DC Motor PD Control To Specification

Uploaded by

ayma.tahrDC Motor PD Control To Specification

Uploaded by

ayma.tahrPD Position Control According to

Specifications

This Workbook and the VIs provided are designed for the second generation black Quanser QNET

2.0 DC Motor Board for NI ELVIS II(+) . Second generation VIs can be identified by the small black

symbol in the upper right corner of the VI. These VIs will not work for blue first generation boards.

Topics Covered

• QNET DC Motor position control.

• Proportional-derivative (PD) compensator.

• Designing control according to specifications.

Prerequisits

• QNET DC Motor Qualitative PD Position Control laboratory experiment.

• Modeling and Qualitative PI Speed Control

QNET DC MOTOR Workbook - INSTRUCTOR v 2.0

1 Background

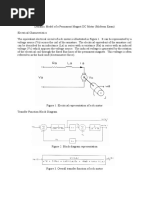

Control of motor position is a natural way to introduce the benefits of derivative action. In this experiment a

proportional-integral-derivative controller is designed according to specifications. The closed-loop PID control block

diagram is shown in Figure 1.1.

Figure 1.1: DC Motor PID closed-loop block diagram

The two-degree of freedom PID transfer function inside the PID block in Figure 1.1 is

∫ t

u = kp (bsp r(t) − y(t)) + ki (r(τ ) − y(τ ))dτ + kd (bsd ṙ(t) − ẏ(t)) , (1.1)

0

where kp is the position proportional control gain, kd is the derivative control gain, ki is the integral control gain, bsp

is the set-point weight on the reference position r(t), and bsd is the set-point weight on the velocity reference of r(t).

The dotted box labeled Motor in Figure 1.1 is the motor model in terms of the back-emf motor constant km , the

electrical motor armature resistance Rm , and the equivalent moment of inertia of the motor pivot Jeq . The direct

disturbance applied to the inertial wheel is represented by the disturbance torque variable Td and the simulated

disturbance voltage is denoted by the variable Vsd .

1.1 PD Control Design

The behavior of the controlling the motor position is first analyzed using a PD control. By setting ki = 0 in the PID

control equation Equation 1.1 and taking its Laplace transform, the PD transfer transfer function is

u = kp (r − y) + kd s(bsd r − y). (1.2)

Combining the position process model

Θm (s) K

= (1.3)

Vm (s) s(τ s + 1)

with the PD control Equation 1.2 gives the closed-loop transfer function of the motor position system

K (kp + bsd kd s)

Gθ,r (s) = . (1.4)

τ s2 + (1 + Kkd )s + Kkp

Similarly to PI speed control, the standard characteristic equation s2 + 2sζωn + ωn2 can be achieved by setting the

proportional gain to

ω2 τ

kp = 0 , (1.5)

K

and the derivative gain to

−1 + 2ζω0 τ

kd = . (1.6)

K

QNET DC MOTOR Workbook - INSTRUCTOR 2

1.2 Peak Time and Overshoot

The standard second-order transfer function has the form

Y (s) ωn2

= 2 , (1.7)

R(s) s + 2ζωn s + ωn2

where ωn is the natural undamped frequency and ζ is the damping ratio. The properties of its response depend

on the values of the ωn and ζ parameters. Consider when a second-order system, as shown in Equation 1.7, is

subjected to a step input given by

R0

R(s) = (1.8)

s

with a step amplitude of R0 = 1.5. The system response to this input is shown in Figure 1.2, where the red trace is

the response (output) y(t) and the blue trace is the step input r(t).

Figure 1.2: Standard second-order step response.

The maximum value of the response is denoted by the variable ymax and it occurs at a time tmax . For a response

similar to Figure 1.2, the percent overshoot is found using

100 (ymax − R0 )

PO = . (1.9)

R0

In a second-order system, the amount of overshoot depends solely on the damping ratio parameter and it can be

calculated using the equation ( )

− √ πζ

1−ζ 2

P O = 100e . (1.10)

QNET DC MOTOR Workbook - INSTRUCTOR v 2.0

From the initial step time t0 , the time it takes for the response to reach its maximum value is

tp = tmax − t0 . (1.11)

This is called the peak time of the system and it depends on both the damping ratio and natural frequency of the

system. It can be derived analytically as

π

tp = √ . (1.12)

ωn 1 − ζ 2

Generally speaking, the damping ratio affects the shape of the response while the natural frequency affects the

speed of the response.

1.3 Position Control Virtual Instrument

Tracking a reference position square wave using PID control is first examined in this laboratory. Then, disturbance

effects using PD and PID are studied through direct manual interaction or a simulated using a control switch in the

VI. The LabVIEW™ virtual instrument for position control is shown in Figure 1.3.

Figure 1.3: Virtual instrument for DC motor position control

See Wikipedia for more information on motion control, control theory and PID.

QNET DC MOTOR Workbook - INSTRUCTOR 4

2 In-Lab Exercise

1. A-2 Calculate the expected peak time tp and percentage overshoot P O given

• ζ = 0.60,

• ω0 = 25.0 rad/s.

Optional: You can also design a VI that simulates the DC motor first-order model with a PD control and have

it calculate the peak time and overshoot.

Answer 2.1

Outcome Solution

A-2 Substituting the ζ above in Equation 1.10 yields

P O = 9.45 %. (Ans.2.1)

Using Equation 1.12, the peak time equation with the ω0 and ζ given above equates to

.tp = 0.16 s (Ans.2.2)

You can also run the DCMC_Position_PD_CD_Instructor.vi to simulate the step response

and find the peak time and percentage overshoot.

2. A-2 Assuming the model steady-state gain is K = 26 V/rad and time constant is τ = 0.145 s, calculate the

proportional and derivative control gains kp and kd , respectively, to meet the specifications above.

Answer 2.2

Outcome Solution

A-2 Substituting the model parameters and natural frequency given above into Equation 1.5

generates the proportional control gain

kp = 3.486 V/rad. (Ans.2.3)

The derivative control gain is obtained by applying the model parameters with the natural

frequency and damping ratio specifications to Equation 1.6

kd = 0.129 V/(rad/s). (Ans.2.4)

You can also run the DCMC_Speed_PI_CD_Instructor.vi to find the PI gains. It also

generates the set-point weight parameter.

3. Open the QNET DC Motor Position Control.vi. Make sure the correct Device is chosen.

4. Run the VI. You should see the DC motor rotating back and forth.

5. In the Signal Generator section set:

• Amplitude (rad) = 0.50

• Frequency (Hz) = 0.40

• Offset (rad) = 0.00

6. In the Control Parameters section, set the PD gains to the values found in Step 2. The PD controller is

implemented with bsd = 0.

QNET DC MOTOR Workbook - INSTRUCTOR v 2.0

7. B-5, K-2 Capture the position response found in the Position (rad) scope and control signal used in the Voltage

(V) scope.

Answer 2.3

Outcome Solution

B-5 If the experimental procedure is followed correctly, the measured QNET DC Motor

closed-loop position step response should be similar to Figure Ans.2.1.

K-2 The closed-loop position response when using the PD control gains Equation Ans.2.3 and

Equation Ans.2.4 with bsd = 0 is shown in Figure Ans.2.1.

(a) Motor Position (b) Motor Voltage

Figure Ans.2.1: Measured PD position control response.

8. K-1, B-9 Measure the peak time and percentage overshoot of the measured position response. Are the

specifications satisfied?

Answer 2.4

Outcome Solution

K-1 Looking at the two cycles in the response in Figure Ans.2.1, the peak of transient occurs

about 0.125 seconds after the rising edge of the step, thus

tp = 0.1 s. (Ans.2.5)

As shown in Figure Ans.2.1, when tracking the square reference the motor position does not

go over 0.52 rad, so the overshoot is approximately less than

P O = 2.0 %. (Ans.2.6)

Note that there is a steady-state error of ≈ 3 %. This is due to relatively small error signal

that results in an input voltage in the deadband of the DC Motor. Adding an integral gain

would increase the tracking performance, see the laboratory experiment on Tracking and

Disturbance Rejection.

B-9 The specifications computed in Equation Ans.2.1 and Equation Ans.2.2 are satisfied.

9. B-2 What effect does changing the specification zeta have on the measured position response and the

generated control gains?

QNET DC MOTOR Workbook - INSTRUCTOR 6

Answer 2.5

Outcome Solution

B-2 Increasing the damping ratio ζ decreases the overshoot of the response but increases the

peak time (slows down the response). In term of control gains, as ζ is increased the

derivative gain kd increases (there is no effect on the proportional gain kp ).

10. B-2 What effect does changing the specification ω0 have on the measured position response and the

generated control gains?

Answer 2.6

Outcome Solution

B-2 Increasing the natural frequency ω0 decreases the peak time (i.e. the response becomes

faster) and has no major effect on the percent overshoot. In term of control gains, as ω0 goes

up both kp and kd increase.

11. Stop the VI by clicking on the Stop button.

QNET DC MOTOR Workbook - INSTRUCTOR v 2.0

© 2014 Quanser Inc., All rights reserved.

Quanser Inc.

119 Spy Court

Markham, Ontario

L3R 5H6

Canada

info@quanser.com

Phone: 1-905-940-3575

Fax: 1-905-940-3576

Printed in Markham, Ontario.

For more information on the solutions Quanser Inc. offers, please visit the web site at:

http://www.quanser.com

This document and the software described in it are provided subject to a license agreement. Neither the software nor this document may be

used or copied except as specified under the terms of that license agreement. Quanser Inc. grants the following rights: a) The right to reproduce

the work, to incorporate the work into one or more collections, and to reproduce the work as incorporated in the collections, b) to create and

reproduce adaptations provided reasonable steps are taken to clearly identify the changes that were made to the original work, c) to distribute

and publically perform the work including as incorporated in collections, and d) to distribute and publicly perform adaptations. The above rights

may be exercised in all media and formats whether now known or hereafter devised. These rights are granted subject to and limited by the

following restrictions: a) You may not exercise any of the rights granted to You in above in any manner that is primarily intended for or directed

toward commercial advantage or private monetary compensation, and b) You must keep intact all copyright notices for the Work and provide the

name Quanser Inc. for attribution. These restrictions may not be waved without express prior written permission of Quanser Inc.

QNET DC MOTOR Workbook - INSTRUCTOR 8

You might also like

- Speed Control of DC Motor Using Pid ControllerNo ratings yetSpeed Control of DC Motor Using Pid Controller20 pages

- P2 - DC Motor PI Control - Workshop PO - 2023No ratings yetP2 - DC Motor PI Control - Workshop PO - 20237 pages

- Lab 09 Speed Control of QNET DC Motor Using PI ControlNo ratings yetLab 09 Speed Control of QNET DC Motor Using PI Control4 pages

- To Observe The Effect of Controller On DC Motor To Control Its Speed and PositionNo ratings yetTo Observe The Effect of Controller On DC Motor To Control Its Speed and Position9 pages

- MECH 450 Lab Assignment 4 - Controlling DC Motor PositionNo ratings yetMECH 450 Lab Assignment 4 - Controlling DC Motor Position3 pages

- Experiment: AIM: Study D.C Position Control SystemNo ratings yetExperiment: AIM: Study D.C Position Control System23 pages

- Me2009 - Control System Technology Lab Assignment 4: Hochiminh City University of Technology Mechatronics DepartmentNo ratings yetMe2009 - Control System Technology Lab Assignment 4: Hochiminh City University of Technology Mechatronics Department10 pages

- Phase-Controlled DC Machines Drives: Components and ModelsNo ratings yetPhase-Controlled DC Machines Drives: Components and Models22 pages

- Time Response of A Second-Order DC Motor Unit Feedback SystemNo ratings yetTime Response of A Second-Order DC Motor Unit Feedback System6 pages

- Lab View Based Speed Control of DC Motor Using PID Controller-1582No ratings yetLab View Based Speed Control of DC Motor Using PID Controller-15826 pages

- Design of Control Systems: Case StudiesNo ratings yetDesign of Control Systems: Case Studies35 pages

- DC Motor Speed Control PID Implementation Simulink PDFNo ratings yetDC Motor Speed Control PID Implementation Simulink PDF12 pages

- Control Lab All Exp and Reports in Single PDF (Abdullah Ibn Mahmud)No ratings yetControl Lab All Exp and Reports in Single PDF (Abdullah Ibn Mahmud)183 pages

- Fundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsFrom EverandFundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsNo ratings yet

- Student Solutions Manual to Accompany Economic Dynamics in Discrete Time, secondeditionFrom EverandStudent Solutions Manual to Accompany Economic Dynamics in Discrete Time, secondedition4.5/5 (2)

- Handbook of Power Systems Engineering with Power Electronics ApplicationsFrom EverandHandbook of Power Systems Engineering with Power Electronics ApplicationsNo ratings yet

- Electric Pow Uality: Tutorial Lntro: G.T. Heydt Arizona Sfufe UniversityNo ratings yetElectric Pow Uality: Tutorial Lntro: G.T. Heydt Arizona Sfufe University5 pages

- Interaction of Neutrons: PNRA Course On Radiation Safety Dr. Muhammad Tufail (Izaz-i-Fazeelat) 1No ratings yetInteraction of Neutrons: PNRA Course On Radiation Safety Dr. Muhammad Tufail (Izaz-i-Fazeelat) 133 pages

- C.1 Simple Harmonic Motion Revision TeacherNo ratings yetC.1 Simple Harmonic Motion Revision Teacher42 pages

- Precalculus with Limits 3rd Edition Ron Larsoninstant download100% (1)Precalculus with Limits 3rd Edition Ron Larsoninstant download43 pages

- WEG Cfw500 Manual Do Usuario 10001278006 Manual Portugues BRNo ratings yetWEG Cfw500 Manual Do Usuario 10001278006 Manual Portugues BR150 pages

- Physics Experiment - Estimating The Wavelengths of Light Using A Plane Diffraction Grating100% (1)Physics Experiment - Estimating The Wavelengths of Light Using A Plane Diffraction Grating3 pages

- Cooling Performance IDAV0811A + CAT3001ECNo ratings yetCooling Performance IDAV0811A + CAT3001EC2 pages

- XE20-853U XE20-A0784: Steam Resistant Silicone ElastomerNo ratings yetXE20-853U XE20-A0784: Steam Resistant Silicone Elastomer2 pages

- Week 3 & 4. Chemical Equilibria in Solution. TitrationNo ratings yetWeek 3 & 4. Chemical Equilibria in Solution. Titration82 pages

- Product Certification and Declaration of ConformityNo ratings yetProduct Certification and Declaration of Conformity1 page

- Lab 09 Speed Control of QNET DC Motor Using PI ControlLab 09 Speed Control of QNET DC Motor Using PI Control

- To Observe The Effect of Controller On DC Motor To Control Its Speed and PositionTo Observe The Effect of Controller On DC Motor To Control Its Speed and Position

- MECH 450 Lab Assignment 4 - Controlling DC Motor PositionMECH 450 Lab Assignment 4 - Controlling DC Motor Position

- Experiment: AIM: Study D.C Position Control SystemExperiment: AIM: Study D.C Position Control System

- Me2009 - Control System Technology Lab Assignment 4: Hochiminh City University of Technology Mechatronics DepartmentMe2009 - Control System Technology Lab Assignment 4: Hochiminh City University of Technology Mechatronics Department

- Phase-Controlled DC Machines Drives: Components and ModelsPhase-Controlled DC Machines Drives: Components and Models

- Time Response of A Second-Order DC Motor Unit Feedback SystemTime Response of A Second-Order DC Motor Unit Feedback System

- Lab View Based Speed Control of DC Motor Using PID Controller-1582Lab View Based Speed Control of DC Motor Using PID Controller-1582

- DC Motor Speed Control PID Implementation Simulink PDFDC Motor Speed Control PID Implementation Simulink PDF

- Control Lab All Exp and Reports in Single PDF (Abdullah Ibn Mahmud)Control Lab All Exp and Reports in Single PDF (Abdullah Ibn Mahmud)

- Fundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsFrom EverandFundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level Systems

- Student Solutions Manual to Accompany Economic Dynamics in Discrete Time, secondeditionFrom EverandStudent Solutions Manual to Accompany Economic Dynamics in Discrete Time, secondedition

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13

- Handbook of Power Systems Engineering with Power Electronics ApplicationsFrom EverandHandbook of Power Systems Engineering with Power Electronics Applications

- Electric Pow Uality: Tutorial Lntro: G.T. Heydt Arizona Sfufe UniversityElectric Pow Uality: Tutorial Lntro: G.T. Heydt Arizona Sfufe University

- Interaction of Neutrons: PNRA Course On Radiation Safety Dr. Muhammad Tufail (Izaz-i-Fazeelat) 1Interaction of Neutrons: PNRA Course On Radiation Safety Dr. Muhammad Tufail (Izaz-i-Fazeelat) 1

- Precalculus with Limits 3rd Edition Ron Larsoninstant downloadPrecalculus with Limits 3rd Edition Ron Larsoninstant download

- WEG Cfw500 Manual Do Usuario 10001278006 Manual Portugues BRWEG Cfw500 Manual Do Usuario 10001278006 Manual Portugues BR

- Physics Experiment - Estimating The Wavelengths of Light Using A Plane Diffraction GratingPhysics Experiment - Estimating The Wavelengths of Light Using A Plane Diffraction Grating

- XE20-853U XE20-A0784: Steam Resistant Silicone ElastomerXE20-853U XE20-A0784: Steam Resistant Silicone Elastomer

- Week 3 & 4. Chemical Equilibria in Solution. TitrationWeek 3 & 4. Chemical Equilibria in Solution. Titration

- Product Certification and Declaration of ConformityProduct Certification and Declaration of Conformity