Baws001 Ex GBR 2

Baws001 Ex GBR 2

Uploaded by

liyuping200809Copyright:

Available Formats

Baws001 Ex GBR 2

Baws001 Ex GBR 2

Uploaded by

liyuping200809Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Baws001 Ex GBR 2

Baws001 Ex GBR 2

Uploaded by

liyuping200809Copyright:

Available Formats

BAWS 001-EX-GBR-2

03/2004

Installation and Operation Manual TSCHAN®

Flexible Coupling

TSCHAN®-S S-St, S-LSt

for use in potentially explosive atmospheres

Design according to Directive 94/9/EC

TSCHAN GmbH Zweibrücker Straße 104 D-66538 Neunkirchen-Saar

Telefon: +49(0) 6821 866 0 Telefax: +49(0) 6821 883 53 www.tschan.de

Table of Contents

Chapter Page

1 Safety Instructions ............................................................................................................ 2

2 Technical Description ....................................................................................................... 3

2.1 Intended Application .................................................................................................. 3

3 Coupling Marking.............................................................................................................. 4

3.1 Marking of Buffer Rings ............................................................................................. 4

3.2 Marking of Coupling................................................................................................... 4

4 Storage ............................................................................................................................. 5

5 Construction ..................................................................................................................... 5

6 Technical Data.................................................................................................................. 6

7 Installation ........................................................................................................................ 8

7.1 To be observed prior to installation............................................................................ 8

7.2 Finish Bores...............................................................................................................8

7.3 Coupling Installation .................................................................................................. 9

8 Coupling Alignment ........................................................................................................ 11

8.1 Angular Misalignment .............................................................................................. 12

8.2 Radial Misalignment ................................................................................................ 12

8.3 Axial Misalignment................................................................................................... 13

9 Operation........................................................................................................................ 14

10 Maintenance .................................................................................................................. 17

10.1 Inspection and Maintenance Intervals ..................................................................... 17

10.2 Wear Inspection while the equipment is at standstill ............................................... 18

10.3 Replacement of the buffer ring ................................................................................ 19

11 Disposal ......................................................................................................................... 19

12 Manufacturer’s Declaration ............................................................................................ 20

13 Declaration of Conformity............................................................................................... 21

1 Safety Instructions

This installation and operation manual is an essential component of the coupling

delivery. Always keep this manual in a readily accessible place near the coupling.

Take care that all persons being charged with the installation, operation, maintenance and

repair of the coupling have read and understood this manual and that all instructions con-

tained therein are carefully observed in order to:

- avoid danger to life and limb of the user or third persons,

- ensure the operational safety of the coupling,

- preclude operation failures and environmental damages due to wrong handling and

misuse.

The relevant instructions and regulations regarding safety at work and environmental protec-

tion have to be observed while transporting, mounting and dismounting the coupling.

The handling and use of aluminium parts in potentially explosive areas requires special

measures in order to avoid spark formation. Make sure that appropriate transportation means

and tools are at disposal.

03/2004 TSCHAN®-S S-St / S-LSt -2-

The coupling shall be operated, mounted, maintained and repaired by authorized, trained and

instructed personnel only.

In the interest of further development, we reserve the right to carry out modifications serving

the technical progress.

It is of utmost importance to strictly observe the installation instructions for devices and

machines intended for use in potentially explosive atmospheres.

We do not assume any liability or warranty for any damages resulting from the use of

accessories and parts that are not originally manufactured by TSCHAN GmbH.

2 Technical Description

The TSCHAN®-S S-St / S-LSt coupling is a torsionally flexible, puncture proof claw coupling.

It compensates for angular, radial and axial shaft misalignments within defined limits. The

coupling transmits torque through elastic buffers loaded in shear. These buffers come in

Perbunan (Pb) or polyurethane (Vk), as standard in Vulkollan red (VkR), and are connected

to each other to form a buffer ring.

This elastic buffer ring dampens shocks and torsional vibrations and is resistant to oil.

Buffer rings made of Perbunan are electrically conductive.

The coupling is suitable for use in every direction of rotation and installation position.

2.1 Intended Application

• The coupling is suitable for use in potentially explosive atmospheres according to Direc-

tive 94/9/EC. The coupling is classified for equipment groups I and II and equipment cate-

gories 2 and 3, and is thus intended to be used in areas in which explosive atmospheres

due to the presence of gases, vapours and dust/ air mixtures may occur. In dependence

on the maximum permissible ambient temperatures in the vicinity of the coupling, the

temperature classes are defined with 80°C, 45°C, 30°C for T4, T5 and T6. This is valid on

the condition, that the operation temperature of the machinery shafts also does not ex-

ceed these values.

• In order to ensure trouble-free and reliable operation, the coupling has to be sized

according to the design specifications, e.g. according to DIN 740, part 2, (or acc. to cata-

logue TSCHAN® -S), with a service factor appropriate for the service conditions.

• Except for the production of a finish bore with keyway (see 7.2 ‘Finish Bores’), no further

modifications are allowed to be carried out on the coupling.

• The coupling shall only be used and operated within the frame of the conditions as

defined in the performance or delivery contract.

• Any change in the operation conditions or service parameters requires the verification of

the coupling design.

03/2004 TSCHAN®-S S-St / S-LSt -3-

3 Coupling Marking

3.1 Marking of Buffer Rings

The buffer rings are marked on the face of one buffer element as follows:

- Coupling size and material abbreviation (Vk for Polyurethane or Pb for Perbunan)

- Year of construction

- Pb72 = buffer ring of Perbunan, 72 Shore(A) / black

- Pb82 = buffer ring of Perbunan, 82 Shore(A) / black

- VkB = buffer ring of Polyurethane, 83 Shore(A) / blue

- VkR = buffer ring of Polyurethane, 93 Shore(A) / red

- Vk60D = buffer ring of Polyurethane, 60 Shore(D) white/beige

Size DA h z

[mm] [mm]

50 48 12 4

70 70 18 6

85 82 18 6

100 100 20 6

125 121 25 6

145 139 30 6

170 166 30 8

200 194 35 8

230 222 35 10

260 253 45 10

300 294 50 10

360 350 55 12

400 393 55 14

3.2 Marking of Coupling

TSCHAN® -S couplings which are approved for use in explosive atmospheres are identified

in the factory by a sticker:

X TSCHAN-S coupling type, size, material of buffer ring,

cal. week/ year of construction, Order Ref. / Item No.

The letter X in this marking stands for:

TSCHAN GmbH / D-66538 Neunkirchen

II 2 G T4/T5/T6 –20°C ≤ Ta ≤ +80°C/+45°C/+30°C

II 2 D T130°C

IM2

The sticker is covered by a protective film which has to be removed after an eventual paint-

ing, so as to make the marking visible.

03/2004 TSCHAN®-S S-St / S-LSt -4-

4 Storage

On receipt of the goods, immediately check that all parts are on hand and are as ordered.

Eventual shipping damages and/or missing parts have to be reported in writing.

The coupling parts can be stored in the delivered state in a dry place under roof at normal

ambient temperatures for a time period of 6 months. Storage for a longer period requires the

application of a long-term preservation. (Please consult TSCHAN GmbH in this respect.)

The buffer rings must not be exposed to ozonic media, direct sun light or intensive light

sources with UV light. The air humidity should not exceed 65 %. If the parts are properly

stored, the quality characteristics of the elastic buffer rings remains almost unchanged for up

to three years.

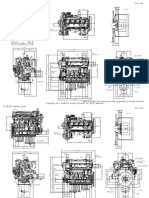

5 Construction

1 Coupling hub S-St, part 200

1L Long hub S-LSt, part 210

2 Elastic buffer ring, part 020

Fig. 1 Construction - TSCHAN-S S-St, S-LSt

03/2004 TSCHAN®-S S-St / S-LSt -5-

6 Technical Data

Fig. 2 TSCHAN-S S-St / S-LSt

Table 1 Technical Data:

Size nmax TKnom TKmax TKnom TKmax TKnom TKmax TKnom TKmax TKnom TKmax

S-St Pb72 Pb72 Pb82 Pb82 VkR VkR Vk60D Vk60D VkB VkB

S-LSt [rpm] [Nm] [Nm] [Nm] [Nm] [Nm] [Nm] [Nm] [Nm] [Nm] [Nm]

50 15000 4 12 7,3 22 15 40 - - - -

70 11000 16 48 29 87 55 160 - - 32 96

85 9000 24 72 40 120 75 225 110 330 44 132

100 7250 40 120 70 210 130 390 195 585 76 228

125 6000 70 210 128 385 250 750 370 1110 140 420

145 5250 120 360 220 660 400 1200 600 1800 240 720

170 4500 180 540 340 1020 630 1900 950 2850 370 1110

200 3750 330 990 590 1770 1100 3300 1650 4950 640 1920

230 3250 500 1500 900 2700 1700 5150 2580 7740 980 2940

260 3000 800 2400 1400 4200 2650 7950 3980 11940 1530 4590

300 2500 1180 3540 2090 6270 3900 11700 5850 17550 2280 6840

360 2150 1940 5820 3450 10350 6500 19500 9700 29100 3760 11280

400 1900 2670 8010 4750 14250 8900 26700 13350 40050 5180 15540

- Pb72 = buffer ring of Perbunan - 72 Shore(A) / black

- Pb82 = buffer ring of Perbunan - 82 Shore(A) / black

- VkR = buffer ring of Polyurethane / red

- Vk60D = buffer ring of Polyurethane / white-beige

- VkB = buffer ring of Polyurethane / blue

03/2004 TSCHAN®-S S-St / S-LSt -6-

Size d1 D1 D2 L l1 l2 S h m

S-St max unbored

S-LSt [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg]

50 41 75 30,0 23,5 0,8

25 50 1,5 12

50 L 42 96 40,5 34,0 1,0

70 38 70 55 100 38,5 31,5 2,5 18 1,8

85 110 43,5 35,0 2,6

40 85 60 2,5 18

85 L 184 80,5 72,0 4,3

100 125 49,5 37,5 4,2

42 105 65 3 20

100 L 187 80,5 68,5 5,8

125 145 56,5 44,0 7,5

55 126 85 3,5 25

125 L 253 110,5 98,0 12,3

145 160 61,0 47,5 10,6

65 145 95 4,0 30

145 L 259 110,5 97,0 16,1

170 190 75,0 60,5 18,0

85 170 120 5,0 30

170 L 321 140,5 126,0 29,6

200 245 99,0 79,5 31,0

95 200 135 6,0 35

200 L 328 140,0 124,0 39,6

230 270 110,0 88,5 43,5

105 230 150 7,0 35

230 L 390 170,0 151,0 59,0

260 285 112,5 88,5 63,0

125 260 180 7,0 45

260 L 400 170,0 146,0 85,3

300 140 300 200 330 131,5 107,5 7,0 50 91,5

360 150 360 210 417 172,0 140,0 8,0 55 146,2

400 400 163,5 137,0 160,4

160 400 225 7,5 55

400 L 440 183,5 157,0 173,0

The torques TKnom and TKmax. are valid for:

- Ambient temperatures of –30°C up to +30°C for Polyurethane (Vk),

- Ambient temperatures of -30°C up to + 60°C for Perbunan (Pb)

- Operation within the range of the specified alignment values.

For determining the size of the coupling according to DIN 740, part 2, (or to catalogue

TSCHAN®-S) various factors have to be taken into account:

- the temperature factor Sυ in case of higher temperatures,

- the start-up factor Sz depending on the frequency of starts,

- the shock factor SA, SL depending on the service conditions.

For circumferential speeds above 22 m/s, referred to the nominal size of the coupling, we

recommend balancing the steel parts of the coupling.

03/2004 TSCHAN®-S S-St / S-LSt -7-

7 Installation

7.1 To be observed prior to installation

• Danger of injuries!

• Disconnect the drive before carrying out any work on the coupling!

• Secure the drive against unintentional re-start and rotation!

• Incorrectly tightened bolts can cause serious personal injuries and

property damages!

• Make sure that the speeds, torques and ambient temperatures as stated in chapter 6

‘Technical Data’ are not exceeded.

• The maximum permissible bore diameters must not be exceeded.

• Check whether the shaft-hub connections safely transmit the occurring operating torques.

• The standard tolerance of TSCHAN for finish bores is fit H7.

• Standard keyways comply with DIN 6885, sheet 1.

• Check the dimensions and tolerances of shafts, hub bores, keys and keyways.

• Set screws as required.

• In compliance with accident prevention regulations, you are

obliged to protect all freely rotating parts by means of permanently

installed guards/covers against unintentional contact and falling

down objects.

• To avoid sparks, the covers for couplings used in explosive

atmospheres should be made of stainless steel!

• As a minimum, the covers have to fulfil the requirements of protec-

tion type IP2X.

• The covers have to be designed to prevent dust from depositing on

the coupling.

7.2 Finish Bores

The following procedure has to be followed to produce a finish bore in a coupling hub:

• Clean and remove all preservatives from the coupling hubs.

• Mount the coupling hub in between the surfaces marked with é and carefully align the hub

to the outer diameter of the claw pattern.

• The values for ød1max listed in table 1 are valid for keyed connections according to DIN

6885/1 and must not be exceeded.

• Select the bore fit so that an interference fit such as H7/m6 results when mating it with the

shaft tolerance.

• Axially lock the hub by means of a setscrew on the back of the hub above the keyway.

Consult TSCHAN GmbH in case of other shaft-hub connections.

03/2004 TSCHAN®-S S-St / S-LSt -8-

• The stated maximum bore diameters are valid for keyed connec-

tions according to DIN 6885/1 and must not be exceeded.

• If these values are exceeded, the coupling can break.

• Flying off coupling fragments are a danger to life!

7.3 Coupling Installation

• Remove the elastic buffer ring (Fig. 3,

pos. 1).

• Prior to installation, carefully clean the

bores of the coupling hubs and the shaft

ends. The surfaces must be clean, dry

and free of grease.

• For larger couplings use suitable

mounting tools and hoisting devices

such as cranes or pulley blocks.

• Mount the coupling hubs in the proper

position on the shaft ends (Fig. 3, pos.2)

Fig. 3

Note:

To facilitate mounting, the hub can be uniformly heated to 80°C to 120°C. Take care not to

damage the identification sticker (see chapter 3 ‘Coupling Marking’)!

03/2004 TSCHAN®-S S-St / S-LSt -9-

§ Attention!

§ Pay attention to the risks of ignition existing in potentially explo-

sive atmospheres!

§ Warning!

§ Always wear heat-resistant gloves to protect yourself against

injuries due to hot coupling components!

• Mount the hubs in such a manner

that the shaft end is flush with the

inner bore openings (Fig. 4).

Observe deviant agreements, which

may exist!

• When tightening setscrews, secure

them with an adhesive, such as e.g.

Loctite 222, to prevent the screws

from working loose and dropping

out.

Fig. 4

ATTENTION!

Let the hot hubs cool down to ambient temperature, before inserting the buffer ring.

• To facilitate mounting, the buffer

ring can be coated with a lubricant

(for ex. talcum for Perbunan Pb, or

commercial roller bearing grease for

polyurethane Vk).

• Install the buffer on one of the

coupling halves.

• Push the shaft ends with the

mounted coupling halves together.

(Fig. 5).

• Align the coupling in accordance

with the instructions given in chapter

8 ‘Coupling Alignment’.

Fig. 5

03/2004 TSCHAN®-S S-St / S-LSt - 10 -

8 Coupling Alignment

§ Danger of Injuries!

§ Disconnect the drive before carrying out any work on the

coupling.

§ Secure the drive against unintentional re-start and rotation!

§ Note:

§ Accurate alignment of the coupling prolongs the lifetime of the

elastic buffer ring and reduces the risks when operating the cou-

pling in explosive atmospheres.

§ It is of utmost importance to observe the recommended alignment

values. Exceeding the permissible misalignment values results in

coupling damages and failures!

§ When aligning the cold equipment take into account the expected thermal growth of the

components, so that the permissible misalignment values for the coupling are not

exceeded in operation.

§ Be aware that the coupling under misalignment imposes restoring forces on the adjacent

shafts and bearings. Take into account that the larger the misalignment, the greater the

restoring forces will be.

§ The maximum permissible misalignments stated in tables 2 to 4 are guiding values. We

recommend utilizing these values up to 50 % only when aligning the coupling, so as to

have sufficient reserves for thermal growth, foundation settlings etc. during service.

In special applications with high demands on quiet running characteristics or higher

speeds, alignment accuracies of ≤ 0,1 mm may be necessary for the three alignment

levels.

§ If the coupling is mounted in a closed housing/ guard, so that alignment at a later point of

time will no longer be possible, make sure that the geometry and the fitting accuracy of

the contact surfaces ensure true alignment of the shafts within the specified tolerances

during service.

03/2004 TSCHAN®-S S-St / S-LSt - 11 -

8.1 Angular Misalignment

• Measure one complete revolution

(360°) on the face of the outer di-

ameter. Determine the largest devia-

tion Kw1 and the smallest deviation

Kw2 (Fig. 6). Calculate the angular

misalignment:

∆Kw = Kw1 – Kw2.

• When aligning, observe the max.

permissible angular misalignment

∆Kwmax acc. to table 2.

• The values are applicable for a

reference speed of 1500 rpm.

Fig. 6

Table 2 Maximum permissible angular misalignment values:

Size 50 70 85 100 125 145 170 200 230 260 300 360 400

∆Kwmax [mm] 0,15 0,2 0,2 0,2 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3

8.2 Radial Misalignment

• Measure one complete revolution

(360°). Determine the largest devia-

tion Kr1 and the smallest deviation

Kr2 (Fig. 7).

Calculate the radial misalignment:

∆Kr = 0,5 x (Kr1 – Kr2). Observe

the preceding sign of the measured

values.

• When aligning, observe 50 % of the

maximum permissible radial mis-

alignment ∆Kr max acc. to table 3.

• The values are applicable for a

reference speed of 1500 rpm.

Fig. 7

Table 3 Maximum permissible

radial misalignment values:

Size 50 70 85 100 125 145 170 200 230 260 300 360 400

∆Krmax [mm] 0,2 0,25 0,3 0,3 0,35 0,35 0,35 0,4 0,4 0,45 0,45 0,5 0,5

03/2004 TSCHAN®-S S-St / S-LSt - 12 -

8.3 Axial Misalignment

• Measure the axial claw overlap ‘h’

as shown in Fig. 8.

• The dimension of h must be in bet-

ween the values hmin and hmax stated

in table 4.

ATTENTION!

Consult TSCHAN GmbH if larger

axial misalignments are expected

during operation.

Fig. 8

Table 4 Recommended axial alignment values:

Size 50 70 85 100 125 145 170 200 230 260 300 360 400

hmax [mm] 12 18 18 20 25 30 30 35 35 45 50 55 55

hmin [mm] 11 16,5 16 18 22,5 27,5 27 32 31,5 41 46 51 51

03/2004 TSCHAN®-S S-St / S-LSt - 13 -

9 Operation

When operating the coupling, its specific technical data have to be carefully observed (see

chapter 6 ‘Technical Data’). These values must never be exceeded without the prior written

approval by TSCHAN GmbH.

In order to ensure trouble-free and reliable performance of the coupling, the coupling has to

be designed according to the selection specifications, e.g. according to DIN 740, part 2, (or

acc. to catalogue TSCHAN®-S), with a service factor appropriate to the service conditions.

Any change in the service conditions or service parameters always necessitates the verifica-

tion of the coupling design.

§ Danger of injuries!

§ Disconnect the drive before carrying out any work on the coupling!

§ Secure the drive against unintentional re-start and rotation!

§ Improperly tightened screws may cause parts to fly off what leads

to most serious personal injuries and property damages!

§ Before putting the coupling into operation, check the alignment and

all screwed connections for correct tightening torque and firm fit!

§ Before starting up the equipment, install all protective guards in

order to avoid unintentional contact with freely moving or rotating

parts.

§ To avoid sparks, the covers for couplings used in explosive atmos-

pheres should be made of stainless steel!

§ The covers have to comply with protection type IP2X as a mini-

mum.

§ The cover shall be designed to prevent dust from depositing on

the coupling parts.

While operating the coupling, pay attention to:

§ Changes in operation noises

§ Occurring vibrations

Attention!

• Disconnect the drive immediately, if any irregularities are observed while operating

the coupling!

• Identify the cause for the problem using table 5 “Operation Faults and Possible Causes“

and correct the fault.

The listed problems are some examples to assist you in troubleshooting.

• All the machinery components and operation modes have to be considered for the

determination and correction of faults.

03/2004 TSCHAN®-S S-St / S-LSt - 14 -

Table 5 Operation Faults and Possible Causes:

Trouble Cause Risk Warning Correction

Irregular Alignment fault Risk of ignition - Disconnect drive

running due to hot surfaces - Remove cause for alignment fault

noises/ and spark forma- - Re-align coupling

vibrations tion - Inspect elastomer for wear

Elastomer Risk of ignition due - Disconnect drive

worn out to spark formation - Check coupling components for

damages and replace parts, if nec-

essary

- Replace elastomer

Unbalance Risk of ignition due - Disconnect drive

to hot surfaces - Verify balance state of plant

components and correct it, if nec-

essary

- Inspect elastomer for wear

Loose screw Risk of ignition due - Disconnect drive

connections to hot surfaces and - Check coupling parts for damages,

spark formation replace parts, if necessary

- Verify alignment of coupling

- Tighten screws to the specified

tightening torque and secure them

against working loose, if necessary,

- Inspect elastomer for wear

Premature Alignment fault Risk of ignition due - Disconnect drive

wear of to hot surfaces and - Remove cause for alignment fault

elastomer spark formation - Re-align coupling

- Inspect elastomer for wear

Unacceptable Risk of ignition due - Disconnect drive

temperatures to hot surfaces and - Replace elastomer

spark formation - Re-align coupling

- Adjust ambient temperature

Contact with Risk of ignition due - Disconnect drive

aggressive to spark formation - Check coupling parts for damages

products and replace parts, if necessary

- Replace elastomer

- Verify alignment of coupling

- Prevent contact with aggressive

products

Torsional Risk of ignition due - Disconnect drive

vibrations in the to hot surfaces and - Analyse and eliminate cause for

drive line spark formation torsional vibrations

- Check coupling parts for damages

and replace parts, if necessary

- Replace elastomer and consult

TSCHAN GmbH concerning even-

tual use of another Shore-hardness

- Verify coupling alignment

03/2004 TSCHAN®-S S-St / S-LSt - 15 -

Trouble Cause Risk Warning Correction

Claw Elstomer worn Risk of ignition due - Disconnect drive

breakage out ===> to hot surfaces and - Replace coupling

contact with spark formation - Inspect the elastomer for wear at

claws shorter intervals

Overload due Risk of ignition due - Disconnect drive

to too high to hot surfaces and - Verify coupling design in coopera-

torque spark formation tion with TSCHAN GmbH

- Replace coupling

- Install larger coupling, if necessary

03/2004 TSCHAN®-S S-St / S-LSt - 16 -

10 Maintenance

The flexible couplings TSCHAN® -S S-St/ S-LSt only require little maintenance during

operation. The elastic buffer ring is subject to wear. The time at which the wear limit of the

elastic buffer ring is reached depends on the service parameters and application conditions.

On the occasion of routine inspections or maintenance of the equipment, check:

• alignment of coupling,

• state of elastomer, and

• remove dust deposits from coupling parts and buffer ring.

10.1 Inspection and Maintenance Intervals

§ Danger of injuries!

§ Disconnect the drive before carrying out any work on the

coupling!

§ Secure the drive against unintentional re-start and rotation!

Perform wear checks, inspections and maintenance operations according to

the intervals stated in table 6. If excessive wear is already detected on the

occasion of the first inspection, check whether the cause for the problem is

listed in table 5 “Operation faults and possible causes”. In such a case the

inspection intervals must be adapted to the prevailing service conditions.

Special operation conditions may necessitate to perform inspections and

maintenance operations at shorter intervals than stated.

Table 6 Inspection and maintenance intervals

Industry II 2 G / II 2 D

1st inspection after 2 weeks visual inspection and wear check of elastomer

1st mainte- after 3 months visual inspection and wear check of elastomer

nance

2nd mainte- after 6 months visual inspection and wear check of elastomer

nance removal of dust deposits from coupling components

each further every 6 months visual inspection and wear check of elastomer

maintenance removal of dust deposits from coupling components

Mines I M 2

1st inspection after 2 weeks visual inspection and wear check of elastomer

1st mainte- after 3 months visual inspection and wear check of elastomer

nance

2nd mainte- after 3 months visual inspection and wear check of elastomer

nance removal of dust deposits from coupling components

each further every 3 months visual inspection and wear check of elastomer

maintenance removal of dust deposits from coupling components

03/2004 TSCHAN®-S S-St / S-LSt - 17 -

On the occasion of maintenance operations on the drive equipment, however, after 3 years at

latest:

• Replace the elastic buffer ring.

• If the wear limit has been reached or exceeded, replace the buffer ring immediately,

irrespective of the inspection intervals of the equipment.

• Check coupling alignment.

• Remove dust deposits from coupling components and buffer ring.

10.2 Wear Inspection while the equipment is at standstill

• To inspect the wear of the elas-

tomer, the plant has to be shut

down and must be unloaded. Turn

the coupling halves in such a man-

ner that the claws rest without

clearance at the buffers of the elas-

tic ring.

• Measure the claw distance ‘V’ in

circumferential direction across the

buffers to which the claws rest on

both sides. The adjacent buffers do

not contact the claws.

• Repeat this measurement on the

adjacent buffers after having turned

the couplings halves against each

Bild / Fig. 9

other in opposed direction.

• If the dimension ‘V’ attains or

exceeds the value „Vmin“ listed in table 7 for the individual coupling sizes, the elastic buffer

ring has to be replaced immediately.

Table 7 Distance dimension Vmin for wear measurement while the plant is at

standstill:

Size 50 70 85 100 125 145 170 200 230 260 300 360 400

Vmin [mm] 11,4 11,7 8,0 11,4 12,7 13,8 13,6 14,3 15,4 15,3 12,1 12,1 15,4

Upon completion of the wear measurement, re-install all the protective devices and covers.

03/2004 TSCHAN®-S S-St / S-LSt - 18 -

10.3 Replacement of the buffer ring

§ Danger of injuries!

§ Disconnect the drive before carrying out any work on the

coupling!

§ Secure the drive against unintentional re-start and rotation!

• Draw back one coupling half (Fig.

10).

• Remove the buffer ring (part 020).

• To facilitate mounting, the elastic

buffer ring can be coated with a

lubricant before installing it (e.g.

talcum for Perbunan Pb, commercial

roller bearing grease for Polyure-

thane Vk).

• Mount a new buffer ring of correct

material and size.

• Push the two coupling halves

together.

• Align the coupling according to the

instructions given in chapter 8 ‘Cou- Fig. 10

pling Alignment’.

Warning!

§ Before putting the equipment into service, all safety guards

must be installed to prevent unintentional contact with

freely rotating parts.

§ To avoid sparks, the covers for couplings used in explosive

atmospheres should be made of stainless steel.

§ The covers have to fulfil the requirements of protection type

IP2X as a minimum.

§ The covers have to be designed to prevent dust from

depositing on the coupling parts.

§ The cover must not touch the coupling and impair the

proper operation of the coupling.

We do not assume any responsibility or warranty for any damages resulting from the use of

accessories or spare parts, which have not originally been manufactured by Tschan GmbH.

11 Disposal

Disposal of the parts must be arranged in accordance with the regulations and laws of the

country where the equipment is installed.

03/2004 TSCHAN®-S S-St / S-LSt - 19 -

12 Manufacturer’s Declaration

Compliant with the EC Machinery Directive 98/37/EC Annex II B

We herewith declare that the flexible shaft couplings of type

TSCHAN®-S S-St, S-LSt

designed in compliance with directive 94/9/EC

and described in this operation manual are intended for installation in a ma-

chine, and that it is only allowed to put them into service after it has been

determined that the machine into which these components will be installed,

complies with the regulations of the EC-Directive.

Neunkirchen, the 09.03.2004

i. V. Norbert Telaar i. V. Volker Carl

Sales and Design Manager Design Manager

TSCHAN GmbH Zweibrücker Straße 104 D-66538 Neunkirchen-Saar

Telefon: +49(0) 6821 866 0 Telefax: +49(0) 6821 883 53 www.tschan.de

13 Declaration of Conformity

For the purposes of the Directive 94/9/EC of April 23, 1994, and legal regula-

tions issued for the implementation of this directive

The manufacturer TSCHAN GmbH, D - 66521 Neunkirchen, declares that the

flexible shaft couplings of Type

TSCHAN® -S S-St, S-LSt

designed acc. to directive 94/9/EC

are devices within the meaning of article 1 and article 8, para. 1) b) ii) of

directive 94/9/EC and comply with the regulations of the directive 94/9/EC

and with the standards EN 1127-1, EN 1127-2 and EN 13463-1.

The technical documentation is kept by the nominated body:

Deutsche Montan Technologie GmbH, D 45307 Essen, ID-number: 0158

This declaration of conformity refers to the state of the coupling at the time of

its delivery and to the permissible rework as described in the operation

manual. This declaration of conformity becomes void if any modifications or

changes are carried out on the product and if non-original spare parts are

used.

Neunkirchen, the 09.03.2004

i. V. Norbert Telaar i. V. Volker Carl

Sales and Design Manager Design Manager

TSCHAN GmbH Zweibrücker Straße 104 D-66538 Neunkirchen-Saar

Telefon: +49(0) 6821 866 0 Telefax: +49(0) 6821 883 53 www.tschan.de

You might also like

- CBM HeatersDocument56 pagesCBM HeatersChristis Savva100% (1)

- LM-770 - Ome - ManualDocument40 pagesLM-770 - Ome - ManualGabriel Gonçalves50% (4)

- Pulptec: MEK-2500 Rotating Consistency TransmitterDocument36 pagesPulptec: MEK-2500 Rotating Consistency TransmitterAbedalhade Alhader100% (2)

- JUPITER2200-01 1233-SA EngDocument189 pagesJUPITER2200-01 1233-SA EngZdenko Nagy100% (2)

- S10-S12 - EXEL Service ManualDocument106 pagesS10-S12 - EXEL Service ManualNgo Ngoc Tu50% (4)

- Owner's Manual: MS Series Multi-SystemDocument109 pagesOwner's Manual: MS Series Multi-SystemCaley Corbett100% (1)

- Mando Final PC-350 Komatsu Desarmado y Armado.Document9 pagesMando Final PC-350 Komatsu Desarmado y Armado.mrcruzito_2099100% (1)

- Service Manual En: Reflex RR B/E, RR B/E CCDocument494 pagesService Manual En: Reflex RR B/E, RR B/E CCAlessandro de Oliveira100% (3)

- Baws014 Ex GBR 2 - 1343603272Document20 pagesBaws014 Ex GBR 2 - 1343603272denisNo ratings yet

- QCG Pe 2020-02Document13 pagesQCG Pe 2020-02Roosevelt A. SantosNo ratings yet

- Tschan CouplingsDocument19 pagesTschan CouplingsCardoso MalacaoNo ratings yet

- Installation and Operations Manual Ringfeder Elastomer Jaw Couplings TNM G en 07 2023Document24 pagesInstallation and Operations Manual Ringfeder Elastomer Jaw Couplings TNM G en 07 2023hunagNo ratings yet

- AH00511n - Installation Procedure For The Swing Circle (SC) - 1Document20 pagesAH00511n - Installation Procedure For The Swing Circle (SC) - 1Mohammad YounesNo ratings yet

- Instrukcja Tschan Posimin NZN NZN MinDocument17 pagesInstrukcja Tschan Posimin NZN NZN MinAkshay SetlurNo ratings yet

- Air End and Pneumatic Circuit: DX, DX - R and DQ500Document77 pagesAir End and Pneumatic Circuit: DX, DX - R and DQ500Yebrail Mojica Ruiz100% (1)

- TD300 900Document102 pagesTD300 900Polished AllNo ratings yet

- F01 - CouplingDocument26 pagesF01 - CouplingIsaac SidibeNo ratings yet

- Acople Torsión Rigida TSCHAN 1241621582Document22 pagesAcople Torsión Rigida TSCHAN 1241621582Juan LopezNo ratings yet

- A73501880 - Instruction ManualDocument48 pagesA73501880 - Instruction ManualSaravana kumar NagarajanNo ratings yet

- Baltech - MRX 2 ManualDocument42 pagesBaltech - MRX 2 Manualbolijon166No ratings yet

- Omml 7 201 300 B enDocument7 pagesOmml 7 201 300 B enEngr Mohammed UsmaniaNo ratings yet

- HanbellRC2 TM ManualDocument109 pagesHanbellRC2 TM Manualdcallahanmasonbarry100% (3)

- Instruction Manual: NXDS Scroll PumpDocument48 pagesInstruction Manual: NXDS Scroll PumpAdam TaylorNo ratings yet

- Gs-2000&Gs-3000 Operation Manual 02verDocument564 pagesGs-2000&Gs-3000 Operation Manual 02verpopsemi3No ratings yet

- UK-Type Examination Certificate 6196aDocument7 pagesUK-Type Examination Certificate 6196acarlosNo ratings yet

- OfiteDocument48 pagesOfitephalanaxusNo ratings yet

- 016-7100-049-A - RCM Sprayer With Sidekick Pro ICD Ratio Rate Quick Installation ReferenceDocument26 pages016-7100-049-A - RCM Sprayer With Sidekick Pro ICD Ratio Rate Quick Installation ReferenceAlex RosaNo ratings yet

- 6Huylfh0Dqxdo %: Valid From Serial Number: 425801AADocument98 pages6Huylfh0Dqxdo %: Valid From Serial Number: 425801AAК ШNo ratings yet

- MP80 Service ManaulDocument10 pagesMP80 Service ManaulJ'Cesar LinaresNo ratings yet

- 06 Rockdrill & SluDocument51 pages06 Rockdrill & SluNiño De la torreNo ratings yet

- NE04 014revbDocument23 pagesNE04 014revbMarlene Yuriserll Ruiz MuñozNo ratings yet

- t3.Kcd - XV.X Speed Blade Auia.167 OmDocument29 pagest3.Kcd - XV.X Speed Blade Auia.167 OmDaniel RegoNo ratings yet

- Alfagomma - Oil & GasDocument115 pagesAlfagomma - Oil & GasIgor Bastos100% (1)

- 8999 0850 00 Diagrams and Drawings PDFDocument85 pages8999 0850 00 Diagrams and Drawings PDFHugo Escobar Huamanyali100% (1)

- DLP enDocument15 pagesDLP enpir8s_xNo ratings yet

- MDC-2200 - 2500 - Installation Manual - Rev07 PDFDocument123 pagesMDC-2200 - 2500 - Installation Manual - Rev07 PDFcostinosNo ratings yet

- User Manual MEK-2500Document38 pagesUser Manual MEK-2500Sofyan AssauriNo ratings yet

- Years of Mowing ExcellenceDocument172 pagesYears of Mowing Excellencelgm.tomleistNo ratings yet

- 1 StormTech Product Catalog ENDocument28 pages1 StormTech Product Catalog ENDominik_LjubicicNo ratings yet

- Ts-100 Operation Manual 11 VerDocument373 pagesTs-100 Operation Manual 11 VersunhuynhNo ratings yet

- B80000880 - Instruction ManualDocument94 pagesB80000880 - Instruction ManualChristian BradleyNo ratings yet

- Centaflex CatalogueDocument33 pagesCentaflex CatalogueKaram El FerhliNo ratings yet

- DoymaDocument28 pagesDoymaMarius100% (1)

- Operating Manual: Hydrogen Plant 250 NM /HDocument8 pagesOperating Manual: Hydrogen Plant 250 NM /HCem CetizNo ratings yet

- Spidex OperatingDocument10 pagesSpidex Operatingwalk001No ratings yet

- Sellos Espejo PC 300-7Document5 pagesSellos Espejo PC 300-7maocaleirlNo ratings yet

- WSM U30-6Document399 pagesWSM U30-6江宗朋No ratings yet

- Operating Instructions: StreamlineDocument12 pagesOperating Instructions: StreamlineMarco AurélioNo ratings yet

- Planos Eléctricos JumboDocument108 pagesPlanos Eléctricos Jumbocarlos farfanNo ratings yet

- Excabadora Hid. Komatsu.Document836 pagesExcabadora Hid. Komatsu.prudenciosotelotrujiNo ratings yet

- R912005856 12Document98 pagesR912005856 12mikeNo ratings yet

- Denison Cam-Cartridge PDFDocument12 pagesDenison Cam-Cartridge PDFmiguel04891100% (1)

- Boomer Jumbos1d PDFDocument115 pagesBoomer Jumbos1d PDFFernando DueñasNo ratings yet

- TB 00700001 eDocument9 pagesTB 00700001 eRicardo LopezNo ratings yet

- Hose Catalogue: Customer Service: +44 (0) 1772 323529Document52 pagesHose Catalogue: Customer Service: +44 (0) 1772 323529po truongNo ratings yet

- PL Nl2500 PartsDocument354 pagesPL Nl2500 PartsDanMan InOhioNo ratings yet

- Ta27 Tier3 - 8681Document380 pagesTa27 Tier3 - 8681Marcoglm100% (5)

- Astm D5185-2005Document8 pagesAstm D5185-2005liyuping200809No ratings yet

- M2BAX 产品介绍 - Bilingual - 20160222Document50 pagesM2BAX 产品介绍 - Bilingual - 20160222liyuping200809No ratings yet

- KORD3 19-414 Dimensions For V1505Document2 pagesKORD3 19-414 Dimensions For V1505liyuping200809No ratings yet

- KORD3 19-276 Technical Information For V2403-CR DPF ModelDocument19 pagesKORD3 19-276 Technical Information For V2403-CR DPF Modelliyuping200809No ratings yet

- KORD3 17-062 Technical Information For D1803-CR-TE4 DPF ModelDocument19 pagesKORD3 17-062 Technical Information For D1803-CR-TE4 DPF Modelliyuping200809No ratings yet

- 无锡伏尔康样本Document34 pages无锡伏尔康样本liyuping200809No ratings yet

- RotexDocument50 pagesRotexliyuping200809No ratings yet

- Warren SM Ch.14 FinalDocument34 pagesWarren SM Ch.14 FinalSonia Veizha SasmayaNo ratings yet

- Semi-Detailed Lesson Plan in Mathematics For Grade 1Document7 pagesSemi-Detailed Lesson Plan in Mathematics For Grade 1angelajuguilon2No ratings yet

- Fieldbus ActuatorsDocument12 pagesFieldbus Actuatorsvsswami_82No ratings yet

- Ansys 15Document3 pagesAnsys 15Ramesh BammankattiNo ratings yet

- Newton'S Laws of Motion: Mark Anthony C. Burgonio, MSCDocument37 pagesNewton'S Laws of Motion: Mark Anthony C. Burgonio, MSCChristel GonzalesNo ratings yet

- Man 8037t PRGDocument272 pagesMan 8037t PRGvuitinhnhd9817No ratings yet

- Huawei AirEngine 5761-21 Access Point DatasheetDocument17 pagesHuawei AirEngine 5761-21 Access Point DatasheetRicardo barbosaNo ratings yet

- 5.0 Discrete Probability DistributionDocument82 pages5.0 Discrete Probability DistributionTanish AgrawalNo ratings yet

- Peak Sun Hours - ExplanationDocument13 pagesPeak Sun Hours - ExplanationdipankarNo ratings yet

- CH-CS Vega S977.031.en PDFDocument28 pagesCH-CS Vega S977.031.en PDFMf Lui100% (1)

- Electron Transport Bilayer (Review Paper)Document17 pagesElectron Transport Bilayer (Review Paper)ashab zakiNo ratings yet

- LogDocument325 pagesLogmiaculimchiNo ratings yet

- Echometer - Acoustic Foam Depression TestsDocument12 pagesEchometer - Acoustic Foam Depression TestsGuiNo ratings yet

- Terex Vibrating Feeder Advantage-Series-VGF-FlyerDocument2 pagesTerex Vibrating Feeder Advantage-Series-VGF-FlyerCarlos Ediver Arias RestrepoNo ratings yet

- ZF 4 HP 16Document6 pagesZF 4 HP 16RIGOBERTO MARTINEZNo ratings yet

- Amortized Loan ExampleDocument8 pagesAmortized Loan ExampleEdward Raymund CuizonNo ratings yet

- Pronoun-Antecedent AgreementDocument55 pagesPronoun-Antecedent AgreementZack DiazNo ratings yet

- CNC 3040 T DJ Mini CNC ManualDocument30 pagesCNC 3040 T DJ Mini CNC ManualLuis Paulo LimaNo ratings yet

- Konstruksi Tes Kemampuan Berpikir Spasial Model Sharpe-HuynhDocument12 pagesKonstruksi Tes Kemampuan Berpikir Spasial Model Sharpe-HuynhElma SitumorangNo ratings yet

- Draw Wire Sensor: Series SX80Document14 pagesDraw Wire Sensor: Series SX80Amilcar MendozaNo ratings yet

- MCQ Ucmp Unit I Introduction and Mechanical Energy Based ProcessesDocument30 pagesMCQ Ucmp Unit I Introduction and Mechanical Energy Based ProcessesBollu SatyanarayanaNo ratings yet

- Equipment Data Sheet Axial Fans: LMC Flotation Project Equipment Data Sheet Prepared by Aker Kvaerner Pty LimitedDocument8 pagesEquipment Data Sheet Axial Fans: LMC Flotation Project Equipment Data Sheet Prepared by Aker Kvaerner Pty Limitedalimoya13No ratings yet

- Diagnostic MethodsDocument35 pagesDiagnostic MethodsSid YamiNo ratings yet

- UT PCN NotesDocument113 pagesUT PCN NotesThiru Raja95% (20)

- Week1b - OverviewOf OOP PDFDocument3 pagesWeek1b - OverviewOf OOP PDFEdrianCliffDelPilarNo ratings yet

- Linear Systems SummaryDocument2 pagesLinear Systems SummaryFrantz ClermontNo ratings yet

- EE650 L11bDocument17 pagesEE650 L11braghav shuklaNo ratings yet

- Learning Activity Answers OEd STATDocument8 pagesLearning Activity Answers OEd STATKeziah VenturaNo ratings yet

- Augmented Triads On GuitarDocument6 pagesAugmented Triads On GuitarRonald García DeronceleNo ratings yet

- Aerospace 10 00021Document16 pagesAerospace 10 00021enatiye2015No ratings yet