DPR Rcpowder

DPR Rcpowder

Uploaded by

Bharat GouripurCopyright:

Available Formats

DPR Rcpowder

DPR Rcpowder

Uploaded by

Bharat GouripurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

DPR Rcpowder

DPR Rcpowder

Uploaded by

Bharat GouripurCopyright:

Available Formats

Model Detailed Project Report

CHILLI POWDER

Under the Formalization of Micro Food Processing Enterprises Scheme

(Ministry of Food Processing Industries, Government of India)

Prepared by

Indian Institute of Food Processing Technology (IIFPT)

Pudukkottai Road, Thanjavur, Tamil Nadu

Ministry of Food Processing Industries, Government of India

Model DPR On Chilli Powder Processing Unit Page 1

TABLE OF CONTENTS

Model Detailed Project Report ........................................................................... 1

1 Executive Summary .................................................................................... 4

2 Objective Of The Project............................................................................. 7

3 Project Profile .............................................................................................. 8

4 General overview of RED Cilli production, clusters, phm and value addition in

india ...................................................................................................................... 9

4.1 Introduction ................................................................................................................. 9

4.2 Origin, Distribution And Production Of Chilli ............................................................... 9

4.3 Health Benefits And Nutritional Importance ............................................................. 10

4.5 Cultivation, Bearing And Post-Harvest Managements ............................................. 12

4.6 Processing And Value Addition In India ................................................................... 14

5 Model Chilli Powder Processing Under FME Scheme ........................... 15

5.1 location Of Proposed Project And Land ................................................................... 15

5.2 Installed Capacity Of Pocessing Plant ..................................................................... 15

5.3 Raw Material Requriment For The Unit .................................................................... 15

5.5 Processing Process .................................................................................................. 16

5.6 Maekrt Demand And Supply For RED CHilli POWDER .......................................... 18

5.7 Detail Rroject Assumptions ...................................................................................... 18

5.8 Machinery Sappliers ................................................................................................. 27

6 Limitations Of Model DPR And Guidelines For Entrepreneurs ............ 28

6.1 Limitations Of Model DPR ........................................................................................ 28

6.2 Guidelines For Enteprenures ................................................................................... 28

Model DPR On Chilli Powder Processing Unit Page 2

LIST OF TABLES

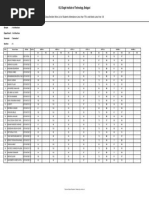

TABLE 1 Project at Glance ................................................................................................................................... 5

TABLE 2 Project Description ................................................................................................................................ 8

TABLE 3 Nutritional Composition Of Chilli ........................................................................................................... 11

TABLE 4 Project Details ...................................................................................................................................... 18

TABLE 5 Fixed Capital Investment ...................................................................................................................... 19

TABLE 6 Working Capital Requirments ............................................................................................................... 20

TABLE 7 Total Project Cost ................................................................................................................................. 21

TABLE 8 Means Of Finance ................................................................................................................................ 21

TABLE 9 Expenditure, Revenue And Profitability ................................................................................................ 21

TABLE 10 Repayment Schedule .......................................................................................................................... 22

TABLE 11 Assets Depreciation ............................................................................................................................ 23

TABLE 12 Financial Assessment Of Project ........................................................................................................ 24

TABLE 13 Break Even Analysis ........................................................................................................................... 25

LIST OF FIGURES

FIGURE 1 Chilli crop ............................................................................................................................................ 12

FIGURE 2 Harvesting of Chilli .............................................................................................................................. 13

FIGURE 3 Red Chilli Powder Process Flowchart ................................................................................................. 16

FIGURE 4 Pia chart for Better Understanding Of Expences Of EACH Head ...................................................... 26

FIGURE 5 Plant Layout ........................................................................................................................................ 26

Model DPR On Chilli Powder Processing Unit Page 3

1 EXECUTIVE SUMMARY

Chili powder (also spelled chile, chilli, or, alternatively, powdered chili) is the dried, pulverized fruit of

one or more varieties of chili pepper, sometimes with the addition of other spices (where it is also

sometimes known as chili powder blend or chili seasoning mix).It is used as a spice (or spice blend) to

add pungency (piquancy) and flavor to culinary dishes.

Chili powder is sometimes known by the specific type of chili pepper used. Varieties of chili peppers

used to make chili powder include Aleppo, ancho, cayenne, chipotle, chile de árbol, jalapeño, New

Mexico, pasilla, and piri piri chili peppers. Gochugaru is a variety used in Korean cuisine traditionally

made from sun-dried Korean red chili peppers known as taeyang-cho, with spicier varieties using

Cheongyang peppers. Kashmiri chili powder is bright red, but mild in heat and used in Indian cuisine,

named after the region of Kashmir.

India is one of the largest consumer and exporter of chillies. It consumes around 6.2 million tonnes i.e.

about 90% of the total produce of the country. The demand from the chilli powder-producing sector

constitutes 30% of total production in the country.

Demand for Indian chilli in Malaysia, Bangladesh, Sri Lanka and USA has been growing on an average

between 20 - 25% because of its quality and price competitiveness.

Andhra Pradesh is the largest producer of Chilli in India and contributes about 26% to the total area

under Chilli, followed by Maharashtra (15%), Karnataka (11%), Orissa (11%), Madhya Pradesh (7%)

and other states contributing nearly 22% to the total area under Chilli

INDIAN CHILLI PRODUCTION

Other States

Andra Pradesh

Madhya Pradesh

Maharashtra

Orissa Karnataka

Model DPR On Chilli Powder Processing Unit Page 4

TABLE 1

PROJECT AT GLANCE

1 Name of the proposed project Chilli Processing Unit

2 Name of the entrepreneur/FPO/SHG/ Cooperative

3 Nature of proposed project

4 Registered office

5 Project site/location

6 Names of Partner (if partnership)

7 No of shareholders (if company/FPC)

8 Technical advisor

9 Marketing advisor/partners

1 Tonn/day (60, 70 & 80%

10 capacity utilization in the 2nd,

3rd and 4th years’ onwards

Proposed project capacity respectively)

11 Raw materials Chilli Processing Unit

12 Major product outputs Chilli Powder

13 Total project cost : Rs. 21.78 Lakhs

· Land development, building & civil : construction Rs. 3.50 Lakhs

· Machinery and equipment’s : (Lakhs) Rs. 11.14 Lakhs

· Utilities (Power & water facilities) : (Lakhs) Rs. 0.7 Lakhs

· Miscellaneous fixed assets : (Lakhs) Rs. 0.8 Lakhs

· Pre-operative expenses : (Lakhs) Rs. 0.9 Lakhs

· Contingencies : (Lakhs) Rs. 2.00 Lakhs

· Working capital margin : (Lakhs) Rs. 2.74 Lakhs

14 Working capital requirement

· 2nd year (Lakhs) Rs. 5.48 Lakhs

· 3rd year (Lakhs) Rs. 6.52 Lakhs

· 4th year (Lakhs) Rs. 7.53 Lakhs

15 Means of Finance

· Subsidy grant by MoFPI (max 10 lakhs) : : Rs. 10.00 Lakhs

· Promoter’s contribution (min 20%) Rs. 4.36 Lakhs

· Term loan (45%) : Rs. 7.42 Lakhs

16 Debt-equity ratio 0.28

17 Profit after Depreciation, Interest & Tax

· 2nd year (Lakhs) Rs. 22.47 Lakhs

· 3nd year (Lakhs) Rs. 18.98 Lakhs

· 4nd year (Lakhs) Rs. 22.60 Lakhs

18 Average DSCR 5.79

Model DPR On Chilli Powder Processing Unit Page 5

19 Benefit-Cost Ratio 1.28

20 7 Years with 1year grace

Term loan repayment period

21 Payback period for investment 1 years 5 months

Model DPR On Chilli Powder Processing Unit Page 6

2 OBJECTIVE OF THE PROJECT

The Prime Objective of the Report is to present a Viable Bankable Model of “Red Chili Powder

Processing Unit” through adoption of appropriate technology, utilization of resources, quality

production and suitable market strategy.

Some important objectives behind setup of “Red Chili Processing Unit” are:

ü The prime objective is to setup this unit is to produce & make available quality product in most

hygienic conditions with good packaging, untouched & with very less human interference during

entire operations till market.

ü To produce & market safe, quality-assured products with highest nutrient value than existing one.

ü Improve customer’s nutrition by allowing them to consume quality processed product.

ü Empowering the lifestyle of promoter by adopting proper techniques in production and marketing of

final product.

ü Proper utilization of land, water, labour & other resources for better plant economics.

ü Employment generation for youth and women in surrounding areas.

Model DPR On Chilli Powder Processing Unit Page 7

3 PROJECT PROFILE

TABLE 2

PROJECT DESCRIPTION

PARTICULARS DESCRIPTION

Project Name “SET UP OF RED CHILLI POWDER PROCESSING UNIT”

Project Location

Project Area 5000 Sq Ft

Project Proposed Economic Activities Setup of Chilli Powder Processing Unit

Project Capacity/Annum Chilli Powder Processing Unit

ü 450 kg / Day Capacity

Model DPR On Chilli Powder Processing Unit Page 8

4 GENERAL OVERVIEW OF RED CILLI PRODUCTION, CLUSTERS, PHM AND VALUE ADDITION

IN INDIA

4.1 INTRODUCTION

It is known as the most valuable crop of India. It is used as a principle ingredient of various curries and

chutneys, also used in vegetables, spices, condiments, sauces and pickles. Pungency in chillies is due

to the active constituent "Capsaicin", an alkaloid. The native home of chilli is considered to be Mexico

with secondary origin of Guatemala. Chilli was introduced in India by the Portuguese in Goa in the

middle of 17th century and since then it had rapidly spread throughout the country. Capsaicin has many

medicinal properties, especially as an anti-cancerous agent and instant pain reliever. It also prevents

heart diseases by dilating blood vessels. Major chilli growing countries are India, China, Pakistan,

Indonesia, Korea, Turkey and Sri Lanka in Asia; Nigeria, Ghana, Tunisia and Egypt in Africa; Mexico,

United States of America in North & Central America; Yugoslavia, Spain, Romania, Bulgaria, Italy and

Hungary in Europe and Argentina, Peru and Brazil in South America. India is the world leader in chilli

production followed by China & Pakistan. Andhra Pradesh, Maharashtra, Karnataka, Orissa, Tamil

Nadu, Bihar, UP and Rajasthan are the main chilly growing states.

Chilli is one of the most important commercial crops of India. It is grown almost throughout the country.

There are more than 400 different varieties of chillies found all over the world. It is also called as hot

pepper, cayenne pepper, sweet pepper, bell pepper, etc. Its botanical name is “Capsicum annuum”.

The world’ shortest chilli “Naga Jolokia” is cultivated in hilly terrain of Assam in a small town Tezpur,

India. Different varieties are grown for vegetables, spices, condiments, sauces and pickles. Chilli

occupies an important place in Indian diet. It is an indispensable item in the kitchen, as it is consumed

daily as a condiment in one form or the other. Among the spices consumed per head, dried chilli fruits

constitute a major share. Currently, chilies are used throughout the world as a spice and also in the

making of beverages and medicines. If some varieties of chillies are famous for red colour because of

the pigment ‘capsanthin,’ others are known for biting pungency attributed to ‘capsaicin.’ India is the only

country which is rich in many varieties with different quality factors. Chillies are rich in vitamins,

especially in vitamin A and C. They are also packed with potassium, magnesium and iron. Chillies have

long been used for pain relief as they are known to inhibit pain messengers, extracts of chilli peppers

are used for alleviating the pain of arthritis, headaches, burns and neuralgia. It is also claimed that they

have the power to boost immune system and lower cholesterol. They are also helpful in getting rid of

parasites of gut.

4.2 ORIGIN, DISTRIBUTION AND PRODUCTION OF CHILLI

Chilies are known from pre-historic times in Peru. They are believed to have originated in the tropical

America. It is also said that chillies have originated in the Latin American regions of the New Mexico

and Guatemala as a wild crop around 7500BC, as per the remains of the pre-historic Peru. The people

native to these places domesticated this crop in and around 5000 BC,. Chilli is said to be the first ever

domesticated crop in America. The three species C. annuum, C. frutescens and C. chinense evolved

from a common ancestor located in the North of the Amazon basin (NW-Brazil, Columbia). Further

evolution brought C. annuum and C. frutescens to Central America, where they were finally

Model DPR On Chilli Powder Processing Unit Page 9

domesticated (in México and Panamá, respectively), whereas C. chinense moved to the West and was

first put to cultivation in Perú. Two other species were first cultivated in Western South America: C.

baccatum in the Peruvian lowlands and C. pubescens at higher elevations, in the Andes (Perú, Bolivia,

Ecuador). At that time, chillies were cultivated by the farmers together with a primary crop to protect the

primary crop from any damage from birds. Columbus carried chilli seed to Spain in 1493. The cultivation

of chilli and Capsicum spread rapidly from Spain to Europe. The Portuguese brought capsicum from

Brazil to India during the year 1584. Chillies became popular in the whole of Asia rapidly and native

Asians started cultivating this crop as well. The south Asian climate suited this crop, and since its

introduction in the 16 century has been increasingly cultivated in south Asia. Chillies are the cheapest

spices available in India and are eaten across all groups of people. The most important chilli growing

states in India are Andhra Pradesh, Maharashstra, Karnataka and Tamil Nadu, which together

constitute nearly 75 percent of the total area. Andhra Pradesh tops the list in dry chilli production

followed by Tamil Nadu, Maharashtra, Orissa and Karnataka.

4.3 HEALTH BENEFITS AND NUTRITIONAL IMPORTANCE

Pungency in chilli is due to the alkaloid “capsaicin” contained in the pericarp and placenta of fruits, it

produces mild to intense spice when eaten. Capsaicin is a potent inhibitor of substance P, a

neuropeptide associated with inflammatory processes. The hotter the chili pepper, the more capsaicin

it contains. The hottest varieties include Naga Jalokia, habañero and Scotch bonnet peppers. Jalapeños

are next in their heat and capsaicin content, followed by the milder varieties, including Spanish

pimentos, and Anaheim and Hungarian cherry peppers. Capsaicin is being studied as an effective

treatment for sensory nerve fiber disorders, including pain associated with arthritis, psoriasis, and

diabetic neuropathy. When animals injected with a substance that causes inflammatory arthritis were

fed a diet that contained capsaicin, they had delayed onset of arthritis, and also significantly reduced

paw inflammation.

Fresh Chilli peppers are very rich in vitamin C: i.e. 111.0 mg. per 74 grams in comparison to only 37

mg. in oranges, which makes them very effective as immune system stimulants and healing agents

especially for cellular damage. Many folk remedies recommend Chilli pepper in wound cleaning

preparations for gangrene and open sores and even as a styptic, though more modern sources

generally advise against using Chilli on broken skin. While drying, Chilli loses most of its vitamin C, it

increases the vitamin A content by 100 times. Vitamin A is a powerful anti-oxidant and anti-inflammatory

agent. Chilli preparations have been used as a gargle to treat sore throat and laryngitis. Surprisingly, it

has been shown that Chillies do not aggravate or cause stomach ulcers. In fact, they have a

preventative effect, as stomach ulcers are mostly caused by bacteria and it’s antibacterial action kills

such bacteria. In folk-medicine they have also long been used to treat worms. Chilli has a very beneficial

effect on the circulatory system. Studies have shown that it counter act on cholesterol build up and

reduces platelet aggregation, thus reducing the risk of heart attacks and strokes. It also lowers high

blood pressure and increase peripheral circulation.

Model DPR On Chilli Powder Processing Unit Page 10

TABLE 3

NUTRITIONAL COMPOSITION OF CHILLI

Value {Per 100 gm}

Parameters CHILLIES DRY CHILLIES (GREEN)

Moisture 10.000 gm 85.700 gm

Protein 15.000 gm 2.900 gm

Fat 6.200 gm 0.600 gm

Minerals 6.100 gm 1.000 gm

Fibre 30.200 gm 6.800 gm

Carbohydrates 31.600 gm 3.000 gm

Energy 246.000 K cal 29.000 K gm

Calcium 160.000 mg 30.000 mg

Phosphorus 370.000 mg 80.000 mg

Iron 2.300 mg 4.400 mg

Vitamins

Carotene 345.000 µg 175.000 µg

Thiamine 0.930 mg 0.190 mg

Riboflavin 0.430 mg 0.390 mg

Niacin 9.500 mg 0.900 mg

Vitamin C 50.000 mg 111.000 mg

Minerals & Trace

Elements

Sodium 14.000 mg --

Potassium 530.000 mg --

Phytin Phosphorus 71.000 mg 7.000 mg

Magnesium -- 272.000 mg

Copper -- 1.400 mg

Manganese -- 1.380 mg

Molybdenum -- 0.070 mg

Zinc -- 1.780 mg

Chromium -- 0.040 mg

Oxalic Acid -- 67.000 mg

Caloric values

Chili (Dry) 297

Chili (Green) 229

Model DPR On Chilli Powder Processing Unit Page 11

4.5 CULTIVATION, BEARING AND POST-HARVEST MANAGEMENTS

Harvesting is done when the pods are well ripened and partially withered in the plant itself. The

harvested pods are kept in heaps either indoor or in shade away fromdirect sun light for 2 or 3 days so

as to develop uniform red colour and then dried in the sun by spreading them on clean dry polythene

sheets, cemented / concrete drying yards etc. Pods are spread out in thin layers for uniform drying with

frequent stirring to prevent mold growth and discolouration. The dried pods are heaped and covered by

clean gunny bags / polythene sheets. The moisture content of dry pods are kept at 8- 10 %. Improved

drying system could be used to ensure cleanliness and uniform colour of the product.

FIGURE 1

CHILLI CROP

Climate Requirement for Chilli Farming

The chili is a plant of tropical and sub -tropical region -It grows well in warm and humid climate and a

temperature of 20-25°C. Low moisture in soil during blossom development and fruit formation causes

the bud, de blossom and fruit drops. Excessive rainfall is detrimental to the crops, because it brings

about defoliation and rotting of the plant. As a rained crop, it is grown in areas receiving an annual

precipitation of 25-30 inches.

Soil Requirement for Chilli Farming

Chilli can be grown in a range of soils, but black soils which retain moisture for long periods are suitable

for rainfed crop whereas well drained soils, deltaic soils and sandy loams are good under irrigated

condition. However, in hills of Uttarakhand, chilli are grown in a wide range of soils ranging from sandy

to clay loam mixed with gravel and coarse sand.

Model DPR On Chilli Powder Processing Unit Page 12

FIGURE 2

HARVESTING OF CHILLI

Post-harvest Management:-

Harvesting is done when the pods are well ripened and partially withered in the plant itself. The

harvested pods are kept in heaps either indoor or in shade away from direct sun light for 2 or 3 days so

as to develop uniform red colour and then dried in the sun by spreading them on clean dry polythene

sheets, cemented / concrete drying yards etc. Pods are spread out in thin layers for uniform drying with

frequent stirring to prevent mold growth and discoloration. The dried pods are heaped and covered by

clean gunny bags / polythene sheets. The moisture content of dry pods are kept at 8- 10 %. Improved

drying system could be used to ensure cleanliness and uniform colour of the product.

After removing the extraneous matters like plant parts, etc. well dried pods should be packed in clean,

dry gunny bags and stored ensuring protection from dampness. Dunnage should be provided to stack

the packed bags to prevent moisture ingress from the floor. Care should be taken to stack the bags at

50 –60 cm away from the wall. Storing chilies for longer period may lead to deterioration. However, if

cold storage facilities are used, the product may be stored for 8-10 months. Insects, rodents and other

animals should be effectively prevented from getting access to the premises where chilli is stored.

1. Harvesting should be done during early mornings, It should be avoided during rains or just after

rains.

2. While harvesting fruits, care should be taken to hold stalks firmly and fruit should be pulled

upward gently, breaking the base of the stalk.

3. For dry chilies, care should be taken that the fruit should not be ripened or over ripened.

4. The harvesting should not be delayed as delayed harvesting gives poor quality produce.

5. The harvested fruits should be heaped indoor for 2-3 days, so that the partially ripe fruits, allows

the whole produce to develop a uniform red colour.

6. The best temperature for ripening is 22-25 C and direct sunlight is to be avoided since this can

result in development of white patches.

7. The ripen pods should be dried in the sun spreading them on clean dry polythene sheets,

cemented drying yard.

8. The moisture content of dry pods should be kept at 8-10%

9. Reverting solar dryer are used for drying helps in reducing of drying time.

Model DPR On Chilli Powder Processing Unit Page 13

10. Chillies should be stack at 50 to 60 cms. away from the wall.

11. Periodic fumigations during storage with methyl bromide and phosphine is useful to control

insects.

12. The product should not be stored for longer period except in case of cold storage with moisture

proof plastic liners (polythene bags) preferably between 0-10 C with 65 to 70 percent humidity.

13. If possible while transporting from field, plastic field crates in places of sacks may be used to

avoid mechanical damage.

4.6 PROCESSING AND VALUE ADDITION IN INDIA

Processed products such as dehydrated chilli, pickle, powder, paste, sauce, etc., can be prepared for

higher returns. Generally growers sell chilli directly even though real return can come only from

processed products. Hence, farmers must be educated in the processing of chilli for value addition.

Juice of chilli brings a warming flush to the skin and eased soreness. Capsicum has a tonic and

carminative effect and is especially useful in a tonic dyspepsia. Pungent types of chillies are used by

the pharmaceutical industry in the preparation of stimulant and counter irritant balms and in stomach

ache, carminative and stimulant formulation.

The pungency in chilli is due to the alkaloid capsaicin contained in the pericarp and placenta of fruits.

Capsaicin is a key ingredient in many liniments and together with other chemical compounds found in

chilli peppers is prescribed in the treatment of rheumatism and bruises. It is also used to treat stomach

aches involves poor functioning of stomach muscles. Capsaicins are also being used in clearing the

lungs and sinuses, enhance the flow of digestive juices, which trigger the brain to release endorphins

(natural pain killers), help to neutralize cavity causing acids, protect the body against cancer through

anti oxidant activity. Because of capsaicin’s specific excitatory and neurotoxic properties on c-fibres,

capsaicin has been extensively used for relieving pain and thermo regulation. Capsicum is administered

in the form of powder, tincture, lineament, plaster, ointment, medicated roll etc. Two types of pain relief

products are currently being marketed including cream containing 0.75 percent capsaicin (eg. Zostrice

TM) and plaster containing three percent oleoresin (Vorwek-TM). It also corrects bowel disorders and

it prevents the formation of puss in the wound and because the red-hot chilli pepper is an inhospitable

place for bacteria, its extracts have been used as antibacterial agents.

Model DPR On Chilli Powder Processing Unit Page 14

5 MODEL CHILLI POWDER PROCESSING UNDER FME SCHEME

5.1 LOCATION OF PROPOSED PROJECT AND LAND

The entrepreneur must provide description of the proposed location, site of the project, distance from

the targeted local and distant markets; and the reasons/advantages there of i.e. in terms of raw

materials availability, market accessibility, logistics support, basic infrastructure availability etc.

The ideal locations for establishment of exclusive Chilli Powder processing unit are in the production

clusters of Chilli growing states/Areas such as Andhra Pradesh, Karnataka, West Bengal, Uttar

Pradesh, Gujrat, Tamil Nadu and Maharashtra where adequate quantities of surplus raw materials can

be available for processing.

5.2 INSTALLED CAPACITY OF POCESSING PLANT

The maximum installed capacity of the Processing unit in the present model project is proposed as 150

tonns/annum or 500 kg/day input capacity of Chilli. The unit is assumed to operate 300 days/annum @

8-10 hrs/day. The 1st year is assumed to be construction/expansion period of the project; and in the

2nd year 70 percent capacity, 3rd year 80 percent capacity and 4th year onwards 90 percent capacity

utilization is assumed in this model project.

5.3 RAW MATERIAL REQURIMENT FOR THE UNIT

A sustainable food processing unit must ensure maximum capacity utilization and thus requires an

operation of minimum 250 days per year to get reasonable profit. Therefore, ensuring uninterrupted raw

materials supply requires maintenance of adequate raw material inventory. The processor must have

linkage with producer organizations preferably FPCs through legal contract to get adequate quantity

and quality of raw materials which otherwise get spoiled.

Model DPR On Chilli Powder Processing Unit Page 15

5.5 PROCESSING PROCESS

FIGURE 3

RED CHILLI POWDER PROCESS FLOWCHART

Harvesting

Drying

Shorting/ Grading

Stem Cutting

Crushing/ Milling

Sieving

Packing

Harvesting

Harvesting is done when the pods are well ripened and partially withered in the plant itself. The

harvested pods are kept in heaps either indoor or in shade away from direct sun light for 2 or 3 days so

as to develop uniform red colour.

Drying

Drying in the sun by spreading them on clean dry polythene sheets, cemented / concrete drying yards

etc. Pods are spread out in thin layers for uniform drying with frequent stirring to prevent mold growth

Model DPR On Chilli Powder Processing Unit Page 16

and discolouration. The dried pods are heaped and covered by clean gunny bags / polythene sheets.

The moisture content of dry pods are kept at 8- 10 %. Improved drying system could be used to ensure

cleanliness and uniform colour of the product.

Shorting and grading

Sorting is the process of grouping according to size, shape, weight, image and color. Grading is pre-

requisite for development of the modern marketing, trade and economy of any commodity. The Indian

chillies are graded mostly by farmers on the basis of colour and size, before they are brought in the

market. The damaged discoloured and immature pods are removed depending on market demand.

However, at traders level the other important quality parameter are moisture and stalks. Excess

moisture add weight to the pods but give room to various fungi to grow. Similarly, if the stalk of the pods

is broken, exposing the seeds entirely, the seeds may fall out. On the other hand in absence of optimum

moisture the pods may break and let off the seeds. Thus the seed and pod ratio in a lot is also a valuable

parameter of grade.

Dry Cleaning

Cleaning the spice prior to packaging and sale, is to ensure that the spice is of the highest quality and

will obtain the highest price. Cleaning should remove all the foreign matter that lowers the quality and

endangers the sale. The first step majorly is of de-stoning & leaf removing. Vibratory sieves are used

to remove sand, small stones, seeds & dust particles & air blower is used to remove leafs.

Steam Cutting

Chillies stem cutting machine is generally used to cut the stem of the red chillies in bulk amount saving

the time and labour costs. By using this machine the red chillies stems are easily cut. This machines

are generally used in mirchi powder making companies.

Crushing/ Milling

Process of milling is commonly also known as grinding process. Under this process the crushed parts

are milled & grinded to powder form. After 2-3 rounds of proper grinding fine chili powder is obtained.

Sieving

Centrifugal sifter with fine mesh can be used & replaced with traditional sifters. The internal shaft with

rubber blades rotate to break the lumps along with it passing through desired size of fine mesh to get

smooth fine chili powder.

Powder chilli packing

Red Chilli Powder Should having 8% moisture content for safe storage. Mostly packed in plastic

pouches.

Model DPR On Chilli Powder Processing Unit Page 17

5.6 MAEKRT DEMAND AND SUPPLY FOR RED CHILLI POWDER

Indian states like Andhra Pradesh, Gujarat, Rajasthan, Orissa and Madhya Pradesh are the five leading

states for the production of spices. The new age urban population around the world is extremely health

conscious which is causing rise in demands for organic spices. The three biggest clients of spice

manufacturers include retail, industrial and catering sector. Andhra Pradesh leads the country in the

production of chilli, with 49% Spices are generally sold at premium spices and also in greater demand

which can further enhance export revenues in major spice producing countries. Spices farming

mechanism starts at grass root level conserving the generative and renewing capacity of the soil, plant

nutrition, and soil management, yields nutritious food rich in vitality which has resistance to diseases.

Increasing demand of natural flavoring and coloring agents in food, medicinal properties and health

benefits are driving the spices market. There is high demand for spices from regions like Asia Pacific,

Middle East and Europe.

5.7 DETAIL RROJECT ASSUMPTIONS

This model DPR for Chilli powder unit is basically prepared as a template based on certain assumptions

that may vary with capacity, location, raw materials availability etc. An entrepreneur can use this model

DPR format and modify as per requirement and suitability. The assumptions made in preparation of this

particular DPR are given in This DPR assumes expansion of existing Red Chilli Processing unit by

adding Red Chilli Powder Processing line. Therefore, land and civil infrastructures are assumed as

already available with the entrepreneurs.

Herewith in this DPR, we have considered the assumptions as listed below in the tables of different

costs, which may vary as per region, seasons and machinery designs and supplier.

TABLE 4

PROJECT DETAILS

Detailed Project Assumptions

Parameter Value

1 Capacity of the processing unit 500 Kg/Day input Capacity of Chilli

2 Utilization of capacity 1st year implementation, 60% in 2nd year, 70% in

3rd year and 80% in 4th year onwards.

3 Working days per year 300 days

4 Working hours per day 8 hrs.

5 Interest on term and working 12%

capital loan

6 Repayment period Seven years with one-year grace period is

considered.

7 Average prices of raw material Rs. 70/Kg.

8 Final Product Chilli Powder

Model DPR On Chilli Powder Processing Unit Page 18

9 Recovery Rate 90%

10 Average Selling Price 140 Rs/Kg

TABLE 5

FIXED CAPITAL INVESTMENT

Sr. Particulars Size/ Quantity Total Unit Amount

No. Dimensions / (No) Area Cost (Rs) Amount

Specification (Sq (Rs) (Lakh)

ft)

A Capital Investment 1 Plot 3,50,000 3.50

Capital Investment 3,50,000

3.50

B Machinery & Equipment’s

1 Micro pulveriser with 1MT/hr 1 260000 2,60,000 2.60

10 HP

motor starter and all

accessories

2 Hanging weighing 100 kg 1 17000 17,000 0.17

Scale

3 Digital Weighing 100 kg 2 4,300 8,600 0.09

Machine

4 Band Sealer 2 2159 4,318 0.04

5 Packaging Machinery 2000 pack/ hr 1 650000 6,50,000 6.50

6 Sieving m/c. 15 kg/ hr 2 82,000 1,64,000 1.64

7 Miscellaneous 1 10000 10,000 0.10

Machinery & 11,13,918 11.14

Equipment’s

C Other Costs

C1 Utilities & Fittings

1 Water 70,000 0.70

2 Power

Total 70,000

0.70

C2 Other Fixed Assets

1 Furniture & Fixtures 80,000 0.80

2 Electrical Fittings

Total 80,000

0.80

C3 Pre-operative

Expenses

Model DPR On Chilli Powder Processing Unit Page 19

1 Legal Expenses, 90,000 0.90

Start -up Expenses,

Establishment Cost,

Consultancy fees,

Trials and others

2 Plastic Tray Capacity

3 Electrical Fittings

Total 90,000 0.90

C4 Contingency 2,00,000 2.00

Total 2,00,000 2.00

C Total Cost

(C1+C2+C3+C4) 4.40

4,40,000

II Total Cost (I+F+G) 19,03,918 19.04

TABLE 6

WORKING CAPITAL REQUIRMENTS

Sr. No. Description Quantity Unit Total Cost Total Total

Rate/ Kg (Rs) /Day Cost Cost

(Rs) / (Rs) /

Month Year

1 Chilli 500 70

35,000 8.75 87.50

2 Packaging Material 1,000 3.5 3,500

(1 kg or ½ Kg) 0.88 8.75

3 Labour - Cleaning, 12 300/day 3,600

Stem Removing 0.90 9.00

4 Supervisor / Manager 1 500/ day

600.00 0.15 1.50

5 Electricity 360

0.09 0.90

6 Transportation 500

0.13 1.25

7 Miscellaneous 300.00

0.08 0.75

Total Cost 43,860.00 10.97 109.65

Working Capital Margin 2,74,125.00 2.74

20%

Model DPR On Chilli Powder Processing Unit Page 20

TABLE 7

TOTAL PROJECT COST

Sr. No. Particulars Amount In Lakhs

i Land Development & Building Structure 3.50

ii Plant & Machinery 11.14

iii Other Fixed Assets 2.40

iv Working Capital Margin 2.74

v Contingency 2.00

vi Total Project Cost 21.78

TABLE 8

MEANS OF FINANCE

Sr. No. Particulars Amount In Lakhs

i Subsidy 10.00

ii Promoters Contribution 4.36

iii Term Loan 7.42

Total Means of Finance (1 to 3) 21.78

TABLE 9

EXPENDITURE, REVENUE AND PROFITABILITY

PARTICULARS+A2:G45 YEAR

1st yr 2nd yr 3rd yr 4th yr 5th yr 6th yr

Capacity % - 60.00 70.00 80.00 90.00 100.00

A. INCOME

Sales of Chilli Powder - 95.45 112.47 129.82 147.51 165.53

Total - 95.45 112.47 129.82 147.51 165.53

B.EXPENSES

Raw Material - 52.50 62.48 72.10 81.90 91.88

Consumables - - - - - -

Packing cost - 5.25 6.25 7.21 8.19 9.19

Transportation cost - 0.75 0.89 1.03 1.17 1.31

Direct employee cost - 6.30 7.50 8.65 9.83 11.03

Depreciation - 2.46 2.13 1.85 1.60 1.39

Office Rent -

Plant Electricity Cost - 0.54 0.64 0.74 0.84 0.95

Miscellaneous - 0.45 0.54 0.62 0.70 0.79

Office Expenses - 0.66 0.73 0.80 0.88 0.97

Model DPR On Chilli Powder Processing Unit Page 21

Telephonic Expenses - 0.06 0.60 0.66 0.73 0.80

Indirect Employee - 0.50 0.50 0.50 0.50 0.50

Repair & Maintenance - 0.50 1.50 1.65 1.82 2.00

Audit, Accounts & - 0.44 0.44 0.48 0.53 0.59

Compliance

Insurance 0.5 2 2 2 3

Total Cost - 70.91 86.19 98.49 111.11 124.03

Add :- Opening Stock - 8.39 9.93 11.46 13.02

Less :- Closing Stock - 8.39 9.93 11.46 13.02 14.61

Cost of Sales - 62.52 84.65 96.96 109.55 122.44

GROSS PROFIT - 32.93 27.81 32.86 37.96 43.09

- 34.50% 24.73% 25.31% 25.73% 26.03%

FINANCE EXPENSES

Interest on Term Loan 0.89 0.82 0.69 0.57 0.44 0.31

Interest On CC - - - - -

Total Interest 0.89 0.82 0.69 0.57 0.44 0.31

PROFIT BEFORE TAX -0.89 32.11 27.12 32.29 37.52 42.78

INCOME TAX (30%) -0.27 9.63 8.14 9.69 11.26 12.83

PROFIT AFTER TAX -0.62 22.47 18.98 22.60 26.26 29.94

TABLE 10

REPAYMENT SCHEDULE

Year Outstandi Disburs Total Surplus Interest Repay Total o/s Balanc

ng loan at e- ment outstan for payme ment of outgo Loan at e left

start of yr. ding repaym nt principa the end

Loan ent l of the

yr.

1 -0.00 1.57 0.89 0 0.89 7.42 0.68

7.42 7.42

2 9.35 0.82 1.06 1.88 6.36 7.47

7.42 7.42

3 14.97 0.69 1.06 1.76 5.30 13.21

6.36 6.36

Model DPR On Chilli Powder Processing Unit Page 22

4 18.29 0.57 1.06 1.63 4.24 16.66

5.30 5.30

5 4.24 21.91 0.44 1.06 1.50 3.18 20.41

4.24

6 3.18 25.13 0.31 1.06 1.37 2.12 23.75

3.18

7 2.12 26.42 0.19 1.06 1.25 1.06 25.17

2.12

8 1.06 31.40 0.06 1.06 1.12 (0.00) 30.28

1.06

TABLE 11

ASSETS DEPRECIATION

PARTICULARS YEAR

1st yr 2nd yr 3rd yr 4th yr 5th yr 6th yr

Land & Building Structure

Opening Bal. 3.50 3.15 2.84 2.55 2.30

Additions 3.50

Less :- Depreciation @ 10% 0.35 0.32 0.28 0.26 0.23

Closing Bal. 3.50 3.15 2.84 2.55 2.30 2.07

PARTICULARS YEAR

1st yr 2nd yr 3rd yr 4th yr 5th yr 6th yr

Plant & Machinery

Opening Bal. 11.14 9.47 8.05 6.84 5.81

Additions 11.14

Less :- Depreciation @ 15% 1.67 1.42 1.21 1.03 0.87

Closing Bal. 11.14 9.47 8.05 6.84 5.81 4.94

PARTICULARS YEAR

1st yr 2nd yr 3rd yr 4th yr 5th yr 6th yr

Model DPR On Chilli Powder Processing Unit Page 23

Other Required Material &

Accessories

Opening Bal. 4.40 3.96 3.56 3.21 2.89

Additions 4.40

Less :- Depreciation @ 10% 0.44 0.40 0.36 0.32 0.29

Closing Bal. 4.40 3.96 3.56 3.21 2.89 2.60

TOTAL DEPRECIATION -

PARTICULARS YEAR

1st yr 2nd yr 3rd yr 4th yr 5th yr 6th yr

Land & Building Structure - 0.35 0.32 0.28 0.26 0.23

Plant & Machinery - 1.67 1.42 1.21 1.03 0.87

-

-

Other Required Material & - 0.44 0.40 0.36 0.32 0.29

Accessories

TOTAL DEPRECIATION - 2.46 2.13 1.85 1.60 1.39

TABLE 12

FINANCIAL ASSESSMENT OF PROJECT

YEAR

1st yr 2nd yr 3rd yr 4th yr 5th yr 6th yr 7th yr 8th yr

Cost 124.03

19.04 70.91 86.19 98.49 111.11 125.05 125.57

Benefit

- 95.45 112.47 129.82 147.51 165.53 167.19 168.86

Discounting

Rate 0.91 0.83 0.75 0.68 0.62 0.56 0.51 0.47

P.V Cost

17.31 58.60 64.75 67.27 68.99 70.01 64.17 58.58

P.V Benefit

- 78.88 84.50 88.67 91.59 93.44 85.79 78.78

Total P.V Cost 469.69

Total P.V Benefit 601.64

Benefit Cost Ratio 1.28

Model DPR On Chilli Powder Processing Unit Page 24

TABLE 13

BREAK EVEN ANALYSIS

PARTICULARS Year

1st yr 2nd yr 3rd yr 4th yr 5th yr 6th yr 7th yr

Annual Production

in Kg - 67,500 78,750 90,000 1,01,250 1,12,5 1,12,5

00 00

Revenue

- 95.45 112.47 129.82 147.51 165.53 167.19

Selling Cost Per -

Kg 141.40 142.81 144.24 145.68 147.14 148.61

Office & General

Expenses - 1.16 1.77 1.94 2.14 2.35 2.59

Depreciation

- 2.46 2.13 1.85 1.60 1.39 1.21

Total Fixed Cost

- 3.62 3.90 3.79 3.74 3.74 3.79

Total Fixed Cost -

Per Kg 5.36 4.95 4.21 3.69 3.33 3.37

Total Variable -

Cost 64.80 77.11 88.99 101.09 113.40 113.40

Variable Cost Per -

Kg 96.00 97.92 98.88 99.84 100.80 100.80

Contribution -

30.65 35.35 40.83 46.42 52.13 53.79

Contribution per -

Unit 45.40 44.89 45.36 45.84 46.34 47.81

Contribution in % - 32% 31% 31% 31% 31% 32%

Break Even Point -

kg 0 0 0 0 0 0

Break Even Point -

Rs 2.94 3.21 3.10 3.05 3.06 3.12

Break Even In % -

11.82 11.02 9.28 8.05 7.18 7.05

Margin Of Safty -

92.50 109.25 126.71 144.45 162.48 164.07

Model DPR On Chilli Powder Processing Unit Page 25

FIGURE 4

PIA CHART FOR BETTER UNDERSTANDING OF EXPENCES OF EACH

HEAD

FIGURE 5

PLANT LAYOUT

Model DPR On Chilli Powder Processing Unit Page 26

5.8 MACHINERY SAPPLIERS

There are many machinery suppliers available within India for processing machineries and

equipment. Some of the suppliers are:

• Stellar Food Tech. Pune, Maharashtra, India

• Proveg Engineering & Food Processing Private Limited

• Near Swad Kolhapur Restaurant, Chikhli, Pune

• Lithotech Food & Spice Machinery

• Vasai East, Mumbai

• Varahi Industries

• GIDC Vatwa, Ahmedabad

• Srinidhi Industries

• 17. Bommasandra, Bengaluru

Model DPR On Chilli Powder Processing Unit Page 27

6 LIMITATIONS OF MODEL DPR AND GUIDELINES FOR ENTREPRENEURS

6.1 LIMITATIONS OF MODEL DPR

i. This DPR has provided only the basic standard components and methodology to be adopted by an

entrepreneur while submitting a proposal under the Formalization of Micro Food Processing Enterprises

Scheme of MoFPI.

ii. This DPR is made to provide general methodological structure not for specific

entrepreneur/crops/location. Therefore, information on the entrepreneur, forms and structure

(proprietorship/partnership/cooperative/ FPC/joint stock company) of business, background of

proposed project, location, raw material base/contract sourcing, entrepreneur’s own SWOT analysis,

market research, rationale of the project for specific location, community advantage/benefit,

employment generation etc are not given in detail.

iii. The present DPR is based on certain assumptions on cost, prices, interest, capacity utilization, output

recovery rate and so on. However, these assumptions in reality may vary across places, markets and

situations; thus the resultant calculations will also change accordingly.

6.2 GUIDELINES FOR ENTEPRENURES

i. The success of any prospective food processing project depends on how closer the assumptions

made in the initial stage are with the reality of the targeted market/place/situation. Therefore, the

entrepreneurs must do its homework as realistic as possible on the assumed parameters.

ii. This model DPR must be made more comprehensive by the entrepreneur by including information

on the entrepreneur, forms and structure (proprietorship/partnership/cooperative/ FPC/joint stock

company) of entrepreneur’s business, project location, raw material costing base/contract sourcing,

detailed market research, comprehensive dehydrated product mix based on demand, rationale of the

project for specific location, community advantage/benefit from the project, employment generation,

production/availability of the raw materials/crops in the targeted area/clusters and many more relevant

aspects for acceptance and approval of the competent authority.

iii. The entrepreneur must be efficient in managing the strategic, financial, operational, material and

marketing aspects of a business. In spite of the assumed parameter being closely realistic, a project

may become unsustainable if the entrepreneur does not possess the required efficiency in managing

different aspects of the business and respond effectively in changing situations.

iv. The machineries should be purchased after thorough market research and satisfactory

demonstration.

Model DPR On Chilli Powder Processing Unit Page 28

v. The entrepreneur must ensure uninterrupted quality raw materials’ supply and maintain optimum

inventory levels for smooth operations management.

vi. The entrepreneur must possess a strategic look to steer the business in upward trajectory.

vii. The entrepreneur must maintain optimum (not more or less) inventory, current assets. Selecting

optimum source of finance, not too high debt-equity ratio, proper capital budgeting and judicious

utilization of surplus profit for expansion is must.

viii. The entrepreneur must explore prospective markets through extensive research, find innovative

marketing strategy, and maintain quality, adjust product mix to demand.

ix. The entrepreneur must provide required documents on land, financial transaction, balance sheet,

further project analysis as required by the competent authority for approval.

x. The entrepreneur must be hopeful and remain positive in attitude while all situations.

Model DPR On Chilli Powder Processing Unit Page 29

You might also like

- Full Download Fundamentals of HVACR 3rd Edition (Ebook PDFDocument41 pagesFull Download Fundamentals of HVACR 3rd Edition (Ebook PDForonzaiorgu100% (2)

- Electrolux EW23BC71IS0 Refrigerator Tech SheetDocument2 pagesElectrolux EW23BC71IS0 Refrigerator Tech SheetEdison Espinal0% (1)

- Ghee DPRDocument25 pagesGhee DPRThirusuganNo ratings yet

- Coastal Marine Eutrophication: A Definition, Social Causes, and Future ConcernsDocument22 pagesCoastal Marine Eutrophication: A Definition, Social Causes, and Future ConcernsAndrés Martínez TrejoNo ratings yet

- Preface ChhilliDocument80 pagesPreface Chhillisatya6a9246No ratings yet

- Chillies-Is 2322 2010Document8 pagesChillies-Is 2322 2010anweshaccNo ratings yet

- Chiles SecosDocument108 pagesChiles Secosnor84c01No ratings yet

- Selecting The Electric Vibrator: Vibration Systems and MethodsDocument15 pagesSelecting The Electric Vibrator: Vibration Systems and Methodsganesh ganeshNo ratings yet

- Naga Bhut JolokiaDocument12 pagesNaga Bhut JolokiaPrahari aichNo ratings yet

- The DIRK PFA Classification Products 01Document15 pagesThe DIRK PFA Classification Products 01Ankit DwivediNo ratings yet

- Introduction To Internship & Industy Profile: Chapter - 1Document40 pagesIntroduction To Internship & Industy Profile: Chapter - 1Ajay Kumar PNo ratings yet

- Unit 2 - Size ReductionDocument7 pagesUnit 2 - Size ReductionAllen de GuzmanNo ratings yet

- Solar Drying of Tropical Agricultural CropsDocument18 pagesSolar Drying of Tropical Agricultural CropsashisbhuniyaNo ratings yet

- AND OOD: Operates in His Life. The Approach Is The FollowingDocument26 pagesAND OOD: Operates in His Life. The Approach Is The FollowingsunyatadvaitaNo ratings yet

- Kamalascreens CatalogueDocument1 pageKamalascreens CatalogueWalid M. Abu-SaraNo ratings yet

- Particle Tech ReportDocument5 pagesParticle Tech ReportBea UyNo ratings yet

- Side Gravy For Biryani: InstructionDocument6 pagesSide Gravy For Biryani: InstructionsaransivamNo ratings yet

- Porter's 5 Forces Benchmarking (Porter's Value Chain) Porter's Generic StrategiesDocument38 pagesPorter's 5 Forces Benchmarking (Porter's Value Chain) Porter's Generic StrategiesSandeep Kaur SraNo ratings yet

- Cryogenic GrindingDocument24 pagesCryogenic GrindingV P SinghNo ratings yet

- Bin Vibrator CatalogDocument30 pagesBin Vibrator CatalogAlvaro Patricio Arroyo HernandezNo ratings yet

- For The Sambhar: 1 Cup 1 1 2 1 Cut Into 4 Pieces 1 1 TBSP To TasteDocument1 pageFor The Sambhar: 1 Cup 1 1 2 1 Cut Into 4 Pieces 1 1 TBSP To TasteKamalambalBNo ratings yet

- 6 Finger MilletDocument30 pages6 Finger Milletbasil piusNo ratings yet

- Food of KarnatakaDocument42 pagesFood of Karnatakaashu346No ratings yet

- INGREDIENTS (Measuring Cup Used, 1 Cup 250 ML) : Dal Makhani - One of The Most Popular Punjabi Lentil RecipeDocument2 pagesINGREDIENTS (Measuring Cup Used, 1 Cup 250 ML) : Dal Makhani - One of The Most Popular Punjabi Lentil Recipekarangulati01No ratings yet

- Tea MasalaDocument1 pageTea Masalavpv433No ratings yet

- Tomato Chutney RecipeDocument1 pageTomato Chutney RecipejyosriNo ratings yet

- Simple Juicing RecipesDocument1 pageSimple Juicing Recipesaabb180890No ratings yet

- Tea GuideDocument6 pagesTea Guidesang2112No ratings yet

- Otti CharuDocument4 pagesOtti CharuPrashanth Kannar KNo ratings yet

- A Study On Consumer Usage and Satisfaction Regarding Sakthi Masala in Chinnamanur TownDocument14 pagesA Study On Consumer Usage and Satisfaction Regarding Sakthi Masala in Chinnamanur TownVijay KarthiNo ratings yet

- Export of Red ChilliesDocument31 pagesExport of Red ChilliesViraj PisalNo ratings yet

- The Secrets of TeaDocument2 pagesThe Secrets of TeaVicente Bercasio IINo ratings yet

- Principles of Trading Based On Moving AveragesDocument2 pagesPrinciples of Trading Based On Moving AveragesJack XuanNo ratings yet

- Tea and CoffeeDocument27 pagesTea and CoffeeRam saran KhanalNo ratings yet

- "Adulteration in Dairy Products and Spices": Project Report OnDocument21 pages"Adulteration in Dairy Products and Spices": Project Report OnShubhangi TiwariNo ratings yet

- Food Grains MachineryDocument39 pagesFood Grains MachinerykarthiNo ratings yet

- Design and Fabrication of A Pedal Powered Sieving MachineDocument34 pagesDesign and Fabrication of A Pedal Powered Sieving MachineJose Anthony Gutang OjedaNo ratings yet

- Effect of Grinding Methods On Powder Quality of King Chilli: Singam Suranjoy Singh Bhupendra M Ghodki T. K. GoswamiDocument9 pagesEffect of Grinding Methods On Powder Quality of King Chilli: Singam Suranjoy Singh Bhupendra M Ghodki T. K. GoswamiAnonymous fG9C1xxooQNo ratings yet

- Ginger Coconut Chutney: IngredientsDocument9 pagesGinger Coconut Chutney: IngredientsSandeep Kaur SraNo ratings yet

- Roti CookBookDocument11 pagesRoti CookBookMKPashaPashaNo ratings yet

- Chilli Peppers BrochureDocument74 pagesChilli Peppers BrochurealbertNo ratings yet

- AimDocument2 pagesAimAmit RaiNo ratings yet

- QuestLock - A Soluble Phosphorus Free Detergent Builder Granule PDFDocument21 pagesQuestLock - A Soluble Phosphorus Free Detergent Builder Granule PDFtmlNo ratings yet

- Machines ManufacturerDocument6 pagesMachines ManufacturerArasan ArasanNo ratings yet

- Red Chilli PowderDocument2 pagesRed Chilli PowderRohan MaliNo ratings yet

- Woodlands Menu 14 Feb 2011.indd 1 22/02/2011 09:20Document9 pagesWoodlands Menu 14 Feb 2011.indd 1 22/02/2011 09:20Rakesh BajajNo ratings yet

- For The Chole Masala:: MethodDocument4 pagesFor The Chole Masala:: MethodleoharshadNo ratings yet

- Value Addition and Market Linkages in MilletsDocument106 pagesValue Addition and Market Linkages in MilletsMitchNo ratings yet

- Clean and GradingDocument26 pagesClean and Gradingvishal_cae4359No ratings yet

- Process of Extracting Chili OleoresinDocument6 pagesProcess of Extracting Chili OleoresinDavid UribeNo ratings yet

- Small Millet Processing Machines Experience of DHANDocument17 pagesSmall Millet Processing Machines Experience of DHANdivakarNo ratings yet

- Idly Podi (Ulunthu Podi) : IngredientsDocument4 pagesIdly Podi (Ulunthu Podi) : IngredientsJay KumarNo ratings yet

- Diversity of Leaves Betel Tulsi Curry Mango Banana Coconut Lemon Neem TeaDocument5 pagesDiversity of Leaves Betel Tulsi Curry Mango Banana Coconut Lemon Neem TeaJasvinder SinghNo ratings yet

- Spices and MasalaDocument29 pagesSpices and MasalaShubham BansalNo ratings yet

- Analysis of Tea Material Culture in China and BritainDocument6 pagesAnalysis of Tea Material Culture in China and Britainavani4593No ratings yet

- Spice Processing Machine USDDocument33 pagesSpice Processing Machine USDMohammed SirelkhatimNo ratings yet

- Saffron Flavour Powder PDFDocument3 pagesSaffron Flavour Powder PDFSureshkumar SekarNo ratings yet

- Title Proposal Sand Sieve MachineDocument7 pagesTitle Proposal Sand Sieve MachinedecrujekylaNo ratings yet

- Spices Cryo-Grinding UnitDocument7 pagesSpices Cryo-Grinding Unitbenrakesh75No ratings yet

- Plant Desin Report For Spice ProductionDocument7 pagesPlant Desin Report For Spice ProductionUmar Mohammad Mir0% (1)

- DPR DcoconutDocument29 pagesDPR DcoconutPRAVEEN KUMARNo ratings yet

- DPR SjuiceDocument28 pagesDPR SjuiceInocencio HoracioNo ratings yet

- DPR - Ginger PasteDocument43 pagesDPR - Ginger PasteAJITHKUMARNo ratings yet

- Pudukkottai Road, Thanjavur, Tamil Nadu Ministry of Food Processing Industries, Government of IndiaDocument22 pagesPudukkottai Road, Thanjavur, Tamil Nadu Ministry of Food Processing Industries, Government of IndiaAnayra SharmaNo ratings yet

- 1Document40 pages1Bharat GouripurNo ratings yet

- Aluminium Glass Shutter Profile 2Document2 pagesAluminium Glass Shutter Profile 2Bharat GouripurNo ratings yet

- Eoi Notice Dated 27.07.2023Document6 pagesEoi Notice Dated 27.07.2023Bharat GouripurNo ratings yet

- MT Handbook GrainDocument250 pagesMT Handbook GrainBharat GouripurNo ratings yet

- ARKA SERIES WSMD 515 545 WEL E and PD 515 545 144 MP HC 08 10 04 2023 63a1cb9b97Document2 pagesARKA SERIES WSMD 515 545 WEL E and PD 515 545 144 MP HC 08 10 04 2023 63a1cb9b97Bharat GouripurNo ratings yet

- RESUME and Work Experience 080723Document9 pagesRESUME and Work Experience 080723Bharat GouripurNo ratings yet

- Eoi Extension NoticeDocument1 pageEoi Extension NoticeBharat GouripurNo ratings yet

- 11 - Chapter 2Document37 pages11 - Chapter 2Bharat GouripurNo ratings yet

- Auditorium PlanDocument1 pageAuditorium PlanBharat GouripurNo ratings yet

- Class - Section - Wise - ATSEC ADocument1 pageClass - Section - Wise - ATSEC ABharat GouripurNo ratings yet

- GROHE Specification Sheet 39328000Document2 pagesGROHE Specification Sheet 39328000Bharat GouripurNo ratings yet

- CIE - MIS Architecture Architecture Semester6 SECBDocument2 pagesCIE - MIS Architecture Architecture Semester6 SECBBharat GouripurNo ratings yet

- CIE - MIS Architecture Architecture Semester6 SECBDocument2 pagesCIE - MIS Architecture Architecture Semester6 SECBBharat GouripurNo ratings yet

- School RequirementsDocument3 pagesSchool RequirementsBharat GouripurNo ratings yet

- Parent LetterDocument38 pagesParent LetterBharat GouripurNo ratings yet

- CIE - MIS Architecture Architecture Semester6 SECADocument2 pagesCIE - MIS Architecture Architecture Semester6 SECABharat GouripurNo ratings yet

- CIE - MIS Architecture Architecture Semester2 SECBDocument1 pageCIE - MIS Architecture Architecture Semester2 SECBBharat GouripurNo ratings yet

- Quiz GuideDocument18 pagesQuiz GuideBharat GouripurNo ratings yet

- Sheet 8Document8 pagesSheet 8Bharat GouripurNo ratings yet

- Resource Center N Exibitin ZoningDocument1 pageResource Center N Exibitin ZoningBharat GouripurNo ratings yet

- Zoning LibraryDocument1 pageZoning LibraryBharat GouripurNo ratings yet

- Mikhail Dzemchanka - The Secret Lives of AnimalsDocument5 pagesMikhail Dzemchanka - The Secret Lives of Animalsz.hiyogu.dmNo ratings yet

- Procedure Text Examples: How To Charge Hand Phone BatteryDocument3 pagesProcedure Text Examples: How To Charge Hand Phone BatteryNonna WiddaNo ratings yet

- 01 Introductin To Cost AccountingDocument8 pages01 Introductin To Cost Accountingankur guptaNo ratings yet

- ENGLISH 6 - REVISION 1ST Term - KEYDocument10 pagesENGLISH 6 - REVISION 1ST Term - KEYWhere KayNo ratings yet

- Types of MilkDocument5 pagesTypes of Milkdeon kumukwayaNo ratings yet

- Ijiiiilessonl: Information Questions With Be Usage and FormDocument9 pagesIjiiiilessonl: Information Questions With Be Usage and FormDOCENTE BARBARA JULIA ARROYO SALGADONo ratings yet

- Chapter1 Milk TeaDocument4 pagesChapter1 Milk TeaFelicity Capiral100% (1)

- Steak 'N Mate Combos Aussie-Tizers: (Served Without Bread)Document1 pageSteak 'N Mate Combos Aussie-Tizers: (Served Without Bread)Manuel GomezNo ratings yet

- Contoh Soal Tryout Bahasa InggrisDocument9 pagesContoh Soal Tryout Bahasa Inggriszein sholikunNo ratings yet

- Watashi No Shiawase Na Kekkon WN Vol.1Document81 pagesWatashi No Shiawase Na Kekkon WN Vol.1Subhasish DasNo ratings yet

- Importance of Healthy Eating - EditedDocument4 pagesImportance of Healthy Eating - EditedEdwin KembzNo ratings yet

- Dutch For EveryoneDocument170 pagesDutch For EveryonewoudttobiasNo ratings yet

- Group 3 EntrepDocument3 pagesGroup 3 EntrepShairene DimaculanganNo ratings yet

- Activities in PhotosynthesisDocument10 pagesActivities in Photosynthesisvanshrajsingh.14082009No ratings yet

- Mr. Karu Manso 800Document1 pageMr. Karu Manso 800metalgirl 221No ratings yet

- Planning Case studyDocument16 pagesPlanning Case studykhushi28inNo ratings yet

- Ncm+105.Lesson9.Minerals WaterDocument11 pagesNcm+105.Lesson9.Minerals WaterBeverly Joy TumilapNo ratings yet

- Colectie Personala DenumiriDocument8 pagesColectie Personala DenumiriDori VioletteNo ratings yet

- English Exams G6Document13 pagesEnglish Exams G6macey3721No ratings yet

- Demala Hotpot - Google SearchDocument1 pageDemala Hotpot - Google SearchAlisya DhaniahNo ratings yet

- How To Cook Sinigang Na Bagang Part 6Document4 pagesHow To Cook Sinigang Na Bagang Part 6KukuruuNo ratings yet

- Feasibility Study - Chapter IDocument3 pagesFeasibility Study - Chapter IBhenil Bon VelasquezNo ratings yet

- Read The Text and Choose The Best Answer. Write Your Answers (A, B, C, or D) in The Numbered BoxDocument4 pagesRead The Text and Choose The Best Answer. Write Your Answers (A, B, C, or D) in The Numbered Boxhuu hungNo ratings yet

- Verbs in Past ParticipleDocument6 pagesVerbs in Past ParticipleNexeli Cristal Ramirez MartinezNo ratings yet

- Soal Bhsa Inggris Kls 2Document3 pagesSoal Bhsa Inggris Kls 2Saidah saidahNo ratings yet

- Ms 2043 2007Document14 pagesMs 2043 2007phcie.wendlamitaNo ratings yet