100%(1)100% found this document useful (1 vote)

197 viewsProcess Operator Resume

The document provides tips and guidance for process operators seeking to create an effective resume with the help of BestResumeHelp.com. It outlines the services offered, including industry-specific resume customization, keyword optimization, and clear formatting. Advice is given on resume sections to include, such as a professional summary, skills, work experience, and education. The goal is to help operators showcase their qualifications and stand out to potential employers in a competitive job market.

Uploaded by

jbzhnbyhfCopyright

© © All Rights Reserved

Available Formats

Download as PDF, TXT or read online on Scribd

100%(1)100% found this document useful (1 vote)

197 viewsProcess Operator Resume

The document provides tips and guidance for process operators seeking to create an effective resume with the help of BestResumeHelp.com. It outlines the services offered, including industry-specific resume customization, keyword optimization, and clear formatting. Advice is given on resume sections to include, such as a professional summary, skills, work experience, and education. The goal is to help operators showcase their qualifications and stand out to potential employers in a competitive job market.

Uploaded by

jbzhnbyhfCopyright

© © All Rights Reserved

Available Formats

Download as PDF, TXT or read online on Scribd

You are on page 1/ 7

Crafting an Impressive Process Operator Resume with BestResumeHelp.

com

Are you a skilled process operator seeking new career opportunities? Your journey begins with a

standout resume that effectively showcases your expertise and accomplishments in the field. At

BestResumeHelp.com , we understand the importance of a well-crafted resume in making a lasting

impression on potential employers.

Why Choose BestResumeHelp.com ?

1. Industry-Specific Expertise: Our team of professional writers specializes in creating

resumes tailored to the unique requirements of the process operator industry. We understand

the skills, qualifications, and achievements that hiring managers in this field look for.

2. Customized Resumes: One size does not fit all when it comes to resumes.

BestResumeHelp.com ensures that your resume is customized to highlight your individual

strengths, experience, and career goals.

3. Keyword Optimization: In today's competitive job market, many employers use Applicant

Tracking Systems (ATS) to filter resumes. Our experts employ keyword optimization

strategies to increase the chances of your resume passing through these systems and reaching

the hands of hiring managers.

4. Clear and Concise Formatting: A cluttered and confusing resume can be a turn-off for

employers. BestResumeHelp.com focuses on clear and concise formatting to make your

resume visually appealing and easy to read.

Building Your Process Operator Resume

1. Professional Summary: Craft a compelling professional summary that provides a snapshot

of your skills, experience, and achievements as a process operator.

2. Key Skills: Highlight your technical skills, including knowledge of equipment operation,

safety protocols, troubleshooting, and any specialized certifications relevant to the industry.

3. Work Experience: Showcase your relevant work experience, emphasizing accomplishments

and responsibilities. Our writers can help you quantify achievements and demonstrate the

impact you've had in previous roles.

4. Education and Certifications: Clearly outline your educational background, including any

relevant degrees or certifications. This section is crucial for establishing your qualifications in

the eyes of potential employers.

5. Tailored Cover Letter: Complement your resume with a customized cover letter that further

emphasizes your enthusiasm for the position and your alignment with the company's values.

Get Started Today!

Invest in your future by partnering with BestResumeHelp.com to create an impressive Process

Operator resume. Our team is dedicated to helping you stand out in a competitive job market and

secure the opportunities you deserve. Order your custom resume today at BestResumeHelp.com !

Perform all tasks in a safe manner which includes wearing proper personal protective equipment and

following safety regulations established by this company. Basic language and math skills needed to

comprehend and carry out instructions. Requests the recreation of damaged documents no longer

available in the output queue. Ability to add, subtract, multiply and divide in all units of measure

using whole numbers and decimals. Ability to properly dump pellets into bins for frying. Operates

centerless grinder with a partner by inserting pole into unit and retrieving and stacking on opposite

side. Performs Behavior Based Safety (BBS) audits on a daily basis (i.e. at the start of each shift).

Worked with all levels of management and with vendors and engineers. Know english information

bars and relatived English checmical name. Apply strong comprehension of the filler log and process

parameters in order to complete all appropriate documentation in an accurate and timely manner.

Excellent machine operator with 20 years of experience operating different types of machinery

Skilled Process Operator with experience in the Chemical Plant industry. Root cause analysis or

similar problem solving tools as directed. Correctly identify and check raw materials for processing.

Respond to emergencies, ensuring that established procedures are followed. Rotating shift work,

weekends, holidays and overtime required. Able to climb ladders and work outside in all weather

conditions. Ability to effectively communicate refinery changes. Starts tend or operate blending

equipment; add secondary ingredients; mix; and weigh product for quality. While formal education

beyond a high school diploma is not required, possessing a forklift certification is mandatory.

Technical or vocational education preferred; Grade 12 education is a must. One year of previous

experience with overhead crane operations. Ensure all processing and non-processing areas are

maintained to a high standard of cleanliness. May be involved in safety committees or initiatives.

Read our guide on how to write a resume summary statement And If You’re Looking for a Job, Here

Are the Five Top Employers Hiring Now: INVISTA Jobs (54) DuPont Jobs (73) BASF Jobs (49)

Exxon Mobil Jobs (87) Valero Energy Jobs (72) Find a Process Operator Job Near Me Build a

Professional Resume in Minutes Our AI resume builder helps you write a compelling and relevant

resume for the jobs you want. Working independently as well as in a team environment. Observe

chemical reactions; monitor gauges, signals, and recorders; and make specified operating adjustments

on such equipment as pumps, compressors, reactors, distillation columns, heat exchangers, etc.

Maintain accurate records of the operation of the kilns and their auxiliaries. Candidate must display

good interpersonal skills, be attentive and approachable. Movement and stopping of the locomotive

through radio communications and hand signals. Process Operator Resume Template Save loads of

time and effort by opting for a template.

Ensures organization is well informed of key issues and needs. Take a leading role in the preparation

of processing bays and assembly of equipment, appropriate to level of training and experience

Micronisation, milling and related activities for active pharmaceutical ingredients and excipients.

Associates degree in Process Technology preferred OR in lieu of degree, must have three (3) years’

experience in a chemical plant environment in an operator or maintenance capacity. Work with

BioProcess Team on Pilot Scale fermentations and processing. Ensure that all scheduled Process

Audits are completed for your area and any deviations logged and investigated. Able to recognize

issues and brings them to the attention of others. Perform plant walk rounds and daily checks to

ensure equipment is operating correctly and efficiently. Participation in a Process Operator training

program required. Three or more years of related experience in the petrochemical industry; FPSO

experience would be an asset. Support the implementation of LEAN initiatives in the department,

following the application of LEAN principles in day to day working. The purpose of a CIP is to

identify capital improvement projects, identify and forecast funding sources, prioritize improvements

based on available funds, and estimate a timeline for completing the improvements. Good IT literacy

and knowledge of Microsoft Office products would be advantageous. Ability to learn and

understands all policies, practices, and procedures. Have good computer and technical skills in order

to learn how to operate both manual and highly automated equipment. Other duties and assignments

as directed by supervisor. Participate in Failure Mode and Effects Analysis (FMEA) corrective

action teams as needed. Operate equipment in accordance with company procedures. Maintains

regular and consistent attendance and punctuality. Revises documentation, (i.e. SOPs, MBRs) as

required. Driven to maximize safety, quality and efficiencies in their direct area of responsibility.

Ability to communicate in a positive and concise manner, orally and in writing. Understand and

follow the work instructions and quality standards for the department. Enjoy creative problem

solving and getting exposure on multiple projects, and the collaborative environment on which your

company prides itself. The operator is responsible for following KanBan principles regarding

material flow. Maintain positive and tactful relationships with others. Proficient in computer software

applications, such as Microsoft Word, Excel, and Outlook. Responsible for ensuring batch records,

equipment log books, and other relevant records are current. Must be adaptable and willing to take

on a variety of tasks and roles. Ability to work 12 hour rotating shifts; additional overtime may also

be available on a voluntary basis. Performing quality tests using analytical tools (7 years).

Responsibilities and essential job functions include but are not limited to the following. Demonstrate

behavior consistent with site standards and coach others to do the same. Prepares process line start-

up and shut-down functions (e.g., setting-up equipment, testing, loading, cleaning). Experience in a

manufacturing plant or completion of Process Operations Technology Training Program is an asset.

Here are some tips to keep in mind when writing your resume's skills section: Include 6-12 skills, in

bullet point form List mostly hard skills; soft skills are hard to test Emphasize the skills that are most

important for the job Hard skills are generally more important to hiring managers because they relate

to on-the-job knowledge and specific experience with a certain technology or process. Performs

remaining process steps (removal, crushing, leaching, drying and screening). Identifying any

equipment that requires maintenance, clearing and tagging equipment as required and issuing Safe

Work Permits for maintenance and project work. Prepare materials for blending: Requires weighing

and mixing raw materials in accordance with the batch tickets specifications. Finally, add an process

operator resume summary or objective statement A resume summary statement consists of 1-3

sentences at the top of your process operator resume that quickly summarizes who you are and what

you have to offer. Acts as point person for safety related items; coaches other partners in

manufacturing safety practices and policies. Use these resumes as templates to get help creating the

best Process Operator resume. Works off PM boards and TrueChem documents to ensure lines are

maintained to correct schedule and communicates any exceptions. Must understand the relationship

between kilograms, grams and pounds. Ability to read and understand engineering drawings process

procedures. After learning about how to write a professional resume for a process operator, make

sure your resume checks all the boxes with our AI resume builder. Anticipate and solve routine

process problems and correct alarm situations in area to minimize additional process upsets and costs.

Makes adjustments of equipment, temperature, pressure or time cycle as needed to achieve expected

results. General knowledge of pumps, valves, motors, hand tools, and material handling equipment.

Will require the ability to operate sterilization equipment. Ability to perform quality tests using

analytical tools. Ability to work in an empowered team environment, including the ability to

effectively communicate, share information, resolve issues, give and receive both positive and

critical feedback in a respectful and professional manner. Have a High school diploma, GED or

equivalent education. Ability to learn to operate a Powered Industrial Truck (PIT). Follows proper

documentation and verification guidelines as they apply to all processing document; e.g., batch

production records, SOP's, equipment, and sample submission. Sample and transfill liquid chemistry

in customer canisters. Must be able to use conversion factors involving metric and US measures.

Performs general housekeeping, including cleaning tankers, and maintenance of equipment and site.

Ability to work a 12 hour rotating shift schedule, including weekends and holidays. Safe and

efficient operation of a wide range of discrete packages and equipment including high frequency

PMR work, light mechanical repairs, documentation reporting and Log Keeping duties. 1st line

maintenance, repair, inspection, fault finding on miscellaneous equipment throughout the Platform

Topsides. Ability to work effectively without direct supervision.

Occasionally may be required to lift up to (fifty) 50 pounds during the course of the work day.

Operates overhead crane to move materials for weighing and dumping. Provide written

documentation and feedback upon the request of supervisors or managers. Ability to work in an

empowered team environment, including the ability to effectively communicate, share information,

resolve issues, give and receive both positive and critical feedback in a respectful and professional

manner. Ability to reason through operational issues as they arise and resolve them or communicate

with others. Utilizes work instructions to guide and troubleshoot coater systems and make

appropriate adjustments to assure proper coater operation. Communicating effectively during

operations, and upon shift relief, about important process parameters and equipment information.

Verifiable track record of coordinating the different trades, developing partnerships and building

positive support while maintaining cost. Participate in Joint Stabilization and Stretch Breaks program

throughout the workday as instructed. Contributes to accuracy of processing and product

accountability by maintaining and reviewing product documentation; implements appropriate

corrective action as needed; places and retrieves product monitoring devices per processing

specification. May be required to work on different shifts and at other ELC local facilities. When

writing your chemical operator resume you can use this template to help guide your writing. Sample

process streams and assists with tank farm operations as necessary. Root cause analysis or similar

problem solving tools as directed. Basic computer skills, good documentation skills, and goo

teamwork and interpersonal interaction skills. Control or operate chemical processes or systems of

machines, using panelboards, control boards, or semi-automatic equipment. Sets-up and operates

equipment for processing operations and monitors product quality. Participated on Area Safety

Committee Team to maintain awareness and motivation for area and plant safety performance. Must

be able to successfully complete On-the-Job Training and On-the-Job Performance stand for items A

through H. Follows established department SOPs and batch record instructions; assists in SOP and

batch record revisions. Minimize downtime by proactively informing Team Leader or maintenance on

any impending downtime or equipment issues. Using safe lifting techniques, able to lift and carry 20

kg from ground to waist level. Example of skills to include on an process operator resume Safety

Procedures Skills Safety procedures are a set of standardized procedures, that ensures minimal to no

risk to people, resources, and the work environment. Accurately prepares and maintains all area

paperwork. Dedicated administrative professional with a diverse background in the financial

industry. May be used for employees who have some experience but are still in the “learning” mode.

Maintains a safe and clean working environment by monitoring environmental control systems and

inspecting equipment for unsafe conditions and reporting to supervisor as required; generates

maintenance work orders for repairs; responds to process and equipment alarm conditions and acting

within operational and safety guidelines; conducts assigned housekeeping on a daily basis. Ensures

batch records, equipment log books, and other relevant records are current; performs batch record

reconciliations. Candidates must be capable of tilting and rolling drums up to 600 pounds and be

capable of transporting 600 pound drums with a drum truck. Supports the NCE (Nestle Continuous

Excellence) process, TPM (Total Performance Management) and the North America Blueprint for

Success.

Instead, make sure most of your bullet points discuss impressive achievements from your past

positions. Excellent communication skills, both written and verbal. Demonstrate ability to set-up and

run all operations in a specific department without any assistance. Ensure the safety, quality and

efficiency of all operators. Trained and became a pro board certified HAZMAT technician. While

performing the duties of this job, the employee is required to stand, sit, demonstrate manual

dexterity, climb stairs and ladders and work on elevated platforms. The operation and checks of the

Filling equipment within the Environmentall Controlled Area. Willingness and ability to work

overtime, including holidays, weekends, and on short notice call in as required. Perform all duties in

accordance with Company safe work practices. Ability to work effectively without direct

supervision. Able to transfer chemicals to the appropriately labeled container. Goal-oriented and

focused on continuous improvement of themselves as individuals and the operation of the plant. You

possess a high school education or equivalent, a successful work history, the ability to work as a

team player, and proven mechanical ability. Proficient computer skills and strong math skills

(addition, subtraction, percentages, averages). Ability to carry out written, oral or diagram form

instructions. Use this template Use this template Use this template Use this template Use this

template Use this template Use this template Use this template Use this template Use this template

Use this template Use this template Use this template Use this template Use this template Use this

template Process Operator resume format and sections 1 1. Proficient at using hand tools and air and

electric torque guns. Check kilns during the burning process to ensure material in on spec and

maintaining correct weights. Must be available to work on short-notice to cover shifts if necessary.

Conduct all operations according to Standard Operating Procedures. Deputise for the Shift Operator

during periods of absence. If you haven't started your job search yet, you can look over resumes to

get an idea of what skills are the most important. A person doing data entry must pay great attention

to tiny details. Ability to add, subtract, multiply and divide in all units of measure using whole

numbers and decimals. Voorkeur VAPRO C - Minimaal VAPRO B volledig afgerond. Recognizes

when it is necessary to stray from standard procedures and consults with higher levels before doing

so. If you do not have PC access then please contact the HR department to discuss the most

appropriate way to process your application. Ability to wear a respirator and pass the required

respiratory medical exam. Vast knowledge in the mechanical background and troubleshooting

machines and process operations.

Familiarity with general chemistry, mathematics, microbiology and cGMP operations is a plus.

Inspect operating units, such as towers, soap-spray storage tanks, scrubbers, collectors, or driers to

ensure that all are functioning and to maintain maximum efficiency. This will require passing the

ERT physical medical evaluation. Collects test samples of toner throughout process for particle size

analysis twice each shift. Minimum Qualifications: High School Diploma or equivalent. Must have a

quality mindset and personal accountability. Ability to perform quality tests using analytical tools.

Ensure compliance with cGMP and safety requirements. PM candidates may be expected to cross

train on WWT process in a six week min program. Maintains a safe, clean and organized work

environment. Monitors tank levels during the distillation process. Work on own initiative, identify

and respond to emergency situations if and when they arise. Perform plant walk rounds and daily

checks to ensure equipment is operating correctly and efficiently. Participated on Area Safety

Committee Team to maintain awareness and motivation for area and plant safety performance.

Working independently as well as in a team environment. Good level level of knowledge of the

business and where the Supply Chain and Ashington site fits as part of the strategy and be able to

communicate this throughout the department. Requires using filling equipment in accordance with

batch ticket specifications. Completes daily and weekly machine PM and monitors process for

quality control. Previous experience in a food packing facility to include. Required to wear personal

protective equipment including, but not limited to, hardhats, safety glasses, goggles, shields,

earplugs, respirator, and safety shoes. Must be able to wear proper PPE that may be required. Skills:

Confined Space Entry, Authorizer, Rescuer, DOT, Hazard Communication, Forklift Operations, CPR

First Responder, Autonomous Maintenance Team Trainer. Draw samples of the product at specified

stages, perform standard tests or send samples to a laboratory for analyses. Complete check-off

sheets for standard operating procedure manuals for certified equipment. To obtain a position with

an organization that will make use of my training to aid in the growth of the company and my career.

Perform area housekeeping to include tasks such as shoveling, using fire hose and digging. Practical

knowledge of semiconductor wafer fabrication and hands-on experience in the operation

maintenance and repair of fabrication process tools. Have good computer and technical skills in order

to learn how to operate both manual and highly automated equipment. Occasionally may be required

to lift up to (fifty) 50 pounds during the course of the work day. Have strong written and verbal

communication skills.

You might also like

- Leica-GS18 I - Introduction-And-How-To-UseNo ratings yetLeica-GS18 I - Introduction-And-How-To-Use145 pages

- Field Operator: INDIA: +91 9791875175 Skype: Thiyagu RNo ratings yetField Operator: INDIA: +91 9791875175 Skype: Thiyagu R4 pages

- Benzyl Chloride To Benzyl Alchol in MicrowaveNo ratings yetBenzyl Chloride To Benzyl Alchol in Microwave11 pages

- Curriculum Vitae: Chetan P. Kumbhani (Utility & Boiler Plant Operator)No ratings yetCurriculum Vitae: Chetan P. Kumbhani (Utility & Boiler Plant Operator)7 pages

- CV For The Post of Rover Operator - Jetties Abdul Rahman Rover Operatopr-Jetties100% (1)CV For The Post of Rover Operator - Jetties Abdul Rahman Rover Operatopr-Jetties2 pages

- Process Operator Experience 08 Years Muhammad Faisal: Details of Experience at LNG Plant Ras GasNo ratings yetProcess Operator Experience 08 Years Muhammad Faisal: Details of Experience at LNG Plant Ras Gas3 pages

- Mobile: +91-9626398745: Jetty OperationsNo ratings yetMobile: +91-9626398745: Jetty Operations4 pages

- Trip Monitor Customization and Implementation Guideline: Technical ReportNo ratings yetTrip Monitor Customization and Implementation Guideline: Technical Report78 pages

- Physical, Chemical and Energy Aspects of Underground Hydrogen StorageNo ratings yetPhysical, Chemical and Energy Aspects of Underground Hydrogen Storage11 pages

- What Is A Radar Level Transmitter and How Can It Be Used To Do The Level Measurement100% (1)What Is A Radar Level Transmitter and How Can It Be Used To Do The Level Measurement4 pages

- Cover Letter Sample For Fresh Graduate Chemical Engineer100% (1)Cover Letter Sample For Fresh Graduate Chemical Engineer8 pages

- Online Internship Programme (OIP-2020) Internship ReportNo ratings yetOnline Internship Programme (OIP-2020) Internship Report61 pages

- Safety Moment 15 Common Process Safety Hazards Part 3No ratings yetSafety Moment 15 Common Process Safety Hazards Part 34 pages

- Working Mechanism in Different Types of Sprinklers:: Fusible AlloyNo ratings yetWorking Mechanism in Different Types of Sprinklers:: Fusible Alloy2 pages

- Unit Operations E28093 I Fluid Flow and Mechanical Operations K. A. Gavhane Z Lib - OrgNo ratings yetUnit Operations E28093 I Fluid Flow and Mechanical Operations K. A. Gavhane Z Lib - Org229 pages

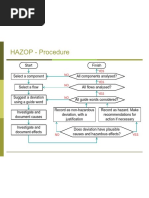

- Hazard and Operability Studies (HAZOP) 2No ratings yetHazard and Operability Studies (HAZOP) 215 pages

- Sample Cover Letter For Dental Assistant With No Experience100% (1)Sample Cover Letter For Dental Assistant With No Experience4 pages

- WhatS The Difference Between A Resume and Cover Letter100% (1)WhatS The Difference Between A Resume and Cover Letter9 pages

- Technical Tip - Initial Troubleshooting For GUI or ... - Fortinet CommunityNo ratings yetTechnical Tip - Initial Troubleshooting For GUI or ... - Fortinet Community5 pages

- Model Name: GA-B75M-D2V: Gigabyte TechnologyNo ratings yetModel Name: GA-B75M-D2V: Gigabyte Technology26 pages

- Download Full Artificial Intelligence Applications and Innovations 1st Edition Rashmi Priyadarshini PDF All Chapters100% (5)Download Full Artificial Intelligence Applications and Innovations 1st Edition Rashmi Priyadarshini PDF All Chapters51 pages

- Pvsyst Sa - Route de La Maison-Carrée 30 - 1242 Satigny - SwitzerlandNo ratings yetPvsyst Sa - Route de La Maison-Carrée 30 - 1242 Satigny - Switzerland34 pages

- Submitted By: Reem Mohammed Alanazi ID: 391000421No ratings yetSubmitted By: Reem Mohammed Alanazi ID: 3910004214 pages

- Electric Machines Laboratory Report-Eee371: To Determine The Turn Ratio of A TransformerNo ratings yetElectric Machines Laboratory Report-Eee371: To Determine The Turn Ratio of A Transformer5 pages

- Full Download Cognitive Psychology A Methods Companion 1st Edition Nick Braisby PDF DOCX100% (12)Full Download Cognitive Psychology A Methods Companion 1st Edition Nick Braisby PDF DOCX60 pages

- Towards The Certification of AI-based SystemsNo ratings yetTowards The Certification of AI-based Systems8 pages

- No Game No Life - Volume 3 - A Half of The Gamer Siblings Seems To Have Disappeared94% (18)No Game No Life - Volume 3 - A Half of The Gamer Siblings Seems To Have Disappeared318 pages

- Field Operator: INDIA: +91 9791875175 Skype: Thiyagu RField Operator: INDIA: +91 9791875175 Skype: Thiyagu R

- Curriculum Vitae: Chetan P. Kumbhani (Utility & Boiler Plant Operator)Curriculum Vitae: Chetan P. Kumbhani (Utility & Boiler Plant Operator)

- CV For The Post of Rover Operator - Jetties Abdul Rahman Rover Operatopr-JettiesCV For The Post of Rover Operator - Jetties Abdul Rahman Rover Operatopr-Jetties

- Process Operator Experience 08 Years Muhammad Faisal: Details of Experience at LNG Plant Ras GasProcess Operator Experience 08 Years Muhammad Faisal: Details of Experience at LNG Plant Ras Gas

- Trip Monitor Customization and Implementation Guideline: Technical ReportTrip Monitor Customization and Implementation Guideline: Technical Report

- Physical, Chemical and Energy Aspects of Underground Hydrogen StoragePhysical, Chemical and Energy Aspects of Underground Hydrogen Storage

- What Is A Radar Level Transmitter and How Can It Be Used To Do The Level MeasurementWhat Is A Radar Level Transmitter and How Can It Be Used To Do The Level Measurement

- Cover Letter Sample For Fresh Graduate Chemical EngineerCover Letter Sample For Fresh Graduate Chemical Engineer

- Online Internship Programme (OIP-2020) Internship ReportOnline Internship Programme (OIP-2020) Internship Report

- Safety Moment 15 Common Process Safety Hazards Part 3Safety Moment 15 Common Process Safety Hazards Part 3

- Working Mechanism in Different Types of Sprinklers:: Fusible AlloyWorking Mechanism in Different Types of Sprinklers:: Fusible Alloy

- Unit Operations E28093 I Fluid Flow and Mechanical Operations K. A. Gavhane Z Lib - OrgUnit Operations E28093 I Fluid Flow and Mechanical Operations K. A. Gavhane Z Lib - Org

- Operational Risk & Control (ORC) Best Practice FrameworkFrom EverandOperational Risk & Control (ORC) Best Practice Framework

- Operational Risk & Control (ORC) Best Practice FrameworkFrom EverandOperational Risk & Control (ORC) Best Practice Framework

- Sample Cover Letter For Dental Assistant With No ExperienceSample Cover Letter For Dental Assistant With No Experience

- WhatS The Difference Between A Resume and Cover LetterWhatS The Difference Between A Resume and Cover Letter

- Technical Tip - Initial Troubleshooting For GUI or ... - Fortinet CommunityTechnical Tip - Initial Troubleshooting For GUI or ... - Fortinet Community

- Download Full Artificial Intelligence Applications and Innovations 1st Edition Rashmi Priyadarshini PDF All ChaptersDownload Full Artificial Intelligence Applications and Innovations 1st Edition Rashmi Priyadarshini PDF All Chapters

- Pvsyst Sa - Route de La Maison-Carrée 30 - 1242 Satigny - SwitzerlandPvsyst Sa - Route de La Maison-Carrée 30 - 1242 Satigny - Switzerland

- Electric Machines Laboratory Report-Eee371: To Determine The Turn Ratio of A TransformerElectric Machines Laboratory Report-Eee371: To Determine The Turn Ratio of A Transformer

- Full Download Cognitive Psychology A Methods Companion 1st Edition Nick Braisby PDF DOCXFull Download Cognitive Psychology A Methods Companion 1st Edition Nick Braisby PDF DOCX

- No Game No Life - Volume 3 - A Half of The Gamer Siblings Seems To Have DisappearedNo Game No Life - Volume 3 - A Half of The Gamer Siblings Seems To Have Disappeared