LLDPE-218BJ Edit

LLDPE-218BJ Edit

Uploaded by

Chu ChuCopyright:

Available Formats

LLDPE-218BJ Edit

LLDPE-218BJ Edit

Uploaded by

Chu ChuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

LLDPE-218BJ Edit

LLDPE-218BJ Edit

Uploaded by

Chu ChuCopyright:

Available Formats

SABIC® LLDPE 218BJ

LINEAR LOW DENSITY POLYETHYLENE

DESCRIPTION

SABIC® LLDPE 218BJ is a butene linear low density polyethylene resin with an additive package typically designed for a

broader range of food applications (TNPP free). The good thermal stability allows to use the resin in critical extrusion

processing conditions. Films produced from SABIC® LLDPE 218BJ have better draw-down ability compared to lower MFR

LLDPE resins. This product is not intended for and must not be used in any pharmaceutical/medical applications.

TYPICAL APPLICATIONS

SABIC® LLDPE 218BJ is typically used for food applications (lamination film, barrier film), melt embossed films, but can also

be used in industrial packaging such as cling film and stretch film for manual and pallet wrap. It can also be used as a

blending partner with other SABIC® PE resins in general-purpose blown and cast film applications.

TYPICAL PROPERTY VALUES Revision 20170913

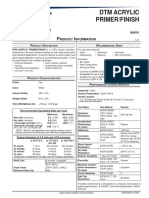

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

POLYMER PROPERTIES

Melt Flow Rate

at 190 °C and 2.16 kg 2.0 dg/min ISO 1133

Density 918 kg/m³ ASTM D1505

DSC

melting point 122 °C SABIC method

MECHANICAL PROPERTIES

Tensile test

stress at break 17 MPa ASTM D638

stress at yield 12 MPa ASTM D638

strain at yield 16 % ASTM D638

strain at break 790 % ASTM D638

Flexural test

Secant modulus at 1% elongation 254 MPa ASTM D790

Hardness Shore D 48 - ISO 868

OPTICAL PROPERTIES (1)

Gloss (45°) 92 ‰ ASTM D2457

Haze 1.2 % ASTM D1003

FILM PROPERTIES (1)

Dart impact 2.8 kJ/m ISO 7765-2

Tear strength TD 185 kN/m ISO 6383-2

© 2017 Copyright by SABIC. All rights reserved

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

Protrusion Puncture resistance 2.2 J ASTM D5748-95

Elastic recovery & Stress retention

Elastic recovery 52.6 % ASTM D5459-95

Stress retention 80 % ASTM D5459-95

Peel cling

0% pre-stretch 0.06 N/mm ASTM D5458-95

200% pre-stretch 0.05 N/mm ASTM D5458-95

THERMAL PROPERTIES

Vicat Softening Temperature

at 10 N (VST/A) 96 °C ISO 306

DSC test

melting point 122 °C SABIC method

HIGHLIGHT PROPERTIES

Ultimate pre-stretch level 310 % -

Retention force at 60 sec 0.97 kg -

ELECTRICAL PROPERTIES

Volume resistivity 5.0E15 Ohm.cm ASTM D257

Dissipation factor at 60 Hz 1.0E3 - ASTM D150

Dielectric constant at 60 Hz 2.17 - ASTM D150

Dielectric strength at 500 V/sec 55 V/µm ASTM D149

(1) Properties have been measured by producing 30 μm film with 2.5 BUR using 100% 218BJ.

PROCESSING CONDITIONS

Typical processing conditions for 218BJ are:

Melt temperature: 250 - 300°C

Chill roll temperature: 20°C

HEALTH, SAFETY AND FOOD CONTACT REGULATIONS

218BJ resin is suitable for Food contact application. Detailed information is provided in relevant Material Safety Datasheet

and for additional specific information please contact SABIC local representative for certificate.

DISCLAIMER: This product is not intended for and must not be used in any pharmaceutical/medical applications.

QUALITY

SABIC® Europe is fully certified in accordance with the internationally accepted quality standard ISO 9001.

© 2017 Copyright by SABIC. All rights reserved

ENVIRONMENT AND RECYCLING

The environmental aspects of any packaging material do not only imply waste issues but have to be considered in relation

with the use of natural resources, the preservations of foodstuffs, etc. SABIC Europe considers polyethylene to be an

environmentally efficient packaging material. Its low specific energy consumption and insignificant emissions to air and water

designate polyethylene as the ecological alternative in comparison with the traditional packaging materials. Recycling of

packaging materials is supported by SABIC Europe whenever ecological and social benefits are achieved and where a social

infrastructure for selective collecting and sorting of packaging is fostered. Whenever 'thermal' recycling of packaging (i.e.

incineration with energy recovery) is carried out, polyethylene -with its fairly simple molecular structure and low amount of

additives- is considered to be a trouble-free fuel.

STORAGE AND HANDLING

Polyethylene resin should be stored in a manner to prevent a direct exposure to sunlight and/or heat. The storage area should

also be dry and preferably do not exceed 50°C. SABIC would not give warranty to bad storage conditions, which may lead to

quality deterioration such as color change, bad smell and inadequate product performance. It is advisable to process PE resin

within 6 months after delivery.

DISCLAIMER

Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale

(available upon request) unless agreed otherwise in writing and signed on behalf of the seller. While the information contained herein

is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND

NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT

TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY

APPLICATION. Each customer must determine the suitability of seller materials for the customer’s particular use through appropriate

testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be

construed, to grant any license under any patent or other intellectual property right.

© 2017 Copyright by SABIC. All rights reserved

You might also like

- SDS PP T03 LogoDocument5 pagesSDS PP T03 LogoChu ChuNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- Sintering. Mechanisims of Convention Nanodensification and Fiels Assisted Processes. Castro BenthemDocument245 pagesSintering. Mechanisims of Convention Nanodensification and Fiels Assisted Processes. Castro Benthemceliamr42100% (1)

- Wettability and Capillary PressureDocument39 pagesWettability and Capillary PressureJames BourneNo ratings yet

- Vacuum Process Casting (V-Process)Document11 pagesVacuum Process Casting (V-Process)Gurudutta MishraNo ratings yet

- Sabic® Ldpe 2201H0Document2 pagesSabic® Ldpe 2201H0Berkosan BalkansNo ratings yet

- SABIC® PP - 5271K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 5271K - Global - Technical - Data - SheetjituniNo ratings yet

- SABIC® PP - 528K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 528K - Global - Technical - Data - SheetjituniNo ratings yet

- SABIC® LLDPE - 118WJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 118WJ - Global - Technical - Data - Sheetsysp92yybvNo ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- Sabic Fortify C5070D TDSDocument2 pagesSabic Fortify C5070D TDSmiya079127No ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- SABIC_320BJ (1)Document2 pagesSABIC_320BJ (1)ahmetogut77No ratings yet

- SABIC® HDPE - C0549 - GlobalDocument2 pagesSABIC® HDPE - C0549 - Globaltechnical kmiNo ratings yet

- SABIC® LLDPE - 218WJA - Americas - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 218WJA - Americas - Technical - Data - Sheetdiana sarmientoNo ratings yet

- SABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetJosiola MariledoNo ratings yet

- SABIC® HDPE P5616N Global Technical Data Sheet-3Document1 pageSABIC® HDPE P5616N Global Technical Data Sheet-3Amit VermaNo ratings yet

- SABIC® PP - 513MN40 - Global - Technical - Data - SheetDocument2 pagesSABIC® PP - 513MN40 - Global - Technical - Data - SheetmeshaktimanNo ratings yet

- Sabic 37MK10Document2 pagesSabic 37MK10Chu ChuNo ratings yet

- SABIC® HDPE - P6006NA - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - P6006NA - Global - Technical - Data - SheetAnel MasloNo ratings yet

- SABIC® LLDPE_M200024_Asia_Technical_Data_SheetDocument2 pagesSABIC® LLDPE_M200024_Asia_Technical_Data_Sheetehabdasoky77No ratings yet

- Sabic - Sabic® Hdpe CC453 PDFDocument4 pagesSabic - Sabic® Hdpe CC453 PDFquangga10091986No ratings yet

- Pmma 20HRDocument2 pagesPmma 20HRChu ChuNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- NG30-02JBK - Next PolymersDocument4 pagesNG30-02JBK - Next PolymersdigiarkanandNo ratings yet

- Sabic PP Raffia 3 Mfi 500pDocument2 pagesSabic PP Raffia 3 Mfi 500pArab Circle tallyNo ratings yet

- Hdi0653u1 Enus AstmDocument1 pageHdi0653u1 Enus AstmJonathan GuadarramaNo ratings yet

- SABIC® PP - QR6711K - Global - Technical - Data - SheetDocument2 pagesSABIC® PP - QR6711K - Global - Technical - Data - SheetMahaNo ratings yet

- SABIC® PP COPO - 412MK49 (MFR 45 DG - Min 2.16 KG)Document2 pagesSABIC® PP COPO - 412MK49 (MFR 45 DG - Min 2.16 KG)yang chinaNo ratings yet

- SABIC® PP - 312MK40 - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 312MK40 - Global - Technical - Data - SheetSayed RehanNo ratings yet

- SABIC® HDPE_M80064S_Global_Technical_Data_SheetDocument2 pagesSABIC® HDPE_M80064S_Global_Technical_Data_Sheetprojet.injection.palettesNo ratings yet

- خامة 952 سابكdownloadfileDocument2 pagesخامة 952 سابكdownloadfileengsayedhanfymahNo ratings yet

- SABIC® LLDPE - MG500026 - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - MG500026 - Global - Technical - Data - Sheetabhimanyu.xplastNo ratings yet

- Mdpe 3305MQDocument2 pagesMdpe 3305MQHữu LộcNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- SABIC® HDPE - B1254 - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - B1254 - Global - Technical - Data - SheetnishantNo ratings yet

- Datasheet - r680s - Randompp - e 3Document2 pagesDatasheet - r680s - Randompp - e 3Gulzar HossainNo ratings yet

- SABIC® HDPE - M80063S - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - M80063S - Global - Technical - Data - SheetJucy ANo ratings yet

- SABIC® LLDPE - 118NJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 118NJ - Global - Technical - Data - SheetgavintiandyNo ratings yet

- SABIC® PP - 412MK49 - Global - Technical - Data - SheetDocument2 pagesSABIC® PP - 412MK49 - Global - Technical - Data - SheetMahaNo ratings yet

- Enable™ 4002MC Blown: Performance PolymerDocument2 pagesEnable™ 4002MC Blown: Performance PolymerCristian RodriguezNo ratings yet

- 400 00285139en Innate st50 Precision Packaging Resin TdsDocument3 pages400 00285139en Innate st50 Precision Packaging Resin Tdsteguh.budi.uNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- LL70600 Technical Data Sheet 20240227112619Document1 pageLL70600 Technical Data Sheet 20240227112619phanplastic299No ratings yet

- KYDEX T-IM Technical Data SheetDocument2 pagesKYDEX T-IM Technical Data SheetMichael KesslerNo ratings yet

- Ficha Técnica Hdpe (Sabic)Document2 pagesFicha Técnica Hdpe (Sabic)Luis LiraNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Product Description: Properties Value Unit Test MethodDocument1 pageProduct Description: Properties Value Unit Test MethodRPM28XINo ratings yet

- SABIC®-PP QR6731K Global Technical Data SheetDocument2 pagesSABIC®-PP QR6731K Global Technical Data SheetPhahad HasimNo ratings yet

- Product PDF 303375Document2 pagesProduct PDF 303375Leductoan LeNo ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- Exceed™ XP 8318MJ: Performance PolymerDocument2 pagesExceed™ XP 8318MJ: Performance PolymerMaram YasserNo ratings yet

- Tricolene Hdi8965uv Tds EnglishDocument1 pageTricolene Hdi8965uv Tds EnglishAlan MoraisNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- 3 mPE Leaflet en LH3750MDocument1 page3 mPE Leaflet en LH3750MfguastaNo ratings yet

- Metallocene Linear Low Density Polyethylene: Physical PropertiesDocument1 pageMetallocene Linear Low Density Polyethylene: Physical PropertiesAkoyoNo ratings yet

- 03-mPE Leaflet LH3750M (E) - 140325Document1 page03-mPE Leaflet LH3750M (E) - 140325Gabs GabrielaNo ratings yet

- Product PDF 243943Document2 pagesProduct PDF 243943Mauricio Alejandro Castillo SorianoNo ratings yet

- TDS Engage 8200Document3 pagesTDS Engage 8200afernandezNo ratings yet

- Data Sheet PEEK Extruded 450CA30Document1 pageData Sheet PEEK Extruded 450CA30shakouri1370_8902064No ratings yet

- Hyosung Topilene HJ646 PPDocument1 pageHyosung Topilene HJ646 PPChu ChuNo ratings yet

- SABIC Cycolac MG47FDocument3 pagesSABIC Cycolac MG47FChu ChuNo ratings yet

- H T NH A Lldpe 1002en TdsDocument1 pageH T NH A Lldpe 1002en TdsChu ChuNo ratings yet

- Mike - Monthly PlannerDocument33 pagesMike - Monthly PlannerChu ChuNo ratings yet

- Lldpe HD21HS Qamar SPDC SpecsDocument2 pagesLldpe HD21HS Qamar SPDC SpecsChu ChuNo ratings yet

- Physics STD XI OpticsDocument29 pagesPhysics STD XI OpticsdextermanuNo ratings yet

- 1500 Dia Pipe Dish End & Flat End (09.01.12)Document11 pages1500 Dia Pipe Dish End & Flat End (09.01.12)Kamal Kumar MallikarjunaNo ratings yet

- 107 RCD BeamsDocument59 pages107 RCD BeamsPia Eleanor SantosNo ratings yet

- 1d Condution (2013) Finite Volume MethodDocument55 pages1d Condution (2013) Finite Volume MethodHuyTqNo ratings yet

- QH Graphene Project Draft 2Document2 pagesQH Graphene Project Draft 2api-245302665No ratings yet

- ChE 122 Lecture Notes 02 II. Basic Concepts and The First Law (2.1-2.6)Document4 pagesChE 122 Lecture Notes 02 II. Basic Concepts and The First Law (2.1-2.6)MarkVergelBorjaNo ratings yet

- Zhang 2007 J. Electrochem. Soc. 154 A910 PDFDocument8 pagesZhang 2007 J. Electrochem. Soc. 154 A910 PDFPeterNo ratings yet

- Namma Kalvi 12th Physics Important Questions em 216618Document10 pagesNamma Kalvi 12th Physics Important Questions em 216618rameshjeya971No ratings yet

- DME AssignmentDocument2 pagesDME Assignmentchirag sanghaniNo ratings yet

- Fiber ElongationDocument7 pagesFiber Elongationel_sharkawy2011No ratings yet

- Development of Long-Term Oxygen Sensor in Molten Copper Using MgO-PSZ ElectrolyteDocument4 pagesDevelopment of Long-Term Oxygen Sensor in Molten Copper Using MgO-PSZ ElectrolyteJESUS DANIEL GONZALES VILCANo ratings yet

- Port Management: Andhi Anas.F, Cp0112Document11 pagesPort Management: Andhi Anas.F, Cp0112Adnan ShaikhNo ratings yet

- Amendment No. 1 JANUARY 2023 TO Is 208: 2020 Door Handles - SpecificationDocument3 pagesAmendment No. 1 JANUARY 2023 TO Is 208: 2020 Door Handles - SpecificationGaurav MittalNo ratings yet

- Berutox FB 22: Technical Product InformationDocument1 pageBerutox FB 22: Technical Product InformationMauricio SánchezNo ratings yet

- Understanding Modern Transistors and Diodes 1st Edition David L. Pulfrey Download PDFDocument84 pagesUnderstanding Modern Transistors and Diodes 1st Edition David L. Pulfrey Download PDFgnadsnh46100% (11)

- Electro ChemistryDocument2 pagesElectro Chemistryradhikanaveen60No ratings yet

- Determination of Shear Strength in Residual Soil For Slope Stability AnalysisDocument18 pagesDetermination of Shear Strength in Residual Soil For Slope Stability AnalysisAbdul Rahman HilmiNo ratings yet

- MCQ Solved by RafiDocument13 pagesMCQ Solved by Rafimahmoodrafi6No ratings yet

- Verification and Implementation of Strut-And-Tie Model inDocument281 pagesVerification and Implementation of Strut-And-Tie Model inrpatel5509No ratings yet

- EI6703-Fibre Optics and Laser Instruments PDFDocument9 pagesEI6703-Fibre Optics and Laser Instruments PDFmalathynarayaniNo ratings yet

- Introduction To Physical Pharmacy IIDocument4 pagesIntroduction To Physical Pharmacy IIAshique FarhadNo ratings yet

- Prediction of Fracture Energy and Flaw SDocument4 pagesPrediction of Fracture Energy and Flaw Slihong.herman1980No ratings yet

- Lecture07 P2Document17 pagesLecture07 P2Trân TerryNo ratings yet

- C01 Part 1 PDFDocument32 pagesC01 Part 1 PDFFatin Natasha NazriNo ratings yet

- Analysis and Design of A Large Raft Foundation in BaghdadDocument1 pageAnalysis and Design of A Large Raft Foundation in BaghdadVisooven UppadooNo ratings yet

- SLOPE/W Analysis: File Informa OnDocument3 pagesSLOPE/W Analysis: File Informa OnLee Chen ChoonNo ratings yet

- RC Module 6 DEVELOPEMTN LENGTH HOOKS AND SPLICING OF REINFORCEMENTDocument23 pagesRC Module 6 DEVELOPEMTN LENGTH HOOKS AND SPLICING OF REINFORCEMENTCyrylle ObenzaNo ratings yet