0 ratings0% found this document useful (0 votes)

12 viewsAdditol-Tpo TDS

Additol-Tpo TDS

Uploaded by

longThis document provides information on ADDITOL® TPO, a radical photoinitiator used in UV curing formulations. It undergoes a photochemical reaction when exposed to UV light to generate radicals that initiate polymerization. ADDITOL® TPO is characterized by low odor and volatility. It is commonly used at 0.5-2% in screen inks, white flexographic inks, white offset inks, thick clear coatings, and pigmented coatings. Precautions include storing it away from light and heat.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Additol-Tpo TDS

Additol-Tpo TDS

Uploaded by

long0 ratings0% found this document useful (0 votes)

12 views1 pageThis document provides information on ADDITOL® TPO, a radical photoinitiator used in UV curing formulations. It undergoes a photochemical reaction when exposed to UV light to generate radicals that initiate polymerization. ADDITOL® TPO is characterized by low odor and volatility. It is commonly used at 0.5-2% in screen inks, white flexographic inks, white offset inks, thick clear coatings, and pigmented coatings. Precautions include storing it away from light and heat.

Original Title

ADDITOL-TPO TDS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides information on ADDITOL® TPO, a radical photoinitiator used in UV curing formulations. It undergoes a photochemical reaction when exposed to UV light to generate radicals that initiate polymerization. ADDITOL® TPO is characterized by low odor and volatility. It is commonly used at 0.5-2% in screen inks, white flexographic inks, white offset inks, thick clear coatings, and pigmented coatings. Precautions include storing it away from light and heat.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

12 views1 pageAdditol-Tpo TDS

Additol-Tpo TDS

Uploaded by

longThis document provides information on ADDITOL® TPO, a radical photoinitiator used in UV curing formulations. It undergoes a photochemical reaction when exposed to UV light to generate radicals that initiate polymerization. ADDITOL® TPO is characterized by low odor and volatility. It is commonly used at 0.5-2% in screen inks, white flexographic inks, white offset inks, thick clear coatings, and pigmented coatings. Precautions include storing it away from light and heat.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

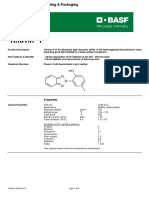

ADDITOL® TPO

Technical Datasheet

ALPHA CLEAVAGE PHOTO INITIATOR

INTRODUCTION TYPICAL PHYSICAL PROPERTIES

ADDITOL® TPO is a radical photoinitiator that can be used alone or in Volatiles ≤ 0.5%

combination with other photo initiators. It is used in formulations Molecular Weight 348

containing unsaturated materials such as acrylates, methacrylates, vinyls Extinction coefficients 296 nm: 8.864

and unsaturated polyesters. With exposure to UV light, ADDITOL® TPO (litres gram-1 cm-1) 380 nm: 1.566

undergoes a photochemical reaction that generates radicals. These

x

radicals will initiate polymerization through the unsaturated groups

present in the system.

ABSORPTION SPECTRUM

ADDITOL® TPO, due to its photo-bleaching properties, is particularly

suited for the UV curing of white pigmented formulations and thick clear

coatings. ADDITOL® TPO is frequently combined with other alpha

cleavage photo initiators such as ADDITOL® CPK and ADDITOL® HDMAP

for improved surface cure.

x

PERFORMANCE HIGHLIGHTS

ADDITOL® TPO is characterized by:

· Low odour

· Low volatility

UV curable formulated products containing ADDITOL® TPO are

characterized by:

· Low yellowing on UV cure

· Increased depth of cure

The final properties of UV cured products also depend on the selection

of other components such as oligomers, reactive diluents and additives.

x

SUGGESTED APPLICATIONS

ADDITOL® TPO is typically used at levels of 0.5 - 2% by weight based on

the reactive components of the formulation. Applications include:

· Screen inks, particularly white

· White flexographic inks x

· White offset inks

PRECAUTIONS

· Thick (~ 0.25 mm or greater) clear coatings

· Pigmented coatings, particularly white Before using ADDITOL® TPO, see the Safety Data Sheet (SDS) for

x

information on the identified hazards of the material and the

recommended personal protective equipment and procedures.

SPECIFICATIONS

x

Appearance Yellow powder STORAGE AND HANDLING

Melting point, °C 87 - 94

Purity, % min. 98 Store the material in a dry area out of direct sunlight. Prevent exposure

to any UV or visible light. Keep containers closed and protect from

physical damage.

See the SDS for the recommended storage temperature range for

ADDITOL® TPO.

version 2.0 Worldwide Contact Info: www.allnex.com Page 1/1

Disclaimer: allnex Group companies ('allnex') exclude all liability with respect to the use made by anyone of the information contained herein. The information contained herein represents allnex's best

knowledge but does not constitute any express or implied guarantee or warranty as to the accuracy, the completeness or relevance of the data set out herein. Nothing contained herein shall be construed as

conferring any license or right under any patent or other intellectual property rights of allnex or of any third party. The information relating to the products is given for information purposes only. No guarantee

or warranty is provided that the product and/or information is suitable for any specific use, performance or result. Any unauthorized use of the product or information may infringe the intellectual property

rights of allnex, including its patent rights. The user should perform his/her own tests to determine the suitability for a particular purpose. The final choice of use of a product and/or information as well as the

investigation of any possible violation of intellectual property rights or misappropriation of trade secrets of allnex and/or third parties remain the sole responsibility of the user.

Notice: Trademarks indicated with ® , TM or * as well as the allnex name and logo are registered, unregistered or pending trademarks of Allnex Netherlands B.V. or its directly or indirectly affiliated allnex Group

companies. ©2019 allnex Group. All Rights Reserved.

You might also like

- Sample Response To OADocument2 pagesSample Response To OAdhyne_619No ratings yet

- SAS Programming 2 Data Manipulation Techniques - Quizzes PDFDocument92 pagesSAS Programming 2 Data Manipulation Techniques - Quizzes PDFaugustocgn100% (1)

- TOGAF 9 Template - Architecture DefinitionDocument70 pagesTOGAF 9 Template - Architecture DefinitionAhmadNo ratings yet

- Scrappy PMDocument156 pagesScrappy PMTuan NguyenNo ratings yet

- e-STUDIO230-280-232-282-233-283 Service Manual V.10Document352 pagese-STUDIO230-280-232-282-233-283 Service Manual V.10kostas_san84% (19)

- Hytera PD40X VHF1&UHF1 Service Manual V00Document123 pagesHytera PD40X VHF1&UHF1 Service Manual V00A&A LABORATORIO100% (1)

- Trademark Application: Intellectual Property Office of The PhilippinesDocument2 pagesTrademark Application: Intellectual Property Office of The PhilippinesJude ItutudNo ratings yet

- Mutants & Masterminds 3e - Power Profile - Cosmic Powers PDFDocument6 pagesMutants & Masterminds 3e - Power Profile - Cosmic Powers PDFlolo197275% (4)

- KPMG Forensic Audit Report Concerning DeKalb County Purchasing and Procurement Policies and Procedures - March 25, 2008Document31 pagesKPMG Forensic Audit Report Concerning DeKalb County Purchasing and Procurement Policies and Procedures - March 25, 2008Viola Davis100% (2)

- Material Safety Data Sheet - LLDPEDocument6 pagesMaterial Safety Data Sheet - LLDPEमनोज चौधरीNo ratings yet

- 3M Particulate Respirators 8825 and 8835 - Datasheet - FVDocument2 pages3M Particulate Respirators 8825 and 8835 - Datasheet - FVkris1960No ratings yet

- Ca1101 TdsDocument2 pagesCa1101 TdsJosevi Jiménez MerinoNo ratings yet

- Material Safety Data Sheet - HDPEDocument6 pagesMaterial Safety Data Sheet - HDPEelbekhusanov19960114No ratings yet

- Safety Data Sheet: 1. IdentificationDocument10 pagesSafety Data Sheet: 1. IdentificationIsmael Enrique ArciniegasNo ratings yet

- Zytel FG101L NC010 SdsDocument7 pagesZytel FG101L NC010 SdsJustin GordonNo ratings yet

- Sds File-55749Document15 pagesSds File-55749Jhon SandovalNo ratings yet

- Material Safety Data Sheet - LLDPE PDFDocument6 pagesMaterial Safety Data Sheet - LLDPE PDFJihād MukhlisNo ratings yet

- Tergitol XD PDFDocument10 pagesTergitol XD PDFIsmael Enrique ArciniegasNo ratings yet

- Engineering Flourosilicone Elastomer: Description ApplicationDocument3 pagesEngineering Flourosilicone Elastomer: Description ApplicationLU CHUNHUINo ratings yet

- Adisorb UV 944Document3 pagesAdisorb UV 944jdiaz87No ratings yet

- LOCTITE ABLESTIK UV300X en - GLDocument2 pagesLOCTITE ABLESTIK UV300X en - GLФедя ИвановNo ratings yet

- Corian MsdsDocument6 pagesCorian MsdsDemetrios GkikasNo ratings yet

- Loctite 7386: Technical Data SheetDocument2 pagesLoctite 7386: Technical Data SheetIbrahim SamadNo ratings yet

- Eracure 100Document2 pagesEracure 100ZunisCanaNo ratings yet

- Tetrahydrofuran: Technical InformationDocument3 pagesTetrahydrofuran: Technical InformationNavieenNo ratings yet

- Plextol R 825 NDocument1 pagePlextol R 825 NmanojNo ratings yet

- Msds - Thinner CMP31 - Rev 1Document4 pagesMsds - Thinner CMP31 - Rev 1tiennv.blcmNo ratings yet

- Loctite SF 8046 en UsDocument2 pagesLoctite SF 8046 en UsEdu Ochoa ArceNo ratings yet

- Tomadol 25-7Document2 pagesTomadol 25-7manos makridakisNo ratings yet

- LOCTITE ECCOBOND UV 9052 en - GLDocument2 pagesLOCTITE ECCOBOND UV 9052 en - GLФедя ИвановNo ratings yet

- .Trashed 1725751992 CRC Contact CleanerDocument7 pages.Trashed 1725751992 CRC Contact CleanerSANINNo ratings yet

- Lotader: Ethylene - Acrylic Ester - Maleic Anhydride TerpolymerDocument2 pagesLotader: Ethylene - Acrylic Ester - Maleic Anhydride TerpolymerLe MinhNo ratings yet

- SDS (ZP4300) MSDSDocument8 pagesSDS (ZP4300) MSDSNisa SutopoNo ratings yet

- Material Safety Data Sheet: Prescription Treatment Brand 565 PLUS XLO Pressurized Contact Insecticide Formula 1Document2 pagesMaterial Safety Data Sheet: Prescription Treatment Brand 565 PLUS XLO Pressurized Contact Insecticide Formula 1BatanNo ratings yet

- Tinuvin 5248 October 2019 R3 ICDocument4 pagesTinuvin 5248 October 2019 R3 ICMarco EstradaNo ratings yet

- OLERIS N-HeptanolDocument2 pagesOLERIS N-HeptanolSnoopyNguyenNo ratings yet

- Z-004K-016-SJ SDS (English) of TPUC ControlDocument8 pagesZ-004K-016-SJ SDS (English) of TPUC Controlvikasverma90No ratings yet

- SDS Sarafil Polyester Film 2023Document4 pagesSDS Sarafil Polyester Film 2023Chiaranan KerdsamutNo ratings yet

- Hytrel Product Reference GuideDocument4 pagesHytrel Product Reference GuideashkansoheylNo ratings yet

- 3M MATERIAL SAFETY DATA SHEET 3M (TM) Transpore (TM) White Surgical Tape - 1534Document7 pages3M MATERIAL SAFETY DATA SHEET 3M (TM) Transpore (TM) White Surgical Tape - 1534Sri Wahyuni HandayaniNo ratings yet

- Z-004K-011-SJ SDS (English) of TPUC KitDocument8 pagesZ-004K-011-SJ SDS (English) of TPUC Kitvikasverma90No ratings yet

- Titanium Blank MSDSDocument5 pagesTitanium Blank MSDSRushikesh GhagNo ratings yet

- Desmodur N 75 BA/X: Aliphatic PolyisocyanateDocument2 pagesDesmodur N 75 BA/X: Aliphatic PolyisocyanateLê TiếnNo ratings yet

- DSA 2011 01590 - HEMPADUR ZINC 15343 DatasheetDocument2 pagesDSA 2011 01590 - HEMPADUR ZINC 15343 DatasheetMehedi HasanNo ratings yet

- Safety Data Sheet: 3M™ Polyurethane Protective Tape 8671, 8671HS and 8672Document8 pagesSafety Data Sheet: 3M™ Polyurethane Protective Tape 8671, 8671HS and 8672Oho My worldNo ratings yet

- 3 - 2 - 4 - Hdpe Blow 9 - B1258 Tasnee - MSDSDocument6 pages3 - 2 - 4 - Hdpe Blow 9 - B1258 Tasnee - MSDSSalman AhmedNo ratings yet

- Trulo Max MSDSDocument10 pagesTrulo Max MSDSdon2791No ratings yet

- SDS001 Polymer Microsphere Suspension enDocument12 pagesSDS001 Polymer Microsphere Suspension enCONFIRMACIÓN FACTURASNo ratings yet

- PRO-880-Ultra®-Clear-Strippable-Wallcovering-Adhesive_GHS_SDS_EnglishDocument8 pagesPRO-880-Ultra®-Clear-Strippable-Wallcovering-Adhesive_GHS_SDS_Englishtexajo2877No ratings yet

- Tinuvin P: Technical Data SheetDocument3 pagesTinuvin P: Technical Data SheetKhoa HuynhNo ratings yet

- Lowilite 22 TDSDocument2 pagesLowilite 22 TDSGİZEM DEMİRNo ratings yet

- LOCTITE ECCOBOND UV 9030 en - GLDocument2 pagesLOCTITE ECCOBOND UV 9030 en - GLФедя ИвановNo ratings yet

- TDS - Encor 2750 - 01-12Document2 pagesTDS - Encor 2750 - 01-12APEX SONNo ratings yet

- MTR Aghs enDocument16 pagesMTR Aghs enaboali8686No ratings yet

- Insert ECO-D 0108063354190c503 V6 enDocument1 pageInsert ECO-D 0108063354190c503 V6 enVegha NedyaNo ratings yet

- MediawebserverDocument8 pagesMediawebserverchetzpujaraNo ratings yet

- Loctite Solvo-Rust Super Penetrating Oil: Technical Data SheetDocument2 pagesLoctite Solvo-Rust Super Penetrating Oil: Technical Data SheetYAELNo ratings yet

- TDS - Trigonox L108P - Nouryon (EN)Document3 pagesTDS - Trigonox L108P - Nouryon (EN)OXY Composite TechNo ratings yet

- AEROTEX NMA LF Monomer - EN - LetterDocument1 pageAEROTEX NMA LF Monomer - EN - LetteryusepsetianaNo ratings yet

- 795 Gray English MSDSDocument17 pages795 Gray English MSDSEmran MiaNo ratings yet

- SGP53932Document7 pagesSGP53932simphiweNo ratings yet

- Preventol ® MP 100 IpDocument5 pagesPreventol ® MP 100 IpFadhli KusumaNo ratings yet

- Fluorosilicone Foam: Description ApplicationDocument2 pagesFluorosilicone Foam: Description ApplicationLU CHUNHUINo ratings yet

- Products 20151008144343 1104Document3 pagesProducts 20151008144343 1104wowCrazy DNo ratings yet

- AntiSkin BDocument3 pagesAntiSkin BLê TiếnNo ratings yet

- Polycor 944 enDocument3 pagesPolycor 944 enALEXANDER FRANCO CASTRILLONNo ratings yet

- Material Safety Data Sheet_PPDocument6 pagesMaterial Safety Data Sheet_PPhseinternalportoNo ratings yet

- Hybrid Electric & Alternative Automotive Propulsion: Low Carbon TechnologiesFrom EverandHybrid Electric & Alternative Automotive Propulsion: Low Carbon TechnologiesNo ratings yet

- DSM Metal 1Document17 pagesDSM Metal 1longNo ratings yet

- ACRYDIC_A-851-HPP_BASIC_ENDocument1 pageACRYDIC_A-851-HPP_BASIC_ENlongNo ratings yet

- ACRYDIC_WXU-880_BASIC_ENDocument1 pageACRYDIC_WXU-880_BASIC_ENlongNo ratings yet

- Setalux 1159 SS 55 - en - A4Document1 pageSetalux 1159 SS 55 - en - A4longNo ratings yet

- Setalux 1284 XX 70 - en - A4Document1 pageSetalux 1284 XX 70 - en - A4longNo ratings yet

- Ebecryl-8894 en A4Document1 pageEbecryl-8894 en A4longNo ratings yet

- 2023 05 Wax Additives ASIA EN Ccab91fb0aDocument24 pages2023 05 Wax Additives ASIA EN Ccab91fb0alongNo ratings yet

- 2019 2020 - Ipox Brochure ENDocument15 pages2019 2020 - Ipox Brochure ENlongNo ratings yet

- CX20671 ConexantDocument67 pagesCX20671 ConexantSocialBits TecnologiaNo ratings yet

- HC2021.C1.3 IBM Cristian Jacobi FinalDocument22 pagesHC2021.C1.3 IBM Cristian Jacobi FinalddscribeNo ratings yet

- Blu-Ray Disc™/ DVD Home Theatre System: Operating InstructionsDocument68 pagesBlu-Ray Disc™/ DVD Home Theatre System: Operating InstructionsGiorgio Frederich OlivierNo ratings yet

- 2018.06.20 Doc 1-15 Exh O To Complaint PDFDocument8 pages2018.06.20 Doc 1-15 Exh O To Complaint PDFJonathan SchwartzNo ratings yet

- Mba Strategic Planning 1Document6 pagesMba Strategic Planning 1Derrick SenyoNo ratings yet

- Tea Board of India Vs Itc Limited: Intellectual Property RightsDocument11 pagesTea Board of India Vs Itc Limited: Intellectual Property RightspriyaNo ratings yet

- Amd App SDK 3.0 Installation Notes: 1 OverviewDocument7 pagesAmd App SDK 3.0 Installation Notes: 1 Overviewpinaki_m771837No ratings yet

- Shangrila V Developers Trademark CaseDocument12 pagesShangrila V Developers Trademark CaseJorel Andrew FlautaNo ratings yet

- Faxb Intellectual Property LawDocument3 pagesFaxb Intellectual Property LawSharmila SubramanianNo ratings yet

- Inetvu Fly-1202 User Manual: The Inetvu Brand and Logo Are Registered Trademarks of C-Com Satellite Systems, IncDocument29 pagesInetvu Fly-1202 User Manual: The Inetvu Brand and Logo Are Registered Trademarks of C-Com Satellite Systems, IncDung, Hoang -VITECNo ratings yet

- Wood Elf PDFDocument3 pagesWood Elf PDFJose Uriel GarciaNo ratings yet

- Quantrix Modeler User GuideDocument434 pagesQuantrix Modeler User GuideddubyaNo ratings yet

- 6-67370-03 SN42101 UserGuide RevABDocument512 pages6-67370-03 SN42101 UserGuide RevABAvl SubbaraoNo ratings yet

- WHATMAN PRICE LIST 2024Document84 pagesWHATMAN PRICE LIST 2024sales.arohienterprises11No ratings yet

- San Miguel Vs FoodsphereDocument8 pagesSan Miguel Vs FoodsphereRobert QuiambaoNo ratings yet

- IP ROBLOX COPYRIGHT Complaint LolDocument63 pagesIP ROBLOX COPYRIGHT Complaint Lolrobloxrodri29No ratings yet

- The Siege of Durgam's FollyDocument42 pagesThe Siege of Durgam's FollyRafael CostaNo ratings yet

- Trademark and Consumer RightsDocument4 pagesTrademark and Consumer Rightsbanerjee97481No ratings yet

- Download Complete Project Management the Agile Way Making It Work in the Enterprise 2nd Edition PDF for All ChaptersDocument24 pagesDownload Complete Project Management the Agile Way Making It Work in the Enterprise 2nd Edition PDF for All Chaptersdukadadjamel100% (4)

- Adobe InDesign CS4 Porting GuideDocument52 pagesAdobe InDesign CS4 Porting GuidelaiscostayNo ratings yet

- Supreme Clear Sulfate Free Structured Conditioning ShampooDocument1 pageSupreme Clear Sulfate Free Structured Conditioning ShampooDaniel QuinteroNo ratings yet