Pump Cal

Pump Cal

Uploaded by

Hendrias A.SCopyright:

Available Formats

Pump Cal

Pump Cal

Uploaded by

Hendrias A.SOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Pump Cal

Pump Cal

Uploaded by

Hendrias A.SCopyright:

Available Formats

JIS G 3452 -1988 JIS G 3454 -1988 JIS G 3455 -1988 JIS G 3456 -1988

Carbon Steel Pipes Carbon Steel Pipes for Carbon Steel Pipes for Carbon Steel Pipes for

for Ordinary Piping Pressure Service High Pressure Service High Temperature Service

( SGP ) ( STPG 370, STPG 410 ) ( STS 370, STS 410, STS 480 ) ( STPT 370, STPT 410, STPT 480 )

TABLE 5 Attached Table 2 Attached Table 2 Attached Table 2

Wall Thickness, mm Wall Thickness, mm Wall Thickness, mm Wall Thickness, mm

Inch Outside

Nominal Diameter, Schedule No. Schedule No. Schedule No. Schedule No.

Size mm

SGP 10 20 30 40 60 80 40 60 80 100 120 140 160 10 20 30 40 60 80

1/8" 10.5 2.0 ... ... ... 1.7 2.2 2.4 1.7 ... 2.4 ... ... ... ... ... ... ... 1.7 ... 2.4

1/4" 13.8 2.3 ... ... ... 2.2 2.4 3.0 2.2 ... 3.0 ... ... ... ... ... ... ... 2.2 ... 3.0

3/8" 17.3 2.3 ... ... ... 2.3 2.8 3.2 2.3 ... 3.2 ... ... ... ... ... ... ... 2.3 ... 3.2

1/2" 21.7 2.8 ... ... ... 2.8 3.2 3.7 2.8 ... 3.7 ... ... ... 4.7 ... ... ... 2.8 ... 3.7

3/4" 27.2 2.8 ... ... ... 2.9 3.4 3.9 2.9 ... 3.9 ... ... ... 5.5 ... ... ... 2.9 ... 3.9

1" 34.0 3.2 ... ... ... 3.4 3.9 4.5 3.4 ... 4.5 ... ... ... 6.4 ... ... ... 3.4 ... 4.5

1.1/4" 42.7 3.5 ... ... ... 3.6 4.5 4.9 3.6 ... 4.9 ... ... ... 6.4 ... ... ... 3.6 ... 4.9

1.1/2" 48.6 3.5 ... ... ... 3.7 4.5 5.1 3.7 ... 5.1 ... ... ... 7.1 ... ... ... 3.7 ... 5.1

2" 60.5 3.8 ... 3.2 ... 3.9 4.9 5.5 3.9 ... 5.5 ... ... ... 8.7 ... ... ... 3.9 ... 5.5

2.1/2" 76.3 4.2 ... 4.5 ... 5.2 6.0 7.0 5.2 ... 7.0 ... ... ... 9.5 ... ... ... 5.2 ... 7.0

3" 89.1 4.2 ... 4.5 ... 5.5 6.6 7.6 5.5 ... 7.6 ... ... ... 11.1 ... ... ... 5.5 ... 7.6

3.1/2" 101.6 4.2 ... 4.5 ... 5.7 7.0 8.1 5.7 ... 8.1 ... ... ... 12.7 ... ... ... 5.7 ... 8.1

4" 114.3 4.5 ... 4.9 ... 6.0 7.1 8.6 6.0 ... 8.6 ... 11.1 ... 13.5 ... ... ... 6.0 ... 8.6

5" 139.8 4.5 ... 5.1 ... 6.6 8.1 9.5 6.6 ... 9.5 ... 12.7 ... 15.9 ... ... ... 6.6 ... 9.5

6" 165.2 5.0 ... 5.5 ... 7.1 9.3 11.0 7.1 ... 11.0 ... 14.3 ... 18.2 ... ... ... 7.1 ... 11.0

7" 190.7 5.3 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

8" 216.3 5.8 ... 6.4 7.0 8.2 10.3 12.7 8.2 10.3 12.7 15.1 18.2 20.6 23.0 ... 6.4 7.0 8.2 10.3 12.7

9" 241.8 6.2 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

10" 267.4 6.6 ... 6.4 7.8 9.3 12.7 15.1 9.3 12.7 15.1 18.2 21.4 25.4 28.6 ... 6.4 7.8 9.3 12.7 15.1

12" 318.5 6.9 ... 6.4 8.4 10.3 14.3 17.4 10.3 14.3 17.4 21.4 25.4 28.6 33.3 ... 6.4 8.4 10.3 14.3 17.4

14" 355.6 7.9 6.4 7.9 9.5 11.1 15.1 19.0 11.1 15.1 19.0 23.8 27.8 31.8 35.7 6.4 7.9 9.5 11.1 15.1 19.0

16" 406.4 7.9 6.4 7.9 9.5 12.7 16.7 21.4 12.7 16.7 21.4 26.2 30.9 36.5 40.5 6.4 7.9 9.5 12.7 16.7 21.4

18" 457.2 7.9 6.4 7.9 11.1 14.3 19.0 23.8 14.3 19.0 23.8 29.4 34.9 39.7 45.2 6.4 7.9 11.1 14.3 19.0 23.8

20" 508.0 7.9 6.4 9.5 12.7 15.1 20.6 26.2 15.1 20.6 26.2 32.5 38.1 44.4 50.0 6.4 9.5 12.7 15.1 20.6 26.2

22" 558.8 ... 6.4 9.5 12.7 15.9 ... ... 15.9 22.2 28.6 34.9 41.3 47.6 54.0 ... ... ... 15.9 22.2 28.6

24" 609.6 ... 6.4 9.5 14.3 ... ... ... 17.5 24.6 31.0 38.9 46.0 52.4 59.5 ... ... ... 17.5 24.6 31.0

26" 660.4 ... 7.9 12.7 ... ... ... ... 18.9 26.4 34.0 41.6 49.1 56.6 64.2 ... ... ... 18.9 26.4 34.0

683624374.xls / JIS ( Page 1 of 9 )

3456 -1988 JIS G 3459 -1994

teel Pipes for Stainless steel pipes

erature Service

PT 410, STPT 480 )

ed Table 2 Attached Table 2

ckness, mm Wall Thickness, mm

dule No. Schedule No. JIS G 3452 -1988 JIS G 3454 -1988 JIS G 3455 -1988

Schedule No. Schedule No.

100 120 140 160 5S 10S 20S 40 80 120 160 SGP 10 20 30 40 60 80 40 60 80 100

... ... ... ... 1.0 1.2 1.5 1.7 2.4 ... ... 6.50 ... ... ... 7.10 6.10 5.70 7.10 ... 5.70 ...

... ... ... ... 1.2 1.65 2.0 2.2 3.0 ... ... 9.20 ... ... ... 9.40 9.00 7.80 9.40 ... 7.80 ...

... ... ... ... 1.2 1.65 2.0 2.3 3.2 ... ... 12.70 ... ... ... 12.70 11.70 10.90 12.70 ... 10.90 ...

... ... ... 4.7 1.65 2.1 2.5 2.8 3.7 ... 4.7 16.10 ... ... ... 16.10 15.30 14.30 16.10 ... 14.30 ...

... ... ... 5.5 1.65 2.1 2.5 2.9 3.9 ... 5.5 21.60 ... ... ... 21.40 20.40 19.40 21.40 ... 19.40 ...

... ... ... 6.4 1.65 2.8 3.0 3.4 4.5 ... 6.4 27.60 ... ... ... 27.20 26.20 25.00 27.20 ... 25.00 ...

... ... ... 6.4 1.65 2.8 3.0 3.6 4.9 ... 6.4 35.70 ... ... ... 35.50 33.70 32.90 35.50 ... 32.90 ...

... ... ... 7.1 1.65 2.8 3.0 3.7 5.1 ... 7.1 41.60 ... ... ... 41.20 39.60 38.40 41.20 ... 38.40 ...

... ... ... 8.7 1.65 2.8 3.5 3.9 5.5 ... 8.7 52.90 ... 54.10 ... 52.70 50.70 49.50 52.70 ... 49.50 ...

... ... ... 9.5 2.1 3.0 3.5 5.2 7.0 ... 9.5 67.90 ... 67.30 ... 65.90 64.30 62.30 65.90 ... 62.30 ...

... ... ... 11.1 2.1 3.0 4.0 5.5 7.6 ... 11.1 80.70 ... 80.10 ... 78.10 75.90 73.90 78.10 ... 73.90 ...

... ... ... 12.7 2.1 3.0 4.0 5.7 8.1 ... 12.7 93.20 ... 92.60 ... 90.20 87.60 85.40 90.20 ... 85.40 ...

... 11.1 ... 13.5 2.1 3.0 4.0 6.0 8.6 11.1 13.5 105.30 ... 104.50 ... 102.30 100.10 97.10 102.30 ... 97.10 ...

... 12.7 ... 15.9 2.8 3.4 5.0 6.6 9.5 12.7 15.9 130.80 ... 129.60 ... 126.60 123.60 120.80 126.60 ... 120.80 ...

... 14.3 ... 18.2 2.8 3.4 5.0 7.1 11.0 14.3 18.2 155.20 ... 154.20 ... 151.00 146.60 143.20 151.00 ... 143.20 ...

... ... ... ... ... ... ... ... ... ... ... 180.10 ... ... ... ... ... ... ... ... ... ...

15.1 18.2 20.6 23.0 2.8 4.0 6.5 8.2 12.7 18.2 23.0 204.70 ... 203.50 202.30 199.90 195.70 190.90 199.90 195.70 190.90 186.10

... ... ... ... ... ... ... ... ... ... ... 229.40 ... ... ... ... ... ... ... ... ... ...

18.2 21.4 25.4 28.6 3.4 4.0 6.5 9.3 15.1 21.4 28.6 254.20 ... 254.60 251.80 248.80 242.00 237.20 248.80 242.00 237.20 231.00

21.4 25.4 28.6 33.3 4.0 4.5 6.5 10.3 17.4 25.4 33.3 304.70 ... 305.70 301.70 297.90 289.90 283.70 297.90 289.90 283.70 275.70

23.8 27.8 31.8 35.7 ... ... ... 11.1 19.0 27.8 35.7 339.80 342.80 339.80 336.60 333.40 325.40 317.60 333.40 325.40 317.60 308.00

26.2 30.9 36.5 40.5 ... ... ... 12.7 21.4 30.9 40.5 390.60 393.60 390.60 387.40 381.00 373.00 363.60 381.00 373.00 363.60 354.00

29.4 34.9 39.7 45.2 ... ... ... 14.3 23.8 34.9 45.2 441.40 444.40 441.40 435.00 428.60 419.20 409.60 428.60 419.20 409.60 398.40

32.5 38.1 44.4 50.0 ... ... ... 15.1 26.2 38.1 50.0 492.20 495.20 489.00 482.60 477.80 466.80 455.60 477.80 466.80 455.60 443.00

34.9 41.3 47.6 54.0 ... ... ... 15.9 28.6 41.3 54.0 ... 546.00 539.80 533.40 527.00 ... ... 527.00 514.40 501.60 489.00

38.9 46.0 52.4 59.5 ... ... ... 17.5 31.0 46.0 59.5 ... 596.80 590.60 581.00 ... ... ... 574.60 560.40 547.60 531.80

41.6 49.1 56.6 64.2 ... ... ... 18.9 34.0 49.1 64.2 ... 644.60 635.00 ... ... ... ... 622.60 607.60 592.40 577.20

683624374.xls / JIS ( Page 2 of 9 )

Calculated Inside Diameter, mm

S G 3455 -1988 JIS G 3456 -1988 JIS G 3459 -1994

Schedule No. Schedule No. Schedule No.

120 140 160 10 20 30 40 60 80 100 120 140 160 5S 10S 20S 40 80 120 160

... ... ... ... ... ... 7.10 ... 5.70 ... ... ... ... 8.50 8.10 7.50 7.10 5.70 ... ...

... ... ... ... ... ... 9.40 ... 7.80 ... ... ... ... 11.40 10.50 9.80 9.40 7.80 ... ...

... ... ... ... ... ... 12.70 ... 10.90 ... ... ... ... 14.90 14.00 13.30 12.70 10.90 ... ...

... ... 12.30 ... ... ... 16.10 ... 14.30 ... ... ... 12.30 18.40 17.50 16.70 16.10 14.30 ... 12.30

... ... 16.20 ... ... ... 21.40 ... 19.40 ... ... ... 16.20 23.90 23.00 22.20 21.40 19.40 ... 16.20

... ... 21.20 ... ... ... 27.20 ... 25.00 ... ... ... 21.20 30.70 28.40 28.00 27.20 25.00 ... 21.20

... ... 29.90 ... ... ... 35.50 ... 32.90 ... ... ... 29.90 39.40 37.10 36.70 35.50 32.90 ... 29.90

... ... 34.40 ... ... ... 41.20 ... 38.40 ... ... ... 34.40 45.30 43.00 42.60 41.20 38.40 ... 34.40

... ... 43.10 ... ... ... 52.70 ... 49.50 ... ... ... 43.10 57.20 54.90 53.50 52.70 49.50 ... 43.10

... ... 57.30 ... ... ... 65.90 ... 62.30 ... ... ... 57.30 72.10 70.30 69.30 65.90 62.30 ... 57.30

... ... 66.90 ... ... ... 78.10 ... 73.90 ... ... ... 66.90 84.90 83.10 81.10 78.10 73.90 ... 66.90

... ... 76.20 ... ... ... 90.20 ... 85.40 ... ... ... 76.20 97.40 95.60 93.60 90.20 85.40 ... 76.20

92.10 ... 87.30 ... ... ... 102.30 ... 97.10 ... 92.10 ... 87.30 110.10 108.30 106.30 102.30 97.10 92.10 87.30

114.40 ... 108.00 ... ... ... 126.60 ... 120.80 ... 114.40 ... 108.00 134.20 133.00 129.80 126.60 120.80 114.40 108.00

136.60 ... 128.80 ... ... ... 151.00 ... 143.20 ... 136.60 ... 128.80 159.60 158.40 155.20 151.00 143.20 136.60 128.80

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

179.90 175.10 170.30 ... 203.50 202.30 199.90 195.70 190.90 186.10 179.90 175.10 170.30 210.70 208.30 203.30 199.90 190.90 179.90 170.30

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

224.60 216.60 210.20 ... 254.60 251.80 248.80 242.00 237.20 231.00 224.60 216.60 210.20 260.60 259.40 254.40 248.80 237.20 224.60 210.20

267.70 261.30 251.90 ... 305.70 301.70 297.90 289.90 283.70 275.70 267.70 261.30 251.90 310.50 309.50 305.50 297.90 283.70 267.70 251.90

300.00 292.00 284.20 342.80 339.80 336.60 333.40 325.40 317.60 308.00 300.00 292.00 284.20 ... ... ... 333.40 317.60 300.00 284.20

344.60 333.40 325.40 393.60 390.60 387.40 381.00 373.00 363.60 354.00 344.60 333.40 325.40 ... ... ... 381.00 363.60 344.60 325.40

387.40 377.80 366.80 444.40 441.40 435.00 428.60 419.20 409.60 398.40 387.40 377.80 366.80 ... ... ... 428.60 409.60 387.40 366.80

431.80 419.20 408.00 495.20 489.00 482.60 477.80 466.80 455.60 443.00 431.80 419.20 408.00 ... ... ... 477.80 455.60 431.80 408.00

476.20 463.60 450.80 ... ... ... 527.00 514.40 501.60 489.00 476.20 463.60 450.80 ... ... ... 527.00 501.60 476.20 450.80

517.60 504.80 490.60 ... ... ... 574.60 560.40 547.60 531.80 517.60 504.80 490.60 ... ... ... 574.60 547.60 517.60 490.60

562.20 547.20 532.00 ... ... ... 622.60 607.60 592.40 577.20 562.20 547.20 532.00 ... ... ... 622.60 592.40 562.20 532.00

683624374.xls / JIS ( Page 3 of 9 )

ANSI/ASME B36.10M-1985 ANSI/ASME B36.19M-1985

TABLE 2A

TABLE 2 DIMENSIONS OF WELDED

DIMENSIONS AND WEIGHTS OF WELDED AND SEAMLESS WROUGHT STEEL PIPE AND SEAMLESS STAINLESS

STEEL PIPE

Wall Thickness, mm Wall Thickness, mm

Inch Outside Standard

Nominal Diameter, Schedule No. Extra-Strong Schedule No. Sched

Size mm Double Extra-Strong

10 20 30 40 60 80 100 120 140 160 STD XS XXS 5S 10S 40S 80S 10

1/8" 10.3 ... ... ... 1.73 ... 2.41 ... ... ... ... 1.73 2.41 ... ... 1.24 1.73 2.41 ...

1/4" 13.7 ... ... ... 2.24 ... 3.02 ... ... ... ... 2.24 3.02 ... ... 1.65 2.24 3.02 ...

3/8" 17.1 ... ... ... 2.31 ... 3.20 ... ... ... ... 2.31 3.20 ... ... 1.65 2.31 3.20 ...

1/2" 21.3 ... ... ... 2.77 ... 3.73 ... ... ... 4.78 2.77 3.73 7.47 1.65 2.11 2.77 3.73 ...

3/4" 26.7 ... ... ... 2.87 ... 3.91 ... ... ... 5.56 2.87 3.91 7.82 1.65 2.11 2.87 3.91 ...

1" 33.4 ... ... ... 3.38 ... 4.55 ... ... ... 6.35 3.38 4.55 9.09 1.65 2.77 3.38 4.55 ...

1.1/4" 42.2 ... ... ... 3.56 ... 4.85 ... ... ... 6.35 3.56 4.85 9.70 1.65 2.77 3.56 4.85 ...

1.1/2" 48.3 ... ... ... 3.68 ... 5.08 ... ... ... 7.14 3.68 5.08 10.15 1.65 2.77 3.68 5.08 ...

2" 60.3 ... ... ... 3.91 ... 5.54 ... ... ... 8.74 3.91 5.54 11.07 1.65 2.77 3.91 5.54 ...

2.1/2" 73.0 ... ... ... 5.16 ... 7.01 ... ... ... 9.53 5.16 7.01 14.02 2.11 3.05 5.16 7.01 ...

3" 88.9 ... ... ... 5.49 ... 7.62 ... ... ... 11.13 5.49 7.62 15.24 2.11 3.05 5.49 7.62 ...

3.1/2" 101.6 ... ... ... 5.74 ... 8.08 ... ... ... ... 5.74 8.08 ... 2.11 3.05 5.74 8.08 ...

4" 114.3 ... ... ... 6.02 ... 8.56 ... 11.13 ... 13.49 6.02 8.56 17.12 2.11 3.05 6.02 8.56 ...

5" 141.3 ... ... ... 6.55 ... 9.53 ... 12.70 ... 15.88 6.55 9.53 19.05 2.77 3.40 6.55 9.53 ...

6" 168.3 ... ... ... 7.11 ... 10.97 ... 14.27 ... 18.26 7.11 10.97 21.95 2.77 3.40 7.11 10.97 ...

8" 219.1 ... 6.35 7.04 8.18 10.31 12.70 15.09 18.26 20.62 23.01 8.18 12.70 22.23 2.77 3.76 8.18 12.70 ...

10" 273.0 ... 6.35 7.80 9.27 12.70 15.09 18.26 21.44 25.40 28.58 9.27 12.70 25.40 3.40 4.19 9.27 12.70 ...

12" 323.8 ... 6.35 8.38 10.31 14.27 17.48 21.44 25.40 28.58 33.32 9.53 12.70 25.40 3.96 4.57 9.53 12.70 ...

14" 355.6 6.35 7.92 9.53 11.13 15.09 19.05 23.83 27.79 31.75 35.71 9.53 12.70 ... 3.96 4.78 ... ... 342.90

16" 406.4 6.35 7.92 9.53 12.70 16.66 21.44 26.19 30.96 36.53 40.49 9.53 12.70 ... 4.19 4.78 ... ... 393.70

18" 457 6.35 7.92 11.13 14.27 19.05 23.83 29.36 34.93 39.67 45.24 9.53 12.70 ... 4.19 4.78 ... ... 444.30

20" 508 6.35 9.53 12.70 15.09 20.62 26.19 32.54 38.10 44.45 50.01 9.53 12.70 ... 4.78 5.54 ... ... 495.30

22" 559 6.35 9.53 12.70 ... 22.23 28.58 34.93 41.28 47.63 53.98 9.53 12.70 ... 4.78 5.54 ... ... 546.30

24" 610 6.35 9.53 14.27 17.48 24.61 30.96 38.89 46.02 52.37 59.54 9.53 12.70 ... 5.54 6.35 ... ... 597.30

26" 660 7.92 12.70 ... ... ... ... ... ... ... ... 9.53 12.70 ... ... ... ... ... 644.16

28" 711 7.92 12.70 15.88 ... ... ... ... ... ... ... 9.53 12.70 ... ... ... ... ... 695.16

30" 762 7.92 12.70 15.88 ... ... ... ... ... ... ... 9.53 12.70 ... 6.35 7.92 ... ... 746.16

32" 813 7.92 12.70 15.88 17.48 ... ... ... ... ... ... 9.53 12.70 ... ... ... ... ... 797.16

34" 864 7.92 12.70 15.88 17.48 ... ... ... ... ... ... 9.53 12.70 ... ... ... ... ... 848.16

36" 914 7.92 12.70 15.88 19.05 ... ... ... ... ... ... 9.53 12.70 ... ... ... ... ... 898.16

38" 965 ... ... ... ... ... ... ... ... ... ... 9.53 12.70 ... ... ... ... ... ...

40" 1016 ... ... ... ... ... ... ... ... ... ... 9.53 12.70 ... ... ... ... ... ...

42" 1067 ... ... ... ... ... ... ... ... ... ... 9.53 12.70 ... ... ... ... ... ...

44" 1118 ... ... ... ... ... ... ... ... ... ... 9.53 12.70 ... ... ... ... ... ...

46" 1168 ... ... ... ... ... ... ... ... ... ... 9.53 12.70 ... ... ... ... ... ...

48" 1219 ... ... ... ... ... ... ... ... ... ... 9.53 12.70 ... ... ... ... ... ...

52" 1321 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

56" 1422 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

60" 1524 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

64" 1626 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

68" 1727 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

72" 1829 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

76" 1930 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

80" 2032 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

683624374.xls / ANSI ( Page 4 of 9 )

Calculated Inside Diameter, mm

Standard

Schedule No. Extra-Strong Schedule No.

Double Extra-Strong

20 30 40 60 80 100 120 140 160 STD XS XXS 5S 10S 40S 80S

... ... 6.84 ... 5.48 ... ... ... ... 6.84 5.48 ... ... 7.82 6.84 5.48

... ... 9.22 ... 7.66 ... ... ... ... 9.22 7.66 ... ... 10.40 9.22 7.66

... ... 12.48 ... 10.70 ... ... ... ... 12.48 10.70 ... ... 13.80 12.48 10.70

... ... 15.76 ... 13.84 ... ... ... 11.74 15.76 13.84 6.36 18.00 17.08 15.76 13.84

... ... 20.96 ... 18.88 ... ... ... 15.58 20.96 18.88 11.06 23.40 22.48 20.96 18.88

... ... 26.64 ... 24.30 ... ... ... 20.70 26.64 24.30 15.22 30.10 27.86 26.64 24.30

... ... 35.08 ... 32.50 ... ... ... 29.50 35.08 32.50 22.80 38.90 36.66 35.08 32.50

... ... 40.94 ... 38.14 ... ... ... 34.02 40.94 38.14 28.00 45.00 42.76 40.94 38.14

... ... 52.48 ... 49.22 ... ... ... 42.82 52.48 49.22 38.16 57.00 54.76 52.48 49.22

... ... 62.68 ... 58.98 ... ... ... 53.94 62.68 58.98 44.96 68.78 66.90 62.68 58.98

... ... 77.92 ... 73.66 ... ... ... 66.64 77.92 73.66 58.42 84.68 82.80 77.92 73.66

... ... 90.12 ... 85.44 ... ... ... ... 90.12 85.44 ... 97.38 95.50 90.12 85.44

... ... 102.26 ... 97.18 ... 92.04 ... 87.32 102.26 97.18 80.06 110.08 108.20 102.26 97.18

... ... 128.20 ... 122.24 ... 115.90 ... 109.54 128.20 122.24 103.20 135.76 134.50 128.20 122.24

... ... 154.08 ... 146.36 ... 139.76 ... 131.78 154.08 146.36 124.40 162.76 161.50 154.08 146.36

206.40 205.02 202.74 198.48 193.70 188.92 182.58 177.86 173.08 202.74 193.70 174.64 213.56 211.58 202.74 193.70

260.30 257.40 254.46 247.60 242.82 236.48 230.12 222.20 215.84 254.46 247.60 222.20 266.20 264.62 254.46 247.60

311.10 307.04 303.18 295.26 288.84 280.92 273.00 266.64 257.16 304.74 298.40 273.00 315.88 314.66 304.74 298.40

339.76 336.54 333.34 325.42 317.50 307.94 300.02 292.10 284.18 336.54 330.20 ... 347.68 346.04 ... ...

390.56 387.34 381.00 373.08 363.52 354.02 344.48 333.34 325.42 387.34 381.00 ... 398.02 396.84 ... ...

441.16 434.74 428.46 418.90 409.34 398.28 387.14 377.66 366.52 437.94 431.60 ... 448.62 447.44 ... ...

488.94 482.60 477.82 466.76 455.62 442.92 431.80 419.10 407.98 488.94 482.60 ... 498.44 496.92 ... ...

539.94 533.60 ... 514.54 501.84 489.14 476.44 463.74 451.04 539.94 533.60 ... 549.44 547.92 ... ...

590.94 581.46 575.04 560.78 548.08 532.22 517.96 505.26 490.92 590.94 584.60 ... 598.92 597.30 ... ...

634.60 ... ... ... ... ... ... ... ... 640.94 634.60 ... ... ... ... ...

685.60 679.24 ... ... ... ... ... ... ... 691.94 685.60 ... ... ... ... ...

736.60 730.24 ... ... ... ... ... ... ... 742.94 736.60 ... 749.30 746.16 ... ...

787.60 781.24 778.04 ... ... ... ... ... ... 793.94 787.60 ... ... ... ... ...

838.60 832.24 829.04 ... ... ... ... ... ... 844.94 838.60 ... ... ... ... ...

888.60 882.24 875.90 ... ... ... ... ... ... 894.94 888.60 ... ... ... ... ...

... ... ... ... ... ... ... ... ... 945.94 939.60 ... ... ... ... ...

... ... ... ... ... ... ... ... ... 996.94 990.60 ... ... ... ... ...

... ... ... ... ... ... ... ... ... 1047.94 1041.60 ... ... ... ... ...

... ... ... ... ... ... ... ... ... 1098.94 1092.60 ... ... ... ... ...

... ... ... ... ... ... ... ... ... 1148.94 1142.60 ... ... ... ... ...

... ... ... ... ... ... ... ... ... 1199.94 1193.60 ... ... ... ... ...

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

683624374.xls / ANSI ( Page 5 of 9 )

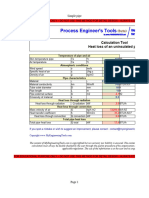

User's Guide for "PMPCAL"

Introduction Rem

PIPING PRESSURE DROP AND Pump Calculation Sheet (TEC Engineering Form A-MD02.032) has been

used to decide the required performance (Head, Capacity and NPSH) of

1

PUMP DESIGN CALCULATION SHEET pump. This tool was developed as Process Engineering Tool for Pump

Calculation and has following features. 2

1)Auto Calc ... Calculations such as hydraulics are done automatically.

Version 1.0 2)Piping Data Base ... System has the dimensional data of pipes

specified in ANSI/ASME and JIS.

3

3)Input/Check Form ... Input/Check Form is provided for easy work on

display. (No scroll is required.)

Input/Check Form

for Display Output(Print) Form

(A4 Portrait)

Input data /

Calculation result

Shut off Press.

NPSH How

System Configuration

Head, BHP 1

This tool was developed on Microsoft Excel Version 5.0 and the file

Dis. Press. includes following 5 Worksheets. 2

Suc. Press.

Sheet

1) User Guide*น Guide 3

2) Calculation Sheet Form*ฒ (Form)

L TOYO ENGINEERING CORPORATION 3) Data Input/Calculation Sheet*ณ

4) Table of dimensional data specified in ANSI/ASME

Calc

ANSI

5) Table of dimensional data specified in JIS JIS

*น developed by Microsoft Word Version 6.0 4

Version *ฒ This sheet can be utilized as a template when Auto Calc

Version 0.0 1996/07/31 Newly developed Function is not desired. (Auto Calc Function can not cover

Version 1.0 1996/09/12 Variable factor for Shut-off Calc. applied various process situations.) 5

*ณ The copies of this sheet shall be used for a Project. 6

It is recommended that the name of copied sheets shall be

changed to Item No. because the default setting of the footer

in page layout is the sheet name with the file name.

<Version> <Remarks> <How to use> <

<Introduction> <System Configuration>

683624374.xls / Guide ( Page 6 of 9 ) L TOYO ENGINEERING CORPORATION

User's Guide for "PMPCAL"

Remarks How to use(cont’d)

1. This tool is a file which will be utilized with Microsoft Excel and [Notes]

Microsoft Word. User should have the license to use Microsoft Excel TITLE ; Text data which will be printed on Output Form and no data entry

and Microsoft Word before using this tool. except followings is permitted.

2. This file is protected and user’s work is limited to the data entry to white REQ’D Working

cells and drawing process flow sketch except the sheet “Form”. will be utilized to decide the default of Flow Rate in hydraulic

3. Friction factor can be calculated with the iteration function in Microsoft calculation.

Excel. User should have the setting of Microsoft Excel in following Type

manner. will be utilized to estimate the Pump Efficiency.

Actuate Automatic and Iteration in the panel of Calculation after 1) FLOW Draw a process flow sketch on Output Form, if required.

selection of Options in Tools on Menu bar. Typical drawing components prepared at the right side of

Maximum Iterations and Maximum change shall be set as follows. sketch area shall be used and edited because new one cannot

Maximum Iterations: min. 100 be drawn due to protection of the sheet.

Maximum change: max. 0.001

Suction Drum / The name of Suction Drum will be utilized to

If above setting is not done,

the legend of process flow sketch.

the message “Cannot resolve circular references. ” will be

Not only Minimum Pressure but also Pressure

indicated and Pump Calculation Sheet will be made without

to be considered for the calculation of shutoff

converged solutions.

pressure should be given.

The Liquid Level shall be inputted as elevation

How to use

EL(mm) from anchor point.

1. Confirm the setting of Microsoft Excel. (refer to previous Remarks.)

Destination / Input the destination and the pressure at the

2. In case of revision for past work, close original file and open the saved

point. The destination will be reflected on the cells

file.

of HYDRAULICS.

3. After making copies of “Data Input/Calculation sheet” as described in

2) PUMP OPE. CONDITIONS

<System Configuration>, input the data and check the calculation result

Temp., Sp.Gr. & Vis. / Operating conditions of pump itself should be

to complete the Calculation Sheet in accordance with [Notes]

inputted. If any other data are not specified in

mentioned later and PDG-105 “Guideline for Pressure Balance &

the cells of HYDRAULICS, these operating

Sizing Relating Calculation”.

conditions will be used for the hydraulic

4. Once the data is changed, calculation will be done automatically.

calculations in the following priority order.

Indication of iteration number in status bar can be seen during

Sp.Gr. ; Min. => Nor. => Max.

calculation. Normally calculation will be converged within iteration of 50.

Viscosity ; Max. => Nor. => Min.

5. After calculation, check the calculation result and print.

Capacity Nor. & Des. / The percentage of overdesign will be

6. Save the file with specified new file name, if required.

calculated and indicated.

Note) It is recommended to save the file without “Guide”, “Form” and

“Calc” sheet to minimize the volume of the file and to keep the

original file as original.

< Introduction> < System Configuration> <How to use(cont’d)>

ฌ <Remarks><How to use> <How to use (cont’d)>

683624374.xls / Guide ( Page 7 of 9 ) L TOYO ENGINEERING CORPORATION

User's Guide for "PMPCAL"

How to use(cont’d) How to use(cont’d)

[Notes](cont’d) [Notes](cont’d)

HYDRAULICS ; 3) SUCTION SIDE / 4) DISCHARGE SIDE HYDRAULICS ; 3) SUCTION SIDE / 4) DISCHARGE SIDE

It is possible to calculate hydraulics in maximum three divided section.

Pressure Loss / Specify the pressure loss of each component.

Therefore the data should be specified to each section respectively, if

required. Right end column in SUCTION SIDE(DISCHARGE SIDE)

% of system dynamic loss / Refer to PDG-105.

should be used for any configuration. Suc. & Dis.Press. / Minimum suction pressure and required discharge

If two destinations are specified, the cells for Destination in pressure resulted from hydraulic calculation are

DISCHARGE SIDE will indicate BRANCH and the name of Desti.1 and indicated.

Desti.2 respectively. In this situation, the first(left) column is for the If two destinations are specified, larger required

section from pump to branch point, the second(right) column is for the discharge pressure is indicated and the value of

section from branch to Desti.1 and the third(right) one is for the section deviation from this are indicated for each

from branch to Desti.2.

destination.

Temp., Sp.Gr. & Vis. / If not specified, the data specified in PUMP

OPE. CONDITIONS will be used for 5) DIFFERENTIAL PRESSURE

calculations. Decide specification of suction and discharge pressure based on

Flow Rate / If not specified, following default will be used. hydraulic calculation and input them. The Margin included and Head

SUCTION SIDE ; Pump Des. Capacity multiplied by will be calculated and indicated.

number of Working pumps is for the ( The guideline of margin is described in PDG-105.)

section to MID1 (left column) and 6) NET POSITIVE SUCTION HEAD

Pump Des. Capa. is for the other

Specify the Specific Gravity for the calculation of NPSH Available, if

sections.

DISCHARGE SIDE ; Pump Nor. Capacity

required.

Nominal Pipe Size / In case of using the attached Piping Data Base, If not specified, specified value in PUMP OPE. CONDITION will be

Inch Index (“) is also required. applied in the following priority order.

Reference Standard / Specify the reference standard in case of using Sp.Gr. ; Min. => Nor. => Max.

the attached Piping Data Base. 7) BRAKE HORSEPOWER

Wall Thickness / Specify the schedule number (or identification such Specify pump efficiency for the calculation of BHP.

as XS applied in reference standard) in case of If not, the estimated value indicated on the right cell will be applied

using the attached Piping Data Base.

and noted on Output Form.

Pipe Inside Dia. / Not specify in case of using the attached Piping Data

Base and confirm the inside diameter indicated 8) MAX. SHUT OFF PRESSURE

below. Specify the Specific Gravity for the calculation of Maximum Liquid

If specified, the data entries for above 2 items will be Static Head, if required.

ignored. If not specified, specified value in PUMP OPE. CONDITION will be

Pipe Roughness / If not specified, the Default will be used. applied in the following priority order.

Total Equiv. Length / For the SUCTION SIDE, input the number of Sp.Gr. ; Min. => Nor. => Max.

Fitting on the cells in Note *4) and specify the

Specify the factors for Max. Shut-off Pressure calculation in NOTE

factor by which calculated Total Equiv. Length

multiplied.

*5). (The guideline of factor is described in PDG-105.)

For the DISCHARGE SIDE, specify the total

equiv. length including actual pipe length.

ฌ <How to use> <How to use (cont’d)> ฌ <How to use>

683624374.xls / Guide ( Page 8 of 9 ) L TOYO ENGINEERING CORPORATION

Work No. D-114 Item No. 0401G-002 REQ'D Working 1 Standby 0 Rev. 1 Date 28 Jan '04 Made NB [ Note ]

Project D-Plant Type 1 ( 1; Centri, 2;Recipro, 3;Gear, 4; Screw) Rev. 0 Date 8 Dec '03 Made Chat *1) Press. to be considered at Shutoff

1) FLOW as Sketch Service HWH Pump 5) DIFFERENTIAL PRESSURE *2) 1 ; ANSI/ASME, 2 ; JIS

Suction Drum T-002 Desti.1 / Desti.2 Press. Dis./Suc. (Kg/cm²G) 3.589 / 0.069 (Rated) *3) 0.04572(=Default) for C.S. , 0.0015 for S.S.

Pressure Min / *1 (Kg/cm²G) 0/ Destination K-602 / Diff. Press. (Kg/cm²) 3.659 *4) No. of Fitting in Suction Line

Liq.Level Min / Max. (EL) 700 / Pressure (Kg/cm²G) 1.2 / ( incl. Margin of 0.000 Kg/cm² ) Fitting / / 6" Eq. Length (m)

2) PUMP OPE. CONDITIONS Fluid HWH Water Head (m) 37.8 at Min. Sp.Gr. Ordinary Ent. / / 1 / /

Temp. Min/Nor/Max (°C) / 85 / Capacity Nor. 60 6) NET POSITIVE SUCTION HEAD Borda Entrance / / / /

Sp.Gr. @PT Min/Nor/Max ( - ) / 0.968 / (m³/hr) Des. Sp.Gr. for NPSH Calc. (-) 0.968 90° Standard Elb. / / / /

Viscosity Min/Nor/Max (cP) / 1/ Overdes. NPSH Avail. / Req'd (m) 3.8 / 1.9 90° L-Sweep Elb. / / 2 / /

Vap.Press. Max. (Kg/cm²A) 0.5894 Nozzle Elevation Suc./ Dis. (EL) 900 / 1,100 7) BRAKE HORSEPOWER 45° Elbow / / / /

HYDRAULICS 3) SUCTION SIDE 4) DISCHARGE SIDE Pump Efficiency (%) (Esti. ) Tee Side Outlet / / / /

Destination MID1 / MID2 / PUMP MID1 / MID2 / K-602 BHP ( kW ) at Max. Sp.Gr. Straight Tee / / / /

Destination Elevation (EL) / / 900 / / 25,000 8) MAX. SHUT OFF PRESSURE (As guide only) Gate Valve / / 1 / /

Temp. (°C) / / 85 / / 85 Sp.Gr. for Max. Suc. Static Head (-) 0.968 3/4 Contraction / / / /

Sp.Gr. (-) / / 0.968 / / 0.99973 Max. Suction Pressure (Kg/cm²G) *5) MAX. SHUT OFF PRESSURE (As guide only)

Viscosity (cP) / / 1 / / 1 Max. Shut-off Press. (Kg/cm²G) = Max.Suc. + 1.2 x Diff. Press. x 1.05

Flow Rate (m³/hr) / / 60 / / 60 L TOYO ENGINEERING CORPORATION

Nominal Pipe Size (inches) / / 6" / / 5" 1 28 Jan '04 NB

Reference Standard*² / / 1 / / 1 PIPING PRESSURE DROP AND

0 8 Dec '03 Chat

Wall Thickness PUMP DESIGN CALCULATION SHEET

(schedule) / / STD / / STD Rev. Date Made Chkd Remarks

Pipe Inside Dia. (mm) / / / / Work No. Project Name Item No. No. of Required Service

/ / / / D-114 D-Plant 0401G-002 1 +0 HWH Pump

Pipe Roughness*³ (mm) / / / / 1) FLOW

Velocity (m/s) / / / / Fitting in Discharge Line

Actual Pipe Length (m) / / 3 / / 60 T-002 Liq. Level L/D K-602

Total Equiv. Length* 4

(m) / / 3 / / 163.51 Max. EL Size (inch.) 5

/ / Min. EL 700 90elbow ###

20 14

Fri. Loss (Kg/cm²/100m) / / / / 45elbow 15 0 Fitting in Suction Line

Press. Loss a. Line / / / / Straight Tee 20 1 6"

(Kg/cm²) b. Strainer / / 0.05 TeeSide 65 2 Ord. Entrance 1

c. Orifice / / Butterfly Valve 13 0

### Borda Entranc

d. Exchangers / / Gate Valve 7 2 90° Elbow (S)

e. Heaters / / Check Valve 80 0 90° Elbow (L) 2

f. Others / / / / Globe Valve 350 1 45° Elbow

Sub-total ( a ~ f ) 0.000 / 0.000 / 0.000 Ordinary Ent. 36 0 Tee Side Outle

Control Valve / / Pump Nozzle Elev. Contraction 7 1 Straight Tee

( % of system dynamic loss ) Suc. EL 900 Equiv. Length 103.505 Gate Valve 1

Liquid Static Head (Kg/cm²) / / 0.019 / / 2.389 Dis. EL 1,100 3/4 Contractio

Suc. & Dis. Press. (Kg/cm²G) (Min.) 0.069 3.589

2) OPERATING CONDITIONS 4) DISCHARGE CONDITIONS

1. Fluid Name HWH Water 0. Destination K-602

2. Temp. Min./Nor./Max. (°C) / 85 / Elevation (EL) 25,000

3. Sp.Gr. Min./Nor./Max. (-) / 0.968 / Flow Rate (m³/hr) 60

4. Vis. Min./Nor./Max. (cP) / 1/ Temperature (°C) 85

5. Vap. Press. Max. (Kg/cm²A) 0.5894 Sp.Gr. (-) 0.99973

6. Capa. Nor/Des/Overdes. (m³/hr) 60 / / Viscosity (cP) 1

1. Line Size ANSI

3) SUCTION CONDITIONS Nominal Pipe Size (inches) 5"

0. Destination PUMP Thickness (-) STD

Flow Rate (m³/hr) 60 Pipe Inside Dia. (mm)

Temperature (°C) 85 Pipe Roughness (mm) 0.0457

Sp.Gr. (-) 0.968 2. Velocity (m/s)

Viscosity (cP) 1 3. Actual Pipe Length (m) 60

1. Line Size ANSI 4. Total Equiv. Length (m) 163.51

Nominal Pipe Size (inches) 6" 5. Friction Loss (Kg/cm²/100m)

Thickness (-) STD 6. Press. Loss a. Line

Pipe Inside Dia. (mm) (Kg/cm²) b. Orifice

Pipe Roughness (mm) 0.0457 c. Exchangers

2. Velocity (m/s) d. Heaters

3. Actual Pipe Length (m) 3 e. Miscellaneous

4. Total Equiv. Length (m) 3.0 Sub-total(a~e) 0.000

x1 7. Control Valve Loss (Kg/cm²)

5. Fri. Loss (Kg/cm²/100m) 8. Max. Desti. Press. (Kg/cm²G) 1.2

6. Min. Drum Press. (Kg/cm²G) 0 9. Elevation Loss (m) 23.90

7. Min. Liq. Static Head (m) 0.20 (Kg/cm²) 2.389

(Kg/cm²) 0.019 10. Req'd Dis. Press. (Kg/cm²G) 3.589

8. Line Loss (Kg/cm²)

9. Strainer Loss (Kg/cm²) 0.05 7) BRAKE HORSEPOWER

10. Other Loss (Kg/cm²) m³/hr (Des.) x 0.968 (Sp.Gr.)*³ x 37.8 m

BHP =

11. Min. Suc. Press. (Kg/cm²G) 0.069 367.1 x (Pump Effi-Frac.)

= kW

5) DIFFERENTIAL PRESSURE

1. Rated Dis. Press. (Kg/cm²G) 3.5893547 8) MAX. SHUT OFF PRESSURE ( As guide only )

2. Rated Suc. Press. (Kg/cm²G) -0.0693610842207164 1. Suction Drum Pressure (Kg/cm²G)

3. incl. Special Margin (Kg/cm²) 0.000 2. Max. Liquid Static Head (m) #VALUE!

4. Differential Press. (Kg/cm²) 3.65871578422072 Sp.Gr. for Max. Suc. Static Head ( - ) 0.968

5. Head *¹ (m) 37.8 Max. Liquid Static Head (Kg/cm²)

3. Max. Suction Pressure (Kg/cm²G)

6) NET POSITIVE SUCTION HEAD 4. Max. Shut-off Pressure

1. Min. Suc. Press. (Kg/cm²G) 0.069 = Max.Suc. + 1.2 x Diff. Press. 3.66 *³ x 1.05

2. Vap. Press. (Kg/cm²G) -0.444 = Kg/cm²G

3. Net (Kg/cm²) 0.374

4. Sp.Gr. (-) 0.968 Notes; *¹ To be checked by controlling case (Min. Sp.Gr.)

NPSH Available *² (m) 3.8 *² To be checked by controlling case (Max. Vap. Press.)

NPSH Required *² (m) 1.9 *³ To be checked by controlling case (Max. Sp.Gr.)

A-MD02.032R(PMPCAL1E) © TOYO ENGINEERING CORPORATION

You might also like

- Note 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Light Blue and GreenDocument6 pagesNote 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Light Blue and Greensunii19847908No ratings yet

- Agathiyar2000Part 1 TextDocument164 pagesAgathiyar2000Part 1 TextsriramktNo ratings yet

- Pratt AirPro Max Air Valve Sizing CalculatorDocument1 pagePratt AirPro Max Air Valve Sizing CalculatorAndrei IngelbergNo ratings yet

- NDCT SpecsDocument121 pagesNDCT Specsthexp0werNo ratings yet

- 48 Steam TablesDocument24 pages48 Steam TablesPriscila HerreraNo ratings yet

- Heat Transfer. Heat Loss From A Pipe in An Indoor Location (This File Is in Working)Document60 pagesHeat Transfer. Heat Loss From A Pipe in An Indoor Location (This File Is in Working)vyrgoNo ratings yet

- BunkerHose DatasheetDocument2 pagesBunkerHose Datasheetmohit_mg100% (1)

- Hazen-Williams Pipe Flow Calculations SI UnitsDocument25 pagesHazen-Williams Pipe Flow Calculations SI UnitsJorge CottonNo ratings yet

- Disturbance FactorDocument46 pagesDisturbance FactorBossNo ratings yet

- Tank Size CalculatorDocument6 pagesTank Size CalculatorNarendra BholeNo ratings yet

- PW-CH-CRX19001-GAD-001 - 5 - GENERAL ARRANGEMENT DRAWING - Pig Launcher Receiv..Document1 pagePW-CH-CRX19001-GAD-001 - 5 - GENERAL ARRANGEMENT DRAWING - Pig Launcher Receiv..DarshAwadNo ratings yet

- Rock Plast Pipe BrochureDocument28 pagesRock Plast Pipe BrochureHusna Mega JayaNo ratings yet

- Hazen Williams EquationDocument1 pageHazen Williams Equationanil4u29No ratings yet

- Surge Suppression Air ValvesDocument2 pagesSurge Suppression Air ValvesjyothiprakashNo ratings yet

- Tankfarm DesignDocument15 pagesTankfarm DesignVaibhavladNo ratings yet

- Consulting Service Report: Comments ActionDocument4 pagesConsulting Service Report: Comments ActionVijayakumar KarunanidhiNo ratings yet

- Density of WaterDocument5 pagesDensity of WaterJean Pajuelo0% (1)

- Langelier-Ryznar-Hardness English v5Document20 pagesLangelier-Ryznar-Hardness English v5RodrigoMoreyraNo ratings yet

- Insulation Thickness by UOPDocument4 pagesInsulation Thickness by UOPOmar EzzatNo ratings yet

- Expansion Tank CalDocument4 pagesExpansion Tank CalapsinghformalNo ratings yet

- A4 Desuperheater PDFDocument6 pagesA4 Desuperheater PDF련서긔No ratings yet

- Critical Line List Rev - 1Document2 pagesCritical Line List Rev - 1Ganjar PutraNo ratings yet

- Heat Loss Pipe Uninsulated CalculatorDocument2 pagesHeat Loss Pipe Uninsulated CalculatorAnil KewalramaniNo ratings yet

- Bungartz CatalogueDocument26 pagesBungartz Cataloguetricky11No ratings yet

- Calculos Hazen WilliamsDocument3 pagesCalculos Hazen WilliamsMiguel HuamaniNo ratings yet

- 10P68 - Annexure For Air Release ValveDocument2 pages10P68 - Annexure For Air Release Valvesanooo3No ratings yet

- CV and Line Sizing For Steam CalculatorDocument2 pagesCV and Line Sizing For Steam CalculatorHiranthaNo ratings yet

- NPSH CalculatorDocument5 pagesNPSH CalculatorhansleyNo ratings yet

- Pipes. Pressure and Temperature Ratings For Carbon Steel Flanges of Material Groups 1.1 and 1.2Document51 pagesPipes. Pressure and Temperature Ratings For Carbon Steel Flanges of Material Groups 1.1 and 1.2JMVNo ratings yet

- System Resistance Curve in ExcelDocument46 pagesSystem Resistance Curve in ExcelkaushalNo ratings yet

- Fuel Gas MonitorDocument2 pagesFuel Gas MonitorfaisalnadimNo ratings yet

- Job No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)Document6 pagesJob No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)A N MadhavanNo ratings yet

- Doc. No. 15 - 42 09 050 - FODocument44 pagesDoc. No. 15 - 42 09 050 - FOdirgan_udyanaNo ratings yet

- Air Vacuum ValvesDocument4 pagesAir Vacuum ValvesmariuspiNo ratings yet

- 1aha054179 ADocument56 pages1aha054179 Adebu1985No ratings yet

- Burst DiscDocument6 pagesBurst DiscMa AlNo ratings yet

- Syn CompressorDocument23 pagesSyn CompressorManish GautamNo ratings yet

- Regenerative Steam Cycle: Error ?Document2 pagesRegenerative Steam Cycle: Error ?Rahul ChandrawarNo ratings yet

- Cerexen Nitrogen 200 Bar Calculation v2-2Document29 pagesCerexen Nitrogen 200 Bar Calculation v2-2Nghia Huynh NgocNo ratings yet

- PWP03 Fire System Pre-Comm PDFDocument3 pagesPWP03 Fire System Pre-Comm PDFJaldoNo ratings yet

- LPG Physical PropertiesDocument6 pagesLPG Physical PropertiesMugeshNo ratings yet

- P&ID Traveling Screen Rev.1Document2 pagesP&ID Traveling Screen Rev.1Ajeng OctaviaNo ratings yet

- Technical Data Sheet BD 004 Rev 4Document9 pagesTechnical Data Sheet BD 004 Rev 4debu1985No ratings yet

- 2K MethodDocument5 pages2K MethodLind D. QuiNo ratings yet

- Inter-Discipline Check Routing Sheet: PEC-EN-FRM-X-2387 Rev 2Document1 pageInter-Discipline Check Routing Sheet: PEC-EN-FRM-X-2387 Rev 2sathishNo ratings yet

- Ne2 Choke Valve SizingDocument238 pagesNe2 Choke Valve SizingreninbabaskiNo ratings yet

- Scaling IndicesDocument13 pagesScaling IndicesecefNo ratings yet

- BLR Efficiency CalculatorDocument2 pagesBLR Efficiency CalculatorPratik Ray ChaudhuryNo ratings yet

- AC Fans Static Calculation Final-1Document20 pagesAC Fans Static Calculation Final-1Hendrias A.SNo ratings yet

- Perhitungan Anaerobik Digester, Floating Dome, Fixed DomeDocument51 pagesPerhitungan Anaerobik Digester, Floating Dome, Fixed DomesehonoNo ratings yet

- P&ID CWP Rev 2Document1 pageP&ID CWP Rev 2Ajeng OctaviaNo ratings yet

- Compressor Settle-Out CalculationDocument4 pagesCompressor Settle-Out CalculationWickyNo ratings yet

- Kvaerner John Brown: Leff (Hor.) /H (Vert.)Document1 pageKvaerner John Brown: Leff (Hor.) /H (Vert.)bharathscdsNo ratings yet

- WQ Report Z0056 HurlinghamDocument11 pagesWQ Report Z0056 HurlinghamkaddourNo ratings yet

- Scrubber Catalogue R0!31!10 2017Document8 pagesScrubber Catalogue R0!31!10 2017ÇaPuLcU TosBaANo ratings yet

- Structural Requirements For The In-Service Inspection of Eroded/Corroded PipingDocument4 pagesStructural Requirements For The In-Service Inspection of Eroded/Corroded PipingSundersingh RubanNo ratings yet

- Pe TS 409 167 A001 PDFDocument95 pagesPe TS 409 167 A001 PDFRaghbir KaushikNo ratings yet

- Hdpe Pe80 Din 8074 / Iso 4427Document79 pagesHdpe Pe80 Din 8074 / Iso 4427Steve WanNo ratings yet

- Calsheet SampleDocument16 pagesCalsheet SampleHendrias A.SNo ratings yet

- Building Type Electrical LoadDocument1 pageBuilding Type Electrical LoadHendrias A.SNo ratings yet

- Ies 009Document9 pagesIes 009Hendrias A.SNo ratings yet

- GCMT-13-CIV-CN-011-Calculation of Pipe Support Bud-1Document27 pagesGCMT-13-CIV-CN-011-Calculation of Pipe Support Bud-1Hendrias A.SNo ratings yet

- HVAC Load Calculation - 1Document7 pagesHVAC Load Calculation - 1Hendrias A.SNo ratings yet

- AC Fans Static Calculation Final-1Document20 pagesAC Fans Static Calculation Final-1Hendrias A.SNo ratings yet