B.E. Automobile Engg.

B.E. Automobile Engg.

Uploaded by

Vijil RajCopyright:

Available Formats

B.E. Automobile Engg.

B.E. Automobile Engg.

Uploaded by

Vijil RajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

B.E. Automobile Engg.

B.E. Automobile Engg.

Uploaded by

Vijil RajCopyright:

Available Formats

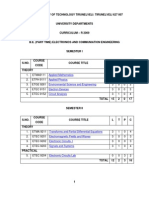

ANNA UNIVERSITY CHENNAI :: CHENNAI 600 025 UNIVERSITY DEPARTMENTS CURRICULUM R 2009 B.E.

(PART TIME) AUTOMOBILE ENGINEERING

SEMESTER I SL. COURSE NO. CODE THEORY 1. PTMA 9111 2. PTPH 9111 3. PTCY 9111 4. PTEI 9161 5. PTGE 9111 COURSE TITLE Applied Mathematics Applied Physics Applied Chemistry Electrical Engineering Fundamentals of Computing TOTAL L 3 3 3 3 3 15 T 0 0 0 0 0 0 P 0 0 0 0 0 0 C 3 3 3 3 3 15

SEMESTER II SL. COURSE NO. CODE THEORY 1. PTMA9262 2. PTGE 9151 3. PTAU9201 4. 5. PTAU9254 PTPR 9161 COURSE TITLE Numerical Methods Engineering Mechanics Thermodynamics and Thermal Engineering Measurements and Metrology Production Processes TOTAL SEMESTER III SL. COURSE NO. CODE THEORY 1. PTAU9203 2. PTAU9252 3. PTAU9202 4. PTAU9253 PRACTICAL 5. COURSE TITLE Automotive Petrol Engines Automotive Chassis Solid Mechanics Automotive Electrical System Automotive Engine &Chassis Components Lab TOTAL L 3 3 3 3 0 12 T 0 0 0 0 0 0 P 0 0 0 0 3 3 C 3 3 3 3 2 14 L 3 3 3 3 3 15 T 0 0 0 0 0 0 P 0 0 0 0 0 0 C 3 3 3 3 3 15

SEMESTER IV SL. COURSE NO. CODE THEORY 1. PTPR9251 2. PTAU9251 3. PTAU9302 4. PTAU9303 5. PTAU9307 COURSE TITLE Theory of Machines Automotive Diesel Engines Automotive Transmission Two and Three Wheeler Technology Vehicle Design Data Characteristics TOTAL L 3 3 3 3 3 15 T 0 0 0 0 0 0 P 0 0 0 0 0 0 C 3 3 3 3 3 15

SEMESTER V SL. COURSE NO. CODE THEORY 1. PTAU9352 2. PTAU9353 3. 4. PTAU9304 PRACTICAL 5. COURSE TITLE Electronic Engine Management Systems Vehicle Body Engineering Machine Components Design Automotive Materials and Production Techniques Engine Testing and Automotive Electronics Laboratory TOTAL L 3 3 3 3 0 12 T 0 0 0 0 0 0 P 0 0 0 0 3 3 C 3 3 3 3 2 14

SEMESTER VI SL. COURSE NO. CODE THEORY 1. PTAU9351 2. PTAU9401 3. E1 4. E2 PRACTICAL 5. PTAU9404 COURSE TITLE Vehicle Design Vehicle Dynamics Elective I Elective II Vehicle Maintenance and ReConditioning Laboratory TOTAL L 3 3 3 3 0 12 T 0 0 0 0 0 0 P 0 0 0 0 3 3 C 3 3 3 3 2 14

SEMESTER VII SL. COURSE NO. CODE THEORY 1. PTAU9402 2. PTAU9305 3. 4. PRACTICAL 5. PTAU9451 COURSE TITLE Vehicle Maintenance Automotive Pollution and Control Elective III Elective IV Project Work TOTAL L 3 3 3 3 0 12 T 0 0 0 0 0 0 P 0 0 0 0 6 6 C 3 3 3 3 6 18

Credits to be earned for the award of Degree: 15 + 15 + 14 + 15 + 14 + 14 +18 = 105

LIST OF ELECTIVES FOR B. E. AUTOMOBILE ENGINEERING SL. NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 COURSE CODE PTAE9354 PTAU9021 PTAU 9022 PTGE 9023 PTAU 9024 PTAU 9025 PTAU9026 PTAU 9027 PTAU 9028 PTAU 9029 PTAU 9030 PTAU9031 PTAU 9032 PTAU 9033 PTAU 9034 PTAU 9035 PTGE 9021 PTGE 9022 PTPR 9404 COURSE TITLE Finite Element Method Automotive Aerodynamics Alternate Fuels and energy systems Fundamentals of Nanoscience Tractor and Farm Equipments Vehicle Air-Conditioning Automotive Safety Rubber Technology for Automobiles Fleet Management Special Types of Vehicles Advanced Production Processes for Automotive Components Combustion Thermodynamics and Heat Transfer Advanced Theory of IC Engines Computer Integrated Manufacturing Systems Theory and Design of Jigs and Fixtures Hydraulic and Pneumatic systems Professional Ethics in Engineering Total Quality Management Manufacturing Process Planning and Cost Estimation L 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 T 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 P 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 C 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3

PTMA 9111

APPLIED MATHEMATICS (Common to all branches of B.E / B.Tech (PT) Programmes) LT P C 3 0 0 3 UNIT I MATRICES 9 Characteristic equation Eigenvalues and Eigenvectors of a real matrix Properties of eigenvalues and eigenvectors Cayley Hamilton Theorem Diagonalization of matrices - Reduction of a quadratic form to canonical form by orthogonal transformation Nature of quadratic forms . UNIT II FUNCTIONS OF SEVERAL VARIABLES 9 Partial derivatives Homogeneous functions and Eulers theorem Total derivative Differentiation of implicit functions Change of variables Jacobians Partial differentiation of implicit functions Taylors series for functions of two variables Maxima and minima of functions of two variables. UNIT III ANALYTIC FUNCTION 9 Analytic functions Necessary and sufficient conditions for analyticity Properties Harmonic conjugates Construction of analytic function Conformal Mapping Mapping by functions w = a + z , az, 1/z, - Bilinear transformation. UNIT IV COMPLEX INTEGRATION 9 Line Integral Cauchys theorem and integral formula Taylors and Laurents Series Singularities Residues Residue theorem Application of Residue theorem for evaluation of real integrals Use of circular contour and semicircular contour with no pole on real axis. UNIT V LAPLACE TRANSFORMS 9 Existence conditions Transforms of elementary functions Basic properties Transforms of derivatives and integrals Initial and Final value theorems Inverse transforms Convolution theorem Transform of periodic functions Application to solution of linear ordinary differential equations with constant coefficients. TOTAL : 45 PERIODS TEXT BOOKS

1. Grewal B.S., Higher Engineering Mathematics (40th Edition), Khanna Publishers,

Delhi (2007). 2. Ramana B.V., Higher Engineering Mathematics, Tata McGraw Hill Co. Ltd., New Delhi (2007). REFERENCES 1. Glyn James, Advanced Modern Engineering Mathematics, Pearson Education (2007). 2. Veerarajan, T., Engineering Mathematics (For First Year), Tata McGraw-Hill Pub. Pvt Ltd., New Delhi (2006).

PTPH 9111

APPLIED PHYSICS L T P C 3 0 0 3

UNIT I ULTRASONICS 9 Introduction Production magnetostriction effect - magnetostriction generatorpiezoelectric effect - piezoelectric generator- Detection of ultrasonic waves properties Cavitations - Velocity measurement acoustic grating - Industrial applications drilling, welding, soldering and cleaning SONAR - Non Destructive Testing pulse echo system through transmission and reflection modes - A, B and C scan displays, Medical applications - Sonograms UNIT II LASERS 9 Introduction Principle of Spontaneous emission and stimulated emission. Population inversion, pumping. Einsteins A and B coefficients - derivation. Types of lasers HeNe, CO2 , Nd-YAG, Semiconductor lasers - homojunction and heterojunction (Qualitative)- Industrial Applications - Lasers in welding, heat treatment and cutting Medical applications - Holography (construction and reconstruction). UNIT III FIBER OPTICS & APPLICATIONS 9 Principle and propagation of light in optical fibres Numerical aperture and Acceptance angle - Types of optical fibres (material, refractive index, mode) Double crucible technique of fibre drawing - Splicing, Loss in optical fibre attenuation, dispersion, bending - Fibre optical communication system (Block diagram) - Light sources Detectors - Fibre optic sensors temperature and displacement - Endoscope. UNIT IV QUANTUM PHYSICS 9 Black body radiation Plancks theory (derivation) Deduction of Wiens displacement law and Rayleigh Jeans Law from Plancks theory Compton effect - Theory and experimental verification Matter waves Schrdingers wave equation Time independent and time dependent equations Physical significance of wave function Particle in a one-dimensional box - Electron microscope - Scanning electron microscope - Transmission electron microscope. UNIT V CRYSTAL PHYSICS 9 Lattice Unit cell Bravais lattice Lattice planes Miller indices d spacing in cubic lattice Calculation of number of atoms per unit cell Atomic radius Coordination number Packing factor for SC, BCC, FCC and HCP structures NaCl, ZnS, diamond and graphite structures Polymorphism and allotropy - Crystal defects point, line and surface defects- Burger vector. TOTAL: 45 PERIODS TEXT BOOKS 1. Palanisamy, P.K., Engineering Physics Scitech publications, Chennai, (2008). 2. Arumugam M. Engineering Physics, Anuradha Publications, Kumbakonam, (2007) 3. Sankar B.N and Pillai S.O. A text book of Engineering Physics, New Age International Publishers, New Delhi, 2007.

REFERENCES 1. 2. R. K. Gaur and S.C. Gupta, Engineering Physics Dhanpat Rai Publications, New Delhi (2003) M.N. Avadhanulu and PG Kshirsagar, A Text book of Engineering Physics, S.Chand and company, Ltd., New Delhi, 2005. Serway and Jewett, Physics for Scientists and Engineers with Modern Physics, 6th Edition, Thomson Brooks/Cole, Indian reprint (2007)

3.

PTCY 9111

APPLIED CHEMISTRY LT P C 3 0 0 3

UNIT I WATER TREATMENT AND POLLUTION CONTROL 9 Treatment of water impurities and disadvantages of hard water-Domestic and Industrial treatment - zeolite and ion exchange processes-Portable water-Boiler feed water conditioning of boiler feed water. Scale and sludge formation prevention caustic embrittlement-boiler corrosionpriming and foaming Sewage treatmentPrimary, secondary and tertiary treatmentsignificance of DO, BOD and COD-desalination reverse osmosis. Control of water,air and land pollution. UNIT II FUELS 9 Classification of fuels-Proximate and ultimate analysis of coal- coke manufacture-Otto Hoffman by product method-cracking-thermal and catalytic (fixed bed and fluidized bed)petroleum-refining-factions-composition and uses synthetic petrol-fischer drops methods- Bergius process- knocking-octane number and cetane number-Preparation, composition and uses of producer gas , water gas and natural gas. Flue gas analysisOrsat apparatus- gross and net calorific values- calculation of minimum requirement of air(simple calculations)- Explosive range spontaneous ignition temperature UNIT III THERMODYNAMICS AND SURFACE CHEMISTRY 9 Second law of thermodynamics-entropy and its significance- criteria for spontaneity- free energy-Gibbs, Helmholts and Gibbs-Helmholts equation-applications and problems Adsorption types of adsorption- adsorption of gases on solids- adsorption isothermFreundlich and Langmuir isotherms-adsorption of solutes from solutions- applications UNIT IV ELECTROCHEMISTRY - CORROSION AND CATALYSIS 9 Reversible and irreversible cells-electrode potentials-types of electrodes-cell reactionsNernst equations- electrochemical and galvanic series-fuel cells and solar cellscorrosion-chemical and electrochemical-factors affecting corrosion-sacrifical anodeimpressed current cathodic protection-surface treatment and protective coatingCatalysis classification-characteristics of catalysis auto catalysis- enzyme catalysis UNIT V POLYMERS-COMPOSITES AND NANOCHEMISTY 9 Polymers-definition-classification-thermoplastics and thermosetting plastics differences Preparation, properties and uses of polystyrene, bakelite, PET, polyurethane, Teflon, ureafromaldehyde, polycarbonates-Elastomers-Preparation, properties of Buna-S, nitrile, neoperene and butyl rubber, silicon rubber. Composites-FRP. Nanochemistryintroduction to nanochemistry- preparation and properties of nonmaterial-nano rods, nano wires-nanotubes-carbon nanotubes and their applications. TOTAL: 45 PERIODS TEXT BOOKS 1. Dhara S S A text book of Engineering Chemistry, S.Chand & Co Ltd, New Delhi,2002 2. Jain. P.C and Monica Jain, Engineering Chemistry,Dhanpet Rai & Sons, New Delhi 2001

REFERENCES 1. Puri B R.,Sharma L R and Madhan S. Pathania, Principles of Physical Chemistry, Shoban Lal Nagin Chand & Co. Jalandar-2000. 2. G.B. Sergeev, Nanochemistry.Elsevier Science, New York,2006 V.R.Gowarikar, N.V.Viswanathan and Jayadev Sreedhar, Polymer Science, Wiley Eastern Limited, Madras (2006).

PTEI 9161

ELECTRICAL ENGINEERING L T P C 3 0 0 3

OBJECTIVE: To impart the knowledge on basic concepts of electrical circuits, electromagnetism and electrical machines. UNIT I BASIC CONCEPTS AND DC CIRCUITS 9 Ohm's law - Electrical resistance - Series /Parallel resistive circuits - Star/Delta transformations - Kirchoff's law - Node and Mesh analysis - Thevenin's and Norton's theorem. UNIT II ELECTROMAGNETISM 9 Magnetic flux - MMF - Flux density - B H curves - Simple and Composite magnetic circuits - Statically induced EMF - Self and Mutual Inductances - Coupling coefficient Stored energy - Force on a conductor - Magnetic pull - Force between parallel conductors. UNIT III A.C.CIRCUITS 9 RMS and average value of periodic waves - Form factor - Phase and Phase difference Simple RC.RL and RLC circuits - series and parallel resonance - power and power factor - introduction to three phase systems power measurement in 3 phase system. UNIT IV D.C. MACHINES 9 Construction details of DC machines - principle of operation of DC generator - EMF equation - characteristics of DC generators - principle of DC motor - Back EMF - Voltage and torque equation - Characteristics of shunt, series and compound motors. UNIT V A.C. MACHINES 9 Principle of ideal transformer - construction and type - EMF equation - Tests on transformer - Equivalent circuit - Voltage regulation - Construction of synchronous machines - Principle of alternator - EMF equation - Torque equation - V-curves Induction motor - Construction and basic principle of operation slip - Starting and Running torques. TOTAL: 45 PERIODS REFERENCES

1. Theraja, B.L., "A Text Books of Electrical Technology ", S.S.Chand and Co.,

New Delhi, 1998. 2. Edminister J.A., "Theory and Problems on Electric circuits ", McGraw Hill International Edition, 1994. 3. Kosow, I.L., "Electrical Machinery and Transformers ", 4th Edition, Prentice Hall of India, 1991. 4. Nagrath I.J. and Kothari D.P., "Theory and Problems of Basic Electrical Engineering", Prentice Hall of India, 1998.

10

PTGE 9111

FUNDAMENTALS OF COMPUTING L T P C 3 0 0 3

UNIT I 9 Computer systems Exploring computers Inside the system processing data CPUs Types of storage devices - Operating systems basics networking basics. UNIT II 9 The internet and the WWW Internet services connecting to the internet - Working with applications software productivity software graphics and multimedia Data base Management systems Creating computer program. UNIT III 9 C programming fundamentals compilation process variables Data types Expressions looping decisions. UNIT IV Arrays - Working with functions structures character strings pre processor. UNIT V Pointers Dynamic memory allocation linked list - Applications 9 9 TOTAL: 45 PERIODS TEXT BOOKS 1. Peter Norton, Introduction to Computers, Sixth Edition, Tata McGraw Hill, 2007. 2. Stephen G. Kochan, Programming in C, Third Edition, Pearson Education, 2007. REFERENCES 1. B.W.Kernighan and D.M.Ritchie, The C Programming language, Second Edition, Pearson Education, 2006 2. Ashok N. Kamthane, Computer programming, Pearson Education, 2007. 3. Kenneth A. Reek, Pointers on C, Pearson Education, 2007. 4. R.G.Dromey, How to solve it by Computer, Pearson Education, 2007.

11

PTMA9262

NUMERICAL METHODS L T P C 3 0 0 3

AIM: This course gives a complete procedure for solving numerically different kinds of problems occurring in engineering and technology. OBJECTIVES: The students would be acquainted with the basic concepts of numerical methods and their applications. UNIT I SOLUTION OF EQUATIONS AND EIGENVALUE PROBLEMS 9 Solution of algebraic and transcendental equations Fixed point iteration method Newton-Raphson method Solution of linear system of equations Gauss Elimination method Pivoting Gauss-Jordan methods Matrix Inversion by Gauss-Jordan method Iterative methods of Gauss-Jacobi and Gauss-Seidel Eigenvalues of a matrix by Power method and by Jacobis method. UNIT II INTERPOLATION AND APPROXIMATION 9

Interpolation with unequal intervals Lagrange interpolation Newtons divided difference interpolation Cubic Splines Interpolation with equal intervals Newtons forward and backward difference formulae. UNIT III NUMERICAL DIFFERENTATION AND INTEGRATION 9 Approximation of derivatives using interpolation polynomials Numerical integration using Trapezoidal, Simpsons 1/3 and Simpsons 3/8 rules Rombergs method Two point and three point Gaussian quadrature formulae Evaluation of double integrals by Trapezoidal and Simpsons rules. UNIT IV INITIAL VALUE PROBLEMS FOR ORDINARY DIFFERENTIAL EQUATIONS 9 Single step-methods Taylors series method Eulers method Fourth order RungeKutta method for solving first and second order equations Multi-step methods Milnes and Adams-Bashforth predictor-corrector methods for solving first order equations. UNIT V BOUNDARY VALUE PROBLEMS IN ORDINARY AND PARTIAL DIFFERENTIAL EQUATIONS 9 Finite difference methods for solving two-point linear boundary value problems. Finite difference techniques for the solution of two dimensional Laplaces and Poissons equations on rectangular domain One dimensional heat-flow equation by explicit and implicit (Crank Nicholson) methods - One dimensional wave equation by explicit method. TOTAL : 45 PERIODS TEXT BOOKS

1. Grewal, B.S. and Grewal,J.S., Numerical methods in Engineering and Science,

6th Edition, Khanna Publishers, New Delhi, (2004). 2. Sankara Rao, K. Numerical methods for Scientists and Engineers, 3rd Edition Prentice Hall of India Private Ltd., New Delhi, (2007).

12

REFERENCES

1. Chapra, S. C and Canale, R. P. Numerical Methods for Engineers, 5th Edition,

Tata McGraw-Hill, New Delhi, (2007). 2. Gerald, C. F. and Wheatley, P. O., Applied Numerical Analysis, 6th Edition, Pearson Education Asia, New Delhi, (2006). 3. Brian Bradie, A friendly introduction to Numerical analysis, Pearson Education Asia, New Delhi, (2007).

13

PTGE 9151

ENGINEERING MECHANICS L T P C 3 0 0 3

OBJECTIVE : At the end of this course the student should be able to understand the vectorial and scalar representation of forces and moments, static equilibrium of particles and rigid bodies both in two dimensions and also in three dimensions. Further, he should understand the principle of work and energy. He should be able to comprehend the effect of friction on equilibrium. The student should be able to understand the laws of motion, the kinematics of motion and the interrelationship. The student should also be able to write the dynamic equilibrium equation. All these should be achieved both conceptually and through solved examples. UNIT I BASICS AND STATICS 9 Introduction - Units and Dimensions - Laws of Mechanics Lames theorem, Parallelogram and triangular Law of forces Vectors Vectorial representation of forces and moments Vector operations on forces, dot product and cross product - Coplanar Forces Resolution and Composition of forces Equilibrium of a forces Forces in space - Equilibrium in space - Equivalent systems of forces Principle of transmissibility Single equivalent force UNIT II EQUILIBRIUM OF RIGID BODIES 9 Free body diagram Types of supports and their reactions requirements of stable equilibrium Moments and Couples Moment of a force about a point and about an axis Vectorial representation of moments and couples Scalar components of a moment Varignons theorem - Equilibrium of Rigid bodies in two dimensions Equilibrium of Rigid bodies in three dimensions Examples UNIT III PROPERTIES OF SURFACES AND SOLIDS 9 Determination of Areas and Volumes First moment of area and the Centroid of standard sections T section, I section, Angle section, Hollow section second and product moments of plane area Rectangle, triangle, circle - T section, I section, Angle section, Hollow section Parallel axis theorem and perpendicular axis theorem Polar moment of inertia Principal moments of inertia of plane areas Principal axes of inertia - Mass moment of inertia Derivation of mass moment of inertia for rectangular solids, prism, rods, sphere from first principle Relation to area moments of inertia. UNIT IV DYNAMICS OF PARTICLES 9 Displacements, Velocity and acceleration, their relationship Relative motion Curvilinear motion Newtons law Work Energy Equation of particles Impulse and Momentum UNIT V CONTACT FRICTION AND ELEMENTS OF RIGID BODY DYNAMICS 9 Frictional force Laws of Coloumb friction simple contact friction Rolling friction Belt friction Translation and Rotation of Rigid Bodies Velocity and acceleration General Plane motion Impact of elastic bodies. TOTAL : 45 PERIODS

14

TEXT BOOKS 1. Beer,F.P and Johnson Jr. E.R, Vector Mechanics for Engineers, Vol. 1 Statics and Vol. 2 Dynamics, McGraw-Hill International Edition, 2007. REFERENCES 1. Irving H. Shames, Engineering Mechanics - Statics and Dynamics, IV Edition PHI / Pearson Education Asia Pvt. Ltd., 2003 2. Hibbeller, R.C., Engineering Mechanics, Vol. 1 Statics, Vol. 2 Dynamics, Pearson Education Asia Pvt. Ltd., 2000. 3. Ashok Gupta, Interactive Engineering Mechanics Statics A Virtual Tutor (CDROM), Pearson Education Asia Pvt., Ltd., 2002 4. J.L. Meriam & L.G. Karige, Engineering Mechanics Vol. I & Vol. II, V edition, John Wiley & Sons, 2006. 5. P. Boresi & J. Schmidt, Engineering Mechanics Statics & Dynamics, Micro Print Pvt. Ltec., Chennai, 2004.

15

PTAU9201 OBJECTIVE:

THERMODYNAMICS AND THERMAL ENGINEERING L T P C 3 0 0 3

To introduce fundamental concepts in thermodynamics, heat transfer, propulsion and refrigeration and air conditioning. UNIT I BASIC THERMODYNAMICS 9

Systems, Zeroth low, First law. Properties of gases and vapours. Steady flow energy equation. Heat and work transfer in flow and non-flow processes. Second law, KelvinPlanck statement - Clausius statement - Concept of Entropy, Clausius inequality, Entropy change in non-flow processes. UNIT II AIR CYCLE AND COMPRESSORS 9

Otto, Diesel, Dual and Brayton cycles. Air standard efficiency. Mean effective pressure, Reciprocating compressors Intercooling Minimum work requirement. UNIT III STEAM ENGINE AND BOILERS 9

Properties of steam Rankine cycle Steam Nozzles Steam Engines Simple jet propulsion system. UNIT IV REFRIGERATION AND AIR-CONDITIONING 9

Principles of Psychrometry and refrigeration - Vapour compression - Vapour absorption types - Co-efficient of performance, Properties of refrigerants Basic Principle and types Air conditioning. UNIT V HEAT TRANSFER 9

Conduction in parallel, radial and composite wall Basics of Convective heat transfer Fundamentals of Radiative heat transfer Flow through heat exchangers. TOTAL : 45 PERIODS (Use of standard thermodynamic tables, Mollier diagram and Refrigerant property tables are permitted) TEXT BOOKS 1. Nag.P.K., Engineering Thermodynamics, Tata McGraw-Hill, New Delhi, 2007. 2. Rathakrishnan E., Fundamentals of Engineering Thermodynamics, Prentice-Hall India, 2005. REFERENCES

1. Ramalingam K.K. Thermodynamics, Sci-Tech Publications, 2006.

2. Holman.J.P., Thermodynamics, 3rd Ed. McGraw-Hill, 2007. 3. Venwylen and Sontag, Classical Thermodynamics, Wiley Eastern, 1987. 4. Arora C.P, Thermodynamics, Tata McGraw-Hill, New Delhi, 2003. 5. Merala C, Pother, Craig W, Somerton, Thermodynamics for Engineers, Schaum Outline Series, Tata McGraw-Hill, New Delhi, 2004.

16

PTAU9254

MEASUREMENTS AND METROLOGY L T P C 3 0 0 3

OBJECTIVE: Study of the theory, construction and operation of different measurement technology, instruments transducers and their application. UNIT I LINEAR MEASUREMENT 9 Units and standards, errors in measurement, linearity, repeatability, precision and accuracy, calibration. Linear measuring instruments, taper, wire and thickness gauge, vernier instruments, micrometer, internal measurements slip gauges and its accessories, dial gauges, comparators. UNIT II FORM AND SURFACE MEASUREMENT 9 Interferometry surface texture measurements, flatness testing, collimators, angular measurements, metrology of screw threads, measurement and testing of gears, measuring machines. UNIT III PRESSURE MEASUREMENT 9 Bourden tube, diaphragm, bellows and pressure capsules: Transducers used in pressure measurement- potentiometer, strain gauges, LVDT, capacitive and variable reluctance type transducers. Dynamic pressure measurement piezo electric and piezo resistive transducers. Farnboro engine indicator. Low pressure measurement Mc leod gauge, Pirani gauge, thermal conductivity type pressure measurement. UNIT IV FLOW AND TEMPERATURE MEASUREMENT 9 Obstruction type flow meter, Positive displacement flow meters turbine flow meter, flouted tube flowmeter, anemometer, ultrasonic flow meter, magnetic flow meters. Alcock viscous air flow meter. Temperature scales mechanical temperature sensors, liquid in glass, vapour pressure, bimetal temperature gauges. RTD, Thermistors, thermocouples, Pyrometers. UNIT V FORCE AND TORQUE MEASUREMENT 9 Force measuring devices- Balances, platform scales, weigh bridges, load cells, proving ring. Torque measurement prony brake, rope brake and fan type brakes. Dynamometers hydraulic, electric cradle and eddy current dynamometers. Transmission dynamometers. Chassis dynamometers. TOTAL : 45 PERIODS TEXT BOOKS 1. Jain R.K., Engineering metrology, Khanna publishers, New Delhi, 2005 2. Rangan C.S., Sarma G.E and Mani V.S Instrumentation devices and systems. TMH Publishing Co. New Delhi, 2001 3. Beckwith T.G & Buck N.L Mechanical measurements, Oxford and IBH publishing house New Delhi, 2004 REFERENCES 1. Patranabis D, Principles of industrial instrumentation, TMH Publishing Co. New Delhi, 2000 2. Jain R.K., Mechanical & Industrial measurements , Khanna publishers, New Delhi, 2005 3. Doeblin,Measurement System Application &Design McGraw Hill ,New Delhi, 2004 4. Gaylor F.W and Shotbolt C.R Metrology for engineers, ELBS, 2006.

17

PTPR 9161

PRODUCTION PROCESSES L T P C 3 0 0 3

OBJECTIVE To familiarise the students with various production processes such as casting, forming, machining, welding and unconventional production processes. UNIT I INTRODUCTION AND CASTING 8 Classification and comparison of manufacturing processes criteria for selection of a process. Casting types Sand casting Green sand, Dry sand, Core sands procedure to make sand moulds and cores principle of die casting gravity and pressure die casting squeeze casting - centrifugal casting, investment casting shell moulding continuous casting UNIT II METAL FORMING AND POWDER METALLURGY 10 Basic concepts and classification of forming processes Principles application of the following processes forging, rolling, extrusion, wire drawing, spinning, sheet metal forming powder metallurgy steps involved, applications. High energy Rate forming Explosive, Electro Hydraulic, Magnetic Pulse forming. UNIT III CONVENTIONAL MACHINING 10 General principles (with schematic diagrams only) of working, types and commonly performed operations in the following machines lathe, shaper, planer, milling, drilling and grinding machines super finishing basics of CNC machines. UNIT IV WELDING 7 Classification of welding processes principles and equipment used in the following processes Arc welding shielded metal arc welding, gas metal arc welding, ags tungsten arc welding, submerged arc welding, electro slag welding,flux cored arc welding - Resistance welding Diffusion bonding Flash butt welding -Thermit welding soldering brazing. UNIT V UNCONVENTIONAL MACHINING PROCESSES 10 Need for unconventional machining processes principles and application of the following processes abrasive jet machining, ultrasonic machining, Electro discharge machinery, electrochemical machining, chemical machining, LASER beam machining, Electron beam machining, plasma arc machining- Hybrid machining processes. TOTAL : 45 PERIODS TEXT BOOKS 1. Serope Kalpakjain, Steven R Schmid, Manufacturing Process for Engineering Materials, Pearson Education, Fourth Edition, 2003 2. Gowri, Hariharan, Suresh Babu, Manufacturing Technology-I, Pearson Education, 2007 REFERENCES 1. Hajra Choudhury, Elements of Workshop Technology, Vol.I and Vol.II, Asia Publishing House, 1996. 2. R.K.Jain and S.C. Gupta, Production Technology, Khanna Publishers,97. 3. H.M.T. Production Technology Hand Book, Tata McGraw Hill, 1990. 4. Rao .P.N. Manufacturing Technology Tata McGraw Hill, 2002.

18

PTAU9203

AUTOMOTIVE PETROL ENGINES L T P C 3 0 0 3

AIM: To impart the knowledge on basic concepts on Automotive SI Engines and its various sub components along with its functions. OBJECTIVE: The main objective of this course is to impart knowledge in automotive petrol engine. The detailed concept, construction and principle of operation of petrol engine (both 4S and 2S) and various engine components, combustion, cooling and lubrication systems will be taught to the students. At the end of the course the students will have command over automotive petrol engines. UNIT I ENGINE CONSTRUCTION AND OPERATION 10 4 stroke engine - Constructional details, working principle. Otto cycle, Actual indicator diagram, Fuel air cycle. Cylinder layout and configurations. Firing order and its significance. Engine balancing. Materials of engine components. UNIT II FUEL SYSTEM 10 Carburettor working principle. Requirements of an automotive carburetor starting, idling, acceleration and normal circuits of a carburetor Compensation Maximum power devices Constant choke and constant vacuum carburetor, multi barrel and multiple venturi systems Fuel feed system Mechanical and electrical pumps Petrol injection. UNIT III COOLING AND LUBRICATION SYSTEM 8 Need for cooling. Types of cooling system air cooling and Liquid cooled systems. Forced circulation system, pressure cooling system Need for Lubrication system. Mist lubrication system, wet sump lubrication Properties of lubricants, properties of coolant. UNIT IV COMBUSTION AND COMBUSTION CHAMBERS 9 Combustion in SI engine Stages of combustion Flame propagation Rate of pressure rise Abnormal combustion pre ignition and knock effect of engine variables on knock Combustion chambers Different types Factors controlling combustion chamber design. UNIT V TWO STROKE ENGINES 8 Two stroke engine types, terminologies, definitions, construction and operation. Comparison of four stroke and two stroke engine operation. Theoretical scavenging methods. Scavenging pumps Types of scavenging. TOTAL : 45 PERIODS TEXT BOOKS 1. Ramalingam. K. K., Internal Combustion Engines, Scitech publications, Chennai, 2003 2. Ganesan.V., Internal Combustion Engines, Tata McGraw Hill Publishing Co., New York, 1994. REFERENCES 1. Heldt.P.M. High Speed Combustion Engines, Oxford IBH Publishing Co., Calcutta, 1975. 2. Obert E.F., Internal Combustion Engines Analysis and Practice, International Text Books: Co., Scranton, Pennsylvania, 1988. 3. William.H.Crouse, Automotive Engines, McGraw Hill Publishers, 1985. 4. Ellinger, H.E., Automotive Engines, Prentice Hall Publishers, 1992.

19

PTAU9252 OBJECTIVE

AUTOMOTIVE CHASSIS L T P C 3 0 0 3

Study of the Constructional details and Theory of important drive line, Structural, Steering, Braking and Suspension Systems of Automobiles. ProblemSolving in Steering Mechanism, Propeller Shaft, Braking and Suspension Systems are to be done. UNIT I INTRODUCTION, FRAME, STEERING SYSTEM 9 Types of Chassis layout, with reference to Power Plant location and drive, various types of frames, Loads acting on vehicle frame, Constructional details and materials for frames, Testing of frames, Types of Front Axles and Stub Axles, Front Wheel Geometry, namely, Castor, Camber, King Pin Inclination and Toein, Condition for True Rolling Motion of Wheels during Steering, Ackermans and Davis Steering Mechanisms, Steering Error Curve, Steering Linkages, Different Types of Steering Gears, Slip Angle, OverSteer and UnderSteer, Reversible and Irreversible Steering, PowerAssisted Steering. UNIT II PROPELLER SHAFT AND FINAL DRIVE 9 Effect of Driving Thrust, torque reactions and side thrust, Hotchkiss drive, torque tube drive, radius rods and stabilizers, Propeller Shaft, Universal Joints, Constant Velocity Universal Joints, Front Wheel drive, Final drive, different types, Double reduction and twin speed final drives, Multiaxled vehicles, Differential principle and types, Differential housings, NonSlip differential, Differential locks, Final drive of Crawler Tractors. UNIT III AXLES AND TYRES 9 Construction and Design of Drive Axles, Types of Loads acting on drive axles, Full Floating, ThreeQuarter Floating and SemiFloating Axles, Axle Housings and Types, Types and Constructional Details of Different Types of Wheels and Rims, Different Types of Tyres and their constructional details. UNIT IV SUSPENSION SYSTEM 9 Need for Suspension System, Types of Suspension Springs, Constructional details and characteristics of Single Leaf, MultiLeaf, Coil, Torsion bar, Rubber, Pneumatic and Hydro elastic Suspension Spring Systems, Independent Suspension System, Shock Absorbers, Types and Constructional details, Design of Leaf and Coil Springs. UNIT V BRAKING SYSTEM 9 Theory of Automobile Braking, Stopping Distance Time and Braking Efficiency, Effect of Weight Transfer during Braking, Theory of Drum Brakes, Leading and Trailing Shoes, Braking Torque, Constructional Details of Drum Brake and its Activators, Disc Brake Theory, Hydraulic, Mechanical, Pneumatic and PowerAssisted Braking System, Servo Brakes, Retarders, AntiLock Braking System. TOTAL : 45 PERIODS TEXTBOOKS 1. Kripal Singh, Automobile Engineering, Standard Publisher, New Delhi , 2006 2. R.K. Rajput, A TextBook of Automobile Engineering, Laxmi Publications Private Limited, 2007 3. N.K. Giri, Automotive Mechanics, Kanna Publishers, 2007 REFERENCES 1. Heldt P.M., Automotive Chassis, Chilton Co., New York, 1990 2. Newton Steeds and Garret, Motor Vehicles, 13th Edition, Butterworth, London, 2005. 3. Heinz Hezler, Modern Vehicle Technology, Butterworth, London, 2005.

20

PTAU9202 OBJECTIVE

SOLID MECHANICS L T P C 3 0 0 3

To gain knowledge of simple stresses, strains and deformation in components due to external loads. To assess stresses and deformations through mathematical models of beams, twisting bars or combinations of both. Effect of component dimensions and shape on stresses and deformations are to be understood. The study would provide knowledge for use in the design courses To provide knowledge on analysis of various structural elements for different loading conditions. UNIT I AXIAL LOADING 9 Stresses and strains Hookes law stress and strain diagrams - elastic constants statically determinate and indeterminate problems in tension & compression thermal stresses impact loading. UNIT II STRESSES IN BEAMS 9 Shear force & bending moment diagrams bending stresses shear stress variation in beams of symmetric sections beams of uniform strength. UNIT III DEFLECTION OF BEAMS 9 Double integration method Macaulays method moment area method conjugate beam method principle of superposition Strain Energy in axial, bending, torsion and shear loadings. Castiglianos theorems and their applications. UNIT IV TORSION SPRINGS COLUMNS 9 Torsion of solid and hollow circular shafts shear stress variation power transmission in shafts open and closed-coiled helical springs stresses in helical springs classification of columns Euler buckling columns with different end conditions. UNIT V BIAXIAL STRESSES 9 Stresses in thin-walled pressure vessels combined bending, torsion and axial loading of circular shafts Mohrs circle and its construction determination of principal stresses. TOTAL : 45 PERIODS TEXT BOOKS 1. Gere & Timoshenko, Mechanics of Materials, McGraw Hill, 1993 2. William Nash, Strength of Materials, Tata McGraw Hill, 2004 REFERENCES 1. Dym,C.L., and Shames,I.H., Solid Mechanics, McGraw Hill, Kogakusha, Tokyo, 1973. 2. Stephen Timoshenko, Strength of Materials, Vol I & II, CBS Publishers and Distributors, Third Edition. 3. R.K.Rajput, Strength of Materials, S. Chand and Co., 1999. 4. Timoshenko,S. and Young,D.H., Elements of Strength of Materials, T.Van Nostrand Co. Inc., Princeton, N.J., 1977.

21

PTAU9253

AUTOMOTIVE ELECTRICAL SYSTEMS L TP C 3 0 0 3

AIM The student will have to know about all theoretical information and about electrical components used in a vehicle. OBJECTIVE To impart knowledge to the students in the principles of operation and constructional details of various Automotive Electrical and Electronic Systems like Batteries, Starting System, charging System, Ignition System, Lighting System and Dash Board Instruments. UNIT I BATTERIES 8 Principle and construction of lead-acid battery. Characteristics of battery, rating, capacity and efficiency of batteries. Various tests on battery condition, charging methods. Details of modern storage batteries. UNIT II STARTING SYSTEM 9 Condition of starting Behavior of starter during starting. Series motor and its characteristics. Principle & construction of starter motor. Working of different starter drive units. Care & maintenance of starter motor, Starter switches. UNIT III CHARGING SYSTEM 9 Function, Components of DC and AC Charging System for Automobile, construction, operating principle, characteristics, charging circuit controls cut out, relays, voltage and current regulators, troubleshooting UNIT IV IGNITION SYSTEM 10 Types, construction & working of battery coil and magneto ignition systems. Relative merits, centrifugal and vacuum advance mechanisms. Types and construction of spark plugs, Electronic Ignition system. Digital ignition system. UNIT V LIGHTING SYSTEM & ACCESSORIES 9 Insulated & earth return systems. Positive & negative earth systems. Details of head light & side light. Head light dazzling & preventive methods. Electrical fuel-pump, Speedometer, Fuel, oil & temperature gauges, Horn, Wiper system, Trafficator, wiring system. TOTAL : 45 PERIODS TEXT BOOKS 1. Judge,A.W., Modern Electrical Equipment of Automobiles, Chapman & Hall, London, 1992. REFERENCES 1. Young,A.P. & Griffiths,L., Automobile Electrical Equipment, English Language Book Society & New Press, 1990. 2. Vinal,G.W., Storage Batteries, John Wiley & Sons Inc., New York, 1985. 3. Crouse,W.H., Automobile Electrical Equipment, McGraw Hill Book Co. Inc., New York, 1980. 4. Spreadbury,F.G., Electrical Ignition Equipment, Constable & Co. Ltd., London, 1962. 5. Kholi,P.L., Automotive Electrical Equipment, Tata McGraw-Hill Co. Ltd., New Delhi, 1975. 6. Automotive Hand Book, fifth edition, Robert Bosch, Bently Publishers, 2003.

22

AUTOMOTIVE ENGINE AND CHASSIS COMPONENTS LABORATORY L T P C 0 0 3 2 AIM: To familiarize and train the students on the constructional arrangements of different engine system and chassis systems of different vehicles.. OBJECTIVE: The main objective of this course is to impart knowledge in the assembling and dismantling and study of different types of an engine and its various systems like steering system, transmission system, electrical system, ignition system, injection system, Braking system. At the end of the course the student will be well versed in the assembling and dismantling of any vehicles. STUDY OF THE FOLLOWING ENGINES AND ITS COMPONENTS: Tata engine Leyland engine Ambassador engine Fiat engine Maruthi engines Ford engines MPFI Engine STUDY AND MEASUREMENT OF THE FOLLOWING CHASSIS Tata Leyland Ambassador Premier Padmini Maruthi car (Front engine, front wheel drive & constant velocity joint) STUDY, DISMANTLING & ASSEMBLING Front axle Rzeppa joint assembly Rear axle Clutch 2 types Coil spring& Diaphragm spring clutches Gear box Sliding mesh, Constant mesh & Synchromesh Gear Box Transfer case Steering system Braking system Differential mechanism Power steering mechanism TOTAL : 45 PERIODS

23

PTPR9251

THEORY OF MACHINES L T PC 3 0 0 3

OBJECTIVES: To understand the basic concepts of mechanisms and machinery To expose the students the different mechanisms, their method of working, Forces involved and consequent vibration during working

UNIT I MECHANISMS 9 Definition Machine and Structure Kinematic link, pair and chain classification of Kinematic pairs Constraint & motion Degrees of freedom slider crank Single and double Crank rocker mechanisms Inversions applications, Kinematic analysis and synthesis of simple mechanisms Determination of velocity and acceleration of simple mechanisms. UNIT II FRICTION 9 Types of friction friction in screw and nut pivot and collar thrust bearings collar bearing plate and disc clutches belt (flat & vee) and rope drives creep in belts Jockey pulley open and crossed belt drives Ratio of tensions Effect of centrifugal and initial tensions Effect of centrifugal and initial tension condition for maximum power transmission. UNIT III GEARS AND CAMS 9 Gear profile and geometry nomenclature of spur & helical gears laws of gearing interference requirement of minimum number of teeth in gears gear trains simple and compound gear trains determination of speed and torque in epicyclic gear trains cams different types of followers cam design for different follower motions. UNIT IV BALANCING 9 Static and dynamic balancing single and several masses in different planes primary and secondary balancing of reciprocating masses balancing single and multi cylinder Engines Governors and Gyroscopic effects. UNIT V VIBRATION 9 Free, forced and damped vibrations of single degree of freedom systems force transmitted to supports vibration Isolation vibration absorption torsional vibration of shafts single and multirotor systems geared shafts critical speed of shafts. TOTAL : 45 PERIODS TEXT BOOKS 1. Bansal Dr.R.K. Theory of Machines Laxmi Publications (P) Ltd., New Delhi 2001 2. Rattan S.S.Theory of machines Tata McGraw Hill publishing Co., New Delhi, 2002. REFERENCES 1. Rao J.S.and Dukkipati R.V. Mechanism and Machine Theory Second Edition, Wiley Eastern Limited, 1992. 2. Malhotra D.R. and Gupta H.C The Theory of machines Satya Prakasam, Tech. India Publications, 1989 3. Gosh A and Mallick A.K. Theory of Machines and Mechanisms affiliated east west press, 1989 4. Shingley J.E. and Vicker J.J. Theory of Machines and Mechanisms McGraw Hill, 1986. 5. Burton Paul Kinematics and Dynamics of Machinery, Prentice Hall, 1979.

24

PTAU9251

AUTOMOTIVE DIESEL ENGINES LTP C 3 0 0 3

OBJECTIVE The objective of this course is to have knowledge in automotive diesel engines. The construction and principle of operation of various types of engines, fuel injection system Theory of combustion and types of combustion chamber air motion air motion will be taught to the students. The design advances in IC engines Electronic fuel injection system will all so be introduce to the students. At the end of the course the students will have command over automotive MPFI concepts and application. UNIT I BASIC THEORY 9 Diesel engine construction and operation. Two stroke and four stroke diesel engines. Diesel cycle Fuel-air and actual cycle analysis. Diesel fuel. Ignition quality. Cetane number. Laboratory tests for diesel fuel. Standards and specifications. UNIT II FUEL INJECTION SYSTEM 9 Requirements solid injection. Function of components common rail direct injection Jerk and distributor type pumps. Pressure waves, Injection lag. Unit injector. Mechanical and pneumatic governors. Fuel injector, Types of injection nozzle, Nozzle tests. Spray characteristics. Injection timing. Pump calibration. Pilot injection. UNIT III AIR MOTION, COMBUSTION AND COMBUSTION CHAMBERS 10 Importance of air motion Swirl, squish and turbulence, Swirl ratio. Fuel air mixing. Stages of combustion. Delay period factors affecting delay period. Knock in CI engines. Comparison of knock in CI & SI engines. Direct and indirect injection combustion chambers. Air cell chamber. Combustion chamber design objectives Different types of combustion chamber. M.Combustion chamber. Combustion chambers for Homogeneous charge compression ignition systems Dual and alternate fueled engine systems. UNIT IV SUPERCHARGING AND TURBOCHARGING 8 Necessity and limitation Charge cooling. Types of supercharging and turbocharging Relative merits. Matching of turbocharger. UNIT V ENGINE PERFORMANCE AND EVALUATION 9 Automotive and stationary diesel engine testing and related standards Engine power and efficiencies - performance characteristics. Variables affecting engine performance Methods to improve engine performance Heat balance Performance maps. TOTAL : 45 PERIODS TEXT BOOKS 1. K. K. Ramalingm, internal Combustion Engines, Scitech publications, Chennai, 2003. 2. Ganesan,V., Internal Combustion Engines, Tata-McGraw Hill Publishing Co., New Delhi, 1994.

25

REFERENCES 1. Heldt,P.M., High Speed Combustion Engines, Oxford IBH Publishing Co., Calcutta, 1985. 2. Obert,E.F., Internal Combustion Engine analysis and Practice, International Text Book Co., Scranton, Pennsylvania, 1988. 3. Maleev,V.M., Diesel Engine Operation and Maintenance, McGraw Hill, 1974. 4. Dicksee,C.B., Diesel Engines, Blackie & Son Ltd., London, 1964. PTAU9302 OBJECTIVES The main objective of this course is to impart knowledge in automotive transmission. The detailed concept, construction and principle of operation of various types of mechanical transmission components, hydrodynamic devices, hydrostatic devisees and automatic transmission system will be taught to the students. The design of clutch and gearbox will all so be introduce to the students. At the end of the course the students will have command over automotive transmission concepts and application. UNIT I CLUTCH AND GEAR BOX 9 Problems on performance of automobile - such as resistance to motion, tractive effort, engine speed, engine power and acceleration. Requirement of transmission system. Different types of clutches, principle, Construction and torque capacity. Determination of gear ratios for vehicles. Different types of gearboxes such as Sliding mesh gearbox, Constant mesh gearbox and Synchromesh gearbox. UNIT II HYDRODYNAMIC DRIVE 9 AUTOMOTIVE TRANSMISSION L T P C 3 0 0 3

Fluid coupling - Principle of operation, Constructional details, Torque capacity, Performance characteristics and Reduction of drag torque. Hydrodynamic Torque converter - Principle of operation, Constructional details and Performance characteristics. Multistage torque converters. Polyphase torque converters. Converter coupling UNIT III PLANETARY GEAR BOXES 9 Construction and operation of Ford T-model gearbox, Wilson Gear box and Cotal electromagnetic transmission. UNIT IV AUTOMATIC TRANSMISSION APPLICATIONS 9 Need for automatic transmission, Principle of operation. Hydraulic control system for automatic transmission. Chevrolet Turboglide Transmission, Continuously Variable Transmission (CVT) Types Operations. UNIT V HYDROSTATIC AND ELECTRIC DRIVE 9 Hydrostatic drive - Various types of hydrostatic systems, Principles of Hydrostatic drive system. Advantages and limitations. Comparison of hydrostatic drive with hydrodynamic drive, Construction and Working of typical Janny hydrostatic drive. Electric drive Principle of operation of Early and Modified Ward Leonard Control system, Advantages & limitations.

26

TOTAL : 45 PERIODS TEXT BOOKS 1. Newton and Steeds, Motor vehicles, Illiffe Publishers, 2000. 2. Judge, A.W., Modern Transmission systems, Chapman and Hall Ltd., 1990. REFERENCES 1. Heldt, P.M., Torque converters, Chilton Book Co., 1992. 2. SAE Transactions 900550 & 930910. 3. Hydrostatic transmissions for vehicle applications, I Mech E Conference, 1981-88. 4. Crouse, W.H., Anglin, D.L., Automotive Transmission and Power Trains construction, McGraw Hill, 1992.

27

PTAU9303

TWO AND THREE WHEELER TECHNOLOGY LT P C 3 0 0 3

OBJECTIVE: The aim of this course is to make the students to know and understand the constructional details operating characteristics and vehicle design aspects UNIT I THE POWER UNIT 9 Two stroke and four stroke SI engine, merits and demerits, Symmetrical and unsymmetrical port timing diagrams. Types of scavenging processes, merits and demerits, scavenging efficiency. Scavenging pumps. Rotary valve engine. Fuel system. Lubrication system. Magneto coil and battery coil spark ignition system. Electronic ignition System. Starting system. Kick starter system. UNIT II CHASSIS AND SUB-SYSTEMS 8 Main frame, its types. Chassis and shaft drive. Single, multiple plates and centrifugal clutches. Gear box and gear controls. Front and rear suspension systems. Shock absorbers. Panel meters and controls on handle bar. UNIT III BRAKES AND WHEELS 8 Drum brakes, Disc brakes, Front and rear brake links lay-outs. Spoked wheel, cast wheel. Disc wheel. Disc types. Tyres and tubes. UNIT IV TWO WHEELERS Case study of motor cycles, scooters and mopeds. Servicing and maintenance. 10

UNIT V THREE WHEELERS 10 Case study of Auto rickshaws, Pick up van, Delivery van and Trailer. Servicing and maintenance. TOTAL : 45 PERIODS TEXTBOOK 1. Irving,P.E., Motor cycle Engineering, Temple Press Book, London, 1992. REFERENCES 1. The Cycle Motor Manual, Temple Press Ltd., London, 1990. 2. Encyclopedia of Motor cycling, 20 volumes, Marshall Cavensih, New York and London, 1989. 3. Bryaut,R.V., Vespa Maintenance and Repair series. 4. Raymond Broad, Lambretta A practical guide to maintenance and repair, 1987.

28

PTAU9307

VEHICLE DESIGN DATA CHARACTERISTICS LT P C 3 0 0 3

AIM: To impart knowledge about the engine behavior at different torque and speed conditions. Exposure will be given about air resistance, rolling resistance, gradient resistance, driving force and brake horse power; OBJECTIVE: Students have to collect important technical specifications of an automobile from Automobile Journals and keeping this, as a guide, they have to calculate and tabulate various vehicle performance parameters and design parameters and to draw curves using these data. After completion of this syllabus students will have idea about differential performance curves and different operating conditions of engines. UNIT I PERFORMANCE CURVE 15 Resistance. Power and torque curves. Driving force against vehicle speed. Acceleration and gradability in different gears for a typical car or truck plotted from specifications available in Automobile Journals. UNIT II EXPECTANCY CURVES 30 Calculation and plotting the curves of Air and Rolling resistances. Driving force. Horse power, Rear axle ratio. Engine speed. Torque and mechanical efficiency for different vehicle speeds. Pressure volume diagram. Frictional mean effective pressure. Engine capacity. Bore and stroke length. Connecting rod length to crank radius ratio. Piston velocity and acceleration against crank angle. Gas force, inertia force and resultant force against crank angle. Turning moment, side thrust against crank angle on cylinder wall. Determination of gear ratios. Acceleration and gradability. Typical problems on vehicle performance. TOTAL : 45 PERIODS TEXT BOOK 1. Heldt,P.M., High Speed Combustion Engine, Oxford & IBH Publishing Co., Calcutta, 1989. REFERENCES: 1. Lichty, IC Engines, Kogakusha Co. Ltd., Tokyo, 1991. 2. Automotive Engineering Journals Auto Car, Automotive Industries, Automobile Engineer. 3. Giri,K., Automobile Mechanics, Khanna Publishers, New Delhi, 1986.

29

PTAU9352

ELECTRONIC ENGINE MANAGEMENT SYSTEM LT P C 3 0 0 3

OBJECTIVE: To explain the principle of engines electronic management system and different sensors used in the systems. UNIT I FUNDAMENTALS OF AUTOMOTIVE ELECTRONICS 9 Components for electronic engine management system, open and closed loop control strategies, PID control, Look up tables, introduction to modern control strategies like Fuzzy logic and adaptive control. Parameters to be controlled in SI and CI engines. UNIT II SENSORS AND ACTUATORS 9 Inductive, Hall Effect, hot wire, thermistor, piezo electric, piezoresistive, based sensors. Throttle position, mass air flow, crank shaft position, cam position, engine and wheel speed, steering position, tire pressure, brake pressure, steering torque, fuel level, crash, exhaust oxygen level (two step and linear lambda), knock, engine temperature, manifold temperature and pressure sensors. UNIT III SI ENGINE MANAGEMENT 9 Three way catalytic converter, conversion efficiency versus lambda. Layout and working of SI engine management systems like Bosch Monojetronic, L-Jetronic and LH-Jetronic. Group and sequential injection techniques. Working of the fuel system components. Advantages of electronic ignition systems. Types of solid state ignition systems and their principle of operation, Contactless electronic ignition system, Electronic spark timing control. UNIT IV CI ENGINE MANAGEMENT 9 Fuel injection system parameters affecting combustion, noise and emissions in CI engines. Pilot, main, advanced post injection and retarded post injection. Electronically controlled Unit Injection system. Layout of the common rail fuel injection system. Working of components like fuel injector, fuel pump, rail pressure limiter, flow limiter, EGR valve. UNIT V DIGITAL ENGINE CONTROL SYSTEM 9 Cold start and warm up phases, idle speed control, acceleration and full load enrichment, deceleration fuel cutoff. Fuel control maps, open loop control of fuel injection and closed loop lambda control Integrated engine control system, Exhaust emission control engineering, Electromagnetic compatibility EMI Suppression techniques Electronic dash board instruments Onboard diagnosis system. TOTAL : 45 PERIODS TEXT BOOKS

1. Understanding Automotive Electronics William B Ribbens, SAE 1998. 2. Automobile Electronics by Eric Chowanietz SAE.

REFERENCES

1. Diesel Engine Management by Robert Bosch, SAE Publications. 2. Gasoline Engine Management by Robert Bosch, SAE Publications. 30

PTAU9353

VEHICLE BODY ENGINEERING LT P C 3 0 0 3

OBJECTIVES The main objective of this course is to impart knowledge in the construction of vehicle, aerodynamic, concept, paneling of passenger car body trim. At the end of the course the student will be well versed in the design and construction of external body of the vehicles. UNIT I CAR BODY DETAILS 10 Types of Car - Saloon, convertibles, Limousine, Estate Van, Racing and Sports car Visibility- regulations, drivers visibility, improvement in visibility and tests for visibility. Safety - safety design, safety equipments for vehicles. Car body construction. Various panels of car bodies. UNIT II VEHICLE AERODYNAMICS 9 Objectives, Vehicle drag and types. Various types of forces and moments. Effects of forces and moments. Side wind effects on forces and moments. Various body optimization techniques for minimum drag. Wind tunnels Principle of operation, Types. Various wind tunnel testing such as: Flow visualization techniques, Airflow management test and Test to measure forces and moments. UNIT III BUS BODY DETAILS 9 Types based on capacity, based on distance traveled and based on construction such as Mini bus, Single Decker, Double Decker, Two level, Split-level and Articulated bus. Bus body lay out, Types of metal sections used, Regulations. Constructional details of Conventional and Integral type construction. UNIT IV COMMERCIAL VEHICLE DETAILS 8 Different types of commercial vehicle bodies. Light commercial vehicle body types. Construction details of flat platform body, Tipper body & Tanker body Dimensions of drivers seat in relation to controls Drivers cab design. UNIT V BODY MATERIALS, TRIM AND MECHANISMS 9 Steel sheet, timber, plastics, GRP, properties of materials. Corrosion: Anticorrosion methods, Modern painting process. Body trim items Body mechanisms. TOTAL : 45 PERIODS TEXTBOOK: 1. Powloski, J., Vehicle Body Engineering, Business Books Ltd., 1998. REFERENCES: 1. Giles, G.J., Body construction and design, Illiffe Books Butterworth & Co., 1991. 2. John Fenton, Vehicle Body layout and analysis, Mechanical Engg. Publication Ltd., London, 1992. 3. Braithwaite, J.B., Vehicle Body building and drawing, Heinemann Educational Books Ltd., London, 1997. 4. Dieler Anselm., The passenger car body, SAE International, 2000.

31

MACHINE COMPONENTS DESIGN AIM:

L T P C 3 0 0 3

This course gives a complete procedure for designing different kinds of problems occurring in design engineering field especially in automobile engineering. OBJECTIVE: To familiarize the various steps involved in the Design Process To understand the principles involved in evaluating the shape and dimensions of a component to satisfy functional and strength requirements. To learn to use standard practices and standard data To learn to use catalogues and standard machine components UNIT I INTRODUCTION 12 Classification of design Engineering materials and their physical properties as applied to design Selection of materials Factors of safety in design Endurance limit of materials Determination of endurance limit for ductile materials Notch sensitivity Principle of design optimization Future trends CAD Eulers formula Rankines formula Tetmajers formula Johnson formula Design of push rods and eccentricity loaded columns Reduction of stress concentration. UNIT II DESIGN OF SHAFTS AND SPRINGS 9 Introduction Material and design stresses Design of axles Design of shafts on the basis of strength Design of shaft on the basis of rigidity Design of hollow shafts Design of close coiled helical spring subjected to axial loading Torsion of helical springs. UNIT III GEAR DESIGN 8 Design considerations strength of gear teeth Lewis equation Terminology of gearsDynamic tooth load Design of spur gears helical gears herringbone gears bevel gears and worm gears. UNIT IV FLYWHEELS 7 Determination of the mass of a flywheel for a given co-efficient of speed fluctuation. Engine flywheels stresses of rim of flywheels. Design of hubs and arms of flywheel Turning moment diagram. UNIT I DESIGN OF BEARINGS 9 Design of journal bearings - Ball and Roller bearings Types of Roller bearings Bearing life Static load capacity Dynamic load capacity Bearing material Boundary lubrication Oil flow and temperature rise. TOTAL : 45 PERIODS TEXTBOOKS: 1. Jain,R.K., Machine Design, Khanna Publishers, 1992. 2. Sundararaja Murthy,T.V., Machine Design, Khanna Publishers, New Delhi, 1991. 3. Bhandari,V.B., Design of Machine elements, Tata McGraw Hill Publishing Co. Ltd., New Delhi, 1990. REFERENCES: 1. Hall Allen,S. & Others, Machine Design, Schaum Publisher Co., 1982. 2. Sigley, Machine Design, McGraw Hill, 1981. 3. Design Data Book, PSG College of Technology, Coimbatore, 1992.

32

PTAU934 AUTOMOTIVE MATERIALS AND PRODUCTION TECHNIQUES

L T P C 3 0 0 3

UNIT I ELASTIC AND PLASTIC BEHAVIOUR OF MATERIALS 9 Elasticity-forms - Stress and strain relationship in engineering materials - Deformation mechanism -Strengthening material - Strain hardening, alloying, polyphase mixture, martensitic precipitation, dispersion, fibre and texture strengthening - iron carbon diagram. UNIT II HEAT TREATMENT AND SURFACE TREATMENT 10 Heat treatment of steel - Annealing - Types, normalising, Types, hardening and tempering with specific relevance to automotive components, surface hardening techniques, Induction, flame and chemical hardening, coating of wear and corrosion resistance, Electroplating. Phosphating, Anodizing, hot dipping, thermal spraying, hard facing and thin film coatings. UNIT III SELECTION OF MATERIALS 9 Criteria of selecting materials for automotive components viz cylinder block, Cylinder head, piston, piston ring, Gudgeon pin, connecting rod, crank shaft, crank case, cam, cam shaft, engine valve, gear wheel, clutch plate, axle, bearings, chassis, spring, body panel - radiator, brake lining etc. Application of non-metallic materials such as composite, ceramic and polymers in automobile. UNIT IV CASTING FOR AUTOMOTIVE ENGINE COMPONENTS 8 Sand casting of cylinder block and liners Centrifugal casting of flywheel, piston rings, bearing bushes, and liners, permanent mould casting of piston, pressure die casting of carburetor and other small auto parts. UNIT V MACHINING OF AUTOMOTIVE ENGINE COMPONENTS 9 Machining of connecting rods - crank shafts - cam shafts - pistons - piston pins - piston rings- valves - front and rear axle housings - fly wheel - Honing of cylinder bores - Copy turning and profile grinding machines Materials and properties. TOTAL : 45 PERIODS TEXTBOOKS: 1. Khanna.O.P., " Material Science and Metallurgy ", Dhanapal Rai & Sons, 1992. 2. Heldt,P.M., High Speed Combustion Engines, Oxford Publishing Co., New York, 1990. REFERENCES: 1. Kapoor, " Material Science and Processes ", New India Publishing House, 1987. 2. Dieter.G.E., Mechanical Metallurgy, McGraw Hill, New York, 1972. 3. Avner.S.H., Introduction to physical metallurgy, MaGraw Hill, New York., 1982. 4. Raghavan.V., Physical Metallurgy, Principle and Practice, Prentice Hall, 1995. 5. Avner S.H". Introduction to Physical Metallurgy" McGraw-Hill, New York, 1982. 6. Haslehurst,S.E., Manufacturing Technology, ELBS, London, 1990. 7. Upton, Pressure Die Casting, Pergamon Press, 1985.

33

ENGINE TESTING AND AUTOMOTIVE ELECTRONICS LAB OBJECTIVE:

L T P C 0 0 3 2

The main objective of this course is to impart practical knowledge in automotive engine testing. The detailed testing of performance characteristics of various IC engine will be taught to the students. At the end of the course the students will have command over testing of performance and emission characteristics of IC engines. To provide hands on training on basic electronic components and to provide knowledge on interfacing of different sensors and actuators used in the automobile systems. 1. Study and use of IC engine testing Dynamometers. 2. Study and use of Pressure pickups, charge amplifier, storage oscilloscope and signal analyzers used for IC engine testing. 3. Performance study of petrol engine at full throttle and part throttle conditions. 4. Performance study of diesel engine both at full load and part load conditions. 5. Morse test on petrol and diesel engines. 6. Determination of compression ratio, volumetric efficiency and optimum cooling water flow rate in IC engines. 7. Head balance test on an automotive diesel engine. STUDY OF THE FOLLOWING DEVICES FOR AUTOMOTIVE APPLICATION Logic gates, Adders, Flip flops SCR and IC Timers Interfacing seven segment displays Study of Microprocessor and Microcontrollers Interfacing Sensors like RTD, LVDT, Load Cell etc. Interfacing ADC for Data Acquistion Interfacing DAC for Control Application Interfacing Actuators EPROM Programming

34

PTAU9351 0 0 3 AIM:

VEHICLE DESIGN

L T P C 3

This course gives a complete procedure for designing different kinds of chassis components in automobile engineering. OBJECTIVES: At the end of the course the student will be able to understand the fundamental principles involved in design of components of automotive chassis, the complete design exercise and arrive at important dimensions of chassis components. UNIT I VEHICLE FRAME AND SUSPENSION 9 Study of loads - moments and stresses on frame members. Design of frame for passenger and commercial vehicle - design of leaf springs - Coil springs and torsion bar springs. UNIT II FRONT AXLE AND STEERING SYSTEMS 9 Analysis of loads - moments and stresses at different sections of front axle. Determination of bearing loads at Kingpin bearings. Wheel spindle bearings. Choice of bearings. Determination of optimum dimensions and proportions for steering linkages ensuring minimum error in steering. Design of Front Axle Beam. UNIT III CLUTCH 9 Torque capacity of single plate, multi plate and cone clutch. Design of clutch components, Design details of roller and sprag type of clutches. . UNIT IV GEAR BOX 9 Gear train calculations, layout of gear box constant mesh and synchrono mesh gear box. Design of three speeds and four speed gear boxes. UNIT V DRIVE LINE AND REAR AXLE 9 Design of propeller shaft and types of propeller shaft. Design details of final drive gearing. Design details of full floating. Semi-floating and three quarter floating rear shafts and rear axle housings. Design aspects of final drive. TOTAL : 45 PERIODS TEXT BOOKS: 1. Heldt,P.M., Automotive Chassis, Chilton Book Co., 1992. 2. Heldt,P.M., Torque Converters, Chilton Book Co., 1992. REFERENCES: 1. Dean Averns., Automobile Chassis Design, Illife Book Co., 1982. 2. Giri,N.K., Automobile Mechanics, Khanna Publishers, New Delhi, 1998. 3. The Automotive Chassis: Engineering Principles, SAE Sep., 1995.

35

PTAU9401 0 0 3 OBJECTIVE:

VEHICLE DYNAMICS

L T P C 3

When the vehicle is at dynamic condition more vibration will be produced. It is essential to study about vibrations and how to reduce the vibration under different loads, speed and road conditions in order to improve the comfort for the passengers and life of the various components of the vehicle. In this subject these aspects have been given. UNIT I INTRODUCTION 9 Fundamentals of vibration, single degree of freedom, two degree of freedom, multidegree freedom, free, forced and damped vibrations, modeling and simulation studies, model of an automobile, magnification factor, transmissibility, vibration absorber. UNIT II MULTI DEGREE FREEDOM SYSTEMS 9 Closed and far coupled system, eigen value problems, orthogonality of mode shapes, modal analysis, forced vibration by matrix inversion. UNIT III NUMERICAL METHODS 9 Approximate methods for determining fundamental frequency, Dunkerleys lower bound, Rayleighs upper bound, Holzer method for closed coupled system and branched systems. UNIT IV VEHICLE HANDLING AND STABILITY OF VEHICLES 9 Load distribution, calculation of acceleration, tractive effort and reactions for different drives, stability of a vehicle on a curved track, slope and a banked road. Oversteer, under steer, steady state cornering, effect of braking, driving torques on steering, effect of camber, transient effects in cornering. UNIT V SUSPENSION, TYRES 9 Requirements, sprung mass frequency, wheel hop, wheel wobble, wheel shimmy, choice of damper characteristics and suspension spring rate, calculation of effective spring rate, vehicle suspension in fore and aft direction, roll axis and vehicle under the action of side forces. Tyre Requirements, types, testing, dynamics, ride characteristics, power consumed by a tyre. TOTAL : 45 PERIODS TEXT BOOKS: 1. Rao J.S and Gupta. K Theory and Practice of Mechanical Vibrations, Wiley Eastern Ltd., 2002. 2. Gillespie, T.D., Fundamentals of vehicle dynamics society of Automotive Engineers, USA, 1992. REFERENCES: 1. Ham B, Pacejka - Tyre and Vehicle Dynamics - SAE Publication - 2002. 2. Ellis.J.R - Vehicle Dynamics- Business Books Ltd., London- 1991 3. Heldt,P.M., Automotive Chassis, Chilton Co., New York, 1992. 4. Giles,J.G., Steering, Suspension and Tyres, Illiffe Books Ltd., London, 1988.

36

5. W. Steeds: Mechanics of road vehicles, illiffe books ltd, London, 1960 6. Giri N.K Automotive Mechanics, Khanna Publishers, 2007.

37

PTAU9404

VEHICLE MAINTENANCE AND RECONDITIONING LABORATORY L T P C 0 0 3 2 1. Study and layout of an automobile repair, service and maintenance shop. 2. Study and preparation of different statements/records required for the repair and maintenance works. 3. Cylinder reboring checking the cylinder bore, Setting the tool and reboring. 4. Valve grinding, valve lapping - Setting the valve angle, grinding and lapping and checking for valve leakage 5. Calibration of fuel injection pump 6. Minor and major tune up of gasoline and diesel engines 7. Study and checking of wheel alignment - testing of camber, caster. 8. Testing kingpin inclination, toe-in and toe-out. 9. Brake adjustment and Brake bleeding. 10. Simple tinkering, soldering works of body panels, study of door lock and window glass rising mechanisms. 11. Battery testing and maintenance. 12. Practice the following: i) Adjustment of pedal play in clutch, brake, hand brake lever and steering wheel play ii)Air bleeding from hydraulic brakes, air bleeding of diesel fuel system iii) Wheel bearings tightening and adjustment iv) Adjustment of head lights beam v) Removal and fitting of tyre and tube TOTAL : 45 PERIODS

38

PTAU9402

VEHICLE MAINTENANCE

L T P C 3 0 0 3

OBJECTIVE: At the end of the course, the students will be able to have a complete knowledge of the vehicle maintenance procedures and acquire skills in handling situations where the vehicle is likely to fail. UNIT I MAINTENANCE RECORDS AND SCHEDULE 9 Importance of maintenance. Scheduled and unscheduled maintenance. Preparation of check lists. Chassis lubrication. Cost effectiveness. Pre-trip, Post-trip. Inspection forms. Log books. Trip sheets. Other maintenance record forms. UNIT II MAINTENANCE, REPAIR AND OVERHAULING OF ENGINE 9 Dismantling of engine components. Cleaning methods. Visual inspection and dimensional check of various engine components. Minor and Major tune up Reconditioning, repairing methods of engine components. Assembly procedure. Special tools used for maintenance, repair and overhauling. UNIT III MAINTENANCE, REPAIR AND OVERHAULING OF CHASSIS DRIVE LINE COMPONENTS 9 Clutch Mechanical, Automatic types. Gear box Mechanical, Automatic types. Final reduction. Propeller shaft. Front and rear suspension system. Rigid and independent types. Brakes systems Hydraulic, Servo, Air. Air bleeding. Steering system. Wheel alignment. Types. UNIT IV MAINTENANCE, REPAIR AND SERVICING OF ELECTRICAL SYSTEMS 9 Battery Testing methods. Starter motor. Charging system DC Generator, AC Alternator, Regulator. Ignition systems Coil ignition, Transistor assisted ignition, Capacitor discharge ignition. Electric Horn, Wiper, Flasher, Electric fuel pump, Gauges. Lighting system. Head lights focusing. Wiring system. UNIT V MAINTENANCE, REPAIR AND SERVICING OF COOLING LUBRICATION SYSTEM, FUEL SYSTEM AND BODY 9 Cooling system types, water pump, radiator, thermostat valve, anti corrosion and anti freezing solutions. Lubricating system Oil analysis, oil topping up, oil change, oil filters, oil relief valve. Fuel system Petrol, diesel fuel feed system components. Body repair tools, minor body panel beating, tinkering, soldering, polishing, painting. Door locks mechanism. Window glass actuating mechanism. TOTAL : 45 PERIODS TEXTBOOKS: 1. Judge, A.N., Motor vehicle engine servicing, 3rd Edition, Pitman Paper pack, London, 69. 2. Venk. Spicer, Automotive Maintenance and Trouble shooting. REFERENCES: 1. John Doke, Fleet management, McGraw Hill Co., 1984. 2. Judge,A.W., Maintenance of High speed diesel engines, Chapman Hall Ltd., London, 56. 3. Maleev,V.L., Diesel Engine operation and Maintenance, McGraw Hill Book Co., New York, 1954. 4. John.W.Vale.J.R., Modern Auto Body and Fender repair.

39

5. Vehicle Service Manuals of reputed manufacturers. PTAU9305 AUTOMOTIVE POLLUTION AND CONTROL

L T P C 3 0 0 3

OBJECTIVE: The main objective of this course is to impart knowledge in automotive pollution control. The detailed concept of formation and control techniques of pollutants like UBHC, CO, NOx, particulate matter and smoke for both SI and CI engine will be taught to the students. The instruments for measurement of pollutants and emission standards will also be introduced to the students. At the end of the course the students will have command over automotive pollution and control. UNIT I INTRODUCTION 6 Pollutants sources formation effects transient operational effects on pollution Standards for Emission of pollutants. UNIT II S.I. ENGINE COMBUSTION AND EMISSIONS 11 Chemistry of SI engine combustion HC and CO formation in 4-stroke and 2-stroke SI engines NO formation in SI engines Particulate emissions from SI engines Effect of operating variables on emission formation. UNIT III CI ENGINE COMBUSTION AND EMISSIONS 10 Basics of diesel combustion Smoke emission in diesel engines NO emission from diesel engines Particulate emission in diesel engines. Color and Aldehyde emissions from diesel engines effect of operating variables on emission formation. UNIT IV CONTROL TECHNIQUES FOR REDUCTION OF SI AND CI ENGINE EMISSION 9 Design changes Optimization of operating factors Exhaust gas recirculation Fumigation Air injector PCV system Exhaust treatment in SI engines Thermal reactors Catalytic converters Catalysts Use of unleaded petrol. UNIT V TEST PROCEDURE & INSTRUMENTATION FOR EMISSION MEASUREMENT AND EMISSION STANDARDS 9 Test procedures NDIR analyzer Flame ionization detectors Chemiluminescent analyser Gas chromatograph Smoke meters Emission standards. TOTAL : 45 PERIODS TEXT BOOK 1. Springer and Patterson, Engine Emission, Plenum Press, 1990. REFERENCES 1. Ramalingam. K.K., Internal Combustion Engines, Scitech Publications, Chennai, 2003. 2. Ganesan,V., Internal Combustion Engines, Tata McGraw Hill Co., 1994. 3. SAE Transactions, Vehicle emission, 1982 (3 volumes). 4. Obert,E.F., Internal Combustion Engines, 1982. 5. Taylor,C.F., Internal Combustion Engines, MIT Press, 1972. 6. Heywood,J.B., Internal Combustion Engine Fundamentals, McGraw Hill Book Co., 1995.

40

7. Automobiles and Pollution SAE Transaction, 1995.

41

PTAU9451

PROJECT WORK

L T P C 0 0 6 0

The objective of project work is to enable the students, to work in convenient groups of not more than four members in a group, on a project involving some design and fabrication work or theoretical and experimental studies related to the respective engineering discipline. Every project work shall have a Guide who is a member of the faculty of the University. Twelve periods per week shall be allotted in the Time table for this important activity and this time shall be utilized by the students to receive directions from the Guide, on library reading, laboratory work, computer analysis, or field work as assigned by the Guide and also to present in periodical seminars or viva to review the progress made in the project. Each student shall finally produce a comprehensive report covering background information, literature survey, problem statement, project work details, estimation of cost and conclusions. This final report shall be in typewritten form as specified in the guidelines. The continuous assessment and semester evaluation may be carried out as specified in the guidelines to be issued from time to time.

42

PTAE9354

FINITE ELEMENT METHODS

L T P C 3 0 0 3 8

UNIT I

INTRODUCTION

Review of various approximate methods Raleigh Ritzs, Galerkin and finite difference methods- Governing equation and convergence criteria of finite element method. UNIT II DISCRETE ELEMENTS 10

Bar elements, uniform section, mechanical and thermal loading, varying section, truss analysis. Beam element - problems for various loadings and boundary conditions longitudinal and lateral vibration. Use of local and natural coordinates. UNIT III CONTINUUM ELEMENTS 8 Plane stress, Plane strain and axisymmetric problems, constant and linear strain, triangular elements, stiffness matrix, axisymmetric load vector, UNIT IV ISOPARAMETRIC ELEMENTS 10 Definitions, Shape function for 4, 8 and 9 nodal quadrilateral elements, Stiffness matrix and consistent load vector, Gaussian integration. UNIT V FIELD PROBLEM 9 Heat transfer problems, Steady state fin problems, Derivation of element matrices for two dimensional problems, Torsion problems. TOTAL: 45 PERIODS TEXT BOOK:

1. Tirupathi.R. Chandrapatha and Ashok D. Belegundu - Introduction to Finite Elements

in Engineering - Printice Hall India, Third Edition, 2003. 2. Rao.S.S., Finite Element Methods in Engineering, Butterworth and Heinemann, 2001 REFERENCES: 1. Reddy J.N. An Introduction to Finite Element Method McGraw Hill 2000. 2. Krishnamurthy, C.S., Finite Element Analysis, Tata McGraw Hill, 2000. 3. Bathe, K.J. and Wilson, E.L., Numerical Methods in Finite Elements Analysis, Prentice Hall of India, 1985. 4. Robert D Cook, David S Malkus, Michael E Plesha, Concepts and Applications of Finite Element Analysis, 4th edition, John Wiley and Sons, Inc., 2003. 5. Larry J Segerlind, Applied Finite Element Analysis, Second Edition, John Wiley and Sons, Inc. 1984.

43

PTAU9021

AUTOMOTIVE AERODYNAMICS

L T P C 3 0 0 3

OBJECTIVE: The main objective of the course is to introduce the importance of vehicle aerodynamics in the design of vehicle bodies. After the complete understanding of the optimization techniques, the students can have the ability to design aerodynamically stable vehicles. UNIT I INTRODUCTION 10 Scope historical development trends Fundamentals of fluid mechanics Flow phenomenon related to vehicles External & Internal flow problems Resistance to vehicle motion Performance Fuel consumption and performance Potential of vehicle aerodynamics. UNIT II AERODYNAMIC DRAG OF CABS 8 Car as a bluff body Flow field around car drag force types of drag force analysis of aerodynamic drag drag coefficient of cars strategies for aerodynamic development low drag profiles. UNIT III SHAPE OPTIMIZATION OF CABS 7 Front and modification front and rear wind shield angle Boat tailing Hatch back, fast back and square back Dust flow patterns at the rear Effect of gap configuration effect of fasteners. UNIT IV VEHICLE HANDLING 10 The origin of force and moments on a vehicle side wind problems methods to calculate forces and moments vehicle dynamics Under side winds the effects of forces and moments Characteristics of forces and moments Dirt accumulation on the vehicle wind noise drag reduction in commercial vehicles. UNIT V WIND TUNNELS FOR AUTOMOTIVE AERODYNAMICS 10 Introduction Principles of wind tunnel technology Limitation of simulation Stress with scale models full scale wind tunnels measurement techniques Equipment and transducers road testing methods Numerical methods. TOTAL : 45 PERIODS TEXTBOOK: 1. Hucho, W.H., Aerodynamics of Road vehicles, Butterworths Co. Ltd., 1997. REFERENCES: 1. Pope, A, Wind Tunnel Testing, John Wiley & Sons, 2nd Edn., New York, 1994. 2. Automotive Aerodynamics: Update SP-706, SAE, 1987. 3. Vehicle Aerodynamics, SP-1145, SAE, 1996.

44

PTAU9026

AUTOMOTIVE SAFETY

L T P C 3 0 0 3

OBJECTIVE: At the end, the student will have good exposure to Automotive safety aspects including safety equipments. UNIT I INTRODUCTION 9

Design of the body for safety, engine location, deceleration of vehicle inside passenger compartment, deceleration on impact with stationary and movable obstacle, concept of crumble zone, safety sandwich construction. UNIT II SAFETY CONCEPTS 9

Active safety: driving safety, conditional safety, perceptibility safety, operating safetypassive safety: exterior safety, interior safety, deformation behaviour of vehicle body, speed and acceleration characteristics of passenger compartment on impact. UNIT III SAFETY EQUIPMENTS 9

Seat belt, regulations, automatic seat belt tightener system, collapsible steering column, tiltable steering wheel, air bags, electronic system for activating air bags, bumper design for safety, antiskid braking system, regenrative braking system, speed control devices. UNIT IV COLLISION WARNING AND AVOIDANCE 9

Collision warning system, causes of rear end collision, frontal object detection, rear vehicle object detection system, object detection system with braking system interactions, driver fitness detection. UNIT V COMFORT AND CONVENIENCE SYSTEM 9