident Report SampleNgoua CalixNo ratings yet

- PPE MatrixDocument2 pagesPPE MatrixDJadee Anuppur AmlaiNo ratings yet

- 005 Procedure For Risk ManagementDocument10 pages005 Procedure For Risk ManagementRizwan KaziNo ratings yet

- PR 01 EHS 007 EHS Compliance AuditDocument7 pagesPR 01 EHS 007 EHS Compliance AuditClarabelle Mae Dela RosaNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- Incident Checklist: Other ActionsDocument1 pageIncident Checklist: Other Actionsloveson709No ratings yet

- Facility Health, Safety and Environmental Management (Hse)Document2 pagesFacility Health, Safety and Environmental Management (Hse)Syahirah NazriNo ratings yet

- Noise MonitoringDocument7 pagesNoise Monitoringshahrul rollNo ratings yet

- JHA-Mechanical Lifting1Document2 pagesJHA-Mechanical Lifting1john jaycoh veranoNo ratings yet

- Saferad LTD: Health, Safety and Environmental Targets - 2016 2018Document3 pagesSaferad LTD: Health, Safety and Environmental Targets - 2016 2018AkhilNo ratings yet

- Emergency Response ProcedureDocument4 pagesEmergency Response ProcedureBèrl YñdåNo ratings yet

- Proper Handling and Storage of Chemicals: December 2014Document54 pagesProper Handling and Storage of Chemicals: December 2014Qais AlzamelNo ratings yet

- Visitor Safety and Agreement 20121Document20 pagesVisitor Safety and Agreement 20121Rahmat BudimanNo ratings yet

- CCDC-GRN-Safety Walk Through Report-27Document52 pagesCCDC-GRN-Safety Walk Through Report-27Saurabh KumarNo ratings yet

- Document Issue & Control RegisterDocument1 pageDocument Issue & Control RegisterArjun RathoreNo ratings yet

- Workplace Hazard Identification & Assessment Sheet: Residual Risk (With Controls) BASE RISK (Without Controls)Document2 pagesWorkplace Hazard Identification & Assessment Sheet: Residual Risk (With Controls) BASE RISK (Without Controls)Tawsif AhmedNo ratings yet

- COVID-19 Risk Assesment For NCCCLDocument3 pagesCOVID-19 Risk Assesment For NCCCLmohit100% (2)

- Near Miss Report FormatDocument2 pagesNear Miss Report FormatSparrow Green StudiosNo ratings yet

- First Aid Box Inspection Checklist-NewDocument16 pagesFirst Aid Box Inspection Checklist-NewSafety DeptNo ratings yet

- RA - LPW Panel ShiftingDocument11 pagesRA - LPW Panel ShiftingZameer Basha Navzath AliNo ratings yet

- 2.2 C New Safety Dashboard Dec2022Document1 page2.2 C New Safety Dashboard Dec2022subodh kumarNo ratings yet

- Incident Report Form: RPSG-IMS-F-24 Accident and Investigation Form 5ADocument2 pagesIncident Report Form: RPSG-IMS-F-24 Accident and Investigation Form 5ARocky BisNo ratings yet

- OCP-11 - Covered Material StorageDocument2 pagesOCP-11 - Covered Material StorageNagendra Kumar SinghNo ratings yet

- Legal Register - Federal Law No.8Document4 pagesLegal Register - Federal Law No.8Priyanka JNo ratings yet

- EHS Monthly MeetingDocument31 pagesEHS Monthly MeetingShaik MohamedNo ratings yet

- Health, Safety and Environment Policy ManualDocument3 pagesHealth, Safety and Environment Policy ManualVikas SinghNo ratings yet

- Training Needs AssessmentDocument5 pagesTraining Needs Assessmentahmad100% (1)

- TGC - Ehsp - 02. Ehs Objectives & TargetsDocument4 pagesTGC - Ehsp - 02. Ehs Objectives & TargetsAhmed El SayedNo ratings yet

- 4 Hydra CraneDocument1 page4 Hydra CraneArmanNo ratings yet

- SWP Manual Bending Rolls AS524Document2 pagesSWP Manual Bending Rolls AS524jason cepadaNo ratings yet

- HSE Management System TemplateDocument8 pagesHSE Management System TemplateMyo LwinNo ratings yet

- Work Permit ProcedureDocument2 pagesWork Permit Procedureवात्सल्य कृतार्थNo ratings yet

- Issue-Based Risk Assessment Sub-Contractor ITS Filters CleaningDocument5 pagesIssue-Based Risk Assessment Sub-Contractor ITS Filters CleaningAhmed AbdulmajeedNo ratings yet

- Injury Statistics SheetDocument4 pagesInjury Statistics SheetEslam IsmaeelNo ratings yet

- Radiography Work Permit (OGF-HSE-23)Document3 pagesRadiography Work Permit (OGF-HSE-23)Mock ProjectNo ratings yet

- Safety ManualDocument31 pagesSafety ManualJosue Sandoval MenaNo ratings yet

- Ppe Hazard AssessmentDocument4 pagesPpe Hazard AssessmentNeha PatelNo ratings yet

- Evacuation Flow Chart 3Document1 pageEvacuation Flow Chart 3Abdul RhmanNo ratings yet

- Audit & Review PlanDocument3 pagesAudit & Review PlanDwitikrushna Rout100% (1)

- Machineguardingsoptech 12Document1 pageMachineguardingsoptech 12api-200253170No ratings yet

- Presentation - Accident InvestigationDocument22 pagesPresentation - Accident InvestigationapexndtNo ratings yet

- Ppe MatrixDocument2 pagesPpe MatrixsandeepNo ratings yet

- EHS Topics For Manual and SOPsDocument1 pageEHS Topics For Manual and SOPsPraveen VankayalapatiNo ratings yet

- R-16 Safety Management Review MeetingDocument2 pagesR-16 Safety Management Review MeetingSandeep Kumar100% (1)

- Incident Investigation ReportDocument2 pagesIncident Investigation ReportRaajha MunibathiranNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitherdianNo ratings yet

- Lind-P001 - MTR - Aghs - en - 2020-04-25 11 - 58 - 13Document11 pagesLind-P001 - MTR - Aghs - en - 2020-04-25 11 - 58 - 13Matej LotričNo ratings yet

- Microbial Disease of Respiratory SystemDocument2 pagesMicrobial Disease of Respiratory SystemJanah AbucayNo ratings yet

- CSEC Biology Labs StudentDocument2 pagesCSEC Biology Labs Studentxy4msvdy46No ratings yet

- Grade 9 Curriculum MapDocument4 pagesGrade 9 Curriculum MapZnar nabinagnap100% (1)

- Casestudyfor Bhopal Gas TragedyDocument6 pagesCasestudyfor Bhopal Gas TragedyPriyanshi ShekharNo ratings yet

- LipexDocument9 pagesLipexCurry FurryNo ratings yet

- Epibond 1534 ABDocument26 pagesEpibond 1534 ABNikolayNo ratings yet

- ETCO2 ReadingDocument19 pagesETCO2 ReadingTuan TrinhNo ratings yet

- Msds N.C. ThinnerDocument3 pagesMsds N.C. ThinnerganeshsaligramaNo ratings yet

- A Child Presenting With Breathing Difficulties (Asthma)Document54 pagesA Child Presenting With Breathing Difficulties (Asthma)Sindhu BabuNo ratings yet

- 1 Respiratory Module Lesson PlanDocument5 pages1 Respiratory Module Lesson PlanKirti kittuNo ratings yet

- Tos CronicaDocument13 pagesTos CronicaFlavio GuillenNo ratings yet

- Approach To Respiratory Disorders: Kurniyanto Department of Internal Medicine FK UkiDocument35 pagesApproach To Respiratory Disorders: Kurniyanto Department of Internal Medicine FK UkiDaud ParluhutanNo ratings yet

- Form ICRA HAIs FarmasiDocument13 pagesForm ICRA HAIs Farmasimarcella budimanNo ratings yet

- Pharyngeal Foreign BodiesDocument14 pagesPharyngeal Foreign BodiesSarit LevinskyNo ratings yet

- 02 SV300 or Eng V1.1 20211115Document37 pages02 SV300 or Eng V1.1 20211115Paulina JonasNo ratings yet

- EMT NREMT Study Guide 2024 Update (1)Document112 pagesEMT NREMT Study Guide 2024 Update (1)xbarreto21No ratings yet

- Lung MechanicsDocument28 pagesLung MechanicshariNo ratings yet

- NCP pAlPITATIONSDocument3 pagesNCP pAlPITATIONSHazel PalomaresNo ratings yet

- Parts and Functions of Respiratory System.Document3 pagesParts and Functions of Respiratory System.Alvin Patrick Colobong AsisNo ratings yet

- BrochureDocument1 pageBrochureFDAVA, JEHANNENo ratings yet

- SDS VIVAPUR XX enDocument10 pagesSDS VIVAPUR XX enKannan Arumugam ANo ratings yet

- Airborne Disease: Arina Mufida Ersanti, M.EpidDocument34 pagesAirborne Disease: Arina Mufida Ersanti, M.EpidMonica Galuh Dhiharsiwi100% (1)

- NCP For OxygenationDocument6 pagesNCP For OxygenationChriz LechNo ratings yet

- Respiratory Tract CytopathologyDocument24 pagesRespiratory Tract CytopathologyNgotelo FunwiNo ratings yet

- Material Safety Data Sheet: Revision Date: 07/11/05 Supercedes: 04/08/05 Activated AluminaDocument4 pagesMaterial Safety Data Sheet: Revision Date: 07/11/05 Supercedes: 04/08/05 Activated Aluminasakura_jNo ratings yet

- Hydrogen Bromide: Information For The PublicDocument3 pagesHydrogen Bromide: Information For The PublicAizat Sera SuwandiNo ratings yet

- Biology 4: Photosynthesis, Respiration & Circulation: Answer MarkDocument2 pagesBiology 4: Photosynthesis, Respiration & Circulation: Answer MarkLazNo ratings yet

- Do's & Don'tsDocument2 pagesDo's & Don'tsShivam BhasinNo ratings yet