Air Trap JA3D

Air Trap JA3D

Uploaded by

M Numan FarooqiCopyright:

Available Formats

Air Trap JA3D

Air Trap JA3D

Uploaded by

M Numan FarooqiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Air Trap JA3D

Air Trap JA3D

Uploaded by

M Numan FarooqiCopyright:

Available Formats

SDS M3200-00

FREE FLOAT ®

AIR TRAP

MODEL JA3D

FREE FLOAT AIR TRAP WITH TIGHT SHUT-OFF FOR AIR SERVICE

Features

Light free-float air trap to automatically

drain condensate and oil from compressed

air systems.

1. Self-modulating free float provides soft,

continuous, and smooth, low velocity

discharge as process loads vary.

2. Perfect air-tight seal, even under low-load

conditions.

3. Only one moving part, the free float, prevents

concentrated wear and provides long

maintenance-free service life.

4. Built-in screen with large surface area ensures

extended trouble-free service.

5. Manual blow down device allows cleaning of

the valve seat from outside during operation in

case of oil and dirt accumulation.

6. All internal parts made of stainless steel.

7. For either horizontal or vertical installation.

Specifications

Model JA3D

Connection Screwed

Size (mm) 15

Maximum Operating Pressure (MPaG) PMO 1.6

Maximum Differential Pressure (MPa) ΔPMX 1.6

Maximum Operating Temperature (°C) TMO 100

Applicable Fluid* Air

* Do not use for toxic, flammable or otherwise hazardous fluids. 1 MPa = 10.197 kg/cm2

PRESSURE SHELL DESIGN CONDITIONS (NOT OPERATING CONDITIONS): Maximum Allowable Pressure (MPaG) PMA: 1.6

Maximum Allowable Temperature (°C) TMA: 100

To avoid abnormal operation, accidents or serious injury, DO NOT use this product outside of the specification range.

CAUTION Local regulations may restrict the use of this product to below the conditions quoted.

No. Description Material JIS ASTM/AISI*

① Body Zinc Alloy ZDC2 B86 AC140A

② Cover Zinc Alloy ZDC2 B86 AC140A

③ Union Nut Zinc Alloy ZDC2 B86 AC140A

④ Float Stainless Steel SUS316L AISI316L

⑤ Screen Stainless Steel SUS430 AISI430

⑥ Cover Gasket Nitrile Rubber NBR D2000BF

⑦ Valve Seat Nitrile Rubber NBR D2000BF

⑧ Valve Seat Holder Stainless Steel SUS420F AISI420F

⑨ Holder Gasket Fluorine Resin PTFE PTFE

⑩ Guard Bushing Carbon Steel SGP A53 Type F

⑪ Coil Spring Stainless Steel SUS304 AISI304

⑫ Plunger O-Ring Nitrile Rubber NBR D2000BF

⑬ Snap Ring Stainless Steel SUS304 AISI304

⑭ Plunger Stainless Steel SUS416 AISI416

* Equivalent

Dimensions

¡JA3D Screwed JA3D Screwed* (mm)

Size L1 H H1 φW Weight (kg)

L1 15 28 104 80 80 0.6

* Rc(PT), other Standards available.

W

NOTE

A pressure-balancing line must be connected to the air system

H

from the balancing port at the top or side of the trap to a place

H1

above any possible condensate accumulation in the system.

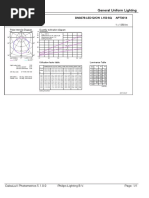

Discharge Capacity

Differential Pressure (kg/cm2)

0.1 0.3 0.5 1 2 4 6 8 10 16

300

200

Discharge Capacity (kg/h)

100

80

60

40

20

0.01 0.03 0.05 0.1 0.2 0.4 0.6 0.8 1.0 1.6

Differential Pressure (MPa)

1. Differential pressure is the difference between the inlet and outlet pressure of the trap.

2. The chart is applicable to condensate below 100 °C.

3. The discharge capacity is for a liquid with specific gravity of 1.

4. Recommended safety factor: at least 1.5.

DO NOT use traps under conditions that exceed maximum differential pressure,

CAUTION as condensate backup will occur!

SDS M3200-00 Rev. 5/2012

Products for intended use only.

Specifications subject to change without notice.

You might also like

- Miracle Equation Implementation GuideDocument2 pagesMiracle Equation Implementation Guidebiglibigli100% (2)

- Contemporary Issues in AccountingDocument29 pagesContemporary Issues in AccountingMichelle Mcmillan0% (1)

- E SVGMD HPDocument2 pagesE SVGMD HPSylvio Santiago LimaNo ratings yet

- Check Pilotada OpenDocument2 pagesCheck Pilotada OpenChrystian Meller Vasquez MaytaNo ratings yet

- E l21s0 HPDocument2 pagesE l21s0 HPrinthusNo ratings yet

- 041308X57ZDocument2 pages041308X57Znorthernwolf123No ratings yet

- 041307X57ZDocument2 pages041307X57Znorthernwolf123No ratings yet

- Pressure Reducing and Relieving, Direct Acting Spool Type: Common Cavity, Size 08Document2 pagesPressure Reducing and Relieving, Direct Acting Spool Type: Common Cavity, Size 08northernwolf123No ratings yet

- 041504X99Z Re18318-22Document2 pages041504X99Z Re18318-22omarhany01221No ratings yet

- Relief, Direct Acting Guided Poppet Type, Hardened Seat Special Cavity, 008Document2 pagesRelief, Direct Acting Guided Poppet Type, Hardened Seat Special Cavity, 008mhasansharifiNo ratings yet

- 041504X99Z RE18318-22 Compressed PDFDocument2 pages041504X99Z RE18318-22 Compressed PDFmhasansharifiNo ratings yet

- Relief, Direct Acting Poppet Type Differential Area Special Cavity, 004Document2 pagesRelief, Direct Acting Poppet Type Differential Area Special Cavity, 004mhasansharifiNo ratings yet

- J3X & JF3X PDFDocument2 pagesJ3X & JF3X PDFMukiara LuffyNo ratings yet

- 049308X57ZDocument2 pages049308X57Znorthernwolf123No ratings yet

- Air Trap JA3Document2 pagesAir Trap JA3M Numan FarooqiNo ratings yet

- Air Vent LA21Document2 pagesAir Vent LA21M Numan FarooqiNo ratings yet

- E j75x0 HP - UnlockedDocument2 pagesE j75x0 HP - Unlockedahmadsweiti11No ratings yet

- Pressure Reducing and Relieving, Pilot Operated Spool Type Common Cavity, Size 10Document2 pagesPressure Reducing and Relieving, Pilot Operated Spool Type Common Cavity, Size 10mhasansharifiNo ratings yet

- U dr20x HP PDFDocument2 pagesU dr20x HP PDFRicardo SanchezNo ratings yet

- 041801X99ZDocument2 pages041801X99Znorthernwolf123No ratings yet

- 041159X85ZDocument2 pages041159X85Znorthernwolf123No ratings yet

- 041210X57ZDocument2 pages041210X57Znorthernwolf123No ratings yet

- Valvula de RealifDocument2 pagesValvula de RealifJoyce AlmeidaNo ratings yet

- 041105X99ZDocument2 pages041105X99Znorthernwolf123No ratings yet

- 049508X99ZDocument2 pages049508X99Znorthernwolf123No ratings yet

- 041127X99ZDocument2 pages041127X99Znorthernwolf123No ratings yet

- 041522X56ZDocument2 pages041522X56Znorthernwolf123No ratings yet

- 041504X99ZDocument2 pages041504X99Znorthernwolf123No ratings yet

- Pressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10Document2 pagesPressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10tecnicomanelNo ratings yet

- 047721X57ZDocument2 pages047721X57Znorthernwolf123No ratings yet

- LPH 65320 LPH 65327Document9 pagesLPH 65320 LPH 65327Eko WageurNo ratings yet

- Pressure Reducing and Relieving, Direct Acting Spool Damped TypeDocument2 pagesPressure Reducing and Relieving, Direct Acting Spool Damped TypetecnicomanelNo ratings yet

- 047510X99ZDocument2 pages047510X99Znorthernwolf123No ratings yet

- 049509X99ZDocument2 pages049509X99Znorthernwolf123No ratings yet

- Check, Poppet Type: Common Cavity, Size 16Document2 pagesCheck, Poppet Type: Common Cavity, Size 16HIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- 041157X99ZDocument2 pages041157X99Znorthernwolf123No ratings yet

- 041158X99ZDocument2 pages041158X99Znorthernwolf123No ratings yet

- 041118X09ZDocument2 pages041118X09Znorthernwolf123No ratings yet

- 049306X85ZDocument2 pages049306X85Znorthernwolf123No ratings yet

- 041169X56Z Re18318-40Document2 pages041169X56Z Re18318-40Wellington Hiroshi Tani HenriquesNo ratings yet

- 047521X56ZDocument2 pages047521X56Znorthernwolf123No ratings yet

- Check, Poppet Reverse Type: Common Cavity, Size 08Document2 pagesCheck, Poppet Reverse Type: Common Cavity, Size 08northernwolf123No ratings yet

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Document10 pagesLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalNo ratings yet

- 041157X99Z RE18318-20 CompressedDocument2 pages041157X99Z RE18318-20 CompressedmhasansharifiNo ratings yet

- Pressure Reducing and Relieving, Direct Acting Spool Damped TypeDocument2 pagesPressure Reducing and Relieving, Direct Acting Spool Damped Typenorthernwolf123No ratings yet

- Xii 1 - Brochure Sihi LPHX 45008 45311 45316Document16 pagesXii 1 - Brochure Sihi LPHX 45008 45311 45316Usri AdiNo ratings yet

- Free Float Steam Trap: Model Stainless SteelDocument2 pagesFree Float Steam Trap: Model Stainless SteelJustin GentryNo ratings yet

- 041156X85ZDocument2 pages041156X85Znorthernwolf123No ratings yet

- 041148X56ZDocument2 pages041148X56Znorthernwolf123No ratings yet

- 049806X99ZDocument2 pages049806X99Znorthernwolf123No ratings yet

- Hydraulic Cylinder - Mill TypeDocument28 pagesHydraulic Cylinder - Mill TypeLe Van TamNo ratings yet

- Counterbalance, Standard Poppet Type Zero Differential Area: Common Cavity, Size 20Document2 pagesCounterbalance, Standard Poppet Type Zero Differential Area: Common Cavity, Size 20tecnicomanelNo ratings yet

- 041523X85ZDocument2 pages041523X85Znorthernwolf123No ratings yet

- Vodokruzne Vyvevy LPHX 55xxxDocument12 pagesVodokruzne Vyvevy LPHX 55xxxJason Wei Han LeeNo ratings yet

- 043137X85ZDocument2 pages043137X85Znorthernwolf123No ratings yet

- VSO-DE Pilot Operated Check, DualDocument2 pagesVSO-DE Pilot Operated Check, DualHector MoragaNo ratings yet

- Cylinder: Data Sheet No. 2.29.001E-1Document10 pagesCylinder: Data Sheet No. 2.29.001E-1sancsa_74No ratings yet

- Free Float Free Float Steam Trap Steam Trap: ModelDocument2 pagesFree Float Free Float Steam Trap Steam Trap: ModelAnonymous cb9s3t0q100% (1)

- Od940118yz Re18323-65Document4 pagesOd940118yz Re18323-65Mechanical2022No ratings yet

- Relief, Direct Acting Poppet Type Pressure Compensated Special Cavity, 008Document2 pagesRelief, Direct Acting Poppet Type Pressure Compensated Special Cavity, 008mhasansharifiNo ratings yet

- Wartsila Vasa - 12v32 - Spare PartsDocument326 pagesWartsila Vasa - 12v32 - Spare PartsNezih Yanıkman100% (2)

- How To ... Teach Vocabulary: Teacher's Book. Pearson Longman Extra Words Feature Which Allows Students ToDocument1 pageHow To ... Teach Vocabulary: Teacher's Book. Pearson Longman Extra Words Feature Which Allows Students ToPaula UrbaniNo ratings yet

- COOLEX 80W - 10M Pole Single Cross - 15 SetsDocument24 pagesCOOLEX 80W - 10M Pole Single Cross - 15 SetsDoudou DIOPNo ratings yet

- Texnomic Tradex Bot: Announcement #3Document1 pageTexnomic Tradex Bot: Announcement #3lawNo ratings yet

- Chapter 2Document59 pagesChapter 2Kiran RajNo ratings yet

- Pastor. The History of The Popes, From The Close of The Middle Ages. 1891. Vol. 02Document626 pagesPastor. The History of The Popes, From The Close of The Middle Ages. 1891. Vol. 02Patrologia Latina, Graeca et Orientalis100% (2)

- ACCA - Approved Learning Partner GuideDocument20 pagesACCA - Approved Learning Partner GuideoscarologyNo ratings yet

- Challenging Problems in Sequences and Series - Special HL Level SumsDocument11 pagesChallenging Problems in Sequences and Series - Special HL Level Sumssriramaniyer81% (16)

- Eakin Living AutobiographicallyDocument11 pagesEakin Living AutobiographicallyzeldavidNo ratings yet

- Om Mani Padme HumDocument2 pagesOm Mani Padme HumGerr McGregorNo ratings yet

- FP ZOOM FunctionalityDocument30 pagesFP ZOOM FunctionalityraghusimhareddyNo ratings yet

- Dn027b Led12cw l150 SQDocument1 pageDn027b Led12cw l150 SQHaianh PhamNo ratings yet

- Info PHPDocument17 pagesInfo PHPAlberto CoutinhoNo ratings yet

- Research Title DefenseDocument14 pagesResearch Title DefenseSydney MoncedaNo ratings yet

- Tech 8Document4 pagesTech 8Anum Zara (Zaari)No ratings yet

- Reality Therapy HandoutDocument6 pagesReality Therapy HandoutKrystal Kim100% (1)

- First Grade Adjective Worksheet Blanks1Document1 pageFirst Grade Adjective Worksheet Blanks1Zaton AinNo ratings yet

- Safety Data Sheet Winsor & Newton Water Colour Granulation Medium (Us MSDS)Document4 pagesSafety Data Sheet Winsor & Newton Water Colour Granulation Medium (Us MSDS)Bull433No ratings yet

- Grades - American Headway 3e Level 3 - Oxford University Press 18-OCTDocument8 pagesGrades - American Headway 3e Level 3 - Oxford University Press 18-OCTDULCE CAROLINA CASTRO HERN�NDEZNo ratings yet

- Royal HaskoningDHV Shipyards Brochure PDFDocument16 pagesRoyal HaskoningDHV Shipyards Brochure PDFSUBIN MATHEWNo ratings yet

- Sensitivity AnalysisDocument6 pagesSensitivity AnalysisLovedale JoyanaNo ratings yet

- CH 9 Portfolio Management QuestionsDocument92 pagesCH 9 Portfolio Management Questionsgustavo eichholzNo ratings yet

- Solar Radiation in MálagaDocument2 pagesSolar Radiation in MálagarodheramNo ratings yet

- MAC3701 Question Bank 2016Document65 pagesMAC3701 Question Bank 2016Blessings Munkuli100% (1)

- BỘ ĐỀ IELTS SPEAKING QUÝ 3 2024Document32 pagesBỘ ĐỀ IELTS SPEAKING QUÝ 3 2024quachchau0110No ratings yet

- Organizational Behavior LEADERSHIPDocument33 pagesOrganizational Behavior LEADERSHIPShyam Tarun100% (1)

- Classification of Bus BarDocument6 pagesClassification of Bus BarVikas SinghNo ratings yet

- NCP 3 in ER Module (Bernales, JLE)Document3 pagesNCP 3 in ER Module (Bernales, JLE)Jan Lianne BernalesNo ratings yet