主機維修保養手冊

主機維修保養手冊

Uploaded by

a1021332124Copyright:

Available Formats

主機維修保養手冊

主機維修保養手冊

Uploaded by

a1021332124Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

主機維修保養手冊

主機維修保養手冊

Uploaded by

a1021332124Copyright:

Available Formats

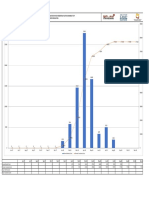

Draw.no: 1012/13 Routine Maintenance Schedule 80.

000

Instruction no: 1502 Valid for Bergen K25:30 Engines for MDO, Marine Application

Revision: November 2015 Rev B

S = Spot Check, C = Check All, L = Lubricate, W = Clean / Adjust, O = Overhaul, R = Replace

10000

11000

12000

13000

14000

15000

16000

17000

18000

19000

20000

21000

22000

23000

24000

25000

26000

27000

28000

29000

30000

31000

32000

33000

34000

35000

36000

37000

38000

39000

40000

41000

42000

43000

44000

45000

46000

47000

48000

49000

50000

51000

52000

53000

54000

55000

56000

57000

58000

59000

60000

61000

62000

63000

64000

65000

66000

67000

68000

69000

70000

71000

72000

73000

74000

75000

76000

77000

78000

79000

80000

1000

1500

2000

2500

3000

3500

4000

4500

5000

6000

7000

8000

9000

Item Instr.

100

500

No. No. a)

1 CYLINDER HEADS 1

101 2404 Cylinder head bolts: retighten approx. 100 hrs after refitting of cyl.head C C C C C C C C C 101

102 2408 Cylinder head: max.firing pressure C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C 102

a) See service 103 4301 Inlet and exhaust valve clearance. Also approx.100 hrs after refitting of cyl.head C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C 103

manual instructions

104 2405 Inlet and exhaust valve rotators (rotocaps) C C C C C C C C C R C C C C C C C C C R C C C C C C C C C R C C C C C C C C C R 104

105 2401 Valve gear system for inlet and exhaust valves C C C C O C C C C O C C C C O C C C C O C C C C O C C C C O C C C C O C C C C O 105

106 2401 Inlet and exhaust valves / valve seats: overhaul / replace according to wear R R R R R R R R 106

b) See separate 107 2401 Inlet and exhaust valve guides C C C C C C C C 107

instructions 108 2408 Indicator valves C C C C C C C C 108

109 2410 Starting air valves O O O O O O O O 109

2 FUEL OIL SYSTEM 2

c) See engine

201 7208 Fuel injection nozzle holder W W W O W W W O W W W O W W W O 201

alarm list

202 7208 Fuel injection nozzles R R R R R R R R R R R R R R R R 202

203 7207 Fuel injection pump drive: alternating spot checks S S S O S S S O S S S O S S S O 203

The schedule is 204 7206 Fuel injection pump O O O O 204

only valid for 205 7206 Fuel injection pump: erosion plug S S S R S S S R S S S R S S S R 205

normal operating 206 5501 Fuel injection pump: auto stop cylinder emergency stop test Check monthly 206

conditions as 207 7206 Fuel injection pump: fuel rack - lubricate and check every pump for signs of sticking Weekly and before start 207

defined in the 208 7205 Fuel oil filter Replace every 6 months or at diff. pressure 208

contracts, service

209 - Flexible fuel connections C C R C C R C C R C C R C C R C C R C C R C C R 209

agreements or

relevant technical

210 8308 Engine driven fuel oil booster pump O O O O 210

documentation 211 - All fuel pipes (high and low pressure) C C C C C C C C C C C C C C C C 211

from Rolls-Royce 212 - Fuel oil sample When bunkering 212

3 CYLINDER LINERS 3

301 2301 Honing: overhaul / replace according to wear O O O O 301

302 2301 Remove liner / check water jacket / replace sealing O O O O 302

The intervals in this

303 2301 Carbon cutting ring (optional) C C C C 303

schedule are for

guidance only and 4 PISTONS / CONNECTING RODS 4

are subject to local 401 3201 Gudgeon pin bushing: replace when off limit C C C R 401

ambient conditions. 402 3201 Gudgeon pin C C C C 402

The schedule is 403 3201 Piston including piston ring grooves (gap / clearence): replace after 80.000 hrs C C C R 403

applicable to 404 3201 Piston rings: also replace after honing of cyl. liner R R R R 404

engines with more 405 3202 Big end bearing shells R R R R 405

than 2000 annual

406 3201 Big end bearing assembly (ovality control, surface check and boroscope inspection of threads) C C C C 406

operating hrs

407 3201 Big end bearing bolts R R R R 407

5 CRANKSHAFT 5

501 2201 Main bearings and thrust washers S R S R 501

S = Dismantle / 502 3102 Crankshaft deflection: check before and after every major overhaul / docking C C C C C C C C C C C C C C C C 502

inspect 1 item and 503 b) Flexible couplings (not applicable to generators directly bolted to the flywheel) S S S S S S S S S S S S S S S S 503

check condition 504 3101 Torsional vibration damper: fluid type (subsequent fluid samples to be taken according to supplier's indications) C 504

(leakage, abnormal

505 3105 Flexible gear wheel, pump drive (pump end) S S S S S S S S S S S S S S S S 505

wear, cracks,

contamination etc.) 6 CAMSHAFTS 6

601 4101 Camshaft bearings and thrust washers S S S R S S S R 601

602 4101 Fuel cams S S S S S S S S S S S S S S S S 602

603 4101 Inlet and exhaust cams with drive S S S S S S S S S S S S S S S S 603

The schedule may 604 4102 Camshaft drive with gear wheels S S S S S S S S S S S S S S S S 604

only be changed

605 4102 Camshaft drive chain (30.000 hrs intervals with lower output and shorter camshaft length) R R R R R 605

by a service letter

606 5202 Governor drive S S S O S S S O S S S O S S S O 606

from Rolls-Royce

607 5103 Pilot starting air distributor with drive L L L O L L L O L L L O L L L O 607

7 LUBRICATING OIL 7

701 - Clean lubr.oil tank / sump when changing lubr.oil W W W W 701

702 1503 Lubr.oil analysis C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C 702

C

703 8204 Main lubricating oil pump O O 703

704 8206 Lub. oil filters, by-pass valves and filter elements: replace at least every 6 months or at diff. pressure R R R R R R R R R R R R R R R R R R R R 704

705 8207 Centrifugal separation filter lubr.oil: clean every 500 hrs, paper insert to be changed when required W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W W 705

706 b) Lubricating oil priming pump (electrical) C C C C C C C C C C C C C C C C 706

707 b) Lubr.oil cooler: see section 9 - cooling water quality / parameters Clean when necessary 707

708 8301 Valve gear lub. oil system: lubricating oil tank W W W W 708

709 8304 Valve gear lub. oil system: filter Clean daily 709

710 8303 Valve gear lub. oil system: strainer W W W W W W W W W W W W W W W W 710

8 CHARGE AIR AND EXHAUST SYSTEM 8

801 b) Turbocharger bearings: see sign on turbo charger housing See separate instructions 801

802 b) Turbocharger rotor: see sign on turbo charger housing See separate instructions 802

803 b) Turbocharger air filters: clean when dirty See separate instructions 803

804 b) Turbocharger lub. oil: change depending on oil quality and operating conditions, 100 hrs after overhaul See separate instructions 804

805 7106 Turbocharger - water washing of compressor: every 50 hrs See separate instructions 805

806 b) Charge air cooler: clean when necessary See separate instructions 806

807 7301 Exhaust manifold bellows C C C C C C C C C C C C C C C C 807

808 7301 Exhaust manifold insulation C C C C C C C C C C C C C C C C 808

9 COOLING WATER 9

901 8501 Cooling water quality and flow: check monthly C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C 901

902 8503 Cooling water pumps with drive (high and low temperature) S O S O S O S O 902

903 b) Jacket water cooler (optional): clean when necessary O O O O 903

904 b) Sea water pump with drive (optional) C O C O C O C O C O C O C O C O 904

10 ALARM / CONTROL SYSTEM - FUNCTION TEST INTERVALS 10

1001 c) Auto stops According to classification requirements 1001

1002 - Interlocks According to classification requirements or at least once a year 1002

1003 - Emergency start Check monthly 1003

1004 b) Oil mist detector (optional) See separate instructions 1004

1005 - Temperature PID controller (optional) Every 3 months 1005

1006 - Control shaft linkages and fuel rack calibration Check weekly / lubricate 1006

1007 - Speed pick-up clearance and cleaning Check monthly 1007

1008 - Tightening of connectors and screw terminals Check once every 6 months 1008

1009 - Pressure transmitters and temperature sensors Every 3 months (according to classification requirements) 1009

1010 - Cleaning and visual checking of all electrical equipment Every 3 months 1010

1011 - Auxiliary equipment Every year 1011

1012 - Earth fault Check weekly 1012

11 MISCELLANEOUS 11

1101 2102 Resilient mounting of engine (optional): check for cracks / damages / loose bolts Every 6 months 1101

1102 - All flexible connections: hoses, bellows etc. Check every 2 months 1102

1103 5301 Governor / actuator Change oil every 3 months R R 1103

1104 - Governor control shaft with linkages and couplings Check / lubricate weekly 1104

1105 - Exhaust pipe insulation According to SOLAS regulations 1105

1106 - Screw and pipe connections - outside and inside on engine C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C 1106

You might also like

- Canter Euro6 GearboxDocument142 pagesCanter Euro6 GearboxsamlohswcNo ratings yet

- Cummins n855 Engine Specs PDF FreeDocument6 pagesCummins n855 Engine Specs PDF Freema.powersource0% (1)

- Pulsar Ns 125 Fi Bsiv SPCDocument74 pagesPulsar Ns 125 Fi Bsiv SPCTienda Bogota Heroes80% (5)

- VW t6 Fitting Locations EngDocument148 pagesVW t6 Fitting Locations EngPaveldj100% (1)

- Sector-29 YEIDADocument1 pageSector-29 YEIDAAnsu YadavNo ratings yet

- Platina 125 Dts-Si SPC Esks Parts CatalogueDocument43 pagesPlatina 125 Dts-Si SPC Esks Parts CatalogueAshish Choudhary90% (20)

- Instruction Manual MGN81GL-1A-11A (M6Z06670E)Document72 pagesInstruction Manual MGN81GL-1A-11A (M6Z06670E)arieznaval75% (4)

- F50TLRBDocument393 pagesF50TLRBPatricia Christine Baldwin100% (2)

- 05-06 YFM250 Bruin 07-09 BigBear 2WDDocument444 pages05-06 YFM250 Bruin 07-09 BigBear 2WDTim Burkett100% (3)

- RMS 0-40000 (KXGS-G TPS) L528 - 61 Rev0012Document1 pageRMS 0-40000 (KXGS-G TPS) L528 - 61 Rev0012ufficio.tecnicoNo ratings yet

- K25 - 30 GAS G4 - Stationary - Updated Routine Maintenance ScheduleDocument2 pagesK25 - 30 GAS G4 - Stationary - Updated Routine Maintenance Scheduleufficio.tecnicoNo ratings yet

- Industrial Brake Technology EnglishDocument76 pagesIndustrial Brake Technology EnglishEmerson BatistaNo ratings yet

- SAJIDDocument14 pagesSAJIDSadi MohammedNo ratings yet

- SB Eldro en 0315 A 1Document12 pagesSB Eldro en 0315 A 1jcsalado9No ratings yet

- Thruster Disc Brakes SB 8 Series: Pintsch BubenzerDocument7 pagesThruster Disc Brakes SB 8 Series: Pintsch Bubenzersholhan azizNo ratings yet

- Frenos Ejesseries Sb23!28!38Document5 pagesFrenos Ejesseries Sb23!28!38Patricio BarraNo ratings yet

- Brake Systems For Mining EnglishDocument96 pagesBrake Systems For Mining Englisht1o2n3i4No ratings yet

- Monitoring EWDocument2 pagesMonitoring EWrfq2brd2ttNo ratings yet

- Mecanismos de Freios IndustriaisDocument60 pagesMecanismos de Freios IndustriaisfabioNo ratings yet

- Dekalb Covid-19 Epidemiology Report: Daily and Cumulative Covid-19 Case Counts, Dekalb CountyDocument13 pagesDekalb Covid-19 Epidemiology Report: Daily and Cumulative Covid-19 Case Counts, Dekalb CountyZachary HansenNo ratings yet

- Construction Industry AnalysisDocument132 pagesConstruction Industry AnalysisEleanorXuNo ratings yet

- Input Voltage 50 Vrms Resistor 20 Ohms Capacitor 35ufDocument2 pagesInput Voltage 50 Vrms Resistor 20 Ohms Capacitor 35ufMark Anthony Salazar ArcayanNo ratings yet

- Thruster Disc Brakes SB 8 Series: Pintsch BubenzerDocument7 pagesThruster Disc Brakes SB 8 Series: Pintsch BubenzerJose Luis Vivanco MontenegroNo ratings yet

- TCC Number 173 4 2Document1 pageTCC Number 173 4 2Dennis RimandoNo ratings yet

- The Pioneer - August - September 07Document20 pagesThe Pioneer - August - September 07nilnilen2009No ratings yet

- Pintsch Bubenzer SB Brakes CatalogDocument12 pagesPintsch Bubenzer SB Brakes CatalogEliud AlcarazNo ratings yet

- PARAN3E ExerciseNo2 Layout1Document1 pagePARAN3E ExerciseNo2 Layout1Mickaela Kassandra ParanNo ratings yet

- Gold - An Ideal Portfolio Diversifier: Retail Research 20 April, 2020Document11 pagesGold - An Ideal Portfolio Diversifier: Retail Research 20 April, 2020Vivek TonapiNo ratings yet

- Minimum Melting Time-Current Characteristic Curves: SMD Fuse Units-S&C Standard SpeedDocument1 pageMinimum Melting Time-Current Characteristic Curves: SMD Fuse Units-S&C Standard SpeedRafaelo09No ratings yet

- 2016CT Compressor Specs at GlanceDocument4 pages2016CT Compressor Specs at Glanceabsahkah100% (1)

- Situación Epidemiológica de Sarampión Rubeola y PFA Macro Norte 17junio2021Document49 pagesSituación Epidemiológica de Sarampión Rubeola y PFA Macro Norte 17junio2021cdc.inmunopreveniblesNo ratings yet

- Minimum Tripping Time-Current Characteristic Curves: S&C Electric CompanyDocument1 pageMinimum Tripping Time-Current Characteristic Curves: S&C Electric CompanyEddy UberguagaNo ratings yet

- Laydown Area For Bullet Option-1Document1 pageLaydown Area For Bullet Option-1vikneshNo ratings yet

- Situación Epidemiológica de Sarampión Rubeola y PFA Macro Oriente 14junio2021Document40 pagesSituación Epidemiológica de Sarampión Rubeola y PFA Macro Oriente 14junio2021cdc.inmunopreveniblesNo ratings yet

- Cumulative CostDocument1 pageCumulative CostadlenaNo ratings yet

- 2017CT CompressorSpecsAtAGlanceDocument4 pages2017CT CompressorSpecsAtAGlanceMadhana GopalNo ratings yet

- TCC Number 153 2 PDFDocument1 pageTCC Number 153 2 PDFOmar VazquezNo ratings yet

- Total Clearing Time-Current Characteristic Curves: S&C Electric CompanyDocument1 pageTotal Clearing Time-Current Characteristic Curves: S&C Electric CompanyEddy UberguagaNo ratings yet

- Minimum Tripping Time-Current Characteristic Curves: S&C Electric CompanyDocument1 pageMinimum Tripping Time-Current Characteristic Curves: S&C Electric CompanyEddy UberguagaNo ratings yet

- Construction of Internal Roads and Infrastructure For 354 Residential Plots in Shakhbout City Kpi Unclassified ExcavationDocument15 pagesConstruction of Internal Roads and Infrastructure For 354 Residential Plots in Shakhbout City Kpi Unclassified ExcavationburereyNo ratings yet

- Draft Part 1Document7 pagesDraft Part 1Brian RamadhanNo ratings yet

- Kantar - Consumer and CovidDocument28 pagesKantar - Consumer and Covidstevanus.tulus19No ratings yet

- Green Synthesis of Fe Nanoparticles Using Citrus Maxima Peels Aqueous ExtractsDocument2 pagesGreen Synthesis of Fe Nanoparticles Using Citrus Maxima Peels Aqueous ExtractsDavid SeguinNo ratings yet

- OSHYIYEDocument1 pageOSHYIYENana BarimaNo ratings yet

- Perspective A: Archen Technologies, IncDocument1 pagePerspective A: Archen Technologies, IncJOHN MICHAEL MADLAINGNo ratings yet

- Xref - Solar System Main Device Layout-ModelDocument1 pageXref - Solar System Main Device Layout-Modeldomanhhiep3112No ratings yet

- CH-CAT-10217126 - MY15 US Trailering Guide - 122215Document15 pagesCH-CAT-10217126 - MY15 US Trailering Guide - 122215Osama HammamNo ratings yet

- Oshiyie Site Organizational Layout PDFDocument1 pageOshiyie Site Organizational Layout PDFNana BarimaNo ratings yet

- Oshiyie Site Organizational LayoutDocument1 pageOshiyie Site Organizational LayoutNana BarimaNo ratings yet

- Catalogo ConductosDocument8 pagesCatalogo ConductosCarlos ManriquezNo ratings yet

- Uas Utilitas GedungDocument2 pagesUas Utilitas GedungRoihatul JannahNo ratings yet

- Brochure Cluster - The Mahogany Residence (Final) PDFDocument21 pagesBrochure Cluster - The Mahogany Residence (Final) PDFTkko riastoNo ratings yet

- Wichmann 10V28 Book - Compressed (091-120)Document30 pagesWichmann 10V28 Book - Compressed (091-120)Ткаченко Павел 234No ratings yet

- Civil Engineering Construction Project (Ecm 317) : Group MembersDocument28 pagesCivil Engineering Construction Project (Ecm 317) : Group MembersSafi HusseinNo ratings yet

- 2017 Chevrolet Trailering and Towing GuideDocument17 pages2017 Chevrolet Trailering and Towing GuideHéctor GodoyNo ratings yet

- Barrel Vault Final DrawingsDocument4 pagesBarrel Vault Final DrawingsLisha AgrawalNo ratings yet

- Trial - EUL-DCH Load BalancingDocument10 pagesTrial - EUL-DCH Load BalancingkafleNo ratings yet

- Strategy MapsDocument2 pagesStrategy Mapsprincemech2004No ratings yet

- 2 Depreciation Comprehensive - ExampleDocument8 pages2 Depreciation Comprehensive - ExampleMr HeraclitusNo ratings yet

- 2018 Chevrolet Trailering and Towing GuideDocument18 pages2018 Chevrolet Trailering and Towing GuideTetsunari KodaNo ratings yet

- OIIIDocument28 pagesOIIISeyi WilliamsNo ratings yet

- Exhaust Valve Installation Guide PDFDocument23 pagesExhaust Valve Installation Guide PDFPugs ThomasNo ratings yet

- Drawing Mtu Punagaya - Rev3Document1 pageDrawing Mtu Punagaya - Rev3I Gede Tias Eka BuanaNo ratings yet

- E-Brosure Water TerraceDocument20 pagesE-Brosure Water TerraceM Rifqi PT. Ryuu IndustryNo ratings yet

- B-H Curve For 1018 SteelDocument1 pageB-H Curve For 1018 SteelMaycon MaranNo ratings yet

- General Notes:: Ground Floor Air Con & Ventilation Layout 2Nd Floor Air Con & Ventilation LayoutDocument1 pageGeneral Notes:: Ground Floor Air Con & Ventilation Layout 2Nd Floor Air Con & Ventilation LayoutAngela CanuelNo ratings yet

- 3 EPT20-15EHJ Daily Maintenance List - 20181115 - 154241Document2 pages3 EPT20-15EHJ Daily Maintenance List - 20181115 - 154241Fabricio ArteagaNo ratings yet

- ISF MainPrint 27012021 0550Document2 pagesISF MainPrint 27012021 0550abdouNo ratings yet

- Section 2 - SteeringDocument275 pagesSection 2 - SteeringMTK2016No ratings yet

- Land Rover LR3 Shop Manual Maintenance SchedulesDocument13 pagesLand Rover LR3 Shop Manual Maintenance Schedulesbmgeisler0% (1)

- Operation of 4-Stroke Cycle EnginesDocument1 pageOperation of 4-Stroke Cycle EnginesRhea NasamNo ratings yet

- RVR 2011 20L PDFDocument99 pagesRVR 2011 20L PDFnicolas sanatanaNo ratings yet

- Modelo M0801 16MM HAMMER DRILL: 1 / 1 PáginaDocument2 pagesModelo M0801 16MM HAMMER DRILL: 1 / 1 PáginaJulio LopezNo ratings yet

- Manual Desarmado y Armado - Bomba Cat 3406Document39 pagesManual Desarmado y Armado - Bomba Cat 3406Gallego Carlos100% (1)

- V Series Vickers 4520v Standard Double Pump Parts DataDocument4 pagesV Series Vickers 4520v Standard Double Pump Parts DataNick OchoaNo ratings yet

- Small Engine Parts IdDocument9 pagesSmall Engine Parts Idolas87No ratings yet

- Technical Trend of The Power Shift Transmission (PST) of Agricultural TractorDocument8 pagesTechnical Trend of The Power Shift Transmission (PST) of Agricultural TractorkazemiNo ratings yet

- Kansai W-8042, W8042-1Document14 pagesKansai W-8042, W8042-1CelsoNo ratings yet

- 424B Disassembly and Assembly (Transmission) (RESM3578-02)Document102 pages424B Disassembly and Assembly (Transmission) (RESM3578-02)veeresh100% (3)

- Disassembly/Assembly Manual Model SR2100 (DRAX) : RJ-DA-16 05/10Document35 pagesDisassembly/Assembly Manual Model SR2100 (DRAX) : RJ-DA-16 05/10Erica HenryNo ratings yet

- Electrical Item ListDocument4 pagesElectrical Item ListDHALIWAL INTERNETNo ratings yet

- Pernos Cat PDFDocument72 pagesPernos Cat PDFTania VélezNo ratings yet

- Maxon GP 32 ADocument2 pagesMaxon GP 32 AElectromateNo ratings yet

- Zf 6hp504c (Лиаз-5292) - Каталог Запасных ЧастейDocument70 pagesZf 6hp504c (Лиаз-5292) - Каталог Запасных Частейsnpeeezy100% (1)

- Power JacksDocument312 pagesPower JacksJohan ConradieNo ratings yet

- 2-Motobomba A Diesel 10HP 4 Pol Auto Escorvante Partida Elãtrica2Document4 pages2-Motobomba A Diesel 10HP 4 Pol Auto Escorvante Partida Elãtrica2Jose Wellington Silva dos SantosNo ratings yet

- QST - QSB 4050052-102Document63 pagesQST - QSB 4050052-102Javier Cevallos0% (1)

- Manual de Partes CAT 3516Document1,664 pagesManual de Partes CAT 3516charly cruzNo ratings yet