0 ratings0% found this document useful (0 votes)

31 viewsSR Al WPS 011 BW

SR Al WPS 011 BW

Uploaded by

hanz bermejoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

SR Al WPS 011 BW

SR Al WPS 011 BW

Uploaded by

hanz bermejo0 ratings0% found this document useful (0 votes)

31 views2 pagesOriginal Title

SR-AL-WPS-011-BW

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

31 views2 pagesSR Al WPS 011 BW

SR Al WPS 011 BW

Uploaded by

hanz bermejoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

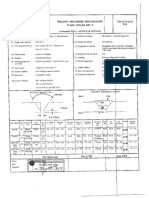

SOLUS WELDING PROCEDURE APPROVAL RECORD FORM (WPAR) Regs 1 ots

a Solus Testing Ltd. Unit I, Cogs Ind. Park, Welded in accordance with Test rasord no.

Testing ‘Morven St,Creswell, Worksop, Notts S80 4AJ BSEN ISO 15614-2 : 2005 SS 106309/P

Tel: 01909 722722 Fax: 01909 722102

Manulacturers name & address issue no.

SHEMARA REFIT LLP - Belvedere Rd, Southampton. $014 SRY. 1

Welding procedure n0. gp. ay -WPS-011-BW Date of Welding 15th September 2015

Extent of Approval

‘Weng Prose Metal Inert Gas (131) - Synergic Pulsed / Single Wire

soint Type: Butt Welds (bs,gg), T-Butt Welds (bs,gg) & Fillet Welds (plate & pipe)

Paral Group 23 to 23 & 22.1 1022.1 conations of tenpored ‘Not Applicable

Mota Thickness (mm) Butt: 3mm to 12mm / Fillet: 3mm to 12mm (Throat Thickness — 4.5mm to mm)

‘Outside Diameter (rm): 500mm & Above (150mm & Above welded in PA & PB Rotated Position)

Ful natal 1905 BSEN ISO 18273 : S AL 5183 or Similar - 1.2mm Diameter

Shloldng Goan BOC Pureshield Argon (99.98% Commercially Pure) - BSEN ISO 14175 : Class I

Type of Welding Curent DC Positive

Welding Postions All Positions (except Vertical Down & J-L045)

Preheat: Minimum 5°C (Interpass Temperature - 175°C Maximum)

Post Weld Heat Treatment andor Ageing:

‘Not Required DO NOT CHILL

OTHER INFORMATION: Procedure Approval for Single Run Welding from Both Sides Only.

Material Type used for Procedure: Aluminium Alloy - BSEN 485-2 : 6082 T651

Material Group: Group 23 - Sub Group 23.1 - Aluminium-Magnesium-Silicon Alloys

Material Heat No.: _ WNRL/IS-14007011 - Certificate No: 150SLB8646

Consumable Type: ESAB Autrod 5183

Consumable LotNo.: RBIS191165 - Test CertNo.: BC23925570 Rev 0

Heat Input: 0.42-0.51 Kj/mm - Approval Range +/- 25% of Heat Input Values

Lloyds 1U 1506

‘The statements in this record are cortect. The test welds were prepared, welded and testad in aovordance wth he raqutements of the above standard,

TEST WITNESSED BY: FOR AND ON BEHALF OF SOLUS TESTI

C.Olsen M.Burnham

Name a Signed. lame, ‘Signed

positon: Lloyds Register - SOU1500725 postion... Test House Manager

15-09-2015 30-09-2015

Date: i Date i

f LUS DETAILS OF WELD TEST Page 2 of 3

Fes wast ns, Unk Capstebstra ru, Manan sieee | Weded i accordance wit Test Record We.

‘resell, Worksop 580 4A)

Be: 01909 722722 Ree 01900 722100 BSEN ISO 15614-2 : 2005, SS 106309/P

‘Manufacturers name & address: Manufacturers welding procedure | Tecaton af teat

SHEMARA REFIT LLP - Southampton. $014 SRY. SR-AL-WPS-011-BW Shop

‘Welder's name & identity No. Wielding Process

ADYER AD ‘Metal Inert Gas (131) - Synergic Pulsed

Joint Type Single Vee Plate Butt Weld Method of Preparation and Cleaning Machine, Grind

(Both Sides, with Gouging) & Wirebrush

Parent Material Specification BSEN 485-2 : 6082 T651 ‘Material Thickness (mm) ‘6mm Plate

Outside Diameter (mm) Not Applicable

Welding Position Vertical Up (PF)

Joint Design Welding Sequence

Welding Details

fun | Process | _Skeof Current [Voltage | Type of Curent] Wire Feed | Travel Heat input

Fille Metal a v Polarity Speed | Speed

1 | i | 12mm 120-195 | 22-23 DC Pos WA | 4Smm/see | 047-0.51Kjmmp

2 | 131 | 12mm 120-125 | 22.23 DC Pos WA | 5.0mm/sec | 0.42-0.46Kjmaq

BSEN ISO 18273 : '

Filer Metal Classification and tradename § AL $183 Any Specs aking orDyjing ‘Not Applicable

ne BOC Pureshield (Class 11) Se ioe me Sitios! 15-20 LPM,

a ‘Not Applicable ‘* Not Applicable

‘Tungsten Electrode Type /Size ‘Not Applicable Details of Back Gouging /Backing Grind & Weld from Reverse

Preneat temperature Minimum s°C Pest Weld Heat Treatment andlor Agcing* Not Applicable

Interpass Temperature Sees Heating and cooling Rates *

Not Required/DO NOT CHILL

The satemants in ths create ae core. The et welds were prepared, welded and tested n accordance withthe eqirment ofthe above standard

TEST WITNESSED BY: Ah, FOR AND ON BEHALF OF SOLUS TESTING Ve

Name:.....C.Olsen Sioned. ae Name:.....MiBurnham....... signeds,.. Oe

position... Lloyds Register - SOU1500725 Postion: . Test House Manager

Date 15:09-2015 ate: 30-09-2015

* For other information see Supplementary Sheet

powr.o1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (6016)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1112)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (908)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (937)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (619)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (546)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (358)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (831)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (478)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (275)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (434)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2281)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (99)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (125)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (273)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (232)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (235)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (75)

- AWS Maintenance-of-Welder-Certification-Form (01-2023)Document1 pageAWS Maintenance-of-Welder-Certification-Form (01-2023)hanz bermejoNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- N-7018-2.5mm-64210048 (F18)Document1 pageN-7018-2.5mm-64210048 (F18)hanz bermejoNo ratings yet

- Son WPS 262 WQTDocument1 pageSon WPS 262 WQThanz bermejoNo ratings yet

- PWPS Image 1 1024x1024Document1 pagePWPS Image 1 1024x1024hanz bermejoNo ratings yet

- JRY 02CS PipeDocument2 pagesJRY 02CS Pipehanz bermejoNo ratings yet

- Tutorial How To Change The Sleep Settings On Your Acer Laptop ScreenshotsDocument3 pagesTutorial How To Change The Sleep Settings On Your Acer Laptop Screenshotshanz bermejoNo ratings yet

- AWS Certified-Welder-Application (01-2023)Document2 pagesAWS Certified-Welder-Application (01-2023)hanz bermejoNo ratings yet