Emery Roller Machine

Emery Roller Machine

Uploaded by

installationsap1Copyright:

Available Formats

Emery Roller Machine

Emery Roller Machine

Uploaded by

installationsap1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Emery Roller Machine

Emery Roller Machine

Uploaded by

installationsap1Copyright:

Available Formats

Jas Enterprises

An ISO 9001:2008 Certified Company

EMERY ROLL MACHINE ( HUSK REMOVER )

Emery Roller is a machine for de-husking pulses thus this

machine some time called as Pulse Splitter. They are used

in various pulse mills for per-treatment and obtaining gota.

It is operated by a motor and the hopper is mounted at one

end. The roller with emary rotates inside a screen. Passing

through the screen husks get removed and pulverized. The

pulses which are shelled gets out of the outlet which is at the

other end of the machine.

Jas Enterprises offer horizontal abrasive carborundum / emery

stone grits roller cylindrical mill of different capacity, run by

electric motor was developed for de-husking and splitting off

food legumes viz.pigeon pea gram and black gram. It consisted

mainly of emery coated roller to give 850-900rpm and dal (splits)

recovery 74.75%. Though the unit is similar to traditional miller

machine and gives more or less the same dal recovery. It is useful for small scale production of dal in

villages & towns.

Key features of Emery Roller Machine ( Husk Remover)

• Suitable for processing of all types of pulses with use of Screen

• Easy to operate. Also having screen setting to get maximum life of abrasives stone

• Operates by “flat / V belt pulley drive”

• Retains proteins and natural shine

Constructions of Emery roller ( Husk Remover )

Emery Roller is used for De husking the pulses, wheat, grains, corn, maize, rice and many more is

consist heavy duty fabricated Cover & Structure. Roller is rotating with a Emery Roller with lower

RPM. Both end of shaft is fixed with Baring & Bearing hosing to reduce the rotating futons of the shaft

and get with higher affectingly. The complete unit is mounted on heavy duty C Section Channel.

Operation of Emery roller ( Husk Remover )

Jas Enterprises is offering Emery roller ( Emery Roller Machine). This machine is simple in construction

and easy to operate & maintain. It consist of horizontal Emery Roller is covered with, surrounded by a

screen. Pulses, rice, wheat, maize, are passes via feeding hopper between screen & Emery roll. Because

of lower RPM of machine grains, pulses et cetera were giving De husked.

Application of Emery roller ( Husk Remover )

Used to remove the impurities adhering to the wheat surface. This machine is also used after the second

dampening to remove the husk which has loosened after the first or second conditioning of the wheat,

gram, green whole lentil, red whole lentil, toor dal whole beans, green gram, Moong, Black gram, urad.

The specialty of our machine is that it takes less powder and give maximum production.

Standard accessories of Emery Roller( Husk Remover )

• Motor Pulley.

• Adjustable Rail For Fixing Motor.

Extra Accessories Of Emery roller ( Husk Remover )

• Suitable totally enclosed fan cooled three phase or Single Phase Squirrel cage motor as per IS: 325

or 996.

• Suitable miniature circuit breaker as per IS: 8828 with 3 meter cable & 3 pin top as per IS: 1293 for

single Phase Electric Motors.

• Starters, main switch, ampere meter, capacitor for Single Phase Electric Motor.

• Foundation bolts

• “V.” Belts

• Magnetic Hopper

© 1990-2013 Jas Enterprises, All Rights Reserved. Page No. # 15

Jas Enterprises

An ISO 9001:2008 Certified Company

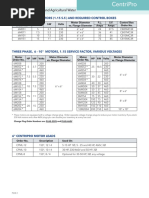

Model In Side Fitted Roll Size Shaft Machine Capacity Electric Motor Over All M/C

No. RPM per hrs Required Size L x W x H

kilograms (MM)

JAS- 228 mm die x 685 mm 40 mm 1000 400-600 5 HP (3.7 kw) 1625 x 480 x 500

HR-1 length or 7.5 H.P. (

5.5 Kw)

JAS- 254 mm die x 760 mm 51 mm 1000 500-800 7.5 HP (5.5 1680 x 500 x 500

HR-2 length kw) or 10 HP

(7.5 Kw)

JAS- 304 mm die x 760 mm 51 mm 1000 800-1200 10 HP (7.5 1680 x 520 x 520

HR-3 length Kw) or 15 HP

(11 kW)

JAS- 355 mm die x 840 mm 51 mm 950 2000-2500 15 HP (11 1830 x 600 x 600

HR-4 length kW) or 20 H.P

(15 kW)

Note:-

The machine body is made out of rigid steel and can be assembled either on a MS Stand or on a

constructed concrete / brick platform according to the requirement of the buyer.150MM Taper fit.

© 1990-2013 Jas Enterprises, All Rights Reserved. Page No. # 16

You might also like

- Auditory Neuroscience - Making Sense of Sound (2010) PDFDocument367 pagesAuditory Neuroscience - Making Sense of Sound (2010) PDFFelipe Helf100% (4)

- Installation Procedure For Pressure Vessel - EnglishDocument8 pagesInstallation Procedure For Pressure Vessel - EnglishApri Dianto92% (13)

- DNVGL CG 0060Document43 pagesDNVGL CG 0060Btwins123No ratings yet

- PE Jaw crusher manual-英文Document22 pagesPE Jaw crusher manual-英文Edwin Forero100% (3)

- Takamaz XC XLseriesDocument24 pagesTakamaz XC XLseriesPham LongNo ratings yet

- Installation of Low Voltage Service Using 3 Core Bunched Wavecon CablesDocument15 pagesInstallation of Low Voltage Service Using 3 Core Bunched Wavecon CablesphilipnartNo ratings yet

- A Cultural History of The Senses in The Middle AgesDocument142 pagesA Cultural History of The Senses in The Middle AgesAriel EirisNo ratings yet

- Product Catalog: Guiberson Quality Products and ServicesDocument63 pagesProduct Catalog: Guiberson Quality Products and ServicesTitanBOP100% (1)

- Commercial, Irrigation and Agricultural Water: Single Phase, 6" Motors (1.15 S.F.) and Required Control BoxesDocument3 pagesCommercial, Irrigation and Agricultural Water: Single Phase, 6" Motors (1.15 S.F.) and Required Control BoxesjtorerocNo ratings yet

- Rocksledger: Primary Jaw CrushersDocument2 pagesRocksledger: Primary Jaw CrushersMechanical department100% (3)

- Terex Jaques - ST JawDocument12 pagesTerex Jaques - ST Jawjonathandyson100% (2)

- Grizzly Feeders: MGF SeriesDocument3 pagesGrizzly Feeders: MGF SeriesSaad SaadNo ratings yet

- Agarwalla: Bpa Projects PVT LTDDocument16 pagesAgarwalla: Bpa Projects PVT LTDKarin Anderson100% (1)

- 3650x200 Es-11115 PDFDocument12 pages3650x200 Es-11115 PDFmpcd07No ratings yet

- Advance Quality Chara Cutter Without Motor, 600 KG/HR: DescriptionDocument3 pagesAdvance Quality Chara Cutter Without Motor, 600 KG/HR: DescriptionvmuthubharathNo ratings yet

- Double Side Planer CatalogueDocument4 pagesDouble Side Planer Cataloguedion.dsiNo ratings yet

- Astro Jaw: Single Toggle Jaw CrusherDocument4 pagesAstro Jaw: Single Toggle Jaw CrusherDanielSantos100% (1)

- Goulds 3355-BulletinDocument8 pagesGoulds 3355-Bulletinjeant2008No ratings yet

- Log Washer 8048 30 Spec Sheet EnglishDocument2 pagesLog Washer 8048 30 Spec Sheet EnglishMohammed Alshami GeologistNo ratings yet

- Single Toggle Jaw Crusher OTSUKATEC-2Document7 pagesSingle Toggle Jaw Crusher OTSUKATEC-2moddysNo ratings yet

- Trio Grizzly Feeders - TF Series: Product CollectionDocument2 pagesTrio Grizzly Feeders - TF Series: Product CollectionEnso E Rosales FNo ratings yet

- Jaw Crusher For Primary Crushing - Fote Heavy MachineryDocument18 pagesJaw Crusher For Primary Crushing - Fote Heavy MachineryIvy100% (1)

- Woodworking ToolsDocument21 pagesWoodworking Toolsbenderman1No ratings yet

- Log Washer 8048 35 Spec Sheet EnglishDocument2 pagesLog Washer 8048 35 Spec Sheet EnglishMohammed Alshami GeologistNo ratings yet

- ZBS600 Marca ZERMADocument2 pagesZBS600 Marca ZERMAJuan Carlos Ortiz PimientaNo ratings yet

- HP - CONICA General-Introduction PDFDocument25 pagesHP - CONICA General-Introduction PDFluisantonio2100% (2)

- Trio TF Series Vibrating Grizzly Feeder BrochureDocument2 pagesTrio TF Series Vibrating Grizzly Feeder Brochurehernandez.ranaivoarivonyNo ratings yet

- B&B MachinesDocument2 pagesB&B MachineskavinkumarmNo ratings yet

- Traversing Head Vertical Plate Saw: JATAS Machinery Sales IncDocument2 pagesTraversing Head Vertical Plate Saw: JATAS Machinery Sales IncMalikNo ratings yet

- General Quotation - NewDocument9 pagesGeneral Quotation - Newmichael oshiobugieNo ratings yet

- Vibrating ScreensDocument12 pagesVibrating ScreenssrinivasakumarNo ratings yet

- Tecnotest 5.2 Coring and Drilling PDFDocument8 pagesTecnotest 5.2 Coring and Drilling PDFRyan A.Y.No ratings yet

- 1845 10 11 - enDocument4 pages1845 10 11 - enSandy ZhangNo ratings yet

- SCHMIDT ServoPressesDocument4 pagesSCHMIDT ServoPressesgmkumar.indNo ratings yet

- 001 - Catalog Of CNC Machine - Tirupati CNCDocument12 pages001 - Catalog Of CNC Machine - Tirupati CNCmanasbhattacharyya44No ratings yet

- Motor PDFDocument5 pagesMotor PDFRO-AM-BD100% (1)

- RASO Series en v001Document12 pagesRASO Series en v001silviolcNo ratings yet

- HRL_Drum_Chipper_englishDocument4 pagesHRL_Drum_Chipper_englishDuc DoanNo ratings yet

- VMC & HMC PDFDocument103 pagesVMC & HMC PDFNARENDER SINGHNo ratings yet

- KubitizerDocument2 pagesKubitizerAnonymous rGIYBtEeNo ratings yet

- CSJ Series Single Toggle Jaw CrushersDocument1 pageCSJ Series Single Toggle Jaw CrushersantNo ratings yet

- ONRAM 1500: Diamond Core Drill Technical SpecificationDocument7 pagesONRAM 1500: Diamond Core Drill Technical SpecificationFedericoButron100% (1)

- BRANDT MA RG Series Agitators Spec Sheet EnglishDocument1 pageBRANDT MA RG Series Agitators Spec Sheet EnglishmuhammadaljabbarsyahNo ratings yet

- MachinesDocument8 pagesMachinesrazanymNo ratings yet

- Nut Crackers For All Types of Nuts: StandardDocument1 pageNut Crackers For All Types of Nuts: StandardHendi HendriansyahNo ratings yet

- ZOLLERN-23312_Flyer_-Recycling-_Drive_TechnologyDocument6 pagesZOLLERN-23312_Flyer_-Recycling-_Drive_TechnologyvaliaxmetovNo ratings yet

- Block MC SpecDocument3 pagesBlock MC SpecP K MisraNo ratings yet

- 3000 Series Pellet Mill BrochureDocument4 pages3000 Series Pellet Mill BrochureVictor Julio Torres DazaNo ratings yet

- Numturn 660-1500Document1 pageNumturn 660-1500Frederik HenderwanzaNo ratings yet

- Ge MD800Document6 pagesGe MD800idontlikeebooksNo ratings yet

- Diamond ToolsDocument152 pagesDiamond ToolsPradeepkumar KpNo ratings yet

- Cutting, Sawing and Grinding: Servicio de Att. Al ClienteDocument2 pagesCutting, Sawing and Grinding: Servicio de Att. Al ClienteCristian ValverdeNo ratings yet

- Cutting, Sawing and Grinding: Servicio de Att. Al ClienteDocument2 pagesCutting, Sawing and Grinding: Servicio de Att. Al ClienteCristian ValverdeNo ratings yet

- Shelf Drilling - Harvey H Ward - Spec Sheet May 2013Document2 pagesShelf Drilling - Harvey H Ward - Spec Sheet May 2013animesh kumar sonkerNo ratings yet

- Anti Vibration PadsDocument5 pagesAnti Vibration PadsNikhil Rajan100% (1)

- Trituradora Eagle 1200 25 CCDocument2 pagesTrituradora Eagle 1200 25 CCRodrigo MartinezNo ratings yet

- Technical Spec ONRAM 1500 0502 EngDocument7 pagesTechnical Spec ONRAM 1500 0502 Engdani sanNo ratings yet

- Mesin Paku - Automatic Nail Machine Technical Parameters-1Document6 pagesMesin Paku - Automatic Nail Machine Technical Parameters-1Arsyad 1No ratings yet

- Wadkin AGSP SawbenchDocument6 pagesWadkin AGSP SawbenchmarkandersonsaNo ratings yet

- 8" Encapsulated 30 °C: Submersible MotorsDocument2 pages8" Encapsulated 30 °C: Submersible Motorswpt_meNo ratings yet

- 1 Compressed - SMT 2019 Catalogue - ResizeDocument24 pages1 Compressed - SMT 2019 Catalogue - ResizeTenry Kusuma NegaraNo ratings yet

- Rack Milling Machine RMDocument4 pagesRack Milling Machine RMAries N. RamadhanyNo ratings yet

- Mills - CatalogDocument4 pagesMills - Catalogdéborah_rosalesNo ratings yet

- Washing and Classifying Brochure EnglishDocument24 pagesWashing and Classifying Brochure EnglishMohammed Alshami GeologistNo ratings yet

- The Ford SOHC Pinto & Sierra Cosworth DOHC Engines high-peformance manual: For Road & TrackFrom EverandThe Ford SOHC Pinto & Sierra Cosworth DOHC Engines high-peformance manual: For Road & TrackNo ratings yet

- 479 Cranford Drive SE: General InformationDocument1 page479 Cranford Drive SE: General Informationinstallationsap1No ratings yet

- Beat It Guide - The TEN Commandments of Weight Training.: by Mateen SDocument36 pagesBeat It Guide - The TEN Commandments of Weight Training.: by Mateen Sinstallationsap1No ratings yet

- Name: Kamala Age: 44 BMI: 29.05 Weight: 82.0 Diet Preference: Non-VegetarianDocument3 pagesName: Kamala Age: 44 BMI: 29.05 Weight: 82.0 Diet Preference: Non-Vegetarianinstallationsap1No ratings yet

- 3-Ingredient Homemade NutellaDocument1 page3-Ingredient Homemade Nutellainstallationsap1No ratings yet

- Curry Leaves Powder Recipe - Karuveppilai Podi Recipe - Subbus KitchenDocument2 pagesCurry Leaves Powder Recipe - Karuveppilai Podi Recipe - Subbus Kitcheninstallationsap1No ratings yet

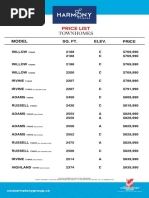

- Harmony CreekDocument10 pagesHarmony Creekinstallationsap1No ratings yet

- Nalla Kara Podi - Subbus KitchenDocument2 pagesNalla Kara Podi - Subbus Kitcheninstallationsap1100% (1)

- 2021-22 Secondary School Quadmester CalendarDocument3 pages2021-22 Secondary School Quadmester Calendarinstallationsap1No ratings yet

- AvonDocument2 pagesAvoninstallationsap1No ratings yet

- Physical Chemistry I, (10802) - Homework FOCUS 7 Quantum Theory 7D - Hand Your Homework Paper To T.A Due: April 27 (Mon.), by 17:00 PMDocument2 pagesPhysical Chemistry I, (10802) - Homework FOCUS 7 Quantum Theory 7D - Hand Your Homework Paper To T.A Due: April 27 (Mon.), by 17:00 PM張湧浩No ratings yet

- Chapters 1 3 Solid Edge Synchronous Technology Ebook PDFDocument43 pagesChapters 1 3 Solid Edge Synchronous Technology Ebook PDFTms ArnNo ratings yet

- BCAS 14 ActivityDocument11 pagesBCAS 14 Activitymitu afrinNo ratings yet

- SP1 Guidance Support Program - Announcement - May 2024 ExamDocument2 pagesSP1 Guidance Support Program - Announcement - May 2024 ExamLovish AroraNo ratings yet

- Criteria For Extemporaneous Speech ContestDocument3 pagesCriteria For Extemporaneous Speech ContestHarlene Marikit Asendido100% (8)

- Chapter Four - Kinematic Steering - 2015 - Essentials of Vehicle DynamicsDocument11 pagesChapter Four - Kinematic Steering - 2015 - Essentials of Vehicle DynamicsJulián AvellaNo ratings yet

- Reinforced Concrete Design To Eurocode 2 - (1 Introduction To Design and Properties of Reinforced Concrete)Document4 pagesReinforced Concrete Design To Eurocode 2 - (1 Introduction To Design and Properties of Reinforced Concrete)audreyNo ratings yet

- Glenna - Research Issues BackgroundDocument19 pagesGlenna - Research Issues Backgroundgrayglenna4869No ratings yet

- European Catalog Single Stage Pulse Valves Series 353 Asco en 7028704Document2 pagesEuropean Catalog Single Stage Pulse Valves Series 353 Asco en 7028704AirteamNo ratings yet

- 1047 Service Manual - SDocument152 pages1047 Service Manual - SPedro AraripeNo ratings yet

- Literature Review On Innovation and EntrepreneurshipDocument8 pagesLiterature Review On Innovation and EntrepreneurshipdrnpguwgfNo ratings yet

- 1150M DOZER Tier 2 - PIN Break NGC105100 and AfterDocument4 pages1150M DOZER Tier 2 - PIN Break NGC105100 and AfterEl PerroNo ratings yet

- Synthetic Strategies in ChemistryDocument361 pagesSynthetic Strategies in Chemistryapi-27482817100% (1)

- Bridging and Switching FundamentalsDocument11 pagesBridging and Switching FundamentalsCarlos CabezasNo ratings yet

- The Bright School System (6th Class)Document2 pagesThe Bright School System (6th Class)waleedpt7No ratings yet

- Parts Manual: Serial Number 5001 and UPDocument410 pagesParts Manual: Serial Number 5001 and UPАнатолий Милючин100% (1)

- Power of Nature / Ep. 1 "Network": Chinese Zero TO HeroDocument20 pagesPower of Nature / Ep. 1 "Network": Chinese Zero TO HeroChica con cara de gatoNo ratings yet

- Revisi Buat April Rev.03 Templete SO Bayanang LAPORAN STOCK NLG CKP FG BAYANGANDocument1,034 pagesRevisi Buat April Rev.03 Templete SO Bayanang LAPORAN STOCK NLG CKP FG BAYANGANOperational NLGNo ratings yet

- About Fish and Fish DishesDocument4 pagesAbout Fish and Fish DishesPRINCESS JHEA ROSACAYNo ratings yet

- Auto-Suggestion: Law of Success For Both The WorldsDocument22 pagesAuto-Suggestion: Law of Success For Both The WorldsZahidAhmed1968No ratings yet

- Payment Gateway _BADocument1 pagePayment Gateway _BAmrugen dangeNo ratings yet

- 1.240 ATP 2023 24 GR 9 LO FinalDocument4 pages1.240 ATP 2023 24 GR 9 LO FinalDave MeyiwaNo ratings yet

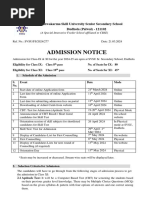

- Admission Notice 9TH And11th Class 2024 25Document6 pagesAdmission Notice 9TH And11th Class 2024 25Seema RaniNo ratings yet

- Ride Details Bill Details: Mukesh DhumalDocument3 pagesRide Details Bill Details: Mukesh DhumalRupesh KhandekarNo ratings yet