0 ratings0% found this document useful (0 votes)

84 viewsA Report Coach

A Report Coach

Uploaded by

abhimanyutiwari1234Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

A Report Coach

A Report Coach

Uploaded by

abhimanyutiwari12340 ratings0% found this document useful (0 votes)

84 views28 pagesOriginal Title

A REPORT COACH

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

84 views28 pagesA Report Coach

A Report Coach

Uploaded by

abhimanyutiwari1234Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 28

Quality Audit report

Of

Coaching Depot

Wadibander, C Rly

Report no. 13/2012

APRIL 2012

(Audit is done by CRSE, WR)

Co-ordinated by

Quality Assurance (Mechanical ) Directorate

Research Designs & Standards Organisation

Manak Nagar, Lucknow - 226051

1.0

14

12

13

2.0

24

2.2

23

24

25

3.0

3.1

3.2

3.3

Quality audit Report of

Wadibunder Coaching depot, Central Railway

Introduction

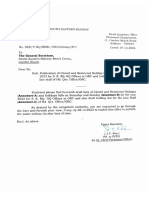

‘As per Railway Board’s directives vide Letter No. 2012/M (Wy/814/5

dated 20.03,2012, Quality audit of coaching depot /workshops were to be

done by nominated railways on the neighbouring railways. Accordingly

QA of Wadibunder Coaching Depot has been done by WR.

Audit Team- — Shri R S Sexena, CRSEIWR

Date(s) of audit- 03.04.2012 & 07.04.2012

Escorting Officials - Shri Saket Mishra, Sr DME/Chg/BDVT, Shri

Sandeep Verma, AME, Shri Ashok Nagpure

Strengths

Infrastructure for maintenance at Wadibunder coaching depot is very good.

The maintenance lines are clean and catwalks are wide permitting smooth

movement of men and material. The ease with which mechanized cleaning

apparatus can be deployed promotes adoption of mechanized cleaning by

staff.

Adequate illumination is available for night maintenance of rakes.

The depot was the first to install a mechanized laundry over IR and prides

itself as a pioneer in the field. The recognition received in the process has

stayed in the form of high morale of the staff.

Proximity to major workshop (MTN), Headquarter (CSTM) and stores depot

have resulted in better availability of material

WEAKNESSES

The depot's system of documenting the work done is inadequate. There are a

large number of maintenance practices for which evidence of satisfactory

compliance is not backed by objective. Lack of documentation would lead to

no analysis of failures & further corrective & preventive action.

The traceability of subassembly in the depot is inadequate.

Certain responsibilities/ information are shared between 4-5 depots which

dilutes the responsibilty

Page 1 of 27 Coaching depot - Wadibander, C.Rly. April 2012

3.4

3.5

3.6

3.7

38

3.9

3.10

The depot is following obsolete MIS and the data is also not updated

promptly. The information is scattered between the OH shed, maintenance

shed and laundry. A single repository of information is not available.

The pit line attention for TN 12141 (CSTM-Rajendra Nagar Express) & 11093

(Mahanagari Express) is less than the stipulated six hours. This is mainly

because of late placement.

TN 12859 (Geetanjali Express ) has been given only 5 hours pit line

occupation time which needs to be corrected.

Joint check of rakes upon arrival with electrical and RPF staff is not being

done.

For condemnation of linen on condition basis nomination of Committee has

not been done yet.

For new linen 5% checks at the level of SSE (Mech) are not being done.

Evidence for quantity of chemicals used for Mechanised cleaning/ OBHS was

not available, in terms of per coach or per rake basis.

Page 2 of 27 Coaching depot - Wadibunder, C.Rly. April 2012

Quality Assurance Directorate (Mechanical)

RDSO Lucknow

Check sheet for Quality audit of coaching depot

Primary maintenance attention and sick line attention

(Based on CAMTECH Maintenance Manual for BG coaches

and Railway Board / RDSO’s guidelines)

S.No. Tem Clause ‘Observation

1. | Periodicty of periodic overhauls (POR) in | 103 of Chg Manual | Coach holding Bare 391 Total 445

designated werkshonsis boing folowed. | Talo .1_ and | Overdue POH - None as on

correction "slip

issued in 2008 9804-2012

RB letter no. 2007/M

C cyiait ata

26.08.08

7% | Maintenance schedules fo be followed | 112(a) of Chg. | 5 Primary and 4 Secondary trains

in coaching depots Manual and | maintained

To maintain coaching stock in good | Correction slip § for

condition, the following maintenance | coaching

schedules are prescribed to be carried out | maintenance manual

in carriage depots on divisions where rake | issued in 2008

has been based for primary maintenance,

3. [Schedule A Monthly (1 month + 3| RB letter no. 2007™M [No coach Is run overdue schedule.

days) in rake {_ cytait dtd | Records of around 20 coaches

28.08.08 checked. The MIS records are not

updated for March, Details in coach

register are in conformance

| Schedule B -Quartery @ month & 7 days) No coach is run overdue schedule,

in rake Records of around 20 coaches

checked. The MIS records are not

updated for March. Details in coach

register are in conformance,

5. | ToH attention - detach coaches ‘One coach no.96265 was found where

Pariodicity of 1OH attention:

Coach

Cetonory Periodicity

atintarval oF 72

New coach months in Depot

Rajdhant at interval of S|

‘Satabdi (Conv) |_months in workshop

‘at interval of

Mail! Express | months in depot

at interval of 9

Passenger months in depot

at interval of 12

Otrer CVs | months in depot

Tolerance for IOH may be kept as +

30-0 days,

Maintenance activities to be carried out

during schedules should be as per

Appendix-F & G.

For IOH attention of newly built coaches,

guidelines as circulated vide RB's letter

no. 2007/M (C)/141/1 dtd 06.08.09

IOH was done 10 days prior to

becoming due as against tolerance of

+30/-0 days. Staff counselled. More

checks did not reveal any other

instances.

Appendix F followed for A and B

schedules,

IOH is done with unit exchange bogies

from workshop, Air brake items like

PEASD and DV are tested. Amenity

provided where missing. Intensive

cleaning and single car testing carried

out as per Appendix G.

Page 3 of 27

Coaching depot - Wadibunder, C.Rly.

April 2012

© | Primary maintenance schedules are) 112(5) of] Records checked. The coaches marked

Foquired to be carried out by the base | Chg Manual sick at the other end are getting returned

depots to which coaches are alloted. In to base depots by WB in the subsequent

emergency, when due to any reason inp.

coaches cannot reach their base depots

and primary maintenance schedules

become due, A & B schedules should be

Undertaken by the carriage depois where

the coaches are available, ‘C’ schedule

should be done at base depot

7__| Examination of originating trains 107 _a of cha

Manual

T1_[Al tains must be examined by the | 107 a () of Chg. | Done

mechanical train examining staff before | Manval

despatch to ensure all coaches are in fit

Condition without rejectable defects,

8. | Terminating Examination of Passenger | 107 _b of Chg, | Carried out at CSTM station, Rolling in

Trains - Rolling in examination Manual lights are provided.

8.1_| Site shall provide unobstructed view of | 107 —(o\@) _ of | The site provides unobstructed view of

Under gear from both sides. (Chg Manual under gear.

‘B2_| Should have adequate space for ing the | 107 _(NN@) of | Lights are avallable. Adequate space

lighting arrangement and for staf Chg Manual exists.

Ba_| As the Wain passes the nominated pat, | 107)" ‘of | Checked for CSTM. During rolling in of

C&W staff should watch out vigilantly for | Chg. Manual Pushpak Exp. On 03.04.2012. Control

loose/hanging/broken under gear parts of messagel Phone message from PIF are

the coaches, any unusual sound coming recorded in the log book. Last message

from the coaches or any other abnormality from PIF on 31/3/2012 for wheel skidded

in the coaches, in an ACCN coach

BA_| Temperature of the axle boxes should be | TO7(B)) of] Electronic temperature sensors _are

measured preferably with the help of the | Chg.Manual available al CSTM platform. Batteries

electronic temperature measuring device. replenished through imprest.

3. [Revised maintenance pattern for | Railway Boards | No JPC is available

coaching trains circulated vide Railway | letter

Board's letter No.95/M(C)/141/1 | No.95/M(C)/144/1

31.01.07 t.31.01.07

‘BA While permiting introduction of round trp | Railway Boards | CR Headquarter letter citing Northem

Primary pattem of maintenance on | eter Railway reference available in the depot.

Coaching trains, approved mandatory | No.9S/M(C)'144/1

Condition at primary end and other end as | dt.31.01.07

detailed in Railway Board's letter

No. 95/N(C)/141/1 dt:31,04 07 is followed.

it Primary End ‘Check record and also check rake and

write observation

| The brake gearing should be properly | -do- Brake gearing checked by a gang of four

adjusted including the slack adjuster ‘A’ artisans. A dimension of BMBC coaches

dimension & the brake cylinder stroke to checked and recorded. Checked rake of

ensure 100% brake power 12137 (Punjab Mail) with Sr. DME/C

CSTM alongwith the depot incharge Sh.

Nagpurker and gang on 03.04.2012

T)__ | Brake blocks should be changed in bogie | -do- Not being done. They are being changed

sets only a a set for brake beams.

ii) [All missing passenger amenity fittings | -do- Based on availabilty as per depot

must be replaced and the rake must be incharge. Sufficient quantity of bottle

turned out as ‘Zero-Missing-Fiting’ rake, holders is not available. However in the

rake checked, deficiency was not seen

W) [Intensive clearing of coach Tollts and | -do- Done during maintenance, The availabiliy

lavatory,

and use of chemicals, Nylon brushes and

‘Scrubber machine was checked on the

Page 4 of 27 Coaching depot - Wadibunder, C.Rly. April 2012

‘spot for availability and practice,

VW | Gear maintenance tme of 6 hours on the | -do- ‘ceassionally not available for train

pit as per train schedule no,12141 (CSTM-Rajendra Nagar) due to

deployment of lie over rake elsewhere

(12141). Not available for 1093

(Mananagri express) for primary

maintenance due to delayed arrival

wi) | Provision of proper washing cum | ~do- Yes. Available

maintenance pit ine facity with adequate

testing equipment and high pressure jet

cleaning plant at primary end

vil) | Adequate gang strength with proper | -do- ‘Yes. Available.

supervision

Bz | The Other End ‘Check record and also check rake and

write observation

| Whenever the Tie-over & more than 2 | dom ‘Only one train Pushpak (2533734) has Tre

hours atthe platform or the rake is stabled over of more than 2 hours and it is

in the yard the rake should be locked and brought in the pitine. 16 RBPC trains are

postive security should be provided received at VT out of which other end

attention is provided to 12 trains in

nominated stabling lines at the station

itself 4 trains are platform returned.

| The minimum infasiructure to be provided | -do- High pressure pipe line and Apron not

at the platforms. from where tains are available al stabling lines at VT.

returned without secondary mainlenance

shouldbe is available

Ti) A joint safely cerificate covering each | -do- Maintenance pattem of tains has not

clause of mandatory conditions wil be been changed in the last three years,

issued by mechanical and operating Joint Safety certificate not available in

branches at’ divisional level prior to depot

changing over any train to revised

coaching maintenance patter,

T0.] Rake mantonance link has provision of | 108 of Chg. Manual | Rake link and occupation chant checked.

maintenance time (pitatention) of 6 hrs at | and Policy circular | Adequate time is nol available for 12141

primary end to enable intensive attention, | no, 4 wherever lia over rake is not available. In

case of delayed arrival of 11093 also, the

time available on pit is close to 5'/, hours

only. Similarly 2859 ( Secondary) gets

only 5 hours on pit as per occupation

chart

T1-| Tntemal dearing, Passenger ameniy | 108 of Chg Manual | Adequate depot infrastructure is avalable

attention and watering is done at platform |Table 1.8 Nominated line available at CSTM station

line or nominated stabling line provided but washable apron and high pressure

stipulated faces are avaiable at such pipe Ine for cleaning is notawvalable in

line is fllowed Fipe line for leg

72] Washing and cleaning of coaches 70a of Chg Manual

721 | Use recommended soliions for leaning | 109 of Chg Manual | Approved cleaning compounds are being

as per RDSO specification No. used. Taski Rand R3 available in the

MECIPCN/101/2001 or use cleaning depot.

agents approved by CME ofthe Railway

722] W shoukd be ensured that the rakelcoach | 109 (bya) of | Yes. Men at work board is available and

is protected with proper board/signal for

safely of the staff working on

washingicleaning job to prevent

movementidisturbance in the activity

Scotch blocks with locking arrangement

should protect fines and keys should be

kept with Engineer (C&W) til the time rake

(Chg. Manual

in use.

Page 5 of 27 Coaching depot - Wadibunder, C.Rly. April 2012

Tg under maintenance:

12.3 | External cleaning washing: 109) (b) of | Checked in the rake of 12137 and 12141

Check that guidelines as detailed in | Chg.Manual Being followed,

CANTECH manual are being followed

724] Cleaning of Tie: TOS _—{e)__ of] Checked in the rake of 12137 and 12147

Check that guidelines as detaled in | ChgManual Being followed

CAMTECH manual are being followed.

TZB_| Iniemal deaning of upper class AC and | 109___{@) of | Checked the rake of 12137 and 12147

sleeper coaches: Chg. Manuel Being followed.

Check that guidelines as detailed in

CANTECH manual are being followed

725 inlemal deaning of GS, SLR To3r) OF | Checked in the rake of 12137 and 12147

Check that guidelines as detlled in Chg Manual Being followed.

CAMTECH manual are being followed

72.7 | Cleaning of buffers and screw couplings 1050) oF | With wire brush

Chg.Manual

T)__| Bulfer plungers should be scrubbed with a | 109(f)) ‘of | Cleaned with wire brush and oil applied.

seraper to remove dit and muck Chg Manual

Thereafter, they should be wiped clean

with cleaning oll and rubbed with coir

rope

T_| Screw coupling threads should be cleaned | TOSI) oT | Only spare screw coupling Is cleaned.

with wire brush to remove all dit and dust. | Chg.Manual

Thereafter, it should be cleaned and given

a light coat of oil. Oiling should be done

an Slack adjuster also

73] Conditions required for maintenance of | 170 of Cha Manaal

24 coach trains (Railway Board's letter

Nosem(cyi37/19. Pt dt287.99 &

55.2000,

75.1] Infrastructural requirements Toa) of

Chg Manual

| 2 coach engin uly equipped pit tine. | 170¢ayi) oT | 26 Coach length Pit ines avaliable

Chg Manual

TH _| High pressure jet cleaning pipeline with | T70(ay) oF | High pressure jet cleaning pipeline are

plant for cleaning at primary pit line. | Chg.Manual available in the maintenance line and are.

Mecanizes extemal deaning 8 extensively being used

preferable

i_| Water hydrants for 24 coach fengih at en 170(ayti) oT As told by the depot, he watering station

route watering stations with 20 minutes | Chg Manual ‘at BSL has the necessary facility, Could

stoppage at nominated stations not be verified

Hy _| Availablity of the prescribed airbraxe 1 70(ayiwy 2F | Available, With calibration periodicity of 6

maintenance and testing equipment Chg Manual months separately forall the four

examination lines.

732 | Coach Design related requirements 170) cy

Chg Manual

TW _| Airbrake with win pipe graduated release | 170(0)() | Yes

system Chg Manual

Ty _| Oniy enhanced capacty draw gear and | TIO) oT Yes

screw coupling to RDSO. sketch No, | Chg Manual

72081 and 79067 are to be provided on

the rake

733] Maintenance practices and system | 170) oF Quantum of regularly to be indicated

related requirements Chg Manual

The integnty of the rakes to be 170(e\) oT | Cannibalization of rakes isnot prevalent

maintained Chg Manual However spare stock is used between

depots of DDR, MZN, LTT, and VT in the

Mumbai area.

iy | Primary maintenance of the rake should ] T70(e) oF No spliting is done.

be done inane hook without spiting | Chg Manual

Page 6 of 27

Coaching depot - Wadibunder, C.Rly.

April 2012

ii) _] Minimum maintenance tne of 6 hours on | 1TO(@\i) of] Available, Exceplions as reported 9.1.1)

the pit during primary maintenance Chg Manual

WI is mandatory to provide secondary | T10(e)(v) oF | Being followed. 12859 gets only 5 hours

maintenance to all rains augmented to 24 | Chg. Manual on the pit due to delayed placement on

coaches (RPC 4 revised and. permit ‘ccount of path from VT.

Roun trip. attention with approval of

ME)

VW _| Trains Teakage rate to be _maintaned | TO(eV) oF | Being checked, Well within Ink

within preserved limits by using rake test | Chg Manual

rig

W) | Provision of proporionate brake system | T1OTe)(™) TNA

on the locometve in good working order Chg Manual

Wi) | Provision of audio visual alarm system on | 170(e\(vi) oT NA

the locomotive Chg Manual

7a] Fire_ extinguishers should be checked T7170) oF | Being done. The new and released

every three months and completely efled | Chg Manual extinguishers are properly segregated

‘after one year. Issue is from centralised stock at VT.

Depot was advised to use up the

extinguishers retumed on expiry for fire

safety drils to train staff and prevent

round tripping

Ta] Provision of DCP ype fre exingusher in| RBS —Teler no, | Being followed

a rake should be in accordance with | 95iSec (spIN76)1 dtd

Guidelines circulated vide leter no. 95(Sec | 30.05.97

(SplV75/t dtd 30.05.97

[Coach ype ——[ Nos of E'S]

Each Break Van 12 nos

Each AC coach | 2 nos

Each Panity car — nos

Each Generator | 2 nos

75] Similarly, other brake van equipment, | 11 Tle) of | Checked SLR of 12137 Punjab Mail by

‘which Mechanical Train Examining staft is | Chg Manual breaking the one time lock. Portable Train

responsible to supply, should be provided Lighting equipment was rt available in

according to the. instructions of each to Guard Vane The joint Inventory memo

Raihiny” Ferable, contol telephones, is not boing signed by al the departments

Portable fre’ extinguisher," wooden except Mechanical. Sr, DME was advise

Wedgesiskids and stretcher are to. be to ensure and advise Sr. DSO about this.

provided,

76-| Watering and cleaning of rakes Tiny oT | The depot does nat have information in

Mechanical department of each railway | Chg Manual this regard beyond CR territory

will nominate the watering andthe

cleaning stations onthe railway

V7] Deficiency Rolling Stock (ORS) for Ti) (or

Coaching Stock

T_[ Railway should devise system for | Chg Manual Printed proforma of DRS cards avaiable.

detecting — deficiencies, Reports of But it is not being signed by RPF and

(one) pert defects in ons Stock Guard. Checked for 12137 Punjab mail of

reports in the proforma given ni ‘

Annexure 1.2, should be prepared for 2104/2012,

each mallexpressipassenger org nating

train. in duplicate by te Engineer

(C&W)Electrical (TL) and should be

signed joint withthe RPF

representaives,

TH] On arrival of the Wain at the destination | T7TS)O) oF | Not being done as the rakes immediately

station, the Engineer (C&W) staff-and | Chg. Manual locked and moved out of CSTM

electrical staff shall check the rakes jointly

with a representative of RPF and

comparison may be made with orginal

report

Individual theft reports are being sent

from rake maintenance as and when

required.

Page 7 of 27

Coaching depot - Wadibunder, C.Rly.

April 2012

Coach Maintenance History Gard

TH oF

Every coaching depot shall_have

computers for maintaining the coach

maintenance history in a software

programme which should be compatible

with the programme of the coaching

workshop,

‘Chg Manual

Local ORACLE based MIS not compatible

with MTN shop.

@

The complete history book of each coach,

Consisting of maintenance history cards,

date card, rial card, etc. will, however, be

maintained by the base workshops

Tou

(Chg Manual

of

‘Could not be verified in the depot

7,

Primary/Secondary maintenance

194

The rakes! coaches of all rains should be

given a Primary/Secondary Maintenance

examination as prescribed by the Chief

Mechanical Engineer of the Railway and

as per Appendix F of Cha Manual

T731a)

(Chg. Manual

of

Being done in accordance with Coaching

Maintenance manual and RPC IV

792

Coaches shall be washed and cleaned

thoroughly from outside and inside as

prescribed in clause 109.

T1315)

(Chg Manual

of

Being done.

Page 8 of 27

Coaching depot - Wadibunder, C.Rly.

April 2012

753] Brake system maintenance TSE) oF] Being. done The depot does not have

Air brake system (Bogie mounted and | Chg.Manual underframe mounted coaches in_ its

underframe mounted): holding. For coaches in the secondary

Attention as detailed in para 113 ( ¢) is maintenance rakes, the staff is

boing given cre primary eeconiery conversant with the underframe mounted

system also.

TS _| Tr addon t above the folowing fame of | T1718) ot | Boing done. Crilical areas of bogie frame

Work. should be attended during” the | Chg Manual are wiped for closer inspections. In the

mmaitenance schedule examination rake of 12137 following were being

Undarames checked

* bogie frames Underframe: Trough floor, turn under Sole

1 pl bores bar and headstock

8 Bogies: Last coil of springs, Spring Plank,

These items should be wiped with wet Hangers ,Brake beam and Axle box wings

waste weaves or cation. waste as were seen being checked after wiping out

necessary so as to facliate examination the muck

Bilunder gear components should then be ‘Axle box: Bolts, oozing of grease from

examined and repaired as necessary to rear cover, and wings were being wiped

ensure. that there is no 'S) marked before Inepection

Tejectable defect as mentoned in Chapler

Ivo IRCA Conference Rules.

TSS] the folowing toms of undergear | T13__(@) af

components should, however, be specially | Chg Manual

examined and attended to

i) Oil in hydraulic dash pots of Rajdhani and | 173° (e) (i) of | No Rajdhani Shatabdi coach is available

Shatabél coaches should be checked | Chg Manval inthe holding of the depot

once in 18 days to detect al leakage from

trom "ough defective seals or hough

the vent screw. Add! replenish wih

speciied grade of ol if te ol level is

Below 40 mm in the tare. conaton for

ensuring beter ring cmon

W[Wheet »proties should be —_wsualy | Tay) GF | Being done. Gauges avalable and sick

examined and gauged in case they | Chg.Manual marking details indicate that coaches are

appear tobe near condemning limits. indeed being examined

Ti)__| The brake gear shouldbe checked and so | T7@(eV)___of | Being checked and piston stoke ©

adjusted thatthe piston stoke 's win | Chg Manval recorded in the proforma available

the limits speciied for diferent types of

coaches. (See table 1.10). A and e

dimensions for slack adjuster should be

8 per ‘able 1.11 (as applicable for under

Frame mounted brake system)

TBS_| The following coach body components | 11S (of

and fitngs should be specialy checked | Chg Manual

and atended to

Doors shouldbe propery secured with he | TINT OF | Checked in the rake of 12137 and 12147

hinges/pvots and should not be grazing | Chg Manual Being followed

with floor or door sl plates

I] Boor itches and safety caiches TaN oF| Checked in the rake of 12137 and 12141

Chg. Manual Being followed.

ii) | Door lock handles 11 3(f(ii) of | Checked in the rake of 12137 and 12141

hg Manual Being followed.

ia) Tower bls Tra) oF| Checked in the rake of 12137 and 12141

(Chg.Manual Being followed.

W_| Window shuts shoud reiter be Tare Tam) GF] Checked in the rake of 12137 and 12147

nor loose (Chg. Manual Being followed.

‘a _| Window shut satay catches Trai GF] Checked in the rake of 12137 and 12147

(Cha Manual Being followed.

wa_[ Window Fame T13iH(vi)_ oF | Checked inthe rake of 12137 and 12141

Chg. Manual Being followed.

Page 9 of 27

Coaching depot - Wadibunder, C.Rly.

April 2012

Wil) ] Vestibule assemblies of all vestibule | 113(0(vi) of] Checked in the rake of 12137 and 12141

coaches should be checked and repaired | Chg Manual Boing followed.

as necessary.

im) _| Water pipe connections, flushing valves, | 113100) of | Checked in the rake of 12137 and 12141

cocks and shower hoses should not be | Chg Manual Being followed.

leaking or choked

%) [Drain gills and drain holes ih the | Tao ‘of | Checked in the rake of 12137 and 12141

bathroom floors and wash basin | Chg Manual No choking seen,

drainpipes should be cleaned and opened

where found choked

3H) [Any other deficiency as per Annexure 12 | TT3(No) oF

should be made good. (Chg Manual

xi) [A proper record should be Kept by | T13(h) of | No DDR is being maintained. Records of

Engineer (C&W) at washing/pit lines of | Chg Manual ‘Schedules are however kept coach-wise

schedules carried out by them, in diaries. The records in the MIS were

especially of items required to be mot updated for March't2

attended at specific periodicity

Record to be maintained in standard

DOR (Damage deficiency register)

20:| Schedule ‘A’ Examination 114 of Che Manual

| Schedule A's requiredto be gven every | 114 ___(@)___of | Periodicity is adhered to. It was

month + 3 days at the nominated primary | Chg Manual suggested that the depot followed the

maintenance depot within the normal Maintenance manual format,

primary maintenance time on a

‘washingipit line in a rake.

i. | Brake system maintenance THA) of | Being followed. Changes in format

Air brake system (bogie mounted) (Chg Manual suggested.

AA schedule maintenance as per alr brake

chapter

|The speciied tems of work should be | T1410) of | Being followed

attended during Schedule ‘A’ examination, | Chg Manual

i.e, monthly examination:

2_| Schedule" Examination 115 of Che Manual

i, _ | Schedule Bis required to be given every | 115(@) of | Being followed

three months + 7 days at the nominated | Chg Manual

primary maintenance depot within the

normal time allowed for primary

maintenance on a washing line in rake,

T._[ The specified items of work should be | 115(5) of Being followed

attended

Ti, | Brake system maintenance Chg Manual Being followed, Recorded in maintenance

Ar brake system (Bogie mounted) diary with signature.

() Same as ‘A’ schedule

wv. _| Other assembly maintenance

Besides brake system other items should | 115(by() of

be attended as given below. (Chg Manual

‘@_| Alltems of Schedule Ts of | Followed

(Chg. Manual

B.__ | Painting of lavatories from inside. Tv) of | Lavatory floor skirting is painted. Pipes

(Chg Manual and panels painted as per requirement.

| Tharough inspection and repars of brake | T75(6)(0) ‘of | Done.

gear components Chg Manual

@_| Thorough checking of tough floor, tum | TSI) of | Done.

unders, et, from underneath’ for | Chg Manual

Page 10 of 27

Coaching depot ~ Wadibunder, C.Rly.

April 2012

& | Touching up of painted portion, Waded or | TTSIb)Qa) a] Done,

soiled (Chg Manual

72, TOW attention Tie of Cha. Manval

and Corecton slip 5

for coaching

maintenance manual

issued in 2008

2a] Periodicity of OH atention: Ti7()_ of Chg. | Followed. Remarks same as lem 5

Coach Manual above

Categor Periodicity and correction slip §

atienalet72—] for coaching

New coach months in Depot _|| maintenance manual

Rayan ‘atinterval ofS —]_ 'ssued in 2008

Satabdi (Conv) | months in workshop

at interval of

Mail / Express months in depot

at interval of 9

Passenger months in depot

atinterval of 12

Other OCVs months in depot

‘Tolerance Tor TOH may be Kept as

300-0 daye,

Maintenance activites to be carried out

during. schedules should be 93 per

Append & 6.

For 1OH attention of newly built coaches,

guidelines 95 circulated vide R's letter

fo. 2007IM{ C)'41/ ata 06.08.09

ZEZ| Coaches are requred'to be detached Fom 1771) oF | Being detached. 1OH cared out in the

the rake and taken to the sick line or sent | Chg Manual IOH shed

to shop for IOH attention ((C" schedule | and Correction sip 5

maintenance) for coaching

maintenance manual

issued In 2008

ZZ3_| Brake system ~C sched mainionance | 117ia\i) oF | Carried out

(JOH) 28 per para 426 of ar broke | Chg Manual

chapter

Za] thoroughly dean Dit colecor erm Ti7(ajwy of | Being done

kerosene or replace on contin basis. | Cha. Mandal

225] Other assemblies maintenance TaN) oF | Being done

Allitems of Schedule "8" Chg Manual

225 | Thorough repairs of running gear Ti7(@ya) & | Being followed. All coaches are being

including. running out of bogies wnere | Chg Manual given |OH

considered necessary. All bogies which

are working. on rake links earning more

than 25 lakhs kms. per annum must

however be runout” and thoroughly

attended to.as laid down in clause 111¢

Linder “Intermediate Overhaul.

Zar | Touching up damaged pant of coaches Ti7Tala a Touch up & being done and seen on

on outside as well a inside hg Manual coaches. Depot has also started screen

printing the seat no. on the side wall. Two

coach doors were suggested for touch up

painting in the rake of 12141,

2Z8_| Polishing ofthe polished surfaces TaN) NIA

hg Manual

22a | Shock absorbers shoud be replaced and ] 117(a)() oF | Adequate spares are avaliable

sent fo the base workshops for repairs, | Chg Manual

testing and retum, For this purpose,

adequate spares must be maintained in

the depot

Page 11 of 27

Coaching depot ~ Wadibunder, C.Rly.

April 2012

2.10

Thorough cleaning and removal of dust

rust, dit, ete,, accumulated at tho pillars

through the turn under holes, with coir

brush and compressed air.

Tia)

(Chg Manual

Not being done.

2a

Thorough examination and repare of

Upholstery, cushions, curtains, etc

Ti7awy

(Chg Manual

of

Being done,

DAZ

Thorough checking and full repairs of all

window shutters, safety catches, safely

latches, staples and hasps.— of,

compartment, lavatory,

Tima

(Chg. Manual

of

‘On the two rakes checked on the spot.

Windows were properly maintained

including smooth running of window

shutters, cleaning of glasses, balancing

mechanism and working of safety catches

and latches.

BAS

Thorough checking and repars of UIC

vestibules, their rubber flanges metal

frames, doors, fall plate, locking gear, etc.

for ease of operation and safety.

Ti7aNe

(Chg.Manual

of

No repaired UIC vestibules were seen.

Fall plates were sturdy and supports were

firmly in place. Better cleaning of support

bracket was advised.

Ae

Thorough checking and repairs of all

cracks and wom out portions of flooring of

the compartments.

THT(ayo

(Chg. Manual

of

Being done.

AS

Engineer (C&W) of Primary Coaching

Maintenance Depots should be fully

familiar with the vulnerable areas of ICF

coaches for corrosion, viz., sole bar at

doorways, lavatories and adjoining areas,

corridor sides - more so in case of those

SLRs which are used for Fish, Salt, et.

For facilitating inspection of ‘sole ‘bars

even spaced elongated holes of (215x127

mm) ate already provided in the tum

tunders,

7 @

(Chg. Manual

of

Rake TXR of 12137 Sh Sanjay Rankhabe

and Sh. Ramesh Behra JE were

‘questioned and found to be aware,

DAS

‘Special allention should be Taken or the

following:-

1718)

(Chg Manual

of

Pocket between sole bars and turn unders

should be thoroughly cleaned through the

inspection opening of the sole bars and

inspected with the help of torch light or

Inspection lamps.

TIEN)

(Chg.Manual

of

Cleaned and inspected with Torch lights,

W.

Drain foles provided in the ough floors

should be kept clean and unclogged. If

during the cleaning of these drain holes

any accumulation of water is observed,

the affected area should be very carefully

inspected for possible corrosion

TI7(eyhi)

(Chg Manual

of

Drain holes checked and were found clear

Ty

‘A register should be maintained of the

primary maintenance coaches on the

subject.

Record of Schedule A, 8 and 1OH

attention are maintained in standard

format and records are maintained.

Tien

(Chg. Manual

of

‘Coach wise records of scheduled and out

of course repairs are available.

BAT

For maintenance of coaches of RajdhaniT

Shatabdi Express Rakes, the instructions

given in ROSO Technical Pamphlet No,

-7807 should be followed,

io)

(Chg. Manual

of

Not Applicable

2.18

The IOH of Rajdhani/Shatabal high speed

coaches should be carried out in

‘workshops

1181)

(Chg Manual

of

Not Applicable.

es

Linen management

Complete adtviy of linen management

including washing, storage, supply &

Boards

Tatler

No.2009)M(C)/165/6

Not being done as linen distribution in

‘some of the trains has not been handed

Page 12 of 27

Coaching depot ~ Wadibunder, C.Rly.

April 2012

Gstibuion of ten Kis ih Wains shall be | G17 12.2008. ‘over by Electrical dept.

done by Mechanical (CBW) Dept as a

single window agen

Tl@y_[ Stock venficaion of Tinen should be | Soard’s Teller | Guarlerly slock verifealion is being done.

cartied out on a quarterly basis No.20097M(C)/16516,

TB) PAL least 5% of new linen should be | dlé.t.2010 Nat being done Tor new Linen:

checked by SSE/Mechanical for

(@) bundles being sealed and having

batch nos., manufacturer's name, year of

manufacture, quantity, size indicated

{b) Linen terns having marking of month /

year of manufacture, Railway, etc.

{c) dimensional check, colour, fee! and

workmanship, etc.

[ey] Monthly report of nspecions Test checks ‘Quarterly checks of contractor’s premises

of the linen washing contractor's are being carried out.

premises by officers / supervisors, should

be prepared and payment should be

made afte recovery of all penalties / dues,

T{@)__| Enough buffer stock of inen toast for 2 Buffer Stock: 61000 Pillow covers, 48000

3 days is available face towel, 114,000 bed sheets on date,

Tle) Life ofinenis adhered to Life of linen is adhered to. Condemnation

Bod sheets: 12 montis for khadi, 2. in March was as under:

months for poly vastra 3914 bed shoots, 2040 Hand towels,

Pillow covertiace towel : 9 months 5312 Pllow covers,

Pillow : 24 months

Blanket : 48 months

TH] Commitee nominated by ORM Tor Ten No committee Is nominated

condemnation on condition basis

| Specified frequency of _washinglary Not being adhered to for blankets. Total

cleaning of blankets and other linen items £8431 blankets. Washing: March 320 no.

is adhered to February 523 no,

Z51_| Passenger complaint on account of nen No feedback at Depot. The feedback is

is analyeed and corrective & preventive with the VT depot forall the train linen,

action is taken

252 |Feedback on nen quality 1s oblained Feedback is gen at VT by coach

through coach attendant as per RB's attendants upon arrival

guidelines

Ba} Pest / Rodent Control

7] Comprehensive contract covering pest | Board's Teter | Contract starled in June 11 for 2 years

rodent conivol in coaches and fodent | No2010(M)CI141/7 | and five depots. CSTM, MZN and DDR

Control in pit ines / coaching depot yards

awarded for 3 years under two packet

system

Voll at.21.12,2010

yards are covered. WB yard is not

covered as it is extensively concretised

‘All reserved (both AC and Non-AG)

covered under contract, unreserved

coaches may also be covered as per

requirement of Railways

Unreserved GSCZ coaches are also

covered. GS and SLR are not being given

Pest/ Rodent Control treatment,

Minimum frequency of pest control

treatment is adhered to

‘AC coaches | Panty cars : Fortnightly,

Reserved Non-AC coaches : Fortnightly in

first 3. months, monthly thereafter,

Unreserved Non-AG coaches : Bi-monthiy

Maximum tolerance +7 days, on account

of operational exigencies, disturbance of

rake inks, ete

‘Adhered to.

‘Chemicals to be used (with brand names),

concentration, dose specified

Chemicals not specified and itis left to the

contractor who is allowed to rotate various

permitted chemicals for efficacy

Vv] Minimum frequency of rodent control Yes.

treatment is adhered to

AC coaches | Pantry cars : during every

Page 13 of 27

Coaching depot ~ Wadibunder, C.Rly.

April 2012

Primary maintenance,

Reserved Non-AC coaches : Weokly

Maximum Tolerance #7 days, on account

of operational exigencies, disturbance of

rake inks, ete

Personnel trained by cerlifed training

institutes deputed for pestrodent contro!

Trained and cerlified supervisor _is

available as laid down in the contract. Sh.

Ajay Jagannath Shahane and Shaka

\Venkatrao Bagade are trained by CFTRI

Fumigationimist teatment carried out

whenever coaches detached for

IOHIPOH, Pestirodent control carried out

before inducting the coach in service after,

IOHIPOH

Followed.

Vil, [In ofder to prevent cross infestation, Not rigorously followed. 2-3 adjacent

contractor may make effort to treat all AC coaches are being treated together

and all Non-AC coaches of a particular depending upon requirement and

rake together periodicity

‘Stickers indication date of past control and

next due date provided in doorwayitolet

‘Stickers are not being pasted. The date is

stencilled on the end panel outside the

coach. Sr. DME confirmed that they shall

switch to stickers within a fortnight,

Railways shall_make effon to detach

pantry cars from rakes once a month

(within reasonable tolerance) to facilitate

Complete vacation and intensive cleaning

for thorough pest J rodent control

treatment

Being done through sick marking,

Broad methodology for measuring the

level of infestation of cockroaches and

rodents and expected reduction over time

is in place

‘As par board's guideline for scale of

reduction over the period of contract.

ro Yas: required unscheduled veaiments

bre analysand corestve acon also carried out by the contractor

isten

i) Passenger amenlies ROVERS VaPOIN | Boas THUS Bag prOVIGES

types of coaches as specified No.2006/M(C)/141/2

Seuzrsaso0e

i) astrasre —Teclies ———Siandard | Appana Et | Standard pi no wih wide anobstracod

imegeted modulor pt ine Fave uned | Coscnng anal” | catwalts sper CAMTECH design

maintenance, CAMTECH nn However, the pit line rails are supported

NeCAMTECHINIS! | yy contmuous was rater than pars

ier

2 Examination and ropa padice in Para 1009 of Chg

cammage maintenance depot for wea | manuel

sete and roller bering

277] Whee snails Fara 108 a Ta] neat quant a jection adavon

to observation

Wheel profile should be checked

with Tyre defect gauge to ensure the

profile dimensions are within the

permissible limits,

141 coaches marked sick on account of

wheel

W

Limits for at tyres

The limits for permissible maximum fat

surfaces on tread for BG ICF coaches is

50 mm (reference Rly. Bas Letter no.

83/M (N)/960/1/Vol I dated 15/18.3.99)

Boing followed,

iW

Guidelines for whee! inspection in

open line depots (Ref RDSO CMIK003)

In addition to normal checks exercised on

Guidelines for wheel inspection CMI KOS

are followed.

Page 14 of 27

Coaching depot ~ Wadibunder, C.Rly.

April 2012

‘wheel condition during primarylsecondary

maintenance of coaches, a detailed

inspection of wheels should be done when

the coaches are received in sickline for

attention for either schedules or out of

course attention, The wheels sets shall be

inspected for the following conditions and

acton taken as indicated for each

condition

‘a)_| Shattered Rim

b)_| Spread Rim

©) _| Shelled Tread

@)_| Thermal Cracks

@)_ | Heat checks

1) __| The defective wheel should be sent The depot has a wheel lathe which is out

{to workshop for repairs after entering of order on date. All the wheels are being

inthe maintenance card details of the sent to shop for repairs,

work order and date of dispatch to

workshop.

YW) _ | No repairs, except wheel profling of Followed,

wheel sets is permitted to be done in

the maintenance depot.

272_| Roller Bearing Axle Boxes Para 1009 b of Chg | Indicate quantum of rejection in addition

‘manual

to observation

‘Kcoath should invariably be detached

from service forthe following defects

i) Hot axle box

il) Damaged axle box

ii) Damaged front or rear cover

Iv) Seized roller bearing

V) Coach involved in accident,

derailment, fire, flood etc.

Being done. The warm box Is checked on

arrival at CSTM. Spot check carried out in

the evening of 03.04.2012. Sh. Ishwar

Bagde Gr. Fitter was available at P/F 17

for checking rolling in of 12133 Pushpak

Exp. Axle box temperatures were being

checked with non contact thermometer of

which two were available and only one

was calibrated

Wy

Care Should be Taken nat to Keap coach

fitted with roller bearing stationary for a

long time. Coaches grounded for long

lime should be shunted up and down at

regular intervals,

Coaches fitted with roller bearing should

be checked to ensure that :-

i) No wash basin drain hole / discharge

pipe is directly above the axle box

li) The front and rear covers of the axle

boxes are not damaged, cracked or loose

ili) Clearance between axle box and wheel

is such that the axle box does not bind

against the wheel

Iv) Brake gear is properly adjusted to

avoid possibilty of brake binding

Followed.

2721 | Axle box is examined for grease oozing Being checked for grease oozing on the

ut from rear cover and corrective action rear cover during maintenance.

is taken. Concerned shop needs to be

advised for necessary corrective and

preventive action.

27.3 _| Axle box temperature measurement by | Carriage Dle/RDSO | Being done.

letter no. MC [AB dtd

21.08.09

‘non contact lype temperature measuring

instrument during rolling in examination:

Temperature to be checked at axle box

top (crown) at front face of axle

Followed. Please see 27 2() above.

iy

If temperature is found above 80°C, the

Ts being done, For Primary trains coaches

Page 15 of 27

Coaching depot ~ Wadibunder, C.Rly.

April 2012

affected coach will be detached

with 70°C on arrival are also detached

274 | Minimum permissible wheel diameter | RB Tetler no. 921M

In ICH design BG coaches. (©)N37I2 Vol V dtd

254.11

1) _| Shop issue size of wheel set should be Followed. The depot has not received

837 mm diameter less than 837mm in ex POH

coaches.

| Condemning diameter of the wheel in ‘Gauge available and staff is conversant.

service, measured at a distance of 66.5

mmm from the outer face of the rim shall be

825 mm.

28 | Attention brake block hangers on ICF | Carlage DtelRDSO

coaches ~ to avoid failures letter no. MC

IICFIBID dtd

03.07.08

2B.1_| The new brake block should be procured The depot is obtaining Brake blocks from

as per revised spec C ~ 9808 Rev 2 and MTN store depot. The detalis of

dg no. SK - 93286 Alt § purchased description are not available in

the depot. The description procured in

IREPS is for C 9809 rev. 4 of May ‘09 or

latest. C-9808 is used for Brake block

hanger.

2B2_| Maintenance of brake gear rigging should Being done.

be given as per guidelines circulated by

EDICarriage IRDSO vide letter no. MC

JIGFIBID dtd 03.07.09

2 _| Other items:

28.1_| Changing of air brake hose pipe: Carriage Die/RDSO | Could not be checked as depot does not

Air brake hose pipe to be changed in | letter no. MC /APB | maintain records. The hose pipes are

every alternate POH attention. dtd 19.02.09 changed in the workshop. A few hose

pipes on spare coaches were checked

which were not more than 3 years (2 POH

cycles) old. There were however new

pipes of May’07 make make available in

the substore

292 | Fire retardant Tems are provided in| RDSO spec and | Rexene, Curfains Laminates PVC ele. are

coaches as per RDSO specification STR centrally procured by COS office to

RDSO's fire retardant specifications as

per IREPS.

253 [FAC ameniies are provided as per Carpets are not being provided

guidelines circulated vide

DGiCarrgiRDSO's —etter_ «no

MGIGBIACIBG dtd 28.04.10

284 [Additonal amenities / ‘aciliies in GSCN | RB Teller no. 20047 | Full complement of snack tables not

type of coaches are provided as under: | M_(C)/165/16 td | provided.

> Snack table in each bay. 29.03.05

> Mirrors in each bay

> Magazine holders on partition

wall

> Bottle and tumbler holder

255 _| Maintenance of Duronto express?

7

Patiem of maintenance for Duronto Wain

as being followed for Rajdhani trains with

pit examination at both end should also be

foliwed,

RB latter no. 2008/M

(oytati2 ‘td

25.08.09

W

Rolling — in and roling- out examination

may also be conducted for each of the

Duronto tains at the respective

operational halts and also at the terminals

during the joumey. Such safety

examinations of the Duronto trains may be

RB letter no. 2000/M

(cyrati2 dtd

25.08.09

NO DURONTO RAKES ARE BASED IN

WB DEPOT

Page 16 of 27

Coaching depot ~ Wadibunder, C.Rly.

April 2012

Periodically super checked at the level of

officers.

i

‘Short distance Duronto with only only ACT

Non AC chair car may be permitted to run

fon the extant patter for Shatabdi trains

with a terminal attention at other end on

platform / stabling line. A minimum 2 hrs

‘may be planned at the non primary end to

tenable thorough attention to cleanliness,

hygiene and passenger amenities at other

end,

RB latter no. 2008/M

(cytati2 td

26.07.11

™

Cleaning of Vinyl wrapping on Duranto

rake coaches

Mild detergent should be used with normal

Jot of water. High pressure water jet

should not be directed towards Vinyl

‘wrapping,

RFs letler no, MD

22.151 ata 09.02.10

BES Rteatoh Oa apg EDICaRGROSOT

Lee feter a

rooadar Tr alg in Da aTOT

fetrampassesthemomnated pa, caw | MCICBMM cd

Sat shod wat aut aglanty Tose /| 09092000, &

hang! Gren under gear parte | Maerance manual

coaches special atenion should be pad | ,, a", sping for

to air springs in case of coaches provided | ™2niNe a

Mio apg, a semaay Seren acy

Slo tsa be enuured ae a |RODSCI209

springs are in inflated condition by noting | “0t» SeP'

bra he leveling wave. lover eB

horton postion. Incase oot

tobi ot the a sings ot any

parted caach tase shuld ted

By er apg ian cock ed epee ot

hn shoul bo reac 160 gh ot he

coaul shuld be dace

BET anaiyaisof sick marking and onvouls

Sach detache

7] titer pinay coach-aataaimen © By Gna GecRInOR are ara

Dnahoed ard toner revenive

tcton ian. “Dele of pnary

fetscamart for last" years Yo" be

soloed

i] wetter secondary deiachnent bang Briary coach detachments are analyaed

analysed and corrective & preventive 51 cases of secondary coach detachment

action taken. Detalls of secondary ‘of WB based trains have taken place in

detachment for ast "3 Yous tobe of. based 9

este

i Weta -onrous ach deterrent Wo eiroute coach detachment oT WE

Inesieted tnd coecive 8 srovrive opal nthe lat toe years

solar ‘akan Dota entute conch

Setacumart flan 9 year lobo eaocd

stthesigaon ep

255 Panes ar pins and Sa Wo CANTEGTT

sention Namtenance Moral

T [Facts avalale a6 por CAVTEGHT for Coasnes of

pulldnes av doaled h amenae Tis | 27 00,2

Be observed ie sin.

1 conection lp

Ganiteorvacoin

e

cares.

oifo7 208)

30 Fansenger tata

Oct OBHS & escorng oan

Page 17 of 27

Coaching depot ~ Wadibunder, C.Rly.

April 2012

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5991)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1112)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (899)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (932)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (619)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (546)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (357)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (831)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (477)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (275)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (426)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2281)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (99)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (125)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (270)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (232)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (235)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (75)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tech Spec Bje CraneDocument80 pagesTech Spec Bje Craneabhimanyutiwari1234No ratings yet

- SeniorityDocument1 pageSeniorityabhimanyutiwari1234No ratings yet

- Inspection Note of Sri Anand Kumar21.01.23Document1 pageInspection Note of Sri Anand Kumar21.01.23abhimanyutiwari1234No ratings yet

- Annex1 Bje CraneDocument4 pagesAnnex1 Bje Craneabhimanyutiwari1234No ratings yet

- Holiday 2023.Document4 pagesHoliday 2023.abhimanyutiwari1234No ratings yet

- Bje 12 DN Memo PDFDocument1 pageBje 12 DN Memo PDFabhimanyutiwari1234No ratings yet

- Cancel PDFDocument1 pageCancel PDFabhimanyutiwari1234No ratings yet

- Leave Rules: Leave On Average PayDocument10 pagesLeave Rules: Leave On Average Payabhimanyutiwari1234No ratings yet

- Draft - Smart Yard Spec. 2Document14 pagesDraft - Smart Yard Spec. 2abhimanyutiwari1234No ratings yet

- Type of CoachesDocument2 pagesType of Coachesabhimanyutiwari1234No ratings yet

- Steel Melting Shop Procedures..: Prepared By: M G Sunil, Sse /TTCDocument50 pagesSteel Melting Shop Procedures..: Prepared By: M G Sunil, Sse /TTCabhimanyutiwari1234No ratings yet

- LHB Coaches DetailsDocument5 pagesLHB Coaches Detailsabhimanyutiwari1234No ratings yet

- Zonal Railway Training Institute, C. Rly., BhusawalDocument6 pagesZonal Railway Training Institute, C. Rly., Bhusawalabhimanyutiwari1234No ratings yet

- Article RdsoDocument18 pagesArticle Rdsoabhimanyutiwari1234No ratings yet

- Fundamental of Coach DesignDocument9 pagesFundamental of Coach Designabhimanyutiwari1234No ratings yet

- Information of Technicain Marks of CEN No 01-2014Document2,668 pagesInformation of Technicain Marks of CEN No 01-2014abhimanyutiwari1234No ratings yet

- 1434531469746-Coach & Wagon Bogies PDFDocument156 pages1434531469746-Coach & Wagon Bogies PDFabhimanyutiwari12340% (2)

- RWF DraftDocument87 pagesRWF Draftabhimanyutiwari1234No ratings yet

- RWF DraftDocument87 pagesRWF Draftabhimanyutiwari1234No ratings yet