1299 EC2153 Signed

1299 EC2153 Signed

Uploaded by

Deepak HoleCopyright:

Available Formats

1299 EC2153 Signed

1299 EC2153 Signed

Uploaded by

Deepak HoleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

1299 EC2153 Signed

1299 EC2153 Signed

Uploaded by

Deepak HoleCopyright:

Available Formats

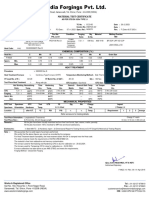

MATERIAL TEST CERTIFICATE

AS PER STD EN 10204 TYPE 3.1

Customer : GTN Engineering (India) Ltd Unit-II (PMS) TC No. : EC2153 Date : 20.12.2023

Invoice No.:DWIF/23-24/ Date :

P.O. No.: 4710048186-0 Line Item: 3 PO Date : 07.11.2023 Spec. Ref.: M25070 Rev. : F (Date:16.07.2021)

Die No. Description Part No. Condition Forging Qty Material Melting Practice

Drg. No. PSL Level Ratio Sr.No. Mill

BODY FORGING, ULT PLUG Forged,

1299-GTN VALVE 1 ULT150 F/UNION 3257105 Rev L Normalized, 8.30 : 1 100 Nos. AISI 4140 BF-EOF-LRF-VD-CCM

ENDS AISI 4140 ALLOY STEEL Quenched &

FMC SPEC M25070 Tempered, - JSW STEEL

Shot Blasted

Heat Code: OUR DU500001271 Rev C

CHEMICAL COMPOSITION ( % )

Heat No :- C Mn Si S P Cr Mo V Ni Grain Size

F18157 0.40 0.87 0.20 0.010 0.018 1.04 0.22 0.001 0.02 7

Specn. Min. 0.38 0.75 0.15 - - 0.80 0.15 - - 6

Max. 0.43 1.00 0.35 0.025 0.025 1.10 0.25 0.30 1.00 -

HEAT TREATMENT

Procedure :- Q00025 Rev S

Heat Treatment Furnace :- Continous Type Furnace (CHTF) Temperature Monitoring Method:- Side Thermocouples in the Working Zone ( Method A)

HT Load No. of N :- AG-984 HT Batch No. of Q&T:- AG-991 Qty :- 100 Nos.

Test Piece Heat Treatment :- Along with job QTC location:- Sacrificial QTC Size- Actual Part

Hot Working Normalising Time Hardening Time Quench Quench Bath Temp. 1st Temper Time

Ratio Temp. Hrs. Temp. Hrs. Media Start End Temp. Hrs.

QTC 8.30 : 1 900⁰C 3 Hrs 20 Min 870⁰C 3 Hrs 20 Min OIL 37°C 50°C 570°C 5 Hrs (Air Cool)

Forging 8.30 : 1 900⁰C 3 Hrs 20 Min 870⁰C 3 Hrs 20 Min OIL 37°C 50°C 570°C 5 Hrs (Air Cool)

Specn. Min. 870⁰C 840⁰C --- --- 540⁰C

Max. 925⁰C 900⁰C --- 80⁰C 700⁰C

MECHANICAL PROPERTIES

QTC Test Specimen QTC Test UTS YS Elg RA Charpy Impact

Specimen Orientation Hardness Temp. 0.2 % Offset Test ( Charpy ) J

Location after H.T. ⁰C PSI PSI % % Temp. Requirement 1 2 3 Average

Refer annexure for testing details

Test Piece Orientation:- Longitudinal & Transverse Charpy 'V' notch

Test Piece Size :- 8.75 mm Dia, 35 mm Gauge Length 10 mm X 10 mm X 55 mm LG

Remarks : All the jobs have been visually examined and are free from bursts, laps, seams, cracks, porosity.

All the jobs have been 100% checked for MPI test and found satisfactory.

Enclosures: 1) Steel Mill TC 2) Hardness report 3) Testing Annexure 4) Lab Reports 5) HT Graphs 6) Dimensional Report

Note :- We hereby guarantee that no weld repairs have been performed.

. We hereby certify that the above figures are accurate and are contained in the records of the company

For heat treatment batch traceability, "AG-991" is stamped near the heat code.

Furnace calibration has been conducted in accordance with AMS 2750G and meets the specified requirements.

The material is free from radioactive and mercury contamination.

Furnace used for normalizing and austenitizing (CF3): Calibration is due on 22.02.2024.

Furnace used for tempering (CF4): Calibration is due on 24.02.2024.

The above material meets the requirements of ASTM A788/A788M-23.

Method of Forging : Closed Die Forging

Ajay Joshi (HEAD-MQC, HT & NDT)

Authorised Signatory

F-MQC-10 / Rev. 00 / 01-Apr-2016

Works & Registered Office Tel : +91-02137-679819

Gat No. 163, Hissa No.1, Pune-Nagar Road, Fax : +91-02137-679820

Sanaswadi, Tal. Shirur, Pune- 412208 (INDIA) customerservice@westernindiaforgings.com

www.westernindiaforgings.com CIN : U28910PN1981PTC024155

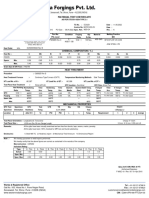

HARDNESS TEST REPORT

Customer:- GTN Engineering (India) Ltd Unit-II (PMS) TC No: EC2153

P.O. No.:- 4710048186-0 Line Item: 3 PO Date : 07.11.2023 Date : 20.12.2023

BODY FORGING, ULT PLUG VALVE 1

Item : ULT150 F/UNION ENDS AISI 4140 ALLOY Material : AISI 4140

STEEL FMC SPEC M25070

Part No.: 3257105 Rev L Heat No. : F18157

Drawing No.: DU500001271 Rev C Ambient Temp : 25°C

Die No.: 1299-GTN Hardness Range:- 277 - 331 HBW

Qty.: 100 Nos. Test Method : Brinell Hardness Test

Vendor Sr.No.: - Equipment Used: Brinell Hardness Tester

HT Load No.: N: AG-984 QT: AG-991 Sr No. 19/05/007

Reference Standard: ASTM E10 Machine Make: FSA

Load Applied: 3000 Kgs Calibration Agency: MME

Type of Penetrator: Dia 10 mm Carbide Ball Cert. No.: MME/CAL/337/23-24

Std Block Details: SH-0346/23 (Hardness value - 303.2 HBW) Calibrated On: 07.08.2023

Entity Performing Test: WIF Sanaswadi Calibration Due On: 06.02.2024

Hardness

Q03006 Rev. AC / Q03009 Rev. X Date of Test :- 10.12.2023

Procedure :-

Precise Measuring Method of HBW Impression : Type B : Hand-Held Microscope with fixed measuring lines.

Qty. Hardness in HBW

100 Nos. 285-321 HBW

Test Performed By Reviewed By Approved By :

Atul Jedhe Satish Gadgil (Sr.Manager HT) Ajay Joshi (HEAD-MQC, HT & NDT)

F-HT-10 / Rev. 00 / 01-Apr-2016

MAGNETIC PARTICLE EXAMINATION REPORT

Customer : GTN Engineering (India) Ltd Unit-II (PMS)

PO No. : 4710048186-0 Line Item : 3 Report No : EC2153 Date : 20.12.2023

PO Date : 07.11.2023 Test Date : 11 & 12.12.2023

BODY FORGING, ULT PLUG VALVE 1 ULT150

Description : F/UNION ENDS AISI 4140 ALLOY STEEL FMC Die No. : 1299-GTN Heat Code : OUR

SPEC M25070

Part No. : 3257105 Rev L Qty. : 100 Nos.

Material : AISI 4140 Sr. No. : -

Heat No. : F18157 Heat Load No : N AG-984 QT AG-991

Stage of Examination

Drg. No. : DU500001271 Rev C Forged, Normalized, Quenched & Tempered, Shot Blasted

:

Standard /

Acceptance

Spec. / Q00207 Rev E , ASTM E 709-2021 Ed. Q00207 Rev E Clause no: 5.0

Standard / Criteria

Procedure :

Magnetic Particle Equipment (AC / FWDC) : Make - Vector NDT Technologies Model : V6000C

Calibration Date: 30.07.2023 : Calibration Due Date: 29.01.2024

Machine Sr. No : 30040419

Bath Temp.

Bath Concentration - 0.1 to 0.4 ml/ 100 ml Bath : 0.35 ml/ 100 ml Bath 48°C Observed 28°C

Required

UV-A Lamp irradiance Intensity - 1000 µWatt / cm² Minimum : 2700µWatt / cm² Make: NDT Consultant (UK) Sr no: 2137 (UV-

A + LUX Meter) Calibrated on: 11.07.2023

Ambient Visible illumination Intensity - 21.5 LUX Max. : 01 LUX Due on:11.01.2024

Type Of Magnetic Particle Material : Wet Fluorescent

Magnetic Particle Used : MG 410 Magnaflux Make Batch no: 23J19 Sep-23

Bath Medium : LTM 105 Carrier oil Batch no: VO9P1572 Sep-23

Surface Temp.

Surface Condition : As Shot Blasted 48°C Observed 25°C

Req.

Area to be examined : 100 % of accessible Surfaces

Magnetizing Process / Method : Wet Fluorescent Continuous Method

Means Of Establishing Magnetization : Current (in Head shot) + En Circling Coil On FWDC Mode

: 48 Gauss - Digital Hall Effect Probe Sr no:6050 Make: NDT Consultant (UK)

Observed Field Strength (Tangential)

Calibrated on: 11.07.2023 Due on:11.01.2024

Magnetization Field : Circular + Longitudinal

Applied Current : Circular : 2640 AMP , Longitudinal : 3600 AMP Technique Sheet No. -

WIF/MT/78 Rev -01

Sensitivity ensured By : QQI - SHIMS CX-430 Date - 09.12.2023

: Within (± 3 Gauss) - Make: GNAT, DRFI Digital Gauss Meter Sr

Residual field ensured after Demagnetization

no:218001 Calibrated on:08.09.2023 Due on:08.03.2024

Result : No relevant linear or rounded indication observed.

Remark : Material is accepted

Examined By Reviewed & Accepted By

Sign Sign

Name : More Vitthal.D. Name : Hemant Takawale

Cert. Type & Level - NDE Level II UT,MT,PT As Per SNT-TC-1A. Cert. Type & Level - NDE Level II UT,MT,PT,VT As Per SNT-TC-1A.

Doc. No:- F-NDT-03 Rev-02 - 09-July 2018

Mechanical Test Annexure

Die No.: 1299-GTN Material Grade: AISI 4140

Heat No.: F18157 HT Lot No. : AG-991

Heat Code: OUR TC No. : EC2153

TENSILE TEST

QTC Test QTC Hardness after UTS YS Elg RA

Specimen Test Temp. NABL Lab Sample

Specimen H.T. 0.2 % Offset

Orientation (⁰C) Report No. No.

Location HBW KSI KSI % %

0.5" below HT

L 311, 311 Ambient I-23-1016-P 1 149.40 132.29 19.49 59.33

Surface

277 - 331 Spec. Min. 120.00 100.00 16.00 35.00

IMPACT TEST

QTC Test

Specimen Requirement Test Temp. NABL Lab Sample

Specimen 1 2 3 Average

Orientation (⁰C) Report No. No.

Location

Avg. - 42 J Min

70 68 60 66.00

Single - 32 J Min

LE - 0.51 mm Min -29°C I-23-1017-P 0.88 0.86 0.80 0.85

%Shear - Report 65 65 60 63.33

L

Avg. - 27 J Min

56 58 66 60.00

Single - 20 J Min

LE - Report -40°C I-23-1018-P 0.78 0.80 0.85 0.81

%Shear - Report 60 60 65 61.67

0.5" below

Avg. - 28 J Min 1

HT Surface 32 66 36 44.67

Single - 18.7 J Min

LE - Report

-29°C I-23-1019-P 0.45 0.86 0.51 0.61

%Shear - Report 40 65 40 48.33

T

Avg. - 20 J Min

34 34 66 44.67

Single - 14 J Min

LE - Report -40°C I-23-1020-P 0.47 0.48 0.84 0.60

%Shear - Report 40 40 65 48.33

Ajay Joshi (HEAD-MQC, HT & NDT)

Authorised Signatory

CERTIFICATE OF COMPLIANCE

Customer : GTN Engineering (India) Ltd Unit-II (PMS) TC No.: EC2153

Date: 20.12.2023

Die No. : 1299-GTN Heat Code : OUR

PO No : 4710048186-0 Line Item No : 3

Offer Qty. : 100 Nos.

Part No/ Rev : 3257105 Rev L Drg No / Rev : DU500001271 Rev C

BODY FORGING, ULT PLUG VALVE

Part Name : Serial No. : -

1 ULT150 F/UNION ENDS AISI 4140

ALLOY STEEL FMC SPEC M25070

I. Material

A. Material Type : AISI 4140

B. Material Spec/ Rev. : As per Spec no : M25070 Rev No. F (Date:16.07.2021)

C. Material Test Report No : Mill Heat No : F18157

II. Dimensional

A. AQL : AS PER QUALITY PLAN B. Sample Size : 20 Nos.

III. Secondary Process : Heat Treatment

A. Process Name : Normalised

Heat Lot No. : AG-984 Process Spec : Q00025 Rev S

B. Process Name : QT

Heat Lot No. : AG-991 Process Spec : Q00025 Rev S

IV. NDE

A. Process Name : MPI

Q00207 Rev E Clause

Certificate No : EC2153 Process Spec :

no: 5.0

B. Process Name : UT

Certificate No : NA Process Spec : NA

This is to certify that the subjected material is manufactured from the material mentioned above and

has been verified by us according to the specified sample size. The material has been found to conform

to the requirements.

For heat treatment batch traceability, "AG-991" is stamped near the heat code.

The above material meets the requirements of ASTM A788/A788M-23.

Method of Forging : Closed Die Forging

Sign with Stamp

Ajay Joshi (HEAD-MQC, HT & NDT)

You might also like

- 694Document1 page694Mauricio Ramirez100% (1)

- 16 MM MS Plate 355 JR - India-MTCDocument1 page16 MM MS Plate 355 JR - India-MTCQc QatarNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5armin heidariNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 1591 EC2213 SignedDocument5 pages1591 EC2213 SignedDeepak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 1299 - Ec0583Document5 pages1299 - Ec0583Deipak HoleNo ratings yet

- 1485 - Ec0251Document6 pages1485 - Ec0251Deepak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- 1485 - Ec0208Document5 pages1485 - Ec0208Deepak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- 1426 Ec1942Document3 pages1426 Ec1942Deipak HoleNo ratings yet

- 1485 - EC2092-signedDocument4 pages1485 - EC2092-signedDeepak HoleNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- HT 003Document1 pageHT 003Sam RajaNo ratings yet

- HT 002Document1 pageHT 002Sam RajaNo ratings yet

- Metallurgical Test Certificate: Doc. No. R-QC.11 Nov.12Document2 pagesMetallurgical Test Certificate: Doc. No. R-QC.11 Nov.12MacelNo ratings yet

- HT 001Document1 pageHT 001Sam Raja100% (1)

- Certificate of Analysis & Testing: P.O. No. P.O. DateDocument1 pageCertificate of Analysis & Testing: P.O. No. P.O. DateFundary ShopNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romero100% (1)

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- GR 70 32MMDocument1 pageGR 70 32MMquality nakodaNo ratings yet

- MTR - HT# 52154Document1 pageMTR - HT# 52154ColinNo ratings yet

- XQT190001050101 HTHDocument10 pagesXQT190001050101 HTHvalveNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- TC AmrDocument1 pageTC AmrbalaNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Sample MTCDocument1 pageSample MTCheavens indiaNo ratings yet

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocument1 pageM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarNo ratings yet

- Certificado EsparragosDocument8 pagesCertificado EsparragosJesus CondoriNo ratings yet

- Material Test Report: Cert No: 697430Document1 pageMaterial Test Report: Cert No: 697430Abozar BilanNo ratings yet

- Inspection Report - Motor+16701004051+KT - 12V1600G80SDocument1 pageInspection Report - Motor+16701004051+KT - 12V1600G80SChristopherNo ratings yet

- Specification Main PartsDocument8 pagesSpecification Main PartsvalveNo ratings yet

- 7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913Document1 page7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913魏利强No ratings yet

- Fairchild Semiconductor P4C8AABDocument6 pagesFairchild Semiconductor P4C8AABFrank CoelhoNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- Ad 1005 WB1Document5 pagesAd 1005 WB1billylu06No ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- Page 3 Tsi MTC Plate (MTC - 249)Document2 pagesPage 3 Tsi MTC Plate (MTC - 249)trayojam.rilNo ratings yet

- Specification Main PartsDocument8 pagesSpecification Main PartsvalveNo ratings yet

- Gate Valve 3in 150 XMK1020754308-27Document5 pagesGate Valve 3in 150 XMK1020754308-27Mygame 1402No ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- VTB-600-2 A105n W1834221,235,230.QR PDFDocument1 pageVTB-600-2 A105n W1834221,235,230.QR PDFJoe KylaNo ratings yet

- Hammer 4 Fig 206 CertificateDocument4 pagesHammer 4 Fig 206 CertificateTiffany DacinoNo ratings yet

- NST 3.1 PDFDocument1 pageNST 3.1 PDFPankaj RaneNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Cricri CriNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5abdulNo ratings yet

- 64-cbc Temp Controller Calibration CartificateDocument1 page64-cbc Temp Controller Calibration CartificateCustomer SupportNo ratings yet

- 1447 - Ec0539Document5 pages1447 - Ec0539Deepak HoleNo ratings yet

- 1485 - Ec0208Document5 pages1485 - Ec0208Deepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1433 Ec0442Document6 pages1433 Ec0442Deepak HoleNo ratings yet

- 1485 - EC2169-signedDocument4 pages1485 - EC2169-signedDeepak HoleNo ratings yet

- Western India Forgings Pvt. LTD.: Test CertificateDocument1 pageWestern India Forgings Pvt. LTD.: Test CertificateDeepak HoleNo ratings yet

- 1591 Ec2203 FTDocument1 page1591 Ec2203 FTDeepak HoleNo ratings yet

- C To DDocument1 pageC To DDeepak HoleNo ratings yet

- Ecn 1Document5 pagesEcn 1Deepak HoleNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- Deepak Dattatray HoleDocument2 pagesDeepak Dattatray HoleDeepak HoleNo ratings yet

- 4340/ BS EN10083 817M40, 140 KSI (965 MPA), FORGINGS AND BAR Stock, Restricted Use SubseaDocument3 pages4340/ BS EN10083 817M40, 140 KSI (965 MPA), FORGINGS AND BAR Stock, Restricted Use SubseaDeepak HoleNo ratings yet

- Htytdjhfjgk LJ K JKFTDRGBNDocument45 pagesHtytdjhfjgk LJ K JKFTDRGBNDeepak HoleNo ratings yet

- Bar No 4086Document1 pageBar No 4086Deepak HoleNo ratings yet

- STK/WIF/20-21/283 Bar No.: QTC With DespatchDocument58 pagesSTK/WIF/20-21/283 Bar No.: QTC With DespatchDeepak HoleNo ratings yet

- Bar No 4084Document1 pageBar No 4084Deepak HoleNo ratings yet

- Bar No 4002Document2 pagesBar No 4002Deepak HoleNo ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanDeepak HoleNo ratings yet

- F-HRA-05 On Job Training Record R04Document3 pagesF-HRA-05 On Job Training Record R04Deepak HoleNo ratings yet

- Deviation Request - Raltech 10 10 2020Document1 pageDeviation Request - Raltech 10 10 2020Deepak HoleNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- Corrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDocument1 pageCorrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDeepak HoleNo ratings yet

- Bar No - 5763: Test CertificateDocument2 pagesBar No - 5763: Test CertificateDeepak HoleNo ratings yet