Afico Duct Liner

Afico Duct Liner

Uploaded by

Chris SolonCopyright:

Available Formats

Afico Duct Liner

Afico Duct Liner

Uploaded by

Chris SolonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Afico Duct Liner

Afico Duct Liner

Uploaded by

Chris SolonCopyright:

Available Formats

Duct

Liner

(DL)

Product Description as thermal and coustical insulation of heating

AFICO Duct Liner is a highly efficient, semi-rigid air-conditioning and interior of dual temperature

insulation composed of fine, stable and uniformly duct work, air handling equipment and plenums

textured inorganic glass fibers bonded together by a operating at air-velocities up to 20 m/s (4000 FPM)

non-water soluble and fire retardant thermosetting and temperatures up to 232°C (450°F).

and heat resistant resin. It is free from coarse fibers

and shot due to its mineral composition. Also used as an efficient sound absorption treatment

of walls and ceiling, acoustic enclosures, generator

Facing

rooms, studios, curtain walls, auditoriums,

AFICO Duct Liner is supplied semi-rigid faced with a

conference rooms, theatres and others.

strong, dimensionally stable Non-Woven Black Glass

Tissue (BGT).

Application

AFICO Duct Liner is intended for use in commercial,

institutional, industrial and residential construction

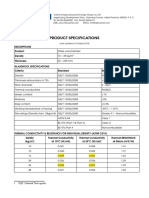

Standard Available Products

Nominal Manufacturing Specifications. check for availability of other dimesnions and densities.

Product

Type Density K Value@24°C R Value / Thickness NRC Value

DL Kg/ Lb/ W/ BTU•in/ 15 ½ 25 1 38 1½ 50 2 15 25 38 50

m3 ft3 m•°K hr•ft2•°F mm in. mm in. mm in. mm in. mm mm mm mm

160 16 1.0 0.037 0.26 - - 0.68 3.78 1.03 5.8 1.35 7.6 - - - -

240 24 1.5 0.034 0.24 - - 0.74 4.1 1.12 6.2 1.47 8.2 0.50 0.65 0.85 0.95

320 32 2.0 0.033 0.23 0.45 2.6 0.76 4.37 1.15 6.5 1.52 8.6 0.50 0.65 0.90 1.00

480 48 3.0 0.031 0.22 0.48 2.7 0.81 4.47 1.23 6.8 1.61 8.9 0.55 0.75 0.90 1.05

Other thicknes available upon request and verification

Apparent Thermal Conductivity ASTM C518, EN12667

W/m.°K or Btu.in/hr.ft².°F for all product range “K” or “λ” value at mean temperatures

Data for 10, 24 and 35°C mean temperature

Product

Type Density Mean Temperature

DL Kg/ Lb/ 10°C 50°F 24°C 75°F 35°C 95°F

m3 ft3

160 16 1 0.034 0.24 0.037 0.26 0.039 0.27

240 24 1.5 0.032 0.22 0.034 0.24 0.036 0.25

320 32 2 0.031 0.21 0.033 0.23 0.034 0.24

480 48 3 0.03 0.21 0.031 0.22 0.033 0.23

Duct Liner

(DL) Duct Liner (DL)

Performance & Physical Characteristics

Thermal Resistance “R” Value (ASTM C518) Working Temperature Limitations AFICO Duct Liner should be adhered to sheet

Specification Compliance

“R” is a measure of the resistance to heat flow of a (ASTM C411) metal ducts with 100% coverage of adhesive, and

AFICO Duct Liner complies with the property

material of any given thickness. Operating temperature up to 232°C (450°F)for the all exposed leading edges and all traverse joints

requirements of the following specifications:

(“R” = m².°K/W or hr.ft².°F/Btu) BGT faced product. At excessive temperatures, lim�- coated with adhesive. The adhesive shall conform

DCL: ASTM C665

ited migration of binder may occur in the insulation to standard ASC-A7001C-1972 or as approved by the

T Where “T”= Thickness CE-EN: EN 13162-T1-1121-CPD-BA0136

R= K Where “K” or “λ “ = Thermal Conductivity in contact with the surface. This is in no way impairs project consultant. The liner should be additionally

UL 723: Classified as FHC 25/50 File no

the performance of the insulation. secured with mechanical fasteners which will

R27731

Thermal Transmittance “U” Value compress the product sufficiently to hold it firmly in

Mold Growth (ASTM C1338) SCS: Recycled Content Certified

(ASTM C167) place.

Does not breed or sustain mold, fungus, bacteria or SCS-MC-02810

“U” is a measure of how much heat is lost through a

rodents. ASTM C795: Thermal Insulation for Use in Contact

given thickness of a particular material. For velocities to 10 m/s: fasteners should start

with Austenitic Stainless Steel tested

(“U” = W/m²K °C or Btu/hr-sq ft °F) Corrosiveness (ASTM C665) within 75 mm of the upstream transverse edges

ASTM C1071: For thermal and sound absorbing

Chemically inert. Will not cause or accelerate of the liner and 75 mm from longitudinal joints,

1 Where “Rt”= Total Thermal Resistance SASO materials

U = Rt corrosion of steel, stainless steel, copper or and should be spaced at maximum of 300 mm on

Composed of all elements/layers SASO: SASO GSO EN 13162

aluminum, due to its particular inorganic and centers around the perimeter of the duct, except

License #201800652111

U-Values are calculated from the thermal mineral composition. they may be maximum of 300 mm from a corner

resistances of the parts making up a particular part Fire Properties break.

Alkalinity (ASTM C871)

of the structure. Transmission of heat is opposed in B.S. 476 PART 4: Non Combustible

pH 9 For velocities to 10 to 20 m/s: fasteners should be

varying amounts dependent on material and surface. B.S. 476 PART 5: Ignitability

placed as above, except to be placed at a maximum

Friction Loss B.S. 476 PART 6: Fire Propagation

U-Value (of building element) = 1 / (Rso+Rsi R1+Rs...) of 150 mm on centers around the perimeter and a

According to TIMA AHS-152T Pressure loss, In W.G., B.S. 476 PART 7: Surface Spread of Flame

maximum of 150 mm from corner break. Elsewhere,

Where Rso is the fixed external resistance AFICO Duct Liner. Class ‘O’ fire rating to the building regulations

they should be at a maximum of 400 mm on

Rsi is the fixed internal resistance sections E15

This is to be used in place of the standard friction centers except to be placed not more than 150 mm

R1, R2 etc are resistivity of all elements from a longitudinal join and 300 mm from corner

loss chart published in the ASHRAE Handbook of Installation Recommendation for felxible

within the application including that of break. In addition to the edge coating of transverse

fundamentals. blanket

cavities within the construction. joints, longitudinal joints should be similarly coated

AFICO Duct Liner Blankets are available in rolls. The

For conversion of round equivalents to rectangular

desired application length can be easily measured with adhesive.

Example Calculation: sizes, use Table C-2 "Circular Equivalents of

and cut from the full roll. Afico Duct Liner is applied

Rectangular Ducts for Equal Friction and Capacity" For velocities to 20 to 30 m/s: fasteners should

Layer & Material Thickness & R Value to the interior of ducts and plenums with the black

from the same reference. Tests conducted in be spaced as for 10 to 20 m/s. In addition, metal

Conductivity surface facing the air stream.

accordance with TIMA AHS 152T. nosing should be installed to secure the liner at all

Rso - Fixed external resistance – 0.40 m2.°K/W Tranverse joints are to be neatly butted, with no upstream transverse edges.

Acoustical Performance (ASTM C423)

Rsi - Fixed internal resistance – 0.13 m2.°K/W interruptions or gaps. Longitudinal corner joints are

Reverberation Chamber Methog Type A mounting.

R1 - Fiberglass insulation 0.100 m; 0.035 W/mK 2.85 m2.°K/W

to be overlapped and compressed.

Verify with manufacturer performance results.

R2 - Clay bricks 0.105 m; 0.710 W/mK 0.15 m2.°K/W

Data is for comparison only and is not meant to

R3 - Concrete blocks 0.100 m; 0.018 W/mK 0.5 5m2.°K/W indicate characteristics in duct service.

When velocity exceeds No. of Liner Interior

R4 - Plaster 0.013 m; 0.016 W/mK 0.08 m2.°K/W

4000 FPM use metal pins Width Lapped

Total 4.16 m2.°K/W Thickness Frequency, Hz NRC nosing on every leading and butted

0 8" dn corner

Therefore the overall wall element inch (mm) 125 250 500 1000 2000 4000 edge. Nosing may be

U-value = 1/R = 1/4.16 = 0.24 W/m2K 2 16-"9"

½ (13) 0.02 0.07 0.18 0.37 0.52 0.67 0.30 formed on duct or by

channel or Zee attached 3 28-"17"

Surface Burning Characteristics Type 1 (25) 0.04 0.19 0.35 0.55 0.69 0.72 0.45

by screws, rivets or 4 40-"29"

(ASTM E84, UL723) I 1½ (38) 0.08 0.31 0.58 0.75 0.82 0.81 0.60 welds. 5 52-"41"

Base glass fiber is non-combustible when tested. 2 (51) 0.16 0.42 0.76 0.85 0.85 0.83 0.70 Alternate

6 64-"53" folded corner

Facing Flame Spread Smoke 7 76-"65"

Index Developed Index All

8 88-"77" transverse

BGT ≤ 25 ≤ 50 edges to be

9 100-"89" Duct section coated with

(Typically 4ft. or 5ft.) adhesive

Maximum spacing for fasteners. Actual intervals are

approximate.

Dimensions

Velocity A B C D The velocity rated side of liner must face

the air flow.

2500 - 0 FPM 3" 12" 4" 18"

Liner adhered to the conduct with 90% min.

Thermal Sound Fire Enviroment Recycled 6000 - 2501 FPM 3" 6" 4" 16" area coverage of adhesive.

Insulation Insulation Resistant Friendly Materials

Duct Liner (DL)

Maintenance

No maintenance is required. AFICO Duct Liner

products have a high resistance to accidental

damage from knocks and handling during

installation and maintenance. Dimensionally stable

under varying conditions of temperature and

humidity, rot proof, odorless, non-hygroscopic and

will not sustain vermin or fungus due to its inorganic

and mineral compositions.

The product will maintain its thermal properties

throughout the lifetime of the construction and will

not age. AFICO fiberglass is non-toxic and presents

no hazard to health.

The AFICO Product Range includes • Acoustical Ceiling Panels • Blanket Insulation Storage

• Board Insulation • Cavity Wall Insulation • Duct Liner • Duct Liner Board • Faced Duct Wrap

• HD Series Blanket Insulation • Heavy Density Pipe Insulation • Mechanical Board Insulation To avoid moisture in the building construction, AFICO

• Pipe Wrap Insulation • Pre-engineered Metal Building Insulation • Quiet Liner insulation products stored outside must be kept dry.

• Quiet Liner Board • Roof Deck Board Insulation • Thermal Insulating Wool We recommend AFICO products to be always stored

in covered and dry areas. AFICO is not liable for

the damage resulting from inadequate utilization,

Call us today for more information & loading and off-loading and mishandling of its

professional guidance: products.

Dammam (H.O. & Factory): +966 13 331 3333

Riyadh: +966 11 472 5555 Warranty

Jeddah: +966 12 670 0020 See manufacturer’s General Terms and Conditions

GCC & Int’l Export Office (Dubai): +971 4 294 1211 of Sale. As AFICO and/or OCF has no control over

installation design, installation workmanship,

Egypt (Cairo): +20 100 009 9209

accessory materials, or conditions of application,

North Africa (Tunis): +216 2 053 1000

AFICO and/or OCF does not warrant the performance

Please send all email inquiries to info@afico.com.sa or results of any installation containing their

products. This warranty disclaimer includes all

implied warranties, including the warranties or

merchantability and fitness for a particular purpose.

People & Planet Arabian Fiberglass Insulation Company AFICO

Always First reserves the right to alter product specifications

without prior notice, as part of its policy of continued

development and improvement. The installation

AFICO’s products are all energy saving,

environmentally friendly, use even more recycled methods described in this leaflet are not compulsory.

materials and contribute to the fight against The choice of materials and methods of fixing are

global warming. the decision of the specifier, consultant or contractor.

For further information or advice on specification of

products, contact your local, sales office.

afico.com.sa

Availability

Manufactured by Arabian Fiberglass Insulation

Company, Ltd. AFICO member of Zamil Industrial

Co. II, with head-quarters and production facilities

AFICO is an affiliate of Owens Corning USA, and is a GIG Company, a subsidiary of Zamil Industrial located in Dammam, Saudi Arabia, under license

from and utilizing the manufacturing specifications

Authorized Distributor: and technology of Owens-Corning Corporation OCF,

Toledo, Ohio, U.S.A. Marketed throughout Saudi

Arabia, the G.C.C. countries, the Middle East and the

Far East. AFICO products are available directly from

as well as through a vast and reliable network of

local distributors.

Special products are manufactured on request.

You might also like

- Procedure For As-Built DrawingDocument736 pagesProcedure For As-Built DrawingSmith Suwan100% (1)

- AFI Data Sheet Board Insulation BD No Pix 1Document3 pagesAFI Data Sheet Board Insulation BD No Pix 1adel.jordan999No ratings yet

- 03_Insulation of PipingDocument5 pages03_Insulation of PipingNice OrioleNo ratings yet

- Duct Liner BoardDocument4 pagesDuct Liner Boardadwa.tachyonNo ratings yet

- PLUMBING PPR-Pipe DesoDocument11 pagesPLUMBING PPR-Pipe DesoOwen Francis Arles MaongatNo ratings yet

- Eil Spec Bo16-000-80-44-Ol-S001 Rev ADocument2 pagesEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganNo ratings yet

- AAS 920 273G Thermometrics NTC Type 95 110117 Web - 1315869Document5 pagesAAS 920 273G Thermometrics NTC Type 95 110117 Web - 1315869a25511995No ratings yet

- S2XX - 50 X 60Document3 pagesS2XX - 50 X 60mohamed hassanNo ratings yet

- Huamei Spec Sheets - 2018Document1 pageHuamei Spec Sheets - 2018Phan LongNo ratings yet

- RO3000 Pour Rogers 3006 PDFDocument4 pagesRO3000 Pour Rogers 3006 PDFTeddy112No ratings yet

- TDS PPR Multilayer PipesDocument2 pagesTDS PPR Multilayer PipesChalew GebruNo ratings yet

- AISI 3100Document3 pagesAISI 3100abdelraouf40No ratings yet

- Extrusion Ingot: ApplicationDocument4 pagesExtrusion Ingot: ApplicationilkerNo ratings yet

- Rogers - Unknown - RO4400 Series BondplyDocument4 pagesRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNo ratings yet

- DIMO 2311 - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument5 pagesDIMO 2311 - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- Technical Data Sheet: Ceramic Wool Mattress /ceramic Fiber BlanketDocument2 pagesTechnical Data Sheet: Ceramic Wool Mattress /ceramic Fiber BlanketMohamed KhaledNo ratings yet

- TailorBird Catalogue 2022 Single #175 CompressedDocument24 pagesTailorBird Catalogue 2022 Single #175 Compressedsreerag13.sr13No ratings yet

- Belzona Protective LiningsDocument32 pagesBelzona Protective Liningsjose corrosion100% (2)

- Thyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetDocument3 pagesThyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetShariq KhanNo ratings yet

- Thyssenkrupp Materials (UK) LTD Stainless Steel 1.4828: Material Data SheetDocument3 pagesThyssenkrupp Materials (UK) LTD Stainless Steel 1.4828: Material Data SheetAvn PrasadNo ratings yet

- 623 C 5088 CB 471214373420Document16 pages623 C 5088 CB 471214373420Chalew GebruNo ratings yet

- CuClad Laminates Data SheetDocument4 pagesCuClad Laminates Data SheetDenis CarlosNo ratings yet

- C&D Flooded Batteries-LCTDocument2 pagesC&D Flooded Batteries-LCTvikasmikkuNo ratings yet

- Kaowool-Organic-Boards Global EngDocument2 pagesKaowool-Organic-Boards Global Eng이승재No ratings yet

- FRF Slabs: Rigid BoartdDocument16 pagesFRF Slabs: Rigid BoartdAmal RajNo ratings yet

- T Top81Document2 pagesT Top81Malek Ellouz (Jay)No ratings yet

- HT & RT ServicesDocument4 pagesHT & RT ServicesIETqatarNo ratings yet

- Freecorev - Micro - 10 - English ARtecoDocument5 pagesFreecorev - Micro - 10 - English ARtecoManh Nguyen TheNo ratings yet

- FRE CompositesDocument2 pagesFRE CompositesKirsvr VenkyNo ratings yet

- 1.4845 EnglDocument3 pages1.4845 EnglpdmsNo ratings yet

- LOCTITE 638 en - GLDocument4 pagesLOCTITE 638 en - GLMARC TIK-CHAPNo ratings yet

- Lesson 7: Thermal InsulationDocument10 pagesLesson 7: Thermal Insulationmehaksinghgill098No ratings yet

- Profile 45 250 Sandwich Panel Techincal DatasheetDocument2 pagesProfile 45 250 Sandwich Panel Techincal DatasheetEle SultanaNo ratings yet

- DIMO 42H - Prehardened CrMnMo-alloyed Steel in Holderblock Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 42H - Prehardened CrMnMo-alloyed Steel in Holderblock Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- ATX ExtremeTemperature Flexible ConduitsDocument3 pagesATX ExtremeTemperature Flexible Conduitsmhoffman.vergaraNo ratings yet

- MineralWoolInsulation (Rockwool) HotInsulation PDFDocument18 pagesMineralWoolInsulation (Rockwool) HotInsulation PDFPuneet MarwahaNo ratings yet

- AHS 187 - Air Handling Systems Product Selector GuideDocument8 pagesAHS 187 - Air Handling Systems Product Selector GuideKhang NguyenNo ratings yet

- 638 - New-EnDocument4 pages638 - New-EnKan Sang MokNo ratings yet

- Reka C0111Document9 pagesReka C0111YahiaEl-obidyNo ratings yet

- Rockwool Slabs Thickness: 30 MM Density: 50 KG/M: ApplicationsDocument3 pagesRockwool Slabs Thickness: 30 MM Density: 50 KG/M: ApplicationsFirst ChoiceNo ratings yet

- Cold Work Tool Steel: K340 BöhlerDocument16 pagesCold Work Tool Steel: K340 Böhlergraziano girottoNo ratings yet

- Turbine Oil - SpecDocument2 pagesTurbine Oil - SpecEid EeidNo ratings yet

- Reflex Type Guage GlassDocument6 pagesReflex Type Guage Glasschamaras.engNo ratings yet

- LOCTITEDocument2 pagesLOCTITEHrNo ratings yet

- Block InsulationDocument2 pagesBlock Insulation1repsaperuNo ratings yet

- Reka C0045Document4 pagesReka C0045YahiaEl-obidyNo ratings yet

- Insultherm Ceramic Blanket InsulationDocument4 pagesInsultherm Ceramic Blanket Insulationmohammad omarNo ratings yet

- Detailed Specification Detailed Specification: GeneralDocument3 pagesDetailed Specification Detailed Specification: GeneralRamachandran SundararamanNo ratings yet

- Tdoct2014b EngDocument2 pagesTdoct2014b Engmahmoud abuelmgdNo ratings yet

- Needle MatDocument1 pageNeedle MatBruce FerreiraNo ratings yet

- DIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- 0001 - POLYFOAM Super (Gen) 09-30.11.2020Document1 page0001 - POLYFOAM Super (Gen) 09-30.11.2020Meeran MohamedNo ratings yet

- 1.4878 Eng PDFDocument3 pages1.4878 Eng PDFRoberto_PrrNo ratings yet

- Fireproof ROOF Panels Technical InformationDocument4 pagesFireproof ROOF Panels Technical InformationMarko MiticNo ratings yet

- Guida Coprax Eng 2015 LightDocument82 pagesGuida Coprax Eng 2015 Lightairsys7projec100% (1)

- Data Sheet VDM 617Document12 pagesData Sheet VDM 617Anonymous lmCR3SkPrKNo ratings yet

- 2 FT-100-GB-Europe - 0Document1 page2 FT-100-GB-Europe - 0Rudy Nizama RosellNo ratings yet

- Datasheet-Sanicro-69-En-V2022-10-26 14 - 22 Version 1Document7 pagesDatasheet-Sanicro-69-En-V2022-10-26 14 - 22 Version 1Agustin CesanNo ratings yet

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Sanjib Mondal-CVDocument5 pagesSanjib Mondal-CVsayakbnrjNo ratings yet

- Advancetech Products Data SheetDocument3 pagesAdvancetech Products Data SheetRanjit S KashyapNo ratings yet

- BSC A0 - Drawing 1 Sbc-ModelDocument1 pageBSC A0 - Drawing 1 Sbc-ModelMelvin John ThomasNo ratings yet

- Lecture 4 - Vertical Alignment Part 2Document27 pagesLecture 4 - Vertical Alignment Part 2Gachirb BratNo ratings yet

- Heavy Duty Pressure Gauges With Bourdon Tube and Glycerine FillingDocument3 pagesHeavy Duty Pressure Gauges With Bourdon Tube and Glycerine FillingRolando Jara YoungNo ratings yet

- Fosroc Conplast NC: Chloride Free Accelerating AdmixtureDocument4 pagesFosroc Conplast NC: Chloride Free Accelerating AdmixtureVincent JavateNo ratings yet

- Industrial Bimetal Thermometer Bottom Connection: Since 1971Document6 pagesIndustrial Bimetal Thermometer Bottom Connection: Since 1971Phượng NguyễnNo ratings yet

- TDS - Masterkure 181Document2 pagesTDS - Masterkure 181Venkata RaoNo ratings yet

- Trissana BridgeDocument3 pagesTrissana BridgeXYZBLACKDRAGONo ratings yet

- Vra SparepartDocument2 pagesVra SparepartMasNo ratings yet

- RFI Check List CivilDocument54 pagesRFI Check List CivilRazi KhanNo ratings yet

- 10,08,2023 02:37:05:PMDocument16 pages10,08,2023 02:37:05:PMizzad89No ratings yet

- SisuDocument43 pagesSisuErmiyasNo ratings yet

- DOB - Unit 3 - 16 MarkDocument17 pagesDOB - Unit 3 - 16 MarkKarthik RajaNo ratings yet

- Office BoqDocument28 pagesOffice Boqelsabet gezahegnNo ratings yet

- 84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsDocument7 pages84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsPeni M. SaptoargoNo ratings yet

- 10 1108 - Ijbpa 10 2020 0087Document22 pages10 1108 - Ijbpa 10 2020 0087bx hanNo ratings yet

- NPT10111-PE-V-DS-621101-033 - R1 - Dial Type Level GaugeDocument5 pagesNPT10111-PE-V-DS-621101-033 - R1 - Dial Type Level Gaugekkumar_717405No ratings yet

- Pani Community Center Case StudyDocument42 pagesPani Community Center Case Studyarkosakib45No ratings yet

- Radaway CatalogueSheet Kyntos FDocument1 pageRadaway CatalogueSheet Kyntos FYlenia BonelloNo ratings yet

- Bifold Door InstallDocument2 pagesBifold Door Installjimlongton1No ratings yet

- 18 - 54.275 Escape Cum CR MeasurementDocument14 pages18 - 54.275 Escape Cum CR Measurementgurumurthy38No ratings yet

- Single Line Riser Diagram: 2-8.0Mm THHN Copper Wire in 32Mm Dia. PVC PipeDocument1 pageSingle Line Riser Diagram: 2-8.0Mm THHN Copper Wire in 32Mm Dia. PVC PipeArnold DominguezNo ratings yet

- Scaffolding Material StockingDocument10 pagesScaffolding Material StockingStarga WhiteNo ratings yet

- BC With PlasticDocument3 pagesBC With PlasticKiran AEE BvrmNo ratings yet

- Chicago SkyscrapersDocument23 pagesChicago SkyscrapersmaneetNo ratings yet

- Fact Sheet Non Deemed To Satisfy External Wall Cladding SystemsDocument4 pagesFact Sheet Non Deemed To Satisfy External Wall Cladding SystemsmuhuyouNo ratings yet

- CC RMP 00054 03Document18 pagesCC RMP 00054 03Andrew ChiramboNo ratings yet

- Advisory Leaflet 9 Repair and Maintenance of Stone BuildingsDocument4 pagesAdvisory Leaflet 9 Repair and Maintenance of Stone BuildingsGone PoojithaNo ratings yet