Iso 20lae05aa101

Iso 20lae05aa101

Uploaded by

Mohd Effiezool YaserCopyright:

Available Formats

Iso 20lae05aa101

Iso 20lae05aa101

Uploaded by

Mohd Effiezool YaserCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Iso 20lae05aa101

Iso 20lae05aa101

Uploaded by

Mohd Effiezool YaserCopyright:

Available Formats

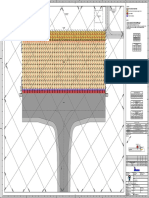

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

NPD Weight

Description Qty

[DN] [Kg]

N

A A

76 76

B 192 7 B

22 3.4

1.6 45

13

1.7 +X=+354/11-30UMY01

+Y=-1795/C-30UMY01

+Z=+10105

S10.2

64

US-03 63

14 12

5 7.2 2.1

59 50X25NPD

20LAE05AA002

0 15 STEM U 22

C 30 11 5

C

07-0050-212 7.1

447 133

51 1.5 192 20LAE05AA001

SEE ISO

1.8 20LAE05BR401

STEM U

8.1 07-0050-212

+X=+354/11-30UMY01 3.3

20LAE05AA101 +Y=-1979/C-30UMY01 10

133 22 76

STEM U +Z=+10054 7

71-0050-203 +X=+354/11-30UMY01 1 PIPE-SMLS, S-160, A106-C, ASME-B36.10M 50 3.8 M 41.8

17

16 1.4 +Y=-2763/C-30UMY01 2 REDUCING BRANCH TEE, S-160 x S-160, A234-WPC, 50X25 1 2.2

G5.2 B6.2 +Z=+10105 ASME-B16.9

S11.1 9

0 3 ELBOW 90 DEG LONG RADIUS (90.0 DEG), S-160, 50 4 6.0

LP-03 27 8 A234-WPC, ASME-B16.9

4 WELD NECK FLANGE, CL2500 WNRF(S-160), A105, 50 2 38.2

D 300 26

3

F4.2 76 ASME-B16.5

D

F4.1 G5.1 B6.1 5 GROOVED GASKET, CL2500, 316L/GRAPHITE 50 2 -

7

6 STUD BOLT, A193-B7 / A194-2H, ZINC NICKEL 25 16 -

1.9 6 PLATING/PTFE BASED COATING, ASME-B18.2.1, WITH 2

NUTS, 2 WASHERS PER BOLT, 210 MM BOLT LENGTH

7 GATE VALVE, CL2500, A105N, ASME B16.34 50 2 86.6

5 8 CONTROL GLOBE VALVE, A216-WCB, CL2500, ASME B16.34 50 1 90.0

23

18 9 THROTTLE VALVE, CL1500, A182-F22, ASME B16.34 50 1 61.0

10 UNDER SUPPORT 50 2 -

838

0 9.1 11 LOCKING POINT 50 1 -

1.1

1.3

D 20LAE05AA003

NP

50 19 STEM U

E 74-0050-221 E

SEE ISO

20LAB05BR001

+X=-2260/11-30UMY01

+Y=-1795/C-30UMY01 3.2 325.8

76

+Z=+10105 5 4 PENGERANG POWER SDN BHD

+X=+354/11-30UMY01

(Company No. 1089490-K)

+Y=-2763/C-30UMY01

+Z=+9115 S10.1 Level 51, Tower 2, PETRONAS Twin Towers

Kuala Lumpur City Centre

1.2 US-03 50088 Kuala Lumpur, Malaysia

F F

77

PETRONAS PETRONAS TECHNICAL SERVICES SDN BHD

68 3.1 TECHNICAL

3 40 (Company No. 347848-X)

0 SERVICES

+X=+354/11-30UMY01 Tower 1, PETRONAS Twin Towers

3 Kuala Lumpur City Centre

+Y=+2651/B-30UMY01 50088 Kuala Lumpur, Malaysia

+Z=+9115

77

2

G G

76

1.1

418

AG Malaysia Sdn Bhd MMC

H Siemens AG Siemens Malaysia Sdn. Bhd. MMC Engineering Services Sdn Bhd

H

Level 1, Reception, CP Tower unit 702, Level 7, Wisma Zelan

PG ES PM No. 11, Jalan 16/11 No. 1, Jalan Tasik Permaisuri 2

50NPD

Pusat Dagang Seksyen 16 Bandar Tun Abdul Razak

63067 Offenbach, Germany 46350 Petaling Jaya, Malaysia 56000 Kuala Lumpur

Malaysia

SEONGHWA

1 Industrial Co., Ltd

SEE ISO PCP-SAG-PIP-ISO-LAE-479250

30LAE05BR001 Ursprung/Original Ursprung-Nr./Original-No. REV Urspr.-PKZ-Nr.

J +X=+354/11-30UMY01 Orig.-PC J

MY1008-20LAE05-&MTB020-111071 01/00

+Y=+2651/B-30UMY01

+Z=+8620

PENGERANG COGENERATION PLANT MY1008

446536507 &MTC030

INCH-DIA

K 20LAE05BR001 K

SHOP 0 479250

FIELD 6.4 L/M SPISO PLMS-P

R0 2018-02-26 S.W.Kim J.W.Han AS BUILT

THK THK THK FIELD SHOP

(mm) (mm) (mm) in% BW SW RFN FIL in% BW SW RFN FIL Definition

1 50 F BW 60.3 8.74 No 9 50 F BW 60.3 8.74 No 17 50 F BW 60.3 8.74 No R 100 0 0 0 R 100 0 0 0 Radiographic Examination

2 50 F BW 60.3 8.74 No 10 50 F BW 60.3 8.74 No 18 50 F BW 60.3 8.74 No U 0 0 0 0 U 0 0 0 0 Ultasonic Examination.

80

3 50 F BW 60.3 8.74 No 11 50 F BW 60.3 8.74 No 19 50 F BW 60.3 8.74 No P P Liquid Penetration Examination

0 0 0 0 0 0 0 0

4 50 F BW 60.3 8.74 No 12 50 F BW 60.3 8.74 No - -

S 10 100 100 100 S 10 100 100 100 Magnetic Examination

5 50 F BW 60.3 8.74 No 13 50 F BW 60.3 8.74 No

L 6 50 F BW 60.3 8.74 No 14 50 F BW 60.3 8.74 No H 0 0 0 0 H 0 0 0 0 Hardness Testing

7 50 F BW 60.3 8.74 No 15 50 F BW 60.3 8.74 No M 0 0 0 0 M 0 0 0 0 Metascope or ferritic check 2016-01-05 M.J.Shin Piping

8 50 F BW 60.3 8.74 No 16 50 F BW 60.3 8.74 No V V Visual Examination 2016-01-05 S.W.Kim

Exportkennzeichnung AL: ECCN:

Remarks

100 100 100 100 100 100 100

The extent of NDE is mandatory for shop and field welds of the

100

2016-01-05 J.W.Han

Isometric 20LAE05BR001

respective piping system as a designated lot.

Bearbeitung dieses Dokumentes, Verwertung und Mitteilung

- Final dimensions of valves and in- line components to be

checked by erection contractor before installation. General Weld type Addition for extent of NDE below 100%: All materials, all nominal pipe sizes Building: 30UMY

gestattet. Zuwiderhandlungen verpflichten zu Schadenersatz. BW : Butt weld and all welders shall be considered for a random spot examination of welds

- Pipe routing NPS < 3" (DN80) should be Position number acc. partlist SW : Socket weld

bzw bei Kennzeichen "AL:N" oder "ECCN:N", kann sich eine Genehmigungspflicht, unter anderem

checked by erection contractor at site Shop weld number O-LET : Weldolet, sockolet Set of Rules for

oder Geschmacks-mustereintragung vorbehalten. RFN : Reinforce Nozzle Construction

Insulation 60 mm

- All pipes without fit-up allowance Field weld number

Transmittal, reproduction, dissemination and/or editing of this FIL : Fillet

Export classification AL: ECCN: - Fit-up allowance of pipe = 150mm, Support type SF : Socket Fusion Pipe Material Class A25C2RA0120 max. allow. work. Temperature 175 C R0

M document as well as utilization of its contents and Goods labeled with "AL not equal to N" are subject to European or German export authorization which is additional marked with "+150" KKS-support number BF : Butt Fusion

20

communication thereof to others without express authorization - For Part No. only figure before dot to be Slope BL : Butt Lamination

are prohibited. Offenders will be held liable for payment of

when being exported out of the EU. Goods labeled with "ECCN not equal to N" are subject to US

matched with BOM Part No.

NL : Nozzle Lamination Internal Coating max. allow. work. Pressure 291 bar MY1008-20LAE05-&MTC030-479250

reexport authorization. Even without a label, or with label "AL:N" or"ECCN:N", authorization may be Flow direction SC : Solvent Cement

damages. All rights created by patent grant or registration of a - For shop pre-fabrication Referance

utility model or design patent are reserved.

required due to the final whereabouts and purpose for which the goods are to be used.

drawing no.

F

S

: Field weld

: Shop weld External Coating MY1008-61810-&MDC080-484504 Test Pressure 436.5 bar 1 /1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

You might also like

- Itp 001 PipelineDocument2 pagesItp 001 PipelineMohd Effiezool YaserNo ratings yet

- Project Specification Piping Class SummaryDocument41 pagesProject Specification Piping Class SummaryMohd Effiezool YaserNo ratings yet

- Adam Smiths Theory of Economic DevelopmentDocument4 pagesAdam Smiths Theory of Economic DevelopmentSazin Mahmud100% (2)

- Property Syllabus (Labitag)Document49 pagesProperty Syllabus (Labitag)ylessinNo ratings yet

- 30lbe51br302 - Rev 0Document1 page30lbe51br302 - Rev 0Mohd Effiezool YaserNo ratings yet

- 30lbe51br303 - Rev 0Document1 page30lbe51br303 - Rev 0Mohd Effiezool YaserNo ratings yet

- 30lbe51br301 - Rev 0Document1 page30lbe51br301 - Rev 0Mohd Effiezool YaserNo ratings yet

- 30LBF11BR411 - 2Document1 page30LBF11BR411 - 2Mohd Effiezool YaserNo ratings yet

- A Detail: Piping Isometric BuildingDocument1 pageA Detail: Piping Isometric BuildingMohd Effiezool YaserNo ratings yet

- 30lbe51br002-Rev 1Document1 page30lbe51br002-Rev 1Mohd Effiezool YaserNo ratings yet

- 10lab12br001-Rev 1 - 2Document1 page10lab12br001-Rev 1 - 2Mohd Effiezool YaserNo ratings yet

- 30lbf11br001-Rev 2Document1 page30lbf11br001-Rev 2Mohd Effiezool YaserNo ratings yet

- 30lae25br004-Rev 2Document1 page30lae25br004-Rev 2Mohd Effiezool YaserNo ratings yet

- 30lbe51br001-Rev 2 - 2Document1 page30lbe51br001-Rev 2 - 2Mohd Effiezool YaserNo ratings yet

- SP0793-6186-15-0020 - PVDC EXPANSION PROJECT LIME STONE MILLING BALL OFFLOADING CONCRETE LAYOUT AND DETAILS Rev.1Document1 pageSP0793-6186-15-0020 - PVDC EXPANSION PROJECT LIME STONE MILLING BALL OFFLOADING CONCRETE LAYOUT AND DETAILS Rev.1Hector HernandezNo ratings yet

- 30lbe51br411-Rev 1Document1 page30lbe51br411-Rev 1Mohd Effiezool YaserNo ratings yet

- 10lab12br001-Rev 1 - 1Document1 page10lab12br001-Rev 1 - 1Mohd Effiezool YaserNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- Sa048 SD TC Sib GN ST BBS 0001 - 02Document1 pageSa048 SD TC Sib GN ST BBS 0001 - 02Belal HyariNo ratings yet

- Note:: Scaleplate DescriptionDocument1 pageNote:: Scaleplate DescriptionAlbet MulyonoNo ratings yet

- TECHNICALPart 5Document1,521 pagesTECHNICALPart 5সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- Campus Map 8 5x11Document2 pagesCampus Map 8 5x11MeiNo ratings yet

- Control Board - Schematic v626Document1 pageControl Board - Schematic v626XuNo ratings yet

- Ricoh C4502 D143 D144 and OPTIONS Point 2 Point Diagrams PDFDocument29 pagesRicoh C4502 D143 D144 and OPTIONS Point 2 Point Diagrams PDFDawood AhmedNo ratings yet

- Limita Zona Protectie Autostrada 50m Fata de Axul Drumului (Conf. OG43/1997-Anexa1, Lit. B)Document1 pageLimita Zona Protectie Autostrada 50m Fata de Axul Drumului (Conf. OG43/1997-Anexa1, Lit. B)ciciNo ratings yet

- 0320289-TE-DAD-6410-006-00 SEPARATOR 10HHA30AT001-ModelDocument1 page0320289-TE-DAD-6410-006-00 SEPARATOR 10HHA30AT001-ModelVivek VinayakumarNo ratings yet

- Hydraulic SchematicDocument1 pageHydraulic Schematicg9f88kkp2tNo ratings yet

- Point To Toint DiagramDocument23 pagesPoint To Toint DiagramApenas MaxNo ratings yet

- De 22 36 DWG PF CH PL 00 FF 110 00Document1 pageDe 22 36 DWG PF CH PL 00 FF 110 00Mahmoud A. HafeezNo ratings yet

- Existing - Earthing - Layout For Bogra 230kV SubstationDocument1 pageExisting - Earthing - Layout For Bogra 230kV SubstationRashad SarwarNo ratings yet

- Ar PRM TDR Phase 02 Dde 0002Document1 pageAr PRM TDR Phase 02 Dde 0002Thota NageshNo ratings yet

- Schematic - Class-D Sub Monoblok - 2021-07-18Document1 pageSchematic - Class-D Sub Monoblok - 2021-07-18Sneha NamdevNo ratings yet

- Ms DD 4200 Ele DWG 0501 - Rev0 1Document1 pageMs DD 4200 Ele DWG 0501 - Rev0 1Agam AditiawarmanNo ratings yet

- B011 000 16 50 01205 - Rev 2Document1 pageB011 000 16 50 01205 - Rev 2GLOBUS ENGINEERSNo ratings yet

- Ed 0900 PRS Pid 000 09041CDocument1 pageEd 0900 PRS Pid 000 09041CMohamed ArafaNo ratings yet

- 21121-EL-DWG-0023 - AC Cable Route Layout & Cross SectionDocument2 pages21121-EL-DWG-0023 - AC Cable Route Layout & Cross SectionvishnutryNo ratings yet

- 150 A Introducción: Standard TuningDocument2 pages150 A Introducción: Standard TuningFelipe JuarezNo ratings yet

- 7-13-22_PB_Agenda_Packet 88Document1 page7-13-22_PB_Agenda_Packet 88smrasteg12No ratings yet

- De 22 36 DWG PF CH PL 01 FF 120 00Document1 pageDe 22 36 DWG PF CH PL 01 FF 120 00Mahmoud A. HafeezNo ratings yet

- Blameless 1200WDocument1 pageBlameless 1200WromllyNo ratings yet

- B01 TJ101MDocument1 pageB01 TJ101Malysamir.eetdNo ratings yet

- PML3 TPL SPC PMR02 02 DR A 30161 - R0Document1 pagePML3 TPL SPC PMR02 02 DR A 30161 - R0mukund maniNo ratings yet

- B01 TJ102MDocument1 pageB01 TJ102Malysamir.eetdNo ratings yet

- Bassbutler Final Corrected 3Document1 pageBassbutler Final Corrected 3Beckenbauer ErnstbergerNo ratings yet

- Oolsgv MSP V3abm GF DR P 009601 c03 - 2023.05.16 Sections & DetailsDocument1 pageOolsgv MSP V3abm GF DR P 009601 c03 - 2023.05.16 Sections & DetailsNitin SeenauthNo ratings yet

- BP2021-C026S-JWN01 - A01-Drainage System-Fp-1003-Roof Floor Plan - Main BuildingDocument1 pageBP2021-C026S-JWN01 - A01-Drainage System-Fp-1003-Roof Floor Plan - Main BuildingMohammad IsmailNo ratings yet

- Aye MRK BRS Arp 40001Document1 pageAye MRK BRS Arp 40001AKASH JANGIRNo ratings yet

- Ab-H-16 - Level 4 WestDocument1 pageAb-H-16 - Level 4 Westicas2017secaNo ratings yet

- C.LY70.SE.84.1-F2000/FLB001 01: NG - Erdgas / Natural GasDocument1 pageC.LY70.SE.84.1-F2000/FLB001 01: NG - Erdgas / Natural GasEngr. AtiqNo ratings yet

- Sbdo Ppa 105 3011 00Document1 pageSbdo Ppa 105 3011 00Douglas de Melo FélixNo ratings yet

- Ar PRM TDR Phase 02 Dse 0006Document1 pageAr PRM TDR Phase 02 Dse 0006Thota NageshNo ratings yet

- Rbs College StationDocument1 pageRbs College StationPooja waniNo ratings yet

- Kitchen SpecDocument1 pageKitchen SpecabebaNo ratings yet

- Oolsgv MSP V4ab GF DR P 009601 c01 - 2023.05.03 Sections & DetailsDocument1 pageOolsgv MSP V4ab GF DR P 009601 c01 - 2023.05.03 Sections & DetailsNitin SeenauthNo ratings yet

- B01 TL104MDocument1 pageB01 TL104Malysamir.eetdNo ratings yet

- Bp2021-C026s-Jwn03-A01-Drain System-Fp-1001-Ground and Roof Floor Plans - Sport HallDocument1 pageBp2021-C026s-Jwn03-A01-Drain System-Fp-1001-Ground and Roof Floor Plans - Sport HallMohammad IsmailNo ratings yet

- Attachement-1 RFC-29-18Document14 pagesAttachement-1 RFC-29-18Mohamed ArafaNo ratings yet

- Ed 0100 PRS Pid 000 01005uDocument1 pageEd 0100 PRS Pid 000 01005uMohamed ArafaNo ratings yet

- Ground Tiling Layout-Model333Document1 pageGround Tiling Layout-Model333SIDHARTH SNo ratings yet

- DHQC Cecb MB Ti Ar DW 1F 02 80705Document1 pageDHQC Cecb MB Ti Ar DW 1F 02 80705Kumudu PereraNo ratings yet

- Schematic - ODM-3 Overdrive Master - 2020-11-11 - 06-14-24Document1 pageSchematic - ODM-3 Overdrive Master - 2020-11-11 - 06-14-24Marcus FeilNo ratings yet

- M BMF 1a2ds0 CPHC SDR 620404Document1 pageM BMF 1a2ds0 CPHC SDR 620404pmcdasygeeNo ratings yet

- Ipu Iob: (PCB1) (PCB11)Document43 pagesIpu Iob: (PCB1) (PCB11)Miguel AlmoraNo ratings yet

- 032 - SECTION 5 - WELD MAP Rev01Document5 pages032 - SECTION 5 - WELD MAP Rev01Mohd Effiezool YaserNo ratings yet

- Job Pack Standardized Format Rev2 - SF Duct Burner View Port Repair InsulationDocument14 pagesJob Pack Standardized Format Rev2 - SF Duct Burner View Port Repair InsulationMohd Effiezool YaserNo ratings yet

- PTS Vs IP & JotunDocument8 pagesPTS Vs IP & JotunMohd Effiezool YaserNo ratings yet

- B Detail: Piping Isometric BuildingDocument1 pageB Detail: Piping Isometric BuildingMohd Effiezool YaserNo ratings yet

- Pipe Bend ReportDocument1 pagePipe Bend ReportMohd Effiezool Yaser100% (1)

- Proposed PipeDocument1 pageProposed PipeMohd Effiezool YaserNo ratings yet

- 5S4 Pipe Support DrawingDocument1 page5S4 Pipe Support DrawingMohd Effiezool YaserNo ratings yet

- MTW NOVATORK AR040983 20-100N.m 12 OCT 22Document2 pagesMTW NOVATORK AR040983 20-100N.m 12 OCT 22Mohd Effiezool YaserNo ratings yet

- MTW HI-FORCE 201700149 85-525N.m 14 JAN 23Document2 pagesMTW HI-FORCE 201700149 85-525N.m 14 JAN 23Mohd Effiezool YaserNo ratings yet

- MTW KING TOYO 438745 50-300N.m 14 JAN 23Document2 pagesMTW KING TOYO 438745 50-300N.m 14 JAN 23Mohd Effiezool YaserNo ratings yet

- Bfja Tag Critical A4Document2 pagesBfja Tag Critical A4Mohd Effiezool YaserNo ratings yet

- 001-FP 001Document2 pages001-FP 001Mohd Effiezool YaserNo ratings yet

- 30lbf11br001-Rev 2Document1 page30lbf11br001-Rev 2Mohd Effiezool YaserNo ratings yet

- 30lae25br005-Rev 2Document1 page30lae25br005-Rev 2Mohd Effiezool YaserNo ratings yet

- 30lbe51br001-Rev 2 - 2Document1 page30lbe51br001-Rev 2 - 2Mohd Effiezool YaserNo ratings yet

- 30LBF11BR411 - 1Document1 page30LBF11BR411 - 1Mohd Effiezool YaserNo ratings yet

- PCP Sag Pip DWG 480460Document2 pagesPCP Sag Pip DWG 480460Mohd Effiezool YaserNo ratings yet

- Welding Olet As PTSDocument1 pageWelding Olet As PTSMohd Effiezool YaserNo ratings yet

- Welding Olet As ASME B31.3Document1 pageWelding Olet As ASME B31.3Mohd Effiezool YaserNo ratings yet

- Jotun LatterDocument1 pageJotun LatterMohd Effiezool YaserNo ratings yet

- SCH PipeDocument1 pageSCH PipeMohd Effiezool YaserNo ratings yet

- TP1 - 04464539030100 - PCP Sag Pip DWG Lbe 47109001Document1 pageTP1 - 04464539030100 - PCP Sag Pip DWG Lbe 47109001Mohd Effiezool YaserNo ratings yet

- Mandatory Appendix 5 - Guideline On The Approval of New Materials Under The ASME BPV CodeDocument4 pagesMandatory Appendix 5 - Guideline On The Approval of New Materials Under The ASME BPV CodeMohd Effiezool YaserNo ratings yet

- Research PRBLMDocument88 pagesResearch PRBLMAarti ChaudharyNo ratings yet

- Economics Class 11 Unit 12-Government-FinanceDocument0 pagesEconomics Class 11 Unit 12-Government-Financewww.bhawesh.com.npNo ratings yet

- Variable Loadsdocx PDF FreeDocument8 pagesVariable Loadsdocx PDF FreeJOHN LENNARD DATUINNo ratings yet

- KuppusamyDocument3 pagesKuppusamyGuna ChandranNo ratings yet

- MK Marketing PoDocument2 pagesMK Marketing PosoumikNo ratings yet

- The Revolt Against Formalism in - Morton WhiteDocument23 pagesThe Revolt Against Formalism in - Morton WhiteMarcelaNo ratings yet

- Nonica CoxDocument4 pagesNonica CoxBiranchi Prasad SahooNo ratings yet

- Cambridge International AS & A Level: Economics 9708/11Document12 pagesCambridge International AS & A Level: Economics 9708/11Lewis HankinNo ratings yet

- Jason Zweig With Seth Klarman - Interview 170510 (CFA Institute)Document6 pagesJason Zweig With Seth Klarman - Interview 170510 (CFA Institute)neo269100% (1)

- Laporan Audit Dan Keuangan PT. Express Transindo Utama TBK PDFDocument89 pagesLaporan Audit Dan Keuangan PT. Express Transindo Utama TBK PDFSeptian TssNo ratings yet

- Philippine Context: Bonds, Insurance, and All Risk in ConstructionDocument20 pagesPhilippine Context: Bonds, Insurance, and All Risk in ConstructionPaulGabriel DelosSantosNo ratings yet

- Aluminium Alloy International Comparison SpecificationsDocument1 pageAluminium Alloy International Comparison Specificationsnethaji nethajiNo ratings yet

- Needed Materials Specifications: Item Quantity Unit Description Unit Weight Total Weight Unit Cost Total Cost RemarksDocument2 pagesNeeded Materials Specifications: Item Quantity Unit Description Unit Weight Total Weight Unit Cost Total Cost RemarksRodel RentaNo ratings yet

- (22560394 - Economics and Business) Model of The Factors Influencing Competitiveness of The Latvian Fisheries Sector ClusterDocument7 pages(22560394 - Economics and Business) Model of The Factors Influencing Competitiveness of The Latvian Fisheries Sector ClusterEnoch TwumasiNo ratings yet

- (Ebooks PDF) Download Heterodox Macroeconomics Models of Demand Distribution and Growth 1st Edition Robert A. Blecker Full ChaptersDocument84 pages(Ebooks PDF) Download Heterodox Macroeconomics Models of Demand Distribution and Growth 1st Edition Robert A. Blecker Full Chaptersgelchuduxa100% (3)

- Market SegmentationDocument18 pagesMarket SegmentationAbhinav JayabalanNo ratings yet

- Globe LetterDocument1 pageGlobe Letterweng castanasNo ratings yet

- Brigada Eskwela Action PlanDocument4 pagesBrigada Eskwela Action PlanRama Grace Tamayo Cabrera88% (8)

- Entrepreneurship and EconomicsDocument14 pagesEntrepreneurship and EconomicskentbnxNo ratings yet

- Infrastructure of India: Presented By:-Nisha Nair Rajeev JhaDocument18 pagesInfrastructure of India: Presented By:-Nisha Nair Rajeev JhaNichu@No ratings yet

- ENVEOLI130301ENDocument3 pagesENVEOLI130301ENcarrei JohnNo ratings yet

- Keurig Financial ProjectionsDocument5 pagesKeurig Financial ProjectionsJacob RandlettNo ratings yet

- Royal Berkshire Hotel UKDocument1 pageRoyal Berkshire Hotel UKRabinarayanNo ratings yet

- LA Pro Express January 20 2011Document3 pagesLA Pro Express January 20 2011Los Angeles Professional ExpressNo ratings yet

- Forex Hedging Handout 1Document9 pagesForex Hedging Handout 1Sheira Mae GuzmanNo ratings yet

- Philippines AgricultureDocument8 pagesPhilippines Agricultureohyeahlazy100% (2)

- 01 DB 9+3 DOA - 1bi mt103 (One-Way)Document17 pages01 DB 9+3 DOA - 1bi mt103 (One-Way)Yadav Arun100% (1)

- Why Study Financial Markets and Institutions?: Chapter #1 by Sajad AhmadDocument15 pagesWhy Study Financial Markets and Institutions?: Chapter #1 by Sajad AhmadMarlon CorpuzNo ratings yet