Taskalfa 3551ci Service Manual

Taskalfa 3551ci Service Manual

Uploaded by

Amedeo DoniniCopyright:

Available Formats

Taskalfa 3551ci Service Manual

Taskalfa 3551ci Service Manual

Uploaded by

Amedeo DoniniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Taskalfa 3551ci Service Manual

Taskalfa 3551ci Service Manual

Uploaded by

Amedeo DoniniCopyright:

Available Formats

TASKalfa 3051ci

TASKalfa 3551ci

TASKalfa 4551ci

TASKalfa 5551ci

SERVICE

MANUAL

Published in April 2015

842N4117

2N4SM067

Rev. 7

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

1-4-1 Paper misfeed detection

1-4 Troubleshooting

(1) Paper misfeed indication

When a paper misfeed occurs, the machine immediately stops printing and displays the paper misfeed mes-

sage on the operation panel. To remove paper misfed in the machine, pull out the cassette, open the paper

conveying unit or paper conveying cover.

The positions and the corrective actions are displayed on the touch panel when a paper jam has occurred.

Jam code: Jam code suggesting the cause of jam

Position code: Code suggesting the place of jam

Figure 1-4-1

1-4-1

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Figure 1-4-2 Paper misfeed indication

A. Misfeed in cassette 1

B. Misfeed in cassette 2

C. Misfeed in cassette 3 or 4 (option)

D. Misfeed in the MP tray

E. Misfeed in paper conveying unit, paper conveying

cover or PF paper conveying cover

F. Misfeed in the duplex section

G. Misfeed in the fuser section

H. Misfeed in document processor (option)

I. Misfeed in job separator (option)

J. Misfeed in bridge unit (option)

K. Misfeed in document finisher (option)

L. Misfeed in Mail box (option)

M. Misfeed Center-folding unit (option)

N. Misfeed in cassette 5 (option)

O. Misfeed in cassette 6 or 7 (option)

1-4-2

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4-3

(2) Paper misfeed detection condition

Machine + Option1

Figure 1-4-3 Paper jam location (Machine + Option1)

1-4-3

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Machine + Option2

Figure 1-4-4 Paper jam location (Matchine + Option2)

1-4-4

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4-1

* : This model does not support the following codes: 0132 /0505 /0515 /9030

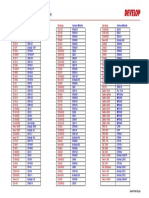

List of JAM Code

Jam

Code Contents Conditions

location*

0000 Initial jam The power is turned on when a sensor in the convey- -

ing system is on.

0100 Secondary paper feed Secondary paper feed request given by the controller -

request time out is unreachable.

0101 Waiting for process

package to become

ready

0102 Waiting for toner pack-

age to become ready

0103 Waiting for the image-

sustaining package to

become ready

0104 Waiting for conveying

package to become

ready

0106 Paper feeding request Paper feeding request for duplex printing given by the -

for duplex printing time controller is unreachable.

out

0107 Waiting for fuser pack-

age to become ready

0108 Waiting for option pack-

age to become ready

0110 Paper conveying unit The paper conveying unit is opened during printing. E

open

0111 Front cover open The front cover is opened during printing. -

0112 Duplex cover open The duplex cover is opened during printing. F

0113 Paper conveying cover The paper conveying cover is opened during printing. E

open

0114 BR conveying unit open The BR conveying unit is opened during printing. J

0115 BR eject cover open The BR eject cover is opened during printing. J

0131 MP lift sensor upper limit MP lift sensor 1 (MPLS1) does not turn on within spec- D

detection ified time of the MP lift plate rising.

0132 Rotary guide detection Rotary sensor (RTS) does not turn on. J

0200 Machine sequence error A sequence error has occurred. -

0210 PF paper conveying The PF paper conveying cover is opened during print- E

cover open ing.

0211 SM paper conveying The SM paper conveying cover is opened during print- N

cover open ing.

0212 SM top cover open The SM top cover is opened during printing. N

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-5

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

0213 SD cover open The SD cover is opened during printing. N

0214 PF paper conveying The PF paper conveying cover (side) is opened during O

cover (side) open printing.

0215 Side multi tray release The side multi tray is released during printing. N

0300 Ejection uncompleted An ejection-completed error has occurred. -

0501 No paper feed from cas- Feed sensor 1 (FS1) does not turn on during paper A

sette 1 feed from cassette 1.

0502 No paper feed from cas- Feed sensor 2 (FS2) does not turn on during paper B

sette 2 feed from cassette 2.

0503 No paper feed from cas- PF feed sensor 1 (PFFS1) does not turn on during C

sette 3 paper feed from cassette 3 (paper feeder).

0504 No paper feed from cas- PF feed sensor 2 (PFFS2) does not turn on during C

sette 4 paper feed from cassette 4 (paper feeder).

0506 No paper feed from cas- PF feed sensor 1 (PFFS1) does not turn on during O

sette 6 paper feed from cassette 6 (side paper feeder).

0507 No paper feed from cas- PF feed sensor 2 (PFFS2) does not turn on during O

sette 7 paper feed from cassette 7 (side paper feeder).

0508 No paper feed from Registration sensor (RS) does not turn on during paper F

duplex section feed from duplex section.

0509 No paper feed from MP MP feed sensor (MPFS) does not turn on during paper D

tray feed from MP tray.

0511 Multiple sheets in cas- Feed sensor 1 (FS1) does not turn off during paper A

sette 1 feed from cassette 1.

0512 Multiple sheets in cas- Feed sensor 2 (FS2) does not turn off during paper B

sette 2 feed from cassette 2.

0513 Multiple sheets in cas- PF feed sensor 1 (PFFS1) does not turn off during C

sette 3 paper feed from cassette 3 (paper feeder).

0514 Multiple sheets in cas- PF feed sensor 2 (PFFS2) does not turn off during C

sette 4 paper feed from cassette 4 (paper feeder).

0516 Multiple sheets in cas- PF feed sensor 1 (PFFS1) does not turn off during O

sette 6 paper feed from cassette 6 (side paper feeder).

0517 Multiple sheets in cas- PF feed sensor 2 (PFFS2) does not turn off during O

sette 7 paper feed from cassette 7 (side paper feeder).

0518 Multiple sheets in duplex Registration sensor (RS) does not turn off during paper F

section feed from duplex section.

0519 Multiple sheets in MP MP feed sensor (MPFS) does not turn off during paper D

tray feed from MP tray.

0523 No paper feed from cas- PF feed sensor 1 (PFFS1) does not turn on during C

sette 3 paper feed from cassette 3 (large capacity feeder).

0524 No paper feed from cas- PF feed sensor 2 (PFFS2) does not turn on during C

sette 4 paper feed from cassette 4 (large capacity feeder).

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-6

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

0525 No paper feed from cas- SM feed sensor (SMFS) does not turn on during paper N

sette 5 feed from cassette 5 (side multi tray).

0526 No paper feed from cas- PF feed sensor 1 (PFFS1) does not turn on during O

sette 6 paper feed from cassette 6 (side large capacity

feeder).

0527 No paper feed from cas- PF feed sensor 2 (PFFS2) does not turn on during O

sette 7 paper feed from cassette 7 (side large capacity

feeder).

0533 Multiple sheets in cas- PF feed sensor 1 (PFFS1) does not turn off during C

sette 3 paper feed from cassette 3 (large capacity feeder).

0534 Multiple sheets in cas- PF feed sensor 2 (PFFS2) does not turn off during C

sette 4 paper feed from cassette 4 (large capacity feeder).

0535 Multiple sheets in cas- SM feed sensor (SMFS) does not turn off during paper N

sette 5 feed from cassette 5 (side multi tray).

0536 Multiple sheets in cas- PF feed sensor 1 (PFFS1) does not turn off during O

sette 6 paper feed from cassette 6 (side large capacity

feeder).

0537 Multiple sheets in cas- PF feed sensor 2 (PFFS2) does not turn off during O

sette 7 paper feed from cassette 7 (side large capacity

feeder).

0545 No paper feed from side SD feed sensor (SDFS) does not turn on during paper N

deck feed from side deck.

0555 Multiple sheets in side SD feed sensor (SDFS) does not turn off during paper N

deck feed from side deck.

1301 Middle sensor non arrival Middle sensor (MS) does not turn on during paper feed A

jam from cassette 1.

1302 Middle sensor (MS) does not turn on during paper feed B

from cassette 2.

1303 Middle sensor (MS) does not turn on during paper feed C

from cassette 3 (paper feeder/large capacity feeder).

1304 Middle sensor (MS) does not turn on during paper feed C

from cassette 4 (paper feeder/large capacity feeder).

1305 Middle sensor (MS) does not turn on during paper feed N

from cassette 5 (side multi tray/side deck).

1306 Middle sensor (MS) does not turn on during paper feed O

from cassette 6 (side paper feeder/side large capacity

feeder).

1307 Middle sensor (MS) does not turn on during paper feed O

from cassette 7 (side paper feeder/side large capacity

feeder).

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-7

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

1311 Middle sensor stay jam Middle sensor (MS) does not turn off during paper feed E

from cassette 1.

1312 Middle sensor (MS) does not turn off during paper feed E

from cassette 2.

1313 Middle sensor (MS) does not turn off during paper feed E

from cassette 3 (paper feeder/large capacity feeder).

1314 Middle sensor (MS) does not turn off during paper feed E

from cassette 4 (paper feeder/large capacity feeder).

1315 Middle sensor (MS) does not turn off during paper feed E

from cassette 5 (side multi tray/side deck).

1316 Middle sensor (MS) does not turn off during paper feed E

from cassette 6 (side paper feeder/side large capacity

feeder).

1317 Middle sensor (MS) does not turn off during paper feed E

from cassette 7 (side paper feeder/side large capacity

feeder).

1502 Paper conveying sensor Paper conveying sensor (PCS) does not turn on during B

non arrival jam paper feed from cassette 2.

1503 Paper conveying sensor (PCS) does not turn on during C

paper feed from cassette 3 (paper feeder/large capac-

ity feeder).

1504 Paper conveying sensor (PCS) does not turn on during C

paper feed from cassette 4 (paper feeder/large capac-

ity feeder).

1512 Paper conveying sensor Paper conveying sensor (PCS) does not turn off during E

stay jam paper feed from cassette 2.

1513 Paper conveying sensor (PCS) does not turn off during E

paper feed from cassette 3 (paper feeder/large capac-

ity feeder).

1514 Paper conveying sensor (PCS) does not turn off during E

paper feed from cassette 4 (paper feeder/large capac-

ity feeder).

1703 PF paper conveying sen- PF paper conveying sensor 1 (PFPCS1) does not turn C

sor 1 non arrival jam on during paper feed from cassette 3 (paper feeder).

1704 PF paper conveying sensor 1 (PFPCS1) does not turn C

on during paper feed from cassette 4 (paper feeder).

1713 PF paper conveying sen- PF paper conveying sensor 1 (PFPCS1) does not turn E

sor 1 stay jam off during paper feed from cassette 3 (paper feeder).

1714 PF paper conveying sensor 1 (PFPCS1) does not turn E

off during paper feed from cassette 4 (paper feeder).

1904 PF paper conveying sen- PF paper conveying sensor 2 (PFPCS2) does not turn C

sor 2 non arrival jam on during paper feed from cassette 4 (paper feeder).

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-8

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

1914 PF paper conveying sen- PF paper conveying sensor 2 (PFPCS2) does not turn C

sor 2 stay jam off during paper feed from cassette 4 (paper feeder).

2106 PF paper conveying sen- PF paper conveying sensor 1 (PFPCS1) does not turn O

sor 1 non arrival jam on during paper feed from cassette 6 (side paper

feeder).

2107 PF paper conveying sensor 1 (PFPCS1) does not turn O

on during paper feed from cassette 7 (side paper

feeder).

2116 PF paper conveying sen- PF paper conveying sensor 1 (PFPCS1) does not turn N

sor 1 stay jam off during paper feed from cassette 6 (side paper

feeder).

2117 PF paper conveying sensor 1 (PFPCS1) does not turn N

off during paper feed from cassette 7 (side paper

feeder).

2307 PF paper conveying sen- PF paper conveying sensor 2 (PFPCS2) does not turn O

sor 2 non arrival jam on during paper feed from cassette 7 (side paper

feeder).

2317 PF paper conveying sen- PF paper conveying sensor 2 (PFPCS2) does not turn O

sor 2 stay jam off during paper feed from cassette 7 (side paper

feeder).

2603 PF paper conveying sen- PF paper conveying sensor 1 (PFPCS1) does not turn C

sor 1 non arrival jam on during paper feed from cassette 3 (large capacity

feeder).

2604 PF paper conveying sensor 1 (PFPCS1) does not turn C

on during paper feed from cassette 4 (large capacity

feeder).

2606 PF paper conveying sensor 1 (PFPCS1) does not turn O

on during paper feed from cassette 6 (side large

capacity feeder).

2607 PF paper conveying sensor 1 (PFPCS1) does not turn O

on during paper feed from cassette 7 (side large

capacity feeder).

2613 PF paper conveying sen- PF paper conveying sensor 1 (PFPCS1) does not turn E

sor 1 stay jam off during paper feed from cassette 3 (large capacity

feeder).

2614 PF paper conveying sensor 1 (PFPCS1) does not turn E

off during paper feed from cassette 4 (large capacity

feeder).

2616 PF paper conveying sensor 1 (PFPCS1) does not turn O

off during paper feed from cassette 6 (side large

capacity feeder).

2617 PF paper conveying sensor 1 (PFPCS1) does not turn O

off during paper feed from cassette 7 (side large

capacity feeder).

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-9

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4-5

Jam

Code Contents Conditions

location*

2704 PF paper conveying sen- PF paper conveying sensor 2 (PFPCS2) does not turn C

sor 2 non arrival jam on during paper feed from cassette 4 (large capacity

feeder).

2707 PF paper conveying sensor 2 (PFPCS2) does not turn O

on during paper feed from cassette 7 (side large

capacity feeder).

2714 PF paper conveying sen- PF paper conveying sensor 2 (PFPCS2) does not turn C

sor 2 stay jam off during paper feed from cassette 4 (large capacity

feeder).

2717 PF paper conveying sensor 2 (PFPCS2) does not turn O

off during paper feed from cassette 7 (side large

capacity feeder).

3405 SM paper conveying SM paper conveying sensor 1 (SMPCS1) does not N

sensor 1 non arrival jam turn on during paper feed from cassette 5 (side multi

tray).

3406 SM paper conveying sensor 1 (SMPCS1) does not O

turn on during paper feed from cassette 6 (side multi

tray).

3407 SM paper conveying sensor 1 (SMPCS1) does not O

turn on during paper feed from cassette 7 (side multi

tray).

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-10

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

3415 SM paper conveying SM paper conveying sensor 1 (SMPCS1) does not N

sensor 1 stay jam turn off during paper feed from cassette 5 (side multi

tray).

3416 SM paper conveying sensor 1 (SMPCS1) does not N

turn off during paper feed from cassette 6 (side multi

tray).

3417 SM paper conveying sensor 1 (SMPCS1) does not N

turn off during paper feed from cassette 7 (side multi

tray).

3505 SM paper conveying SM paper conveying sensor 2 (SMPCS2) does not N

sensor 2 non arrival jam turn on during paper feed from cassette 5 (side multi

tray).

3506 SM paper conveying sensor 2 (SMPCS2) does not O

turn on during paper feed from cassette 6 (side multi

tray).

3507 SM paper conveying sensor 2 (SMPCS2) does not O

turn on during paper feed from cassette 7 (side multi

tray).

3515 SM paper conveying SM paper conveying sensor 2 (SMPCS2) does not N

sensor 2 stay jam turn off during paper feed from cassette 5 (side multi

tray).

3516 SM paper conveying sensor 2 (SMPCS2) does not N

turn off during paper feed from cassette 6 (side multi

tray).

3517 SM paper conveying sensor 2 (SMPCS2) does not N

turn off during paper feed from cassette 7 (side multi

tray).

3605 SM paper conveying SM paper conveying sensor 3 (SMPCS3) does not N

sensor 3 non arrival jam turn on during paper feed from cassette 5 (side multi

tray).

3606 SM paper conveying sensor 3 (SMPCS3) does not N

turn on during paper feed from cassette 6 (side multi

tray).

3607 SM paper conveying sensor 3 (SMPCS3) does not N

turn on during paper feed from cassette 7 (side multi

tray).

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-11

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

3615 SM paper conveying SM paper conveying sensor 3 (SMPCS3) does not N

sensor 3 stay jam turn off during paper feed from cassette 5 (side multi

tray).

3616 SM paper conveying sensor 3 (SMPCS3) does not N

turn off during paper feed from cassette 6 (side multi

tray).

3617 SM paper conveying sensor 3 (SMPCS3) does not N

turn off during paper feed from cassette 7 (side multi

tray).

3705 SM eject sensor non SM eject sensor (SMES) does not turn on during paper N

arrival jam feed from cassette 5 (side multi tray).

3706 SM eject sensor (SMES) does not turn on during paper O

feed from cassette 6 (side multi tray).

3707 SM eject sensor (SMES) does not turn on during paper O

feed from cassette 7 (side multi tray).

3715 SM eject sensor stay jam SM eject sensor (SMES) does not turn off during paper N

feed from cassette 5 (side multi tray).

3716 SM eject sensor (SMES) does not turn off during paper N

feed from cassette 6 (side multi tray).

3717 SM eject sensor (SMES) does not turn off during paper N

feed from cassette 7 (side multi tray).

4001 Registration sensor non Registration sensor (RS) does not turn on during paper E

arrival jam feed from cassette 1.

4002 Registration sensor (RS) does not turn on during paper E

feed from cassette 2.

4003 Registration sensor (RS) does not turn on during paper E

feed from cassette 3 (paper feeder/large capacity

feeder).

4004 Registration sensor (RS) does not turn on during paper E

feed from cassette 4 (paper feeder/large capacity

feeder).

4005 Registration sensor (RS) does not turn on during paper E

feed from cassette 5 (side multi tray/side deck).

4006 Registration sensor (RS) does not turn on during paper E

feed from cassette 6 (side paper feeder/side large

capacity feeder).

4007 Registration sensor (RS) does not turn on during paper E

feed from cassette 7 (side paper feeder/side large

capacity feeder).

4009 Registration sensor (RS) does not turn on during paper E

feed from MP tray.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-12

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

4011 Registration sensor stay Registration sensor (RS) does not turn off during paper E

jam feed from cassette 1.

4012 Registration sensor (RS) does not turn off during paper E

feed from cassette 2.

4013 Registration sensor (RS) does not turn off during paper E

feed from cassette 3 (paper feeder/large capacity

feeder).

4014 Registration sensor (RS) does not turn off during paper E

feed from cassette 4 (paper feeder/large capacity

feeder).

4015 Registration sensor (RS) does not turn off during paper E

feed from cassette 5 (side multi tray/side deck).

4016 Registration sensor (RS) does not turn off during paper E

feed from cassette 6 (side paper feeder/side large

capacity feeder).

4017 Registration sensor (RS) does not turn off during paper E

feed from cassette 7 (side paper feeder/side large

capacity feeder).

4019 Registration sensor (RS) does not turn off during paper E

feed from MP tray.

4101 Loop sensor non arrival Loop sensor (LPS) does not turn on during paper feed E

jam from cassette 1.

4102 Loop sensor (LPS) does not turn on during paper feed E

from cassette 2.

4103 Loop sensor (LPS) does not turn on during paper feed E

from cassette 3 (paper feeder/large capacity feeder).

4104 Loop sensor (LPS) does not turn on during paper feed E

from cassette 4 (paper feeder/large capacity feeder).

4105 Loop sensor (LPS) does not turn on during paper feed E

from cassette 5 (side multi tray/side deck).

4106 Loop sensor (LPS) does not turn on during paper feed E

from cassette 6 (side paper feeder/side large capacity

feeder).

4107 Loop sensor (LPS) does not turn on during paper feed E

from cassette 7 (side paper feeder/side large capacity

feeder).

4108 Loop sensor (LPS) does not turn on during paper feed E

from duplex section.

4109 Loop sensor (LPS) does not turn on during paper feed E

from MP tray.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-13

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

4111 Loop sensor stay jam Loop sensor (LPS) does not turn off during paper feed E

from cassette 1.

4112 Loop sensor (LPS) does not turn off during paper feed E

from cassette 2.

4113 Loop sensor (LPS) does not turn off during paper feed E

from cassette 3 (paper feeder/large capacity feeder).

4114 Loop sensor (LPS) does not turn off during paper feed E

from cassette 4 (paper feeder/large capacity feeder).

4115 Loop sensor (LPS) does not turn off during paper feed E

from cassette 5 (side multi tray/side deck).

4116 Loop sensor (LPS) does not turn off during paper feed E

from cassette 6 (side paper feeder/side large capacity

feeder).

4117 Loop sensor (LPS) does not turn off during paper feed E

from cassette 7 (side paper feeder/side large capacity

feeder).

4118 Loop sensor (LPS) does not turn off during paper feed E

from duplex section.

4119 Loop sensor (LPS) does not turn off during paper feed E

from MP tray.

4201 Fuser eject sensor non Fuser eject sensor (FUES) does not turn on during E

arrival jam paper feed from cassette 1.

4202 Fuser eject sensor (FUES) does not turn on during E

paper feed from cassette 2.

4203 Fuser eject sensor (FUES) does not turn on during E

paper feed from cassette 3 (paper feeder/large capac-

ity feeder).

4204 Fuser eject sensor (FUES) does not turn on during E

paper feed from cassette 4 (paper feeder/large capac-

ity feeder).

4205 Fuser eject sensor (FUES) does not turn on during E

paper feed from cassette 5 (side multi tray/side deck).

4206 Fuser eject sensor (FUES) does not turn on during E

paper feed from cassette 6 (side paper feeder/side

large capacity feeder).

4207 Fuser eject sensor (FUES) does not turn on during E

paper feed from cassette 7 (side paper feeder/side

large capacity feeder).

4208 Fuser eject sensor (FUES) does not turn on during E

paper feed from duplex section.

4209 Fuser eject sensor (FUES) does not turn on during E

paper feed from MP tray.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-14

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

4211 Fuser eject sensor stay Fuser eject sensor (FUES) does not turn off during G

jam paper feed from cassette 1.

4212 Fuser eject sensor (FUES) does not turn off during G

paper feed from cassette 2.

4213 Fuser eject sensor (FUES) does not turn off during G

paper feed from cassette 3 (paper feeder/large capac-

ity feeder).

4214 Fuser eject sensor (FUES) does not turn off during G

paper feed from cassette 4 (paper feeder/large capac-

ity feeder).

4215 Fuser eject sensor (FUES) does not turn off during G

paper feed from cassette 5 (side multi tray/side deck).

4216 Fuser eject sensor (FUES) does not turn off during G

paper feed from cassette 6 (side paper feeder/side

large capacity feeder).

4217 Fuser eject sensor (FUES) does not turn off during G

paper feed from cassette 7 (side paper feeder/side

large capacity feeder).

4218 Fuser eject sensor (FUES) does not turn off during G

paper feed from duplex section.

4219 Fuser eject sensor (FUES) does not turn off during G

paper feed from MP tray.

4301 Duplex sensor 1 non Duplex sensor 1 (DUS1) does not turn on during paper G

arrival jam feed from cassette 1.

4302 Duplex sensor 1 (DUS1) does not turn on during paper G

feed from cassette 2.

4303 Duplex sensor 1 (DUS1) does not turn on during paper G

feed from cassette 3 (paper feeder/large capacity

feeder).

4304 Duplex sensor 1 (DUS1) does not turn on during paper G

feed from cassette 4 (paper feeder/large capacity

feeder).

4305 Duplex sensor 1 (DUS1) does not turn on during paper G

feed from cassette 5 (side multi tray/side deck).

4306 Duplex sensor 1 (DUS1) does not turn on during paper G

feed from cassette 6 (side paper feeder/side large

capacity feeder).

4307 Duplex sensor 1 (DUS1) does not turn on during paper G

feed from cassette 7 (side paper feeder/side large

capacity feeder).

4309 Duplex sensor 1 (DUS1) does not turn on during paper G

feed from MP tray.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-15

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

4311 Duplex sensor 1 stay jam Duplex sensor 1 (DUS1) does not turn off during paper F

feed from cassette 1.

4312 Duplex sensor 1 (DUS1) does not turn off during paper F

feed from cassette 2.

4313 Duplex sensor 1 (DUS1) does not turn off during paper F

feed from cassette 3 (paper feeder/large capacity

feeder).

4314 Duplex sensor 1 (DUS1) does not turn off during paper F

feed from cassette 4 (paper feeder/large capacity

feeder).

4315 Duplex sensor 1 (DUS1) does not turn off during paper F

feed from cassette 5 (side multi tray/side deck).

4316 Duplex sensor 1 (DUS1) does not turn off during paper F

feed from cassette 6 (side paper feeder/side large

capacity feeder).

4317 Duplex sensor 1 (DUS1) does not turn off during paper F

feed from cassette 7 (side paper feeder/side large

capacity feeder).

4319 Duplex sensor 1 (DUS1) does not turn off during paper F

feed from MP tray.

4401 Duplex sensor 2 non Duplex sensor 2 (DUS2) does not turn on during paper F

arrival jam feed from cassette 1.

4402 Duplex sensor 2 (DUS2) does not turn on during paper F

feed from cassette 2.

4403 Duplex sensor 2 (DUS2) does not turn on during paper F

feed from cassette 3 (paper feeder/large capacity

feeder).

4404 Duplex sensor 2 (DUS2) does not turn on during paper F

feed from cassette 4 (paper feeder/large capacity

feeder).

4405 Duplex sensor 2 (DUS2) does not turn on during paper F

feed from cassette 5 (side multi tray/side deck).

4406 Duplex sensor 2 (DUS2) does not turn on during paper F

feed from cassette 6 (side paper feeder/side large

capacity feeder).

4407 Duplex sensor 2 (DUS2) does not turn on during paper F

feed from cassette 7 (side paper feeder/side large

capacity feeder).

4409 Duplex sensor 2 (DUS2) does not turn on during paper F

feed from MP tray.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-16

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

4411 Duplex sensor 2 stay jam Duplex sensor 2 (DUS2) does not turn off during paper F

feed from cassette 1.

4412 Duplex sensor 2 (DUS2) does not turn off during paper F

feed from cassette 2.

4413 Duplex sensor 2 (DUS2) does not turn off during paper F

feed from cassette 3 (paper feeder/large capacity

feeder).

4414 Duplex sensor 2 (DUS2) does not turn off during paper F

feed from cassette 4 (paper feeder/large capacity

feeder).

4415 Duplex sensor 2 (DUS2) does not turn off during paper F

feed from cassette 5 (side multi tray/side deck).

4416 Duplex sensor 2 (DUS2) does not turn off during paper F

feed from cassette 6 (side paper feeder/side large

capacity feeder).

4417 Duplex sensor 2 (DUS2) does not turn off during paper F

feed from cassette 7 (side paper feeder/side large

capacity feeder).

4418 Duplex sensor 2 (DUS2) does not turn off during paper F

feed from duplex section.

4419 Duplex sensor 2 (DUS2) does not turn off during paper F

feed from MP tray.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-17

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

4601 Eject full sensor non Eject full sensor (EFS) does not turn on during paper G

arrival jam feed from cassette 1.

4602 Eject full sensor (EFS) does not turn on during paper G

feed from cassette 2.

4603 Eject full sensor (EFS) does not turn on during paper G

feed from cassette 3 (paper feeder/large capacity

feeder).

4604 Eject full sensor (EFS) does not turn on during paper G

feed from cassette 4 (paper feeder/large capacity

feeder).

4605 Eject full sensor (EFS) does not turn on during paper G

feed from cassette 5 (side multi tray/side deck).

4606 Eject full sensor (EFS) does not turn on during paper G

feed from cassette 6 (side paper feeder/side large

capacity feeder).

4607 Eject full sensor (EFS) does not turn on during paper G

feed from cassette 7 (side paper feeder/side large

capacity feeder).

4608 Eject full sensor (EFS) does not turn on during paper G

feed from duplex section.

4609 Eject full sensor (EFS) does not turn on during paper G

feed from MP tray.

4611 Eject full sensor stay jam Eject full sensor (EFS) does not turn off during paper G

feed from cassette 1.

4612 Eject full sensor (EFS) does not turn off during paper G

feed from cassette 2.

4613 Eject full sensor (EFS) does not turn off during paper G

feed from cassette 3 (paper feeder/large capacity

feeder).

4614 Eject full sensor (EFS) does not turn off during paper G

feed from cassette 4 (paper feeder/large capacity

feeder).

4615 Eject full sensor (EFS) does not turn off during paper G

feed from cassette 5 (side multi tray/side deck).

4616 Eject full sensor (EFS) does not turn off during paper G

feed from cassette 6 (side paper feeder/side large

capacity feeder).

4617 Eject full sensor (EFS) does not turn off during paper G

feed from cassette 7 (side paper feeder/side large

capacity feeder).

4618 Eject full sensor (EFS) does not turn off during paper G

feed from duplex section.

4619 Eject full sensor (EFS) does not turn off during paper G

feed from MP tray.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-18

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

4701 Switchback sensor non Switchback sensor (SBS) does not turn on during G

arrival jam paper feed from cassette 1.

4702 Switchback sensor (SBS) does not turn on during G

paper feed from cassette 2.

4703 Switchback sensor (SBS) does not turn on during G

paper feed from cassette 3 (paper feeder/large capac-

ity feeder).

4704 Switchback sensor (SBS) does not turn on during G

paper feed from cassette 4 (paper feeder/large capac-

ity feeder).

4705 Switchback sensor (SBS) does not turn on during G

paper feed from cassette 5 (side multi tray/side deck).

4706 Switchback sensor (SBS) does not turn on during G

paper feed from cassette 6 (side paper feeder/side

large capacity feeder).

4707 Switchback sensor (SBS) does not turn on during G

paper feed from cassette 7 (side paper feeder/side

large capacity feeder).

4708 Switchback sensor (SBS) does not turn on during G

paper feed from duplex section.

4709 Switchback sensor (SBS) does not turn on during G

paper feed from MP tray.

4711 Switchback sensor stay Switchback sensor (SBS) does not turn off during I

jam paper feed from cassette 1.

4712 Switchback sensor (SBS) does not turn off during I

paper feed from cassette 2.

4713 Switchback sensor (SBS) does not turn off during I

paper feed from cassette 3 (paper feeder/large capac-

ity feeder).

4714 Switchback sensor (SBS) does not turn off during I

paper feed from cassette 4 (paper feeder/large capac-

ity feeder).

4715 Switchback sensor (SBS) does not turn off during I

paper feed from cassette 5 (side multi tray/side deck).

4716 Switchback sensor (SBS) does not turn off during I

paper feed from cassette 6 (side paper feeder/side

large capacity feeder).

4717 Switchback sensor (SBS) does not turn off during I

paper feed from cassette 7 (side paper feeder/side

large capacity feeder).

4718 Switchback sensor (SBS) does not turn off during I

paper feed from duplex section.

4719 Switchback sensor (SBS) does not turn off during I

paper feed from MP tray.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-19

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

4901 BR conveying sensor 1 BR conveying sensor 1 (BRCS1) does not turn on dur- G

non arrival jam ing paper feed from cassette 1.

4902 BR conveying sensor 1 (BRCS1) does not turn on dur- G

ing paper feed from cassette 2.

4903 BR conveying sensor 1 (BRCS1) does not turn on dur- G

ing paper feed from cassette 3 (paper feeder/large

capacity feeder).

4904 BR conveying sensor 1 (BRCS1) does not turn on dur- G

ing paper feed from cassette 4 (paper feeder/large

capacity feeder).

4905 BR conveying sensor 1 (BRCS1) does not turn on dur- G

ing paper feed from cassette 5 (side multi tray/side

deck).

4906 BR conveying sensor 1 (BRCS1) does not turn on dur- G

ing paper feed from cassette 6 (side paper feeder/side

large capacity feeder).

4907 BR conveying sensor 1 (BRCS1) does not turn on dur- G

ing paper feed from cassette 7 (side paper feeder/side

large capacity feeder).

4908 BR conveying sensor 1 (BRCS1) does not turn on dur- G

ing paper feed from duplex section.

4909 BR conveying sensor 1 (BRCS1) does not turn on dur- G

ing paper feed from MP tray.

4911 BR conveying sensor 1 BR conveying sensor 1 (BRCS1) does not turn off dur- J

stay jam ing paper feed from cassette 1.

4912 BR conveying sensor 1 (BRCS1) does not turn off dur- J

ing paper feed from cassette 2.

4913 BR conveying sensor 1 (BRCS1) does not turn off dur- J

ing paper feed from cassette 3 (paper feeder/large

capacity feeder).

4914 BR conveying sensor 1 (BRCS1) does not turn off dur- J

ing paper feed from cassette 4 (paper feeder/large

capacity feeder).

4915 BR conveying sensor 1 (BRCS1) does not turn off dur- J

ing paper feed from cassette 5 (side multi tray/side

deck).

4916 BR conveying sensor 1 (BRCS1) does not turn off dur- J

ing paper feed from cassette 6 (side paper feeder/side

large capacity feeder).

4917 BR conveying sensor 1 (BRCS1) does not turn off dur- J

ing paper feed from cassette 7 (side paper feeder/side

large capacity feeder).

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-20

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

4918 BR conveying sensor 1 BR conveying sensor 1 (BRCS1) does not turn off dur- J

stay jam ing paper feed from duplex section.

4919 BR conveying sensor 1 (BRCS1) does not turn off dur- J

ing paper feed from MP tray.

5001 BR conveying sensor 2 BR conveying sensor 2 (BRCS2) does not turn on dur- J

non arrival jam ing paper feed from cassette 1.

5002 BR conveying sensor 2 (BRCS2) does not turn on dur- J

ing paper feed from cassette 2.

5003 BR conveying sensor 2 (BRCS2) does not turn on dur- J

ing paper feed from cassette 3 (paper feeder/large

capacity feeder).

5004 BR conveying sensor 2 (BRCS2) does not turn on dur- J

ing paper feed from cassette 4 (paper feeder/large

capacity feeder).

5005 BR conveying sensor 2 (BRCS2) does not turn on dur- J

ing paper feed from cassette 5 (side multi tray/side

deck).

5006 BR conveying sensor 2 (BRCS2) does not turn on dur- J

ing paper feed from cassette 6 (side paper feeder/side

large capacity feeder).

5007 BR conveying sensor 2 (BRCS2) does not turn on dur- J

ing paper feed from cassette 7 (side paper feeder/side

large capacity feeder).

5008 BR conveying sensor 2 (BRCS2) does not turn on dur- J

ing paper feed from duplex section.

5009 BR conveying sensor 2 (BRCS2) does not turn on dur- J

ing paper feed from MP tray.

5011 BR conveying sensor 2 BR conveying sensor 2 (BRCS2) does not turn off dur- J

stay jam ing paper feed from cassette 1.

5012 BR conveying sensor 2 (BRCS2) does not turn off dur- J

ing paper feed from cassette 2.

5013 BR conveying sensor 2 (BRCS2) does not turn off dur- J

ing paper feed from cassette 3 (paper feeder/large

capacity feeder).

5014 BR conveying sensor 2 (BRCS2) does not turn off dur- J

ing paper feed from cassette 4 (paper feeder/large

capacity feeder).

5015 BR conveying sensor 2 (BRCS2) does not turn off dur- J

ing paper feed from cassette 5 (side multi tray/side

deck).

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-21

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

5016 BR conveying sensor 2 BR conveying sensor 2 (BRCS2) does not turn off dur- J

stay jam ing paper feed from cassette 6 (side paper feeder/side

large capacity feeder).

5017 BR conveying sensor 2 (BRCS2) does not turn off dur- J

ing paper feed from cassette 7 (side paper feeder/side

large capacity feeder).

5018 BR conveying sensor 2 (BRCS2) does not turn off dur- J

ing paper feed from duplex section.

5019 BR conveying sensor 2 (BRCS2) does not turn off dur- J

ing paper feed from MP tray.

5101 BR eject sensor non BR eject sensor (BRES) does not turn on during paper J

arrival jam feed from cassette 1.

5102 BR eject sensor (BRES) does not turn on during paper J

feed from cassette 2.

5103 BR eject sensor (BRES) does not turn on during paper J

feed from cassette 3 (paper feeder/large capacity

feeder).

5104 BR eject sensor (BRES) does not turn on during paper J

feed from cassette 4 (paper feeder/large capacity

feeder).

5105 BR eject sensor (BRES) does not turn on during paper J

feed from cassette 5 (side multi tray/side deck).

5106 BR eject sensor (BRES) does not turn on during paper J

feed from cassette 6 (side paper feeder/side large

capacity feeder).

5107 BR eject sensor (BRES) does not turn on during paper J

feed from cassette 7 (side paper feeder/side large

capacity feeder).

5108 BR eject sensor (BRES) does not turn on during paper J

feed from duplex section.

5109 BR eject sensor (BRES) does not turn on during paper J

feed from MP tray.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-22

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4-1

Jam

Code Contents Conditions

location*

5111 BR eject sensor stay jam BR eject sensor (BRES) does not turn off during paper J

feed from cassette 1.

5112 BR eject sensor (BRES) does not turn off during paper J

feed from cassette 2.

5113 BR eject sensor (BRES) does not turn off during paper J

feed from cassette 3 (paper feeder/large capacity

feeder).

5114 BR eject sensor (BRES) does not turn off during paper J

feed from cassette 4 (paper feeder/large capacity

feeder).

5115 BR eject sensor (BRES) does not turn off during paper J

feed from cassette 5 (side multi tray/side deck).

5116 BR eject sensor (BRES) does not turn off during paper J

feed from cassette 6 (side paper feeder/side large

capacity feeder).

5117 BR eject sensor (BRES) does not turn off during paper J

feed from cassette 7 (side paper feeder/side large

capacity feeder).

5118 BR eject sensor (BRES) does not turn off during paper J

feed from duplex section.

5119 BR eject sensor (BRES) does not turn off during paper J

feed from MP tray.

6000 DF paper entry error DF paper entry sensor (DFPES) turn on before the K

eject signal is output from the machine (4000-sheet fin-

isher).

6001 DF paper entry sensor (DFPES) turn on before the K

eject signal is output from the machine (1000-sheet fin-

isher).

6020 DF front cover open DF front upper cover is opened during operation K

(4000-sheet finisher).

6021 DF front cover is opened during operation (1000-sheet K

finisher).

6041 DF top cover open DF top cover is opened during operation (1000-sheet K

finisher).

6050 CF eject cover open CF eject cover is opened during operation (4000-sheet M

finisher).

6060 MB cover open MB cover is opened during operation (4000-sheet fin- L

isher).

6070 Center folding unit open Center folding unit is opened during operation (4000- M

sheet finisher).

6080 CF left guide open CF left guide is opened during operation (4000-sheet M

finisher).

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-23

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

6100 DF paper entry sensor DF paper entry sensor (DFPES) does not turned on K

non arrival jam even if a specified time has elapsed after the machine

eject signal was received (4000-sheet finisher).

6101 DF paper entry sensor (DFPES) does not turned on K

even if a specified time has elapsed after the machine

eject signal was received (1000-sheet finisher).

6110 DF paper entry sensor DF paper entry sensor (DFPES) does not turned off K

stay jam within specified time of its turning on (4000-sheet fin-

isher).

6111 DF paper entry sensor (DFPES) does not turned off K

within specified time of its turning on (1000-sheet fin-

isher).

6200 DF sub eject sensor non DF sub eject sensor (DFSES) does not turn on within K

arrival jam specified time of DF paper entry sensor (DFPES) turn-

ing on.

6210 DF sub eject sensor stay DF sub eject sensor (DFSES) does not turned off K

jam within specified time of its turning on.

6300 DF middle eject sensor DF middle eject sensor (DFMES) does not turn on K

non arrival jam within specified time of DF paper entry sensor

(DFPES) turning on (4000-sheet finisher).

6301 DF middle eject sensor (DFMES) does not turn on K

within specified time of DF paper entry sensor

(DFPES) turning on (1000-sheet finisher).

6310 DF middle eject sensor DF middle eject sensor (DFMES) is not turned off K

stay jam within specified time of its turning on (4000-sheet fin-

isher).

6311 DF middle eject sensor (DFMES) is not turned off K

within specified time of its turning on (1000-sheet fin-

isher).

6400 DF tray upper surface DF tray upper surface sensor (DFTUSS) does not turn K

sensor non arrival jam on within specified time of DF middle eject sensor

(DFMES) turning on (4000-sheet finisher).

6401 DF tray upper surface sensor (DFTUSS) does not turn K

on within specified time of DF middle eject sensor

(DFMES) turning on (1000-sheet finisher).

6410 DF tray upper surface DF tray upper surface sensor (DFTUSS) is not turned K

sensor stay jam off within specified time of its turning on (4000-sheet

finisher).

6411 DF tray upper surface sensor (DFTUSS) is not turned K

off within specified time of its turning on (1000-sheet

finisher).

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-24

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

6500 DF eject paper sensor DF eject paper sensor (DFMTS) does not turn on K

non arrival jam within specified time of DF middle eject sensor

(DFMES) turning on.

6510 DF eject paper sensor DF eject paper sensor (DFMTS) is not turned off since K

stay jam the bundle discharge starts (4000-sheet finisher).

6511 DF eject paper sensor (DFMTS) is not turned off since K

the bundle discharge starts (1000-sheet finisher).

6600 DF drum sensor non DF drum sensor (DFDRS) does not turn on within K

arrival jam specified time of DF paper entry sensor (DFPES) turn-

ing on.

6610 DF drum sensor stay jam DF drum sensor (DFDRS) is not turned off within spec- K

ified time of its turning on.

6710 Center folding unit stay During paper conveying to center folding unit, DF drum K

jam sensor (DFDRS) is not turned off within specified time

of its turning on.

6810 DF side registration sen- DF side registration sensor 1 (DFSRS1) is not turned K

sor 1 stay jam off within specified time after driving the DF side regis-

tration motor 1 (DFSRM1) (4000-sheet finisher).

6811 DF side registration sensor 1 (DFSRS1) is not turned K

off within specified time after driving the DF side regis-

tration motor 1 (DFSRM1) (1000-sheet finisher).

6910 DF side registration sen- DF side registration sensor 2 (DFSRS2) is not turned K

sor 2 stay jam off within specified time after driving the DF side regis-

tration motor 2 (DFSRM2) (4000-sheet finisher).

6911 DF side registration sensor 2 (DFSRS2) is not turned K

off within specified time after driving the DF side regis-

tration motor 2 (DFSRM2) (1000-sheet finisher).

7000 DF staple operation error DF staple sensor (DFSTS) is not turned on within K

specified time after driving the DF staple motor

(DFSTM) (4000-sheet finisher).

7001 DF staple sensor (DFSTS) is not turned on within K

specified time after driving the DF staple motor

(DFSTM) (1000-sheet finisher).

7100 CF paper entry sensor CF paper entry sensor (CFPES) is not turned on even M

non arrival jam if a specified time has elapsed after the machine eject

signal was received.

7110 CF paper entry sensor CF paper entry sensor (CFPES) is not turned off within M

stay jam specified time of its turning on.

7200 CF eject sensor non CF eject sensor (CFES) is not turned on within speci- M

arrival jam fied time since centerfold operation starts.

7210 CF eject sensor stay jam During centerfold operation, CF eject sensor (CFES) is M

not turned off within specified time of its turning on.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-25

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4-2

Jam

Code Contents Conditions

location*

7300 CF eject sensor non CF eject sensor (CFES) is not turned on within speci- M

arrival jam fied time since three fold operation starts.

7310 CF eject sensor stay jam During three fold operation, CF eject sensor (CFES) is M

not turned off within specified time of its turning on.

7400 CF side registration sen- CF side registration sensor 2 (CFSRS2) is not turned M

sor 2 non arrival jam on within specified time after driving the CF side regis-

tration motor 2 (CFSRM2).

7500 CF side registration sen- CF side registration sensor 1 (CFSRS1) is not turned M

sor 1 non arrival jam on within specified time after driving the CF side regis-

tration motor 1 (CFSRM1).

7600 CF staple operation error CF staple sensor (CFSTS) is not turned on within M

specified time after driving the CF staple motor

(CFSTM).

7700 CF paper conveying sen- CF paper conveying sensor (CFPCS) is not turned on M

sor non arrival jam even if a specified time has elapsed after the machine

eject signal was received.

7710 CF paper conveying sen- CF paper conveying sensor (CFPCS) is not turned off M

sor stay jam within specified time of its turning on.

7800 MB eject sensor non MB eject sensor (MBES) is not turned on even if a L

arrival jam specified time has elapsed after the machine eject sig-

nal was received.

7810 MB eject sensor stay jam MB eject sensor (MBES) is not turned off within speci- L

fied time of its turning on.

7900 Middle paddle error jam DF paddle sensor (DFPDS) is not turned on within K

specified time after driving the DF middle motor

(DFMM) (4000-sheet finisher).

7901 DF paddle sensor (DFPDS) is not turned on within K

specified time after driving the DF middle motor

(DFMM) (1000-sheet finisher).

7950 Paper interval error jam An illegal inter-page or inter-copy interval has occurred K

(4000-sheet finisher).

7951 An illegal inter-page or inter-copy interval has occurred K

(1000-sheet finisher).

9000 No original feed jam DP feed sensor (DPFS) does not turn on within speci- H

fied time during the first sheet feeding (Retry 5 times).

9001 DP original conveying DP timing sensor (DPTS) turn off within the specified H

jam time since the sensor turn on.

9002 DP sensor stay jam Sensor in the conveying system is on since original H

feeding starts.

9004 DP switchback jam 2 DP registration sensor (DPRS) is not turned on within H

specified time since original switchback operation

starts.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-26

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

9005 No original feed jam 2 DP lift sensor 1 (DPLS1) does not turn on within speci- H

fied time of the lift plate rising.

9006 DP switchback jam 3 DP eject sensor (DPES) is not turned on within speci- H

fied time since original switchback operation starts.

9007 DP switchback jam 4 DP eject sensor (DPES) is not turned off within speci- H

fied time since original switchback operation starts.

9008 No original feed jam 3 DP CIS sensor (DPCS) does not turn on within speci- H

fied time of the paper feed starting.

9009 DP original conveying Next feed original became the stand-by states of paper H

jam 2 feed while reading the image.

9010 Document processor Document processor is opened during original feeding. H

open

9011 DP top cover open The DP top cover is opened during original feeding. H

9020 Original skew feed jam DP skew sensor (DPSS) does not turn on within speci- H

fied time of DP registration sensor (DPRS) turning on.

9110 DP feed sensor stay jam DP feed sensor (DPFS) does not turn off within speci- H

fied time of DP timing sensor (DPTS) turning on.

9200 DP registration sensor DP registration sensor (DPRS) does not turn on within H

non arrival jam specified time of DP feed sensor (DPFS) turning on.

9210 DP registration sensor DP registration sensor (DPRS) does not turn off within H

stay jam specified time of DP timing sensor (DPTS) turning on.

9300 DP CIS sensor non DP CIS sensor (DPCS) does not turn on within speci- H

arrival jam fied time of DP registration sensor (DPFS) turning on.

9310 DP CIS sensor stay jam DP CIS sensor (DPCS) does not turn off within speci- H

fied time of DP registration sensor (DPFS) turning off.

9400 DP timing sensor non DP timing sensor (DPTS) does not turn on within spec- H

arrival jam ified time of DP feed sensor (DPFS) turning on.

9410 DP timing sensor stay DP timing sensor (DPTS) does not turn off within spec- H

jam ified time of DP feed sensor (DPFS) turning off.

9500 DP switchback sensor DP switchback sensor (DPSBS) does not turn on H

non arrival jam within specified time of DP timing sensor (DPTS) turn-

ing on.

9600 DP eject sensor non DP eject sensor (DPES) does not turn on within speci- H

arrival jam fied time of DP timing sensor (DPTS) turning on.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-27

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam

Code Contents Conditions

location*

9610 DP eject sensor stay jam DP eject sensor (DPES) does not turn off within speci- H

fied time of DP timing sensor (DPTS) turning off.

*: Refer to figure 1-4-1 for paper misfeed indication (see page 1-4-1).

1-4-28

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4-1

1-4-2 Troubleshooting

(1) First check items

If the paper is fed askew, jammed, curled, or leading-edge dog-eared, first perform to check the following

items.

Check items Check description Corrective measures

Paper 1. Check the paper delivered is If a dog-ear has happened, check there are no objects

dog-eared, skewed, rumpled, existing in the conveying paths and, if any, fix.

loosely fused, or curled. If the paper is fed askew or crumpled, perform the fol-

lowing No.2.If an inferior fusing or curling is observed

and the fuser temperature is set to a abnormal value,

when measured by performing maintenance mode

U161, reset to the default. (see page 1-3-110)

2. Check how paper is loaded in Adjust the cursors to the size of the paper.

the cassette (deck). (If paper is fed askew, perform a skew cancellation

Check that the paper has adjustment of the width adjuster cursor.) (see page 1-5-

been properly aligned with 123)

width adjuster cursor and the

rear guide; it has been loaded

without skewing; or it is not

damaged. (Crumpled paper,

main unit/DF jam)

3. Check how paper is loaded. If the cutting edge of the paper bundle is crumpled, fan

Check if the cutting edge of the paper before loading.

the paper bundle inside is If the paper is folded, stretch before loading in the

cumpled or bent. cassette

4. If a large-capacity deck is Reloard the paper so that its edges won't be situated

being used, check how paper above the platform.

is loaded in the deck.

Check if the paper inside the

deck is placed above the

guide.

5. Check the paper is damp, 1. Load the paper bundle in the cassette upside down.

wavy, or curled.

reload.

3. Change the paper.

6. Check if the paper loaded Instruct the user to store paper in a dry, less humid

was stored in a continuously place.

humid place. Install a cassette heater and configure using U327. (see

page 1-3-161)

7. Check if the paper conforms Isolate the cause of the problem by replacing the paper

to the requirements. with the recommended paper.

(see page 1-1-1)

1-4-29

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Check items Check description Corrective measures

Paper 8. Check the paper ejected is If the maintenance mode U161 shows that the fuser

dog-eared, skewed, rumpled, temperature is set to an abnormal value, reset it to the

loosely fused, or curled. default. (see page 1-3-110)

Settings/ 1. Check if the margin is

Detection 4.0+1.5/-1.0mm from the leading edge, adjust the leading margin by U402. (see

leading edge of paper. page 1-3-167)

2. Perform U034 to check the

reference mark is situated at

(Fuser jam)

(see page 1-3-38)

3. Check the panel if the paper If the paper size is incorrectly displayed, adjust the

size is correctly detected and positions of the paper set guide cursors in accordance

the cassette size is not with the paper size, making sure that the paper is not

fixed.(Paper jam caused by askew to activate the size detector switch.

continously fed paper, DF

Jam J611X) Perform U000 to

obtain a Event Log to check if

the paper size and the size of

the paper loaded are met

when jam has occurred and if

the size of the original

document and the paper size

are met. see page 1-3-12)

4. Check that paper settings are Select Original/ Paper settings under common settings

made in accordance with the in the system menu to set media type and weight of

paper being used. (Jam paper.

caused by faulty separation)

Coveying unit Check the main unit vertical To open, first open the right-side conveying unit and

conveying unit or the front and close firmly. (Check the position of the safery switch)

back parts and right and left parts

of the deck's horizontal

conveying unit are slightly

strained and closed.

1-4-30

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Check items Check description Corrective measures

Conveying 1. Check that the foreign If foreign objects such as scrips, etc., remain in the

guide, objects including scrips, paper conveying path, remove.

approaching paper clips, etc., do not exist

guide, feed- in the paper conveying paths.

shift guide 2. Check that the paper If dirty, clean the guide, ribs (by a cloth), and the

conveying guide and the separation needles (by a cleaning brush).If the ribs of

separation needles are not the conveying guides were broken or deposited with

contaminated with toner, toner, replace.

paper dusts, etc.

3. Check that the paper Clean the conveying guide or the paper approaching

conveying guide has no guide.Remove any protrusions including barrs.If floated,

barrs, deformations, or fix it properly.If deformation or abrasion is observed,

abrasions; and it is properly replace.

mounted without being

floated.

4. Check that the guide. If the guide is inoperative or won't operate smoothly,

Check that the guide is replace the guide or the unit.

smoothly operative when

manipulated.

5. Check that the guide. If the guide is inoperative or won't operate smoothly, re-

Perform U033 to check the assemble the guide or replace the solenoid or the unit.

operation of the solenoid to

sight-check or audio-check its

action. (see page 1-3-37)

1-4-31

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Check items Check description Corrective measures

Conveying 1. Check the conveying rollers Clean the conveying rollers or the pollyes.

roller, feed have no paper dusts, toner, If variation in the external diameter or abrasion is

roller or foreign objects observed, replace.

stucked.Check a variation of

the external diameter of the

roller or abrasion is not

observed with the coveying

roller.

2. Turn the cover safety switch If the conveying motor or the clutch is inoperative,

on and perform U030 - Motor, replace.

U032 - Clutch, and U240 - If stained, replace the clutch.

Finished, check they operate If the clutch is kept turned on due to a tensioned wire,

normally. reroute wires.

* : At checking the clutch by

U032, confirm that the

roller won't turn when the

motor is turned on. (see

page 1-3-34,1-3-36,1-3-

134)

3. Check the conveying roller Clean the roller axle or the axle holder.Re-assemble it

rotates without overloading. while checking the pressure of the spring.

Check the axle holder or the

roller shaft are not

contaminated.

Check that the spring has not

fallen off and is mounted so

that it is properly applying

pressure against the rollers

or pulleys.

Sensor 1. Check if it does not operate Re-assemble the actuator or the return spring.

with smoothness due to an

abnormal move or dropping

off of the actuator of the

coveying switch.

2. Check that the surface of the If dirty, clean the sensor or the black felt piece.

sensor and the recveptor

black felt pieces are not

contaminated with toner,

paper dusts, etc.

3. Perform U031 - Conveying If U031has revealed that the sensor is inoperative,

switch and U241 - Finisher replace the switch.

switch to check the sensors

are normal without flickering,

etc. (see page1-3-35, 1-3-

136)

1-4-32

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Check items Check description Corrective measures

Static Check if the location is Re-assemble and re-wire the static discharge sheet at

susceptible to build static the ejection unit or the metal guide at the tranfer unit so

discharge at the conveying guide that they are properly grounded.

during printing.

(2) Items and corrective actions relating to the device that will cause paper jam

Jam types Check description Corrective measures

No-paper-feed jam or 1. Check if the jammed Replace the primary feed roller.(Service life of rubber

the leading edge of paper or the printed roller is 150k.)

paper is curled back at paper has a tear Increase the spring pressure to pinch the separation

the position of the caused by the roller at rollers if the component is undue to its expected

roller its leading edge. life.Replace the spring.

(J0501,J0502, 2. Check abrasion and Clean the feed roller and the forward roller.Or, if not

J0503,J0504, J0505, paper dusts on the feed amended, replace.

J0506, J0507, J0509, roller and forward

J0523, J0524, J0525, rollers.

J0526, J0527, J0545)

3. Perform U032 to check If disconnected or or stained, replace the primary

the forward roller and feed clutch.

feed roller are rotating.

4. Check if a primary feed Distinguished by color: White x 2, black x 1

roller of a wrong Check that the feed rollers are installed at (1) Feed

material of rubber is Roller (Collar is white.), (2) Retard roller (black), and

installed. (3) Pickup Roller (white). 45-ppm/55-ppm devices

* : If not, install then at the correct positions.

5. Check that the Increase the conveying force during paper pickup by

conveying force of the increasing the spring load of the pickup roller.

pickup roller is

sufficient.

6. Check the film is Amount of protrusion of film in approaching (Gap: 0.2

sufficiently protruded in - 0.5 mm) must be maintained after adjustment.

front of approching the

feed roller and the

nip.(Too wide a gap

against the feed roller.)

1-4-33

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam types Check description Corrective measures

No-paper-feed jam or 7. Check the separation If it gets in contact, replace the primary feed unit.

the leading edge of roller is not disturbed as

paper is curled back at a driving component is

the position of the in contact with the

roller frame during the

(J0501,J0502, separation roller is in

J0503,J0504, J0505, motion.

J0506, J0507J0509, 8. Depress the release Modify mounting the retard holder fixing plate.

J0523, J0524, J0525, lever to release the

J0526, J0527, J0545) pressure of the primary

feed rollers to check

that the retard holder

falls.(The pressure by

the retard roller to the

feed roller is

decreased.)

Multiple-feed Jam 1. Check if the cutting If the cutting edge of the paper bundle is crumpled or

(J0511, J0512, J0513, edge of the paper the cassette is loaded with multiple times of

J0514, J0516, J0517, bundle is crumpled or replenishing paper, load new paper.

J0519) the cassette is loaded

with multiple times of

replenishing paper.

2. Checking paper size. If the paper size does not agree.

Check that the size of 1. If the cassette cursors are open against the

the loaded paper and paper, set it properly.

the paper size chosen 2. Insert the cassette until the paper size detector

on the operator panel switch is turned on.

are met. If the size is not detectable while automatic sizing

is enabled, replace the size detection switch.

If the paper size agrees

1. If paper other than complying the requirements

such as coated paper, inkjet paper, etc., is used,

replace the paper.

2. RE-assemble the pulley retard in the primary

feed unit if it is mounted to the oppisite direction.

3. Check if the spring retard has not been fallen off

of the mounting position. If the spring retard is

not dropped off of the mount position, decrease

the spring pressure that is applied to the

separation rollers.

4. Replace the primary feed unit.

3. Check if paper dusts If the paper fanning roller is dirty, clean.

and abrasion are If abrasion is observed, replace.

observed on the paper

fanning roller and retard

roller.

1-4-34

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam types Check description Corrective measures

Multiple-feed Jam 4. Select the motor by If the clutch rotates following the other component

(J0511, J0512, J0513, U032 and check the and its stain is observed, replace the clutch.

J0514, J0516, J0517, clutch rotates following

J0519) the other component

when the motor is

turned on. (see page 1-

3-36)

Duplex No-original- Perform U031 to check if If the duplex sensor 2 is not working, replace the

feed Jam (J0508) the duplex sensor 2 is duplex sensor 2.

Duplex Multiple-feed detected. (see page 1-3-34)

Jam (J0518)

Intermediate/ 1. Check to see if the If it won't operate without hinderance, re-assemble or

conveying sensor stay actuator is operative replace the actuator's return spring.

jam without hinderance.

(J1313, J1314, J1513, 2. Perform U031 to check If the sensor is inoperative, replace.

J1514) the operation of the

sensor.

3. Select the motor by If stained, replace the clutch.Re-assmeble the clutch

U032 and check if the so that it is not continuously energized. (Change of

coveying clutch rotates wirings, etc.)

following the other

component. (see page

1-3-36)

4. Check if the conveying If the bracket is twisted to be mounted, remove the

guide is twisted to be screw fixing the conveying guide and properly mount

mounted.(If the the bracket in the right position and fix again.

mounting parts of the

guide is floated, the

actuator won't protrude

sufficiently.)

5. Check no wrinkles are Adjust the cursors to the size of the paper.

observed at the sluck of (If paper is fed askew, perform a skew cancellation

paper during paper adjustment of the width adjuster cursor.) (see page 1-

feeding. 5-123)

1-4-35

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam types Check description Corrective measures

Conveying sensor non 1. Check to see if the Re-assemble or replace the actuator's return spring.

arrival jam (J1503/ actuator is operative

J1504) without hinderance.

SM conveying sensor 2. Perform U030 to check If the roller won't rotate without hinderance, loosen

2 stay jam (J3415, the operation of the the screws for adjusting the position (at the gear train

J3416, J3417) motor. bracket) to mount the driving gears, and tighten so

Check the transmission that a gap between the gears and frame is

of the gear drive using eliminated.

U032.

* : Check the convey-

ing roller rotates and

is movable in the

direction of thrust

without hinderance.

(see page 1-3-36)

Loop sensor non 1. Check no wrinkles are Adjust the cursors to the size of the paper.

arrival jam (J4101, observed at the sluck of (If paper is fed askew, perform a skew cancellation

J4102, J4103, J4104, paper during paper adjustment of the width adjuster cursor.) (see page 1-

J4105, J4106, J4107) feeding. 5-123)

2. Check that the paper is Reload paper.

entirely loaded inside

the cassette without

being skewed.

Fuser eject sensor 1. If paper jam occurrs at If the distance between the housing and the feedshift

stay jam (J421X) the feedshift guide in guide is too small for the guide to move without

the eject unit, check if hinderance, replace the eject unit.

Ejection-full sensor the guide is operative

non arrival jam without hinderance.

(J460X)

2. Perform U031 to check Replace the defective eject sensor or the eject unit.

Inversion sensor non if the eject sensor does

arrival jam (J470X) not show a false

detection.

(see page 1-3-35)

1-4-36

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam types Check description Corrective measures

Duplex sensors 1 and 1. Check that the duplex Clean or replace the duplex roller in the coveying

2, stuck/ non arrival rollers cause slipage in unit.

Jam (J43XX, J44XX) feeding paper.

2. Perform U031 to check Replace the defective duplex sensors 1 and 2 or the

if the duplex sensors 1 coveying unit.

and 2 do not show false

detections.

3. Check if the second Replace the paper with new paper.Try feeding paper

side of plain paper is lengthwise.

curled at its tail and

slacked in the middle

making the switch

disguised as no

existance of paper.

BR conveying sensor 1. Check contamination of Clean or replace the rollers.

1/2 non arrival/stay the rollers of the bridge

jam (J49XX) eject unit.

Eject sensor non 2. Check contamination or Clean the axle holder or replace with a new axle

arrival jam (J50XX) abrasion of the axle holder.

Eject sensor stay jam holders of the bridge

(J51XX) eject unit.

DF paper entry error

3. Check the location the Re-mount.

JAM (J600X)

bridge relay conveying

unit is mounted.

DF conveying sensor 1. Check it the main unit Perform the height adjustment by referring to the

non arrival jam and the DF are installation instructions.

(J610X) vertically flush with

DF conveying sensor each other.

stay jam (J611X)

1-4-37

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam types Check description Corrective measures

DF conveying sensor 2. Check if the jammed 2.If a down-curled sheet is jammed at the DF

non arrival jam paper has a dog-ear. conveying guide ribs by being dog-eared, replace the

(J610X) DF conveying lower guide.

DF conveying sensor

stay jam (J611X)

3. Check if dog-ears are If a welding protrusion on the coveying side causes

caused within the paper to be trapped, try replacing the punch unit.

punch unit.

DF intermediate sen- 1. If there is not the Re-mount the actuator.

sor stay jam (J631X) jammed paper which is

DF main tray ejection causing J631, at the

stay JAM (J641X) paper processing area,

DF eject sensor non check to see if the

arrival jam (J6500) actuator (DF middle

DF eject sensor stay sensor) is operative.

jam (J651X)

1-4-38

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4-1

Jam types Check description Corrective measures

DF intermediate sen- 2. Check the range of the If the gap is not correct, fix balance of the bundle

sor stay jam (J631X) up and down eject unit.

DF main tray ejection movement of the If (1): Correct the phase shifting with meshing of the

stay JAM (J641X) ejection guide. front and back gears.

DF eject sensor non Check if the operating (Turn on U240 - Motor-EjectUnlock (30) to check the

arrival jam (J6500) position after feeding in balance of the front and back rollers with the bundle

DF eject sensor stay the first sheet is normal. eject unit opened.see page 1-3-134)

jam (J651X) (1)If it moves askew (due to

the forward and backward

shift of phase on the eject

guide)

(2)If the range of motion is

too small

Check if the gap between

the ejection roller and the

ejection pulleys is approxi-

mately 3.5 - 5.5 mm.

(Check gaps while making If (2): Adjust the positioning of or replace the Mount

paper still in the intermedi- PI upper guide.

ate process tray.)

3. Execute U240 Motor - If the width adjuster cursor is wrongly positioned,

Width Test A3/LD to perform U246 Finisher - Width Front HP/Width Tail

adjust the position of HP. (see page 1-3-142)

the width adjuster

cursor of the process

tray. Check if the cursor

is located at 0 - +0.5

from the paper edge.

Or check if the cursor is

abnormally shifted.

(The DF and the main

unit paper sources)

(see page 1-3-134)

1-4-39

Downloaded from www.Manualslib.com manuals search engine

2L6/2N6/2N5/2N4

Jam types Check description Corrective measures

DF intermediate sen- 4.With stapling at one point 1. If a wire from the ejection motor is pinched by

sor stay jam (J631X) with about 65 sheets, other component or a connector is loosely

DF main tray ejection check for the failure on connected, correct.

stay JAM (J641X) the bundle when it is If a loss of synchronism is observed with the

DF eject sensor non delivered in the shape ejection motor due to lack of torque, replace the

arrival jam (J6500) of an arc. motor.

DF eject sensor stay 2. If paper slippage occurs due to the lack of

jam (J651X) pressure by the ejection rollers, check if the

pressure sufficient (3 springs, at the center).

If a malfunction to encumber the ejection rollers

to generate pressure is observed, correct.

5. With stapling set at 2 If the paper is curled, change the direction of loading