BPR TABLET Jar

BPR TABLET Jar

Uploaded by

BIONIAL HEALTHCARECopyright:

Available Formats

BPR TABLET Jar

BPR TABLET Jar

Uploaded by

BIONIAL HEALTHCAREOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

BPR TABLET Jar

BPR TABLET Jar

Uploaded by

BIONIAL HEALTHCARECopyright:

Available Formats

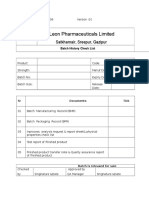

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

1 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

1.0 PRODUCT INFORMATION

Brand Name

Product Generic name :

Batch Number :

Batch Size :

Manufacturing Date :

Expiry Date :

M.R.P : Shelf :

Life

Mfg. Lic. No. : 1994-OSP & 2054 B

Packing Specification :

Date of commencement :

Date of completion :

AFTER BATCH COMPLETION:

Checked By(Manager -Production) Signature: Date:

Approved By(Manager -Q.A) Signature: Date:

2.0 CONTENTS OF BPR

S. No. Particulars Checked by Checked

Production by IPQA

1. Set Parameter of Alu Alu, Poly Strip & Blister packing machine & change part

2. Packing Material Requisition Slip

3. Line Clearance of dispensing

4. Weighing Tags

5. General instruction

6. Over printing Details of Packing Material

7. Line Clearance for Batch Coding

8. Specimen of carton

9. Line Clearance for Packing & Packing Instructions

10. Specimen of Foil

11. Testing Requisition Slip of finished Tablets samples

12. In process Sheets of Packing

13. Reconciliation of Packing Material

14. Finish Good Transfer Note

15. Revision History

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER MANAGER

Designation

PRODUCTION PRODUCTION QA

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

2 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

Sign. of Production Chemist Sign. of IPQA Officer

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER MANAGER

Designation

PRODUCTION PRODUCTION QA

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

3 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

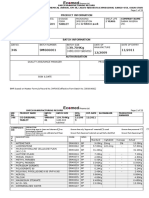

6.0 PACKING MATERIAL REQUISITION SLIP Brand Name :

Sr. Std. Qty. Qty.

Issued Checked Verified.

No Units Qty. Required Issued Analytical

Ingredient By . By By.

. for 1.0 for _____ Report No.

(Store) (Prod.) (IPQA)

Lac Lac

HDPE Jar Nos. ………

1.

(………..cc) +

2%

Label

Nos.

2. …………….. Tablet ………

5%

Carton Nos. ………

3. ………...…. Tablets +1%

5/7 Ply Shipper Nos.

4.

BOPP Tape Nos.

5.

Requested by Verified by Issued by Received by

Production Head QA Head Store Production Chemist

(Sign/Date) (Sign/Date) (Sign/Date) (Sign/Date)

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

4 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

7.0 DISPENSING PROCESS: Check for line clearance as per SOP No. : BH/QA/031

LINE CLEARANCE FOR DISPENSING

Date: Time:

Previous Product Name: Previous Product Batch No.:

Sr. Check points Checked by Verified Remarks

No. (Production) by (Ok/Not

(✓)or (X) (IPQA) Ok)

(✓)or (X)

Check the cleanliness of the room and ensure

1. that it is free from the remains of the previous

batch.

Ensure that the area is free from previous

2.

product.

Check the temperature & relative humidity of

the area

3.

[I.H. Limit: Temp = NMT 300C, RH=

NMT 70%]

Containers / Poly bags used for dispensing

4.

are clean & bear status labels.

5. Check authorized BPR is available

6. Waste bin should be cleaned

Checked By (Production Chemist) Verified By (IPQA Officer)

Signature & Date Signature & Date

8.0 SPACE FOR WEIGHING TAGS

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

5 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

Check point Checked By Verified By Remarks

(Production Chemist) (IPQA Officer)

Check the Weighing tags are attached or not.

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

6 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

9.0 GENERAL INSTRUCTIONS

Line Clearance to be taken by Production in presence of QA at the start of batches and every day before

start of operation.

Start up checks to be performed by Production & QA everyday at the start of activity or after any

Breakdown.

All the Operations must be carried out under strict Environmental Conditions. Temperature Limit

NMT30 and Relative Humidity (RH) NMT50

Product shall be properly labeled at all stages during the processing.

Check that the right packaging materials are received from stores & quantities of each item are as per the

standard packaging order.

Destroyed The Entire Leak Test Sample.

Wear hand gloves and nose mask during primary packing of batch.

Do not overwrite in the BPR. If the initial data is wrongly entered, cancel the data by single stroke across

and across the initial with data and write the correct data.

Receive QC released batch from manufacturing department and counter check the weight.

Perform in-process check and reconcile the batch and record the same in BPR.

After completion of batch, transfer the Finished Goods to Finished Goods Store.

After completion of batch/shift, ensure that the machine is switched off and area is cleaned.

The persons working in area must follow proper gowning as per the respective SOP.

Any deviation from the BPR must be done with prior approval of QA.

In case of any non compliance, stop the operation and report to the officer concerned.

10.0 OVER PRINTING DETAILS OF PACKING MATERIAL

MOTHER BATCH DETAILS

PRODUCT GENERIC NAME :

MOTHER BATCH NUMBER :

Overprinting for foil & cartons

Product Name :

Batch No. : Mfg. license No. : 1994-OSP & 2054-B

Mfg. Date : Exp. Date :

Order qty : M.R.P :

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

7 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

Checked By (Production Chemist) Verified By (IPQA Officer)

*(For Batch details refer to Batch Allocation Sheet of BMR)

11.0 CODING PROCESS: Check for Line Clearance as per SOP No. BH/QA/031

LINE CLEARANCE FOR BATCH CODING

Date: Time:

Previous Product Name: Previous Product Batch No.:

Equipment Name Equipment ID No.

Over printing coding machine BH/PGT/OPR/PCM/01

Sr. Check points Checked by Verified Remarks

No. (Production) by (Ok/Not

(✓)or (X) (IPQA) Ok)

(✓)or (X)

1. Check the cleanliness of the Area.

Ensure the machine & conveyor belt are neat

2.

& clean.

3. Ensure the area is free from previous product.

Check the temperature & relative humidity of

the area

4.

[I.H. Limit: Temp.= NMT 300C, RH=

NMT 50%]

Check the proper status labeling on the

5.

machines.

Check proper gowning should be followed in

6.

respective area.

7. Waste bin should be cleaned

8. Ensure the status label updated

Checked By (Production Chemist) : Verified By (IPQA Officer) :

Signature & Date: Signature & Date:

11.1 EQUIPMENT OPERATION DETAILS :-

Name of Date of Coding time Coding In Actual Done Checked Remarks

Material Coding Rejection Coded by By (Prod.)

From To

Material

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

8 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

11.2 IN-PROCESS CHECKS OF CARTONS OVERCODING :-

MRP (PER Checked Verified by

Date/Time Product Batch No. Mfg Exp By (Prod.) (IPQA)

………...TAB.)

11.3 SPECIMEN OF CARTON

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

9 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

10 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

12.0 PACKING: Check for Line Clearance as per SOP No. : BH/QA/031

LINE CLEARANCE FOR PACKING

Date: Time:

Previous Product Name: Previous Product Batch No.:

Equipment Name Equipment ID No.

Sr. Check points Checked by Verified Remarks

No. (Production) by (Ok/Not

(✓)or (X) (IPQA) Ok)

(✓)or (X)

Check the cleanliness of the respective

1.

material air lock/Pass box/Area.

Ensure the machine & conveyor belt are neat

2.

& clean.

3. Ensure the area is free from previous product.

Check the temperature & relative humidity of

the area

4.

[I.H. Limit: Temp.= NMT 300C, RH=

NMT 50%]

Check the differential pressure of the area

5.

[I.H. Limit: NLT 6 Pascal]

Toolkit and other unwanted things should be

6.

removed from the area .

Check proper gowning should be followed in

7.

respective area.

8. Waste bin should be cleaned

9. Ensure the status label updated

Checked By (Production Chemist) Verified By (IPQA Officer)

Signature & Date Signature & Date

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

11 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

S. Packing Instructions Date Time Done Checked Verified

No. From To By By by

(Prod.) (IPQA)

12. Jar Filling:

1 a)Ensure the Jar filling area should be clean before

the start of jar filling.

b)Fill the required no. of tablets according to weight

manually in recommended jar.

c)Put the silica gel in the filled bottle.

d)Tight the jar with lid.

Jar Sealing:

After filling of tablets in jar seal the bottle through

induction sealing machine by tracing the induction

heat bottom on filled bottle cap up to 0.5 to 0.8 sec.

Labeling of Jar:

a)After filling and sealing of the jar transfer the bottle

in secondary packing department.

b)Take the printed label and paste on the jar manually

and packed in corrugated boxes

12. Start Packing as per current packing order with REFER TO IN PROCESS CONTROL SHEET

2 following Instruction

Packing of Jar in Carton:

Place 1 labeled jar in 1 carton.Each carton is inspected

for clarity and corrections of printed matter.

Packing of cartons in Master Pack:

Pack _____ cartons (each containing 1 jar ) in one

master pack.

a) Master pack is then closed by another worker, who

checks that correct numbers of cartons packed in

master pack. Master pack is closed using BOPP

adhesive tape.

Packing in Master(without carton ) \

______jar is packed in one shrink poly bag,

which is then sealed properly using hand sealing

machine. After sealing, it is then passed through

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

12 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

Shrink Packing Machine, for shrink packing.

Master packs are packed with ____ labeled

bottles in a manner(in one layer)

A corrugated plate is placed above these bottles.

Again pack _____labeled bottles are packed in a

manner(2nd layer).Master pack is closed using

BOPP adhesive tape

S.No Parameters Limit Frequency

1. Clarity of overprinted matter Should be clean& At the start &after every 60 min.

legible

2. Correctness of overprinted As per printing At the start & after change of roll

matter Instructions

3. Number of tablets per Jar ______ tablets /Jar At the start &after every 60 min.

4. No. of strips per carton/Catch ______ tablets /Jar At the start &after every 60 min.

Cover

12. .FINISHED PRODUCT TESTING & RELEASE :

3 *On completion of batch packing, send ‘Testing Requisition Slip’ to IPQA asking to withdraw the control

sample & sample of finished product for complete analysis as per ‘Finished Product specifications’.

*On getting the Release order from QC, transfer the finished product to finished goods store along with

‘Transfer ticket’.

*Send the BPR to Q.A. department for review & batch is released for dispatch after getting approval from

QA Manager.

12.4 SPECIMEN OF Label

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

13 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

10.0 IN PROCESS SHEET OF LABELLING & PACKING

10.1 INPROCESS CHECKS DURING LABELLING

Sr. Date Time No. of Parameters Checked Checked

No Bottles Label Batch Mfg. Exp. M.R.P Dose Printed Matter By

. taken for Pasting No. Date Date Cap (OK or Not (Prod.)

checking on OK)

bottles

10.2 Check for Clarity & Correctness of Printed/Overprinted Matter of carton

S. Date Time No. of Parameters Checked Checked

No. Bottles Batch No. Mfg. Exp. M.R.P Printed Matter By

taken for Date Date (OK or Not OK) (Prod.)

checking

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

14 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

*Note: Additional pages to be issued as per batch size at the time of BMR issuance.

JAR PACKING

NO. OF TABLETS _________TABLETS AVERAGE WEIGHT OF

FILLED IN JAR TABLET

AVG. WEIGHT OF WEIGHT OF ______NO. OF

EMPTY JAR TABLETS

WEIGHT OF FILLED JAR LIMIT OF FILLED JAR ________to ______gm(+

____%)

S. NO. DATE TIME WEIGHT OF FILLED PACK PRINTED MATTER CHECKED RE

JAR(gm) SIZE (OK OR NOT) BY

13.4 Shipper Weighing Record: - Weighing balance ID:

G. Wt. Weighed G. Wt. Weighed G. Wt.

S. No. S. No. S. No. Weighed By

(Kg) By (Kg) By (Kg)

1. 13. 25.

2. 14. 26.

3. 15. 27.

4. 16. 28.

5. 17. 29.

6. 18. 30.

7. 19. 31.

8. 20. 32.

9. 21. 33.

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

15 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

10. 22. 34.

11. 23. 35.

12. 24. 36.

Min. Wt. Observed: ____________kg Max. Wt. Observed:_____________kg

Checked By (Production Chemist) Verified By (IPQA Officer)

14.0 PACKING GOODS DETAILS :-

DATE Control sample Stability Finish sample No. of boxes packed PACK

Sample transferred to SIZE CHECKED

Finished Goods Store BY

*Enter these details in the yield statement attached in BMR

15. 0 RECONCILIATION OF PACKING MATERIAL:-

S. Name of Material Requisitioned Received Used Returned Quantity Destroyed Checked

No. Qty. Qty. Qty. Qty. destroyed by By

1 HDPE Jar

(………..cc)

2 Label

…………….. Tablet

3 Carton

………...…. Tablets

16.0 FINISHED PRODUCT TRANSFER RELEASE NOTE:-

Date T.T No. Total No. of Qty. of boxes Total No. Qty. of Boxes In Total No. Of Boxes

full shipper in one of loose Loose C. Box. To Ready For

shipper shipper Dispatch

Packed batch is release/ not release for sale.

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

BIONIAL HEALTHCARE PVT. LTD. Page No.

D-97,PHASE-7,INDUSTRIAL AREA,MOHALI,PIN-160055

16 of 16

BATCH PACKING RECORD

PRODUCT NAME:

BATCH

BATCH No. MFG. DATE EXP. DATE BPR No.

SIZE

BPR/A/001-00

EFFECTIVE REVIEW REVISION

07/08/2023 06/08/2025 01

DATE DATE No.

Production head QA head

(Sign & Date) (Sign & Date)

17.0 REVISION HISTORY

Revision No. Change Control No. Reason for Revision

00 NA First Issuance

01 CC/QA/23-005 To Revise the BMR/BPR for proper execution and documentation

purpose & to Revise the format No.

Prepared By Checked By Approved By

JUNAID DEVENDRA SAHILA

Name

KUMAR

SR.EXECUTIVE MANAGER- MANAGER-QA

Designation

PRODUCTION PRODUCTION

Signature

Date 07/08/2023 07/08/2023 07/08/2023

Format No.BH/QA/051/F02-00

You might also like

- D1.1 - 2015-Exam1-50 Questions W Answers PDFDocument22 pagesD1.1 - 2015-Exam1-50 Questions W Answers PDFCalidad Pellizzari100% (4)

- IQ - 6 TRAY DRYER - Ari Healthcare PVT LTDDocument31 pagesIQ - 6 TRAY DRYER - Ari Healthcare PVT LTDRavii CurtisNo ratings yet

- BMR - Reference - Moisturizing CreamDocument6 pagesBMR - Reference - Moisturizing CreamNIKHIL YEMUL100% (1)

- Hedley - Keeping Contract in Its Place Balfour V BalfourDocument26 pagesHedley - Keeping Contract in Its Place Balfour V BalfourAllisha BowenNo ratings yet

- Aphrin Pfs BPR p1 v-1Document13 pagesAphrin Pfs BPR p1 v-1ShagorShagor100% (1)

- BPR - FP025-1 V-1Azinil 35ml PFSDocument17 pagesBPR - FP025-1 V-1Azinil 35ml PFSShagorShagor100% (2)

- Aphrin 500 MG Capsule BPR 1Document12 pagesAphrin 500 MG Capsule BPR 1ShagorShagor100% (1)

- Idea - User GuideDocument159 pagesIdea - User GuideNoor Cano100% (2)

- Manufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Document5 pagesManufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Mohammed ZubairNo ratings yet

- Aroflam BPRDocument26 pagesAroflam BPRHamidNo ratings yet

- BMR Calamine CreamDocument5 pagesBMR Calamine Creamzaraorganics99No ratings yet

- Index For SOP-newDocument3 pagesIndex For SOP-newvibhutiNo ratings yet

- Process Validationprotocol and ReportDocument18 pagesProcess Validationprotocol and ReportGMH LaboratoriesNo ratings yet

- Cefpodoxime 200 Tab New 1Document25 pagesCefpodoxime 200 Tab New 1Gurdev SinghNo ratings yet

- Actpro Al Drysyrup 3b001Document48 pagesActpro Al Drysyrup 3b001joerichladNo ratings yet

- BMR - Elfexo 120 TabletDocument13 pagesBMR - Elfexo 120 TabletShagorShagor100% (1)

- PRODUCT: Mediplex-L Syrup: Manufacturing FormulaDocument7 pagesPRODUCT: Mediplex-L Syrup: Manufacturing FormulaMohammed Zubair100% (1)

- Stability ProtocolDocument10 pagesStability ProtocolShinde sujata shahajiNo ratings yet

- Inprocess Testing Capsule 1Document4 pagesInprocess Testing Capsule 1AKKAD PHARMANo ratings yet

- Batch History Check List 1Document2 pagesBatch History Check List 1ShagorShagorNo ratings yet

- Aphrin PFS BMR V-01Document13 pagesAphrin PFS BMR V-01ShagorShagorNo ratings yet

- Hold Time Study 1Document3 pagesHold Time Study 1aboemadaldeen100% (1)

- Sterille Production AreaDocument12 pagesSterille Production AreaNavdeep ChaudharyNo ratings yet

- Quality Dossier of Asmatab TabletDocument16 pagesQuality Dossier of Asmatab TabletShagorShagor100% (1)

- BMR SuspensionsDocument16 pagesBMR SuspensionsMohammed Zubair50% (2)

- A Product Which Has Completed All Stages of Manufacture, Including Final PackagingDocument4 pagesA Product Which Has Completed All Stages of Manufacture, Including Final Packagingom shankar JhaNo ratings yet

- 13 SOP Cleaning For Dispensing AreaDocument3 pages13 SOP Cleaning For Dispensing Areaanoushia alviNo ratings yet

- Analytical Report For Ketofast 10 TabletDocument20 pagesAnalytical Report For Ketofast 10 TabletShagorShagorNo ratings yet

- STP Montelukast Sa.Document6 pagesSTP Montelukast Sa.ShagorShagor100% (2)

- Prepared by Production: Approved by QA/QC:: NVIDAZOLE® 2500 BolusDocument17 pagesPrepared by Production: Approved by QA/QC:: NVIDAZOLE® 2500 BolusLegese HailuNo ratings yet

- Annexure A - Stability Summary ReportDocument2 pagesAnnexure A - Stability Summary ReportDeepak KumarNo ratings yet

- CV Protocol-Coated TabletsDocument22 pagesCV Protocol-Coated Tabletsqaheadjml007No ratings yet

- Xrex 50mg CapDocument20 pagesXrex 50mg Capziauddin bukhariNo ratings yet

- Annexure - II Product DevelopmentDocument50 pagesAnnexure - II Product DevelopmentLife PearlNo ratings yet

- Mega Iron 1200.Document6 pagesMega Iron 1200.Muhammad ZubairNo ratings yet

- BMR Cephracap 500 Cap Checked 1Document16 pagesBMR Cephracap 500 Cap Checked 1jordan7half7don100% (2)

- Process Validation Protocol XXX 60 MG TabletsDocument33 pagesProcess Validation Protocol XXX 60 MG TabletsfarNo ratings yet

- Manufacturing Formula: PRODUCT: Neuropal Suspension (Pyritinol Dihydrochloride 100mg)Document6 pagesManufacturing Formula: PRODUCT: Neuropal Suspension (Pyritinol Dihydrochloride 100mg)Mohammed ZubairNo ratings yet

- Co Dabamal Tablet 9m606001Document22 pagesCo Dabamal Tablet 9m606001joerichladNo ratings yet

- RM-Method Validation ProtocolDocument12 pagesRM-Method Validation ProtocolShagorShagorNo ratings yet

- Design Qualification Protocol FOR Static Passbox (MODEL NO.: AJE/SPB/2DS/01)Document10 pagesDesign Qualification Protocol FOR Static Passbox (MODEL NO.: AJE/SPB/2DS/01)Druva MNo ratings yet

- Performance Re-Qualification RMGDocument13 pagesPerformance Re-Qualification RMGJaswant SinghNo ratings yet

- Raw Material Requisition Slip - For MergeDocument1 pageRaw Material Requisition Slip - For Mergeasit_mNo ratings yet

- Aromet ER 1000Document14 pagesAromet ER 1000HamidNo ratings yet

- Cleaning ValidationDocument16 pagesCleaning ValidationBabu JadhavNo ratings yet

- HoldTime Study Potocol Cum Report For OintmentsDocument9 pagesHoldTime Study Potocol Cum Report For OintmentsAKKAD PHARMANo ratings yet

- Cleaning Validation ProcessDocument11 pagesCleaning Validation Processsamia khan100% (1)

- Source Water STP 31-05-2019Document11 pagesSource Water STP 31-05-2019saptaksamadder4No ratings yet

- Hold Time Study SOP Indian Pharma 1Document3 pagesHold Time Study SOP Indian Pharma 1ziadddNo ratings yet

- F Ex of e Nadine Hydrochloride Master Batch RecordDocument18 pagesF Ex of e Nadine Hydrochloride Master Batch RecordKrisnanti Angela SariNo ratings yet

- Raw Material Hold Time Study Protocol Cum ReportDocument13 pagesRaw Material Hold Time Study Protocol Cum ReportAKKAD PHARMA100% (1)

- Ethical Drugs LTD.: Siddhirganj, NarayanganjDocument10 pagesEthical Drugs LTD.: Siddhirganj, NarayanganjBejoy Karim100% (1)

- 2.Pv Semisolid FDADocument37 pages2.Pv Semisolid FDARahayu Maulida RNo ratings yet

- List of Raw Material ActiveDocument11 pagesList of Raw Material ActiveShagorShagor0% (1)

- Site Master File of PharmacureDocument43 pagesSite Master File of PharmacureAbebe100% (2)

- Prepared by Production: Approved by QA/QC:: TERASOL® 600 BolusDocument19 pagesPrepared by Production: Approved by QA/QC:: TERASOL® 600 BolusLegese HailuNo ratings yet

- Emiset - BPRDocument25 pagesEmiset - BPRjordan7half7donNo ratings yet

- Stability Protocol For LiquidDocument2 pagesStability Protocol For LiquidPrashant Khemariya100% (1)

- Protocol Jacketed MFG Tank LV02Document7 pagesProtocol Jacketed MFG Tank LV02pooja aswal100% (4)

- Juvia Protocol 50-1000Document16 pagesJuvia Protocol 50-1000ziauddin bukhariNo ratings yet

- Good Documentation Practices (GDP) in Pharmaceutical IndustryFrom EverandGood Documentation Practices (GDP) in Pharmaceutical IndustryNo ratings yet

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument4 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

- Questions Important Message:: A-01-P2J-EM-00002-1Document4 pagesQuestions Important Message:: A-01-P2J-EM-00002-1lynn fordNo ratings yet

- 1 Project OutlineDocument199 pages1 Project Outlinepaolo sangalangNo ratings yet

- Enterprize Design Patterns PDFDocument149 pagesEnterprize Design Patterns PDFDimitris IracleousNo ratings yet

- Barriers in Adoption of AM in Medical Sector Supply ChainDocument24 pagesBarriers in Adoption of AM in Medical Sector Supply ChainAnonymous 5AmJ13mLkNo ratings yet

- Infor OSDocument10 pagesInfor OSNot Yet DecidedNo ratings yet

- MKT 202Document30 pagesMKT 202Zahidul IslamNo ratings yet

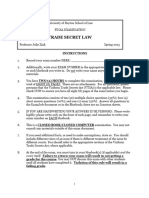

- Trade Secrets Zink Spring 2013Document8 pagesTrade Secrets Zink Spring 2013iyesha.campbell-andriesNo ratings yet

- Cross-Cultural Variations in Consumer BehaviorDocument14 pagesCross-Cultural Variations in Consumer BehaviorChhavi KunwarNo ratings yet

- Trade SecretDocument12 pagesTrade SecretMUHAMMAD TALHA TAHIRNo ratings yet

- Marketing Chapter 8Document19 pagesMarketing Chapter 8decemaefuentes0801No ratings yet

- Quantity Surveyor 1575543075Document3 pagesQuantity Surveyor 1575543075GANESHNo ratings yet

- Food Terminal Inc. Executive Summary 2021Document4 pagesFood Terminal Inc. Executive Summary 2021Robien Ray InfanteNo ratings yet

- Business and Management IADocument3 pagesBusiness and Management IANikol DashanovaNo ratings yet

- Assembly Processing in SD and PS: CommunityDocument1 pageAssembly Processing in SD and PS: CommunityAtul JaiswalNo ratings yet

- Events Report - Events Head and HostsDocument25 pagesEvents Report - Events Head and Hostsgwen reyesNo ratings yet

- How To Measure Fair Value in AgricultureDocument10 pagesHow To Measure Fair Value in AgricultureSebesebie FassilNo ratings yet

- (RO) MS7SL82O - 21598794 - Ethical AuditDocument21 pages(RO) MS7SL82O - 21598794 - Ethical AuditKrishan hunukumburaNo ratings yet

- Sample Labor Pakyaw ChecklistDocument5 pagesSample Labor Pakyaw ChecklistJohn Oliver Guiang100% (1)

- Rbi Assistant Mains ResultDocument17 pagesRbi Assistant Mains ResultsKNo ratings yet

- RR No. 7-2003Document9 pagesRR No. 7-2003Lorenzo BalmoriNo ratings yet

- Corporate FinanceDocument4 pagesCorporate Financegianluigi de rubertisNo ratings yet

- Ac8 Assessment of Materiality 1Document4 pagesAc8 Assessment of Materiality 1Mark Anthony B. BacayoNo ratings yet

- Dujeds 001 - Ibrahim Umar BambaleDocument8 pagesDujeds 001 - Ibrahim Umar Bambale0703055No ratings yet

- Quote Date: Quotation: Ariba AttnDocument1 pageQuote Date: Quotation: Ariba AttnNestorNo ratings yet

- Machine Made Candles Processes and ManufacturingDocument10 pagesMachine Made Candles Processes and ManufacturingEldad AfeworkNo ratings yet

- Protection Against Unfair Competition Protection Against Unfair CompetitionDocument4 pagesProtection Against Unfair Competition Protection Against Unfair CompetitionMonikaNo ratings yet

- Tutorial 10 - Law of AgencyDocument17 pagesTutorial 10 - Law of AgencyWayn YapNo ratings yet