See Note 7: Gland End View

See Note 7: Gland End View

Uploaded by

AliZenatiCopyright:

Available Formats

See Note 7: Gland End View

See Note 7: Gland End View

Uploaded by

AliZenatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

See Note 7: Gland End View

See Note 7: Gland End View

Uploaded by

AliZenatiCopyright:

Available Formats

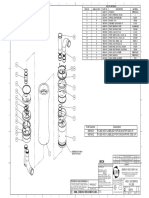

DWG NO.: REV.

REVISION HISTORY: ITEM PART NUMBER DESCRIPTION MATERIAL QTY

REV 1 - ECN 5581 - 2/4/22 - FH

* 1 FS26716-C17-022 MONOLITHIC PRIMARY RING CBN 1

FS58961 3 REV 2 - ECN 5883 - 8/8/22 - WC

* 2 FS26717-H02-022 CARTRIDGE SEAT MATING S SIC 1

REV 3 - ECN 6418 - 7/17/23 - WC

2.081 .770 RING

MIN N.O. BOLT SURFACE * 3 FS568-VT-126 O-RING FKM 1

* 4 FS568-VT-031 O-RING FKM 3

* 5 GG5500-TEF-022 BIG BORE GLAND GASKET PTFE 1

.601 * 6 FS10971-TEF-127 ANTI-EXTRUSION RING PTFE 1

MIN BOX 2.018 7 FS27048-TEF-022 THROTTLE BUSHING GLASS FILLED PTFE 1

16 DEPTH

8 FS27181-022 DYNAMIC DRIVE RING

ASSEMBLY

316 SS 1

SEE NOTE 7 10

9 FS27150-022 SINGLE SEAL WELDED 316 SS 1

SLEEVE ASSEMBLY

17 10 FS27146-R01-022 SPRING HOUSING 316 SS 1

11 FS27156-CST-022 GLAND 316 SS / CF8M 1

12 FS26728-R01-022 SETTING COLLAR 316 SS 1

.538 .970 [1] * 13 FS26722-R02-000 COIL SPRING ALLOY C276 6

* 14 #10-24 X 5/16 LG. CUP POINT SET SCREW 316 SS 4

B-B * 15 SHDSS 10-24 X 1/4 SLOTTED HALF DOG SET 316 SS 2

SCREW

* 16 FS23215-000 SOCKET HEAD CAP SCREW 316 SS 4

* 17 FS22798-000 SETTING CLIP POWDERED METAL 4

11

8

5

12

C-C

2.875

MIN 1.375 +- .000

BORE 1.950 3 9 4 2 1 4 6 10 4 7 .002

NOTES:

(*) RECOMMENDED SPARE PARTS

WARRANTY APPLIES TO DIMENSIONAL DATA ONLY.

COMPLETE SERVICE DATA WAS NOT SUPPLIED.

SEAL SHAFT/ 13

OD SLEEVE

2.010

[1] 3/8 NPT

5 1/4

14 SEE NOTE 6. 15

[4] 3/8 NPT 291 HURRICANE LANE

2X 30 WILLISTON, VT 05495

FLAT GASKETED GLAND

BOLT TORQUE SPECIFICATIONS

CUP POINT SET SCREW

TORQUE SPECIFICATIONS [in.-lbs.]

(802) 878-8307

SHAFT SIZE RECOMMENDED TORQUE SCREW SIZE ALLOY STEEL STAINLESS [2]/[3] CUSTOMER INFO APPLICATION DATA

1.000-2.000 in. 20 ft.-lbs. #10 36 26 CLIENT: PRODUCT:

[24-50 mm] [27 N-m]

1/4 87 70 1.064 [2]

2.125-3.250 in. 25 ft.-lbs. END USER: TEMPERATURE:

[53-80 mm] [34 N-m] 5/16 165 130 1/4 NPT LOCATION: SHAFT SPEED:

3.375-4.000 in. 30 ft.-lbs. 3/8 290 230 45

[85-100 mm] [41 N-m] 1/2 620 500 10 PLANT: BOX PRESSURE:

PLANT ITEM NO.: SUCTION PRESS.:

EQUIPMENT INFO DISCHARGE PRESS.:

CARTRIDGE SEAL INSTALLATION NOTES: OEM: VAPOR PRESSURE:

1. SURFACE OF SHAFT OR SLEEVE ON WHICH SEAL IS INSTALLED MUST BE MACHINED TO 63

RA- IN FINISH OR BETTER. EQUIPMENT TYPE: ANSI B73.1/B73.2 SPECIFIC GRAVITY:

2. LIGHTLY LUBRICATE THE SHAFT WITH A SUITABLE AND COMPATIBLE LUBRICANT TO GLAND CONNECTIONS 4X .525 SLOTS MODEL/FRAME SIZE: GROUP I VISCOSITY:

ASSIST IN INSTALLATION.

3. GENTLY SLIDE THE SEAL ON THE SHAFT WITH THE GLAND GASKET FACING, BUT CLEAR

LABEL PURPOSE

EQUI-SPACED ON A SERIAL/DWG NO.: API PLAN:

OF THE SEAL CHAMBER. 1 FLUSH

4.000 B.C. [3] 1/4 NPT

4. REASSEMBLE THE PUMP AS DESCRIBED BY THE PUMP OEM.

2 QUENCH/VENT STYLE VBSMS3 VANTAGE SERIES LARGE/TAPERED BORE

5. LUBRICATE AND TIGHTEN GLAND BOLTS USING THE LEGACY METHOD (STAR PATTERN).

6. ALTERNATELY TIGHTEN THE PROVIDED SET SCREWS UNTIL THEY ARE SECURE. 3 DRAIN 2.090 STATIONARY MULTI-SPRING CARTRIDGE SEAL WITH FVD

7. REMOVE THE SOCKET HEAD SCREWS AND SETTING CLIPS FROM THE SEAL. SAVE THESE

4 FLUSH 3 TYP. GLAND END VIEW DWG NO.: SHAFT SIZE:

FOR FUTURE USE IN SEAL REMOVAL OR IMPELLER ADJUSTMENT.

8. PLUG UNUSED CONNECTIONS. B FS58961 1 3/8

THIS CONFIDENTIAL DESIGN IS OWNED BY FLEXASEAL AND MAY NOT BE USED EXCEPT IN CONFIDENCE AND FOR THE BENEFIT OF FLEXASEAL. ALL RIGHTS ARE RESERVED. SEAL CODE: 22VBSMS3-04C2VS2-6 JOB NO.: REV.

DRAWING NOT TO SCALE

THIS MEDIUM (PRINT, DIGITAL ETC.) IS SUBJECT TO RETURN ON DEMAND ALONG WITH ALL COPIES AND ALL IMPROVEMENTS, DESIGNS AND PROPERTY DERIVED THEREFROM. DRAWN BY: DW DATE: 8/25/2020 SHEET 1 OF 1 3

You might also like

- CIP Level 1 Quiz 4Document6 pagesCIP Level 1 Quiz 4antonioviamontNo ratings yet

- EstoperoDocument2 pagesEstoperoMARIO100% (1)

- Plano ERIDocument1 pagePlano ERIDennis Guajardo Lara100% (1)

- SF15 XCM DS RL 29 80,100Document1 pageSF15 XCM DS RL 29 80,100Vagner PaludoNo ratings yet

- SF19 XCT30 DS 29 80 - 100Document1 pageSF19 XCT30 DS 29 80 - 100breyneralexanderca52No ratings yet

- Uf1002a01 2Document2 pagesUf1002a01 2MARTIN GONZALEZNo ratings yet

- BinaryDocument1 pageBinarybilbaogarzaNo ratings yet

- PT. Pamapersada Nusantara PSE T300 Shop - ADRO DistrictDocument1 pagePT. Pamapersada Nusantara PSE T300 Shop - ADRO DistrictElvin PebriansyahNo ratings yet

- SRSuntour - SF13 XCM DS RL 26 80,100,120Document1 pageSRSuntour - SF13 XCM DS RL 26 80,100,120ДмитрийNo ratings yet

- Lns125-I Mio M3 Leg Shield PDFDocument2 pagesLns125-I Mio M3 Leg Shield PDFTeguhNugrohoNo ratings yet

- 08 E-Mechanical DrawingsDocument2 pages08 E-Mechanical DrawingsmechaengrNo ratings yet

- Not Applicable: H1 H2 H3 D 390 670 1060 600 20K T 708 1.6 400 LDocument1 pageNot Applicable: H1 H2 H3 D 390 670 1060 600 20K T 708 1.6 400 LraulNo ratings yet

- BinaryDocument1 pageBinarypedro RodriguezNo ratings yet

- Uf1003a56 1Document2 pagesUf1003a56 1MARTIN GONZALEZNo ratings yet

- BinaryDocument1 pageBinarydff_jxNo ratings yet

- 223-9147 Pump Gp-WaterDocument2 pages223-9147 Pump Gp-WaterAmir J.No ratings yet

- VXN150 Vixion Fender PDFDocument1 pageVXN150 Vixion Fender PDFHarris Jum'aniandaNo ratings yet

- Sis 2.0Document2 pagesSis 2.0Dashzeveg BayrsaikhanNo ratings yet

- Assembly and Parts Album: KGP30/KDP30Document1 pageAssembly and Parts Album: KGP30/KDP30Ринат АхмеровNo ratings yet

- 15 LCF125-F Fazzio Lux Side CoverDocument1 page15 LCF125-F Fazzio Lux Side Coverardiarsyah25No ratings yet

- Blade Steering Tip Cyl 14mDocument2 pagesBlade Steering Tip Cyl 14makaliko075No ratings yet

- Blade Steering-Tip Cyl-14mDocument2 pagesBlade Steering-Tip Cyl-14mDashzeveg BayrsaikhanNo ratings yet

- SH-ERI-DW-PR-0042-ERD01_01__Dimensional Drawings ...Document4 pagesSH-ERI-DW-PR-0042-ERD01_01__Dimensional Drawings ...Robertino LangostinoNo ratings yet

- Electronic Copy of Original Generated On Jul 11, 2014 7:01 AMDocument1 pageElectronic Copy of Original Generated On Jul 11, 2014 7:01 AMJuan OrtegaNo ratings yet

- SF14 XCT DS 29 100Document1 pageSF14 XCT DS 29 100André OliveiraNo ratings yet

- Ug1003a22 1Document2 pagesUg1003a22 1MARTIN GONZALEZNo ratings yet

- T105se Vega-R Crankcase Cover 1Document1 pageT105se Vega-R Crankcase Cover 1Rian DeonNo ratings yet

- Manual Compresor C7550Document6 pagesManual Compresor C7550WUILLIANSNo ratings yet

- Al115s Mio Crankcase CoverDocument2 pagesAl115s Mio Crankcase Coverdonwload bunkNo ratings yet

- 1 LCF125-F Fazzio Lux CylinderDocument1 page1 LCF125-F Fazzio Lux Cylinderardiarsyah25No ratings yet

- Gambar 24 Seat: Nomor Refere Nomor Part Nama Part KeteranganDocument2 pagesGambar 24 Seat: Nomor Refere Nomor Part Nama Part KeteranganShade CormacNo ratings yet

- V110e F1-Z Rear WheelDocument2 pagesV110e F1-Z Rear WheelSinar WiratamaNo ratings yet

- Tenere700 Parts-ListDocument69 pagesTenere700 Parts-ListstephpovoNo ratings yet

- T105e Vega-R Cylinder HeadDocument1 pageT105e Vega-R Cylinder HeadAlésaNo ratings yet

- 4020-188-M-017 - 3 Exploded ViewDocument1 page4020-188-M-017 - 3 Exploded Viewthoriq ikhwanNo ratings yet

- VXN150 Vixion Steering PDFDocument1 pageVXN150 Vixion Steering PDFHarris Jum'aniandaNo ratings yet

- Vega R VegaDocument2 pagesVega R VegaapsriksNo ratings yet

- 01 Cylinder HeadDocument2 pages01 Cylinder HeadRohaizad SallehNo ratings yet

- Ic R36Document1 pageIc R36Franklin Jose Almera AcostaNo ratings yet

- StackDocument10 pagesStackmanh hung leNo ratings yet

- Belt 426FDocument2 pagesBelt 426FYapi YapiNo ratings yet

- 213-4540 Valve Gp-Relief - Transmission Oil PressureDocument2 pages213-4540 Valve Gp-Relief - Transmission Oil PressureEdsw Riv ́sNo ratings yet

- Kioti PX1053PC-EU Tractor Parts ManualDocument10 pagesKioti PX1053PC-EU Tractor Parts ManualLisakolyNo ratings yet

- LNS125 Mio M3 CylinderDocument1 pageLNS125 Mio M3 Cylinderwa.onegtrNo ratings yet

- TPL76-C.. List of Spare Parts: Kit 2 / 97075 / ZS09Document1 pageTPL76-C.. List of Spare Parts: Kit 2 / 97075 / ZS09Yash PandyaNo ratings yet

- bsv550 W - Type 1Document3 pagesbsv550 W - Type 1Avelicio VidalNo ratings yet

- NS50 Aerox R Water PumpDocument1 pageNS50 Aerox R Water PumptsimposthomasNo ratings yet

- Date 2012.4.23 1 AmendedDocument1 pageDate 2012.4.23 1 AmendedamiltonferrazzNo ratings yet

- BinaryDocument1 pageBinaryJose EspejoNo ratings yet

- LNR125 Soul GT Leg ShieldDocument2 pagesLNR125 Soul GT Leg ShieldRaynaldi GunawanNo ratings yet

- Catalog - Jupiter Z 2009 PDFDocument49 pagesCatalog - Jupiter Z 2009 PDFHari Susandi100% (5)

- VXN150 Vixion Camshaft & Chain PDFDocument1 pageVXN150 Vixion Camshaft & Chain PDFHarris Jum'aniandaNo ratings yet

- 22 LCF125-F Fazzio Lux Rear WheelDocument1 page22 LCF125-F Fazzio Lux Rear Wheelardiarsyah25No ratings yet

- T105se Vega-R Camshaft & ChainDocument1 pageT105se Vega-R Camshaft & ChainRian DeonNo ratings yet

- Current Revision Approved: Eccentric Assy, 68H/SbsDocument1 pageCurrent Revision Approved: Eccentric Assy, 68H/Sbscapslive_001No ratings yet

- 036909C 2bae03 Iso FW 57743 01 0S4Document21 pages036909C 2bae03 Iso FW 57743 01 0S4NguyenCanhBaoNo ratings yet

- M71 (New Design)Document1 pageM71 (New Design)Paško KelavaNo ratings yet

- Двигатель. насосы.Document6 pagesДвигатель. насосы.Павлик МорозNo ratings yet

- Sfax TankDocument7 pagesSfax TankAliZenatiNo ratings yet

- 20107-040-000-SPC-0058 Rev A1Document5 pages20107-040-000-SPC-0058 Rev A1AliZenatiNo ratings yet

- Results Tank SfaxDocument4 pagesResults Tank SfaxAliZenatiNo ratings yet

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)AliZenatiNo ratings yet

- IOM-Air CannonDocument16 pagesIOM-Air CannonAliZenatiNo ratings yet

- Spua 351Document3 pagesSpua 351AliZenatiNo ratings yet

- SBF Tank and Impeller RecommendationDocument4 pagesSBF Tank and Impeller RecommendationAliZenatiNo ratings yet

- DATA SHEET FOR PIG RECEIVER - Rev.1Document4 pagesDATA SHEET FOR PIG RECEIVER - Rev.1AliZenati100% (1)

- TDS For Spray PolyueraDocument2 pagesTDS For Spray PolyueraAliZenatiNo ratings yet

- Goulds Data Sheets & Performance CurvesDocument7 pagesGoulds Data Sheets & Performance CurvesAliZenatiNo ratings yet

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down Vents - Drains (T 120°C)AliZenatiNo ratings yet

- Sonatrach: Project SpecificationDocument13 pagesSonatrach: Project SpecificationAliZenatiNo ratings yet

- Attachment G - Environmental Design Criteria - E352921-00000-200-210-0001 - Rev BDocument13 pagesAttachment G - Environmental Design Criteria - E352921-00000-200-210-0001 - Rev BAliZenatiNo ratings yet

- MTM - KMPP-00-PRC-TB-067 Loading Arms Technical Bid Evaluation Rev C-July 16,2018Document3 pagesMTM - KMPP-00-PRC-TB-067 Loading Arms Technical Bid Evaluation Rev C-July 16,2018AliZenatiNo ratings yet

- PRICE E1203257Mrev4-20-EST-JON EPPM MARAFIQ STG 5&6 FPS OPTION 2Document13 pagesPRICE E1203257Mrev4-20-EST-JON EPPM MARAFIQ STG 5&6 FPS OPTION 2AliZenatiNo ratings yet

- Attachment E - H&S Spec - H352921-00000-110-078-0001 - Rev0Document173 pagesAttachment E - H&S Spec - H352921-00000-110-078-0001 - Rev0AliZenatiNo ratings yet

- DATA SHEET FOR MOGAS STORAGE TANK - Rev.0Document6 pagesDATA SHEET FOR MOGAS STORAGE TANK - Rev.0AliZenati100% (1)

- Attachment N - El Aouj - Execution Schedule - Draft H35921-00000-610-076-002Document4 pagesAttachment N - El Aouj - Execution Schedule - Draft H35921-00000-610-076-002AliZenatiNo ratings yet

- Sonatrach: Project SpecificationDocument12 pagesSonatrach: Project SpecificationAliZenati100% (1)

- S 0100 1520 201 - 1 PDFDocument15 pagesS 0100 1520 201 - 1 PDFAliZenati100% (1)

- 2503-01483-MR-042 - Check Valves Rev.a (JTF) PDFDocument1 page2503-01483-MR-042 - Check Valves Rev.a (JTF) PDFAliZenatiNo ratings yet

- P4D Paep TM Eppm 0673Document1 pageP4D Paep TM Eppm 0673AliZenatiNo ratings yet

- Sonatrach: Project SpecificationDocument23 pagesSonatrach: Project SpecificationAliZenatiNo ratings yet

- 13.0 Temperature TransmitterDocument2 pages13.0 Temperature TransmitterAliZenatiNo ratings yet

- Typical Loading Arm Low Level Process and Instrumentation Diagram (P&ID) (For Ref. Only)Document1 pageTypical Loading Arm Low Level Process and Instrumentation Diagram (P&ID) (For Ref. Only)AliZenatiNo ratings yet

- Pages de Scope of SupplyDocument5 pagesPages de Scope of SupplyAliZenatiNo ratings yet

- Typical Loading Arm and Metering Skid Assembly G.A Drawing-1 (For Ref. Only)Document1 pageTypical Loading Arm and Metering Skid Assembly G.A Drawing-1 (For Ref. Only)AliZenatiNo ratings yet

- Reference ListDocument4 pagesReference ListAliZenatiNo ratings yet

- 2.0 DCV-Brochure BV Valves (Pages) R01 PDFDocument12 pages2.0 DCV-Brochure BV Valves (Pages) R01 PDFAliZenatiNo ratings yet

- Fusion4 Portal: Global Experience. Locally AppliedDocument8 pagesFusion4 Portal: Global Experience. Locally AppliedAliZenatiNo ratings yet

- PDS Stopaq Wrappingband SZ V3 EN1Document2 pagesPDS Stopaq Wrappingband SZ V3 EN1AndyNo ratings yet

- Lecture 16 - 21: MM 362 Ceramics and Glasses Spring Semester 2020, FMCE, GIKIDocument38 pagesLecture 16 - 21: MM 362 Ceramics and Glasses Spring Semester 2020, FMCE, GIKIUsamaNo ratings yet

- PDS - Solucut SuperDocument1 pagePDS - Solucut Supervishesh.messer213No ratings yet

- Alfa Laval Product Leaflet She LTL enDocument2 pagesAlfa Laval Product Leaflet She LTL enalejandropavlov.promoNo ratings yet

- TL 226 - Out-2016Document12 pagesTL 226 - Out-2016Filipe FrancoNo ratings yet

- Over All ExcelDocument4 pagesOver All ExcelAnil kumar RNo ratings yet

- Geography UACE Paper 2 Revision Questions For Manufacturig Industries in The WorldDocument12 pagesGeography UACE Paper 2 Revision Questions For Manufacturig Industries in The WorldSilas TonnyNo ratings yet

- G2 Sci, U2, L2, T2, 23-24Document6 pagesG2 Sci, U2, L2, T2, 23-24Black arab GaladimaNo ratings yet

- EUROWATER RO Units LeafletDocument4 pagesEUROWATER RO Units LeafletNoah MusundiNo ratings yet

- FOI Response To The Data Requested of Ms. BabaranDocument3 pagesFOI Response To The Data Requested of Ms. BabaranJeremy BaluyoNo ratings yet

- Literature Review On Iron and Steel IndustryDocument6 pagesLiterature Review On Iron and Steel Industrysmvancvkg100% (1)

- Indian Minerals Yearbook 2017: 56 EditionDocument15 pagesIndian Minerals Yearbook 2017: 56 EditionArman ArshyNo ratings yet

- Metal Grating & Fiberglass GratingDocument64 pagesMetal Grating & Fiberglass Gratingjohn leeNo ratings yet

- Classic Sheet Metal Processing in New Dimensions - Punching, Nibbling, FormingDocument15 pagesClassic Sheet Metal Processing in New Dimensions - Punching, Nibbling, FormingHamada HamadaNo ratings yet

- Activity-Based CostingDocument25 pagesActivity-Based Costinghaech jaemNo ratings yet

- Welding Filler Metals For Power Generation: Voestalpine Böhler Welding Voestalpine Böhler WeldingDocument27 pagesWelding Filler Metals For Power Generation: Voestalpine Böhler Welding Voestalpine Böhler WeldingKrisNo ratings yet

- Research Papers On Friction Stir WeldingDocument10 pagesResearch Papers On Friction Stir Weldingnbaamubnd100% (1)

- Chapter 3 Smart Sensor Fabrication TechnologyDocument83 pagesChapter 3 Smart Sensor Fabrication TechnologyTruong Van HungNo ratings yet

- FordEtis-technical Service BulletinDocument17 pagesFordEtis-technical Service BulletinslobodanNo ratings yet

- KINLONG Profile PDFDocument57 pagesKINLONG Profile PDFmikafreightNo ratings yet

- Indian Standard: Specification For Plain WashersDocument13 pagesIndian Standard: Specification For Plain WashersrahulmechdceNo ratings yet

- Machine Shop TheoryDocument28 pagesMachine Shop Theoryjulito paquitNo ratings yet

- Lean Fundamentals Simplilearn GBDocument32 pagesLean Fundamentals Simplilearn GBsajeebyNo ratings yet

- Types Liner Material Problems in Liner Liner Inspection Liner Calibration Difference Between MAN B&W and SULZER LinersDocument7 pagesTypes Liner Material Problems in Liner Liner Inspection Liner Calibration Difference Between MAN B&W and SULZER LinersRicardo Garing100% (2)

- Wall Finishes PlasteringDocument10 pagesWall Finishes PlasteringJUMIOTNo ratings yet

- Condenser 44m2Document5 pagesCondenser 44m2Naam Ka KyaNo ratings yet

- Bakelite PF6507Document4 pagesBakelite PF6507dioguitomsolhaNo ratings yet

- Lesson - 09 - UG77 - UG120 - Material, Nameplate & Data ReportDocument19 pagesLesson - 09 - UG77 - UG120 - Material, Nameplate & Data Reportmohamed.eldesouky9120No ratings yet

- Tolerances and Measuring Technnology - Nhom 01FIE: Câu hỏiDocument18 pagesTolerances and Measuring Technnology - Nhom 01FIE: Câu hỏiKTS ChannelNo ratings yet