OB2268

OB2268

Uploaded by

HichEm MaAmErIaCopyright:

Available Formats

OB2268

OB2268

Uploaded by

HichEm MaAmErIaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

OB2268

OB2268

Uploaded by

HichEm MaAmErIaCopyright:

Available Formats

OB2268

OB2269

Current Mode PWM Controller

OB2268/9 is offered in SOP-8 and DIP-8 packages.

GENERAL DESCRIPTION

OB2268/9 is a highly integrated current mode PWM FEATURES

control IC optimized for high performance, low ■ Green Mode and Burst Mode Control For

standby power and cost effective offline flyback Improved Efficiency and Minimum Standby

converter applications in above 20W power level. Power Design

The external programmable PWM frequency was ■ Audio Noise Free Operation

internally adjusted according to the load condition. ■ External Programmable PWM Switching

Consequently, a better power efficiency is achieved Frequency

over full load range. At no load condition, the IC ■ Internal Synchronized Slope Compensation

operates in ‘burst mode’ and the standby power is ■ Low VIN/VDD Startup Current(4uA) and Low

reduced to minimum. At light load condition, the Operating Current (2.3mA)

device enters frequency reduction ‘green mode’. ■ Leading Edge Blanking on Current Sense Input

Switching loss is reduced and higher conversion ■ Complete Protection Coverage With Auto Self-

efficiency is thus achieved. Recovery

VDD low startup current and low operating current o External Programmable Over Temperature

contribute to a reliable power on startup design with Protection (OTP)

OB2268/9. A large value resistor could thus be used o With or Without On-chip VDD OVP for

in the startup circuit to minimize the standby power. Output Over Voltage Protection.

The internal slope compensation improves system o Under Voltage Lockout with Hysteresis

large signal stability and reduces the possible sub- (UVLO)

harmonic oscillation at high PWM duty cycle output. o Gate Output Maximum Voltage Clamp (18V)

Leading-edge blanking on current sense input o Line Compensated Cycle-by-Cycle Over-

removes the signal glitch due to snubber circuit diode current Threshold Setting For Constant Output

reverse recovery. and greatly reduces the external Current Limiting Over Universal Input Voltage

component count and system cost in the design. Range (OCP)

OB2268/9 offers complete protection coverage with o Over Load Protection. (OLP)

automatic self-recovery feature including Cycle-by- ■ On-Bright Proprietary Frequency Shuffling

Cycle current limiting (OCP), over load protection Technology for Improved EMI Performance

(OLP), over temperature protection (OTP), VDD (OB2269 only)

over voltage protection (OVP) and under voltage

lockout (UVLO). The Gate-drive output is clamped APPLICATIONS

to maximum 18V to protect the power MOSFET. Offline AC/DC flyback converter for

Excellent EMI performance is achieved with On- ■ Laptop Power Adaptor

Bright proprietary frequency shuffling technique ■ PC/TV/Set-Top Box Power Supplies

(OB2269 only) together with soft switching control at ■ Open-frame SMPS

the totem pole gate drive output. ■ Battery Charger

The tone energy at below 20KHZ is minimized in

operation. Consequently, audio noise performance is

greatly improved..

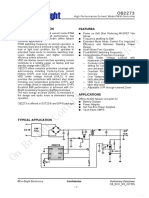

TYPICAL APPLICATION

1

EMI

AC IN 4 2

F i l te r

+ +

D C O UT

+

3

V I N V DD

RT GA TE

NTC

O B 2 2 6 8/ 9

RI S E NSE

OB 43 1

FB GND

©On-Bright Electronics Confidential

A Lite-on Semiconductor Company

-1- V1.2

OB2268

OB2269

Current Mode PWM Controller

GENERAL INFORMATION

Pin Configuration Package Dissipation Rating

The OB2268/9 is offered in DIP and SOP packages Package RθJA (°C/W)

shown as below.

DIP8 90

SOP8 150

Absolute Maximum Ratings

Parameter Value

VDD Input Voltage 36 V

VIN Input Voltage 36 V

VDD Clamp Continuous Current 10 mA

VFB Input Voltage -0.3 to 7V

VSENSE Input Voltage to Sense -0.3 to 7V

Pin

VRT Input Voltage to RT Pin -0.3 to 7V

VRI Input Voltage to RI Pin -0.3 to 7V

Min/Max Operating Junction -20 to 150 oC

Ordering Information

Temperature TJ

Part Number Description

Min/Max Storage Temperature -55 to 150 oC

OB2268AP No Frequency Shuffling,

Tstg

DIP8, Pb-free

Note: Stresses beyond those listed under “absolute maximum

OB2268APV No Frequency Shuffling, ratings” may cause permanent damage to the device. These are

DIP8, Pb-free and no OVP stress ratings only, functional operation of the device at these or

OB2269CP With Frequency Shuffling, any other conditions beyond those indicated under “recommended

operating conditions” is not implied. Exposure to absolute

SOP8, Pb-free maximum-rated conditions for extended periods may affect device

OB2269CPV With Frequency Shuffling, reliability.

SOP8, Pb-free and no OVP

©On-Bright Electronics Confidential

A Lite-on Semiconductor Company

-2- V1.2

OB2268

OB2269

Current Mode PWM Controller

Marking Information

TERMINAL ASSIGNMENTS

Pin Num Pin Name I/O Description

1 GND P Ground

2 FB I Feedback input pin. PWM duty cycle is determined by voltage level into this

pin and current-sense signal level at Pin 6.

3 VIN I Connected through a large value resistor to rectified line input for Start up

chip supply and line voltage sensing.

4 RI I Internal Oscillator frequency setting pin. A resistor connected between RI

and GND sets the PWM frequency.

5 RT I Temperature sensing input pin. Connected through a NTC resistor to GND.

Once the voltage of the RT pin drops below a fixed limit of 1.05V, PWM

output will be disabled.

6 SENSE I Current sense input pin. Connected to MOSFET current sensing resistor

node.

7 VDD P DC power supply pin.

8 GATE O Totem-pole gate drive output for power MOSFET.

©On-Bright Electronics Confidential

A Lite-on Semiconductor Company

-3- V1.2

OB2268

OB2269

Current Mode PWM Controller

BLOCK DIAGRAM

©On-Bright Electronics Confidential

A Lite-on Semiconductor Company

-4- V1.2

OB2268

OB2269

Current Mode PWM Controller

ESD INFORMATION

Symbol Parameter Test Conditions Min Typ Max Unit

HBMNote Human Body Model MIL-STD 2 KV

MM Machine Model on JEDEC-STD 250 V

All Pins

Note: HBM all pins pass 2KV except VIN pin. The details are VIN passes 1kV, VDD and GATE pass 2KV, all other I/Os pass 8KV. In

system application, VIN pin is either a high impedance input or left floating. The lower rating has minimum impacts on system ESD

performance.

ELECTRICAL CHARACTERISTICS

(TA = 25OC if not otherwise noted)

Symbol Parameter Test Conditions Min Typ Max Unit

Supply Voltage (VDD, VIN)

I_VDD_Startup VDD Start up VDD =15V, RI=100K 4 20 uA

Current Measure current into VDD

I_VDD_Operation Operation Current VDD=18V, RI=100Kohm, 2.3 mA

VFB=3V, Gate floats

UVLO(ON) VDD Under 9.5 10.5 11.5 V

Voltage Lockout

Enter

UVLO(OFF) VDD Under 15.5 16.5 17.5 V

Voltage Lockout

Exit (Recovery)

*Optional

OVP(ON) VDD Over Voltage 23.5 25 26.5 V

Protection Enter

OVP(OFF)*Optional VDD Over Voltage 21.5 23 24.5 V

Protection Exit

(Recovery)

OVP_Hysteresis OVP(ON)- 2 V

OVP(OFF)

TD_OVP VDD OVP 80 uSec

Debounce time

VDD_Clamp VDD Zener Clamp I(VDD ) = 10 mA 35 V

Voltage

Feedback Input Section(FB Pin)

VFB_Open VFB Open Loop 6.0 V

Voltage

IFB_Short FB pin short circuit Short FB pin to GND and 0.65 mA

current measure current

VTH_GM Green Mode FB 2.3 V

Threshold Voltage

VTH_BM Burst Mode FB 1.8 V

Threshold Voltage

VTH_PL Power Limiting FB 4.4 V

Threshold Voltage

TD_PL Power limiting 80 mSec

Debounce Time

ZFB_IN Input Impedance 9.0 Kohm

Current Sense Input(Sense Pin)

T_blanking Leading edge RI = 100Kohm 400 ns

©On-Bright Electronics Confidential

A Lite-on Semiconductor Company

-5- V1.2

OB2268

OB2269

Current Mode PWM Controller

blanking time

ZSENSE_IN Input Impedance 40 Kohm

TD_OC Over Current From Over Current Occurs 120 nSec

Detection and to GATE output turns off,

Control Delay Sense voltage ramp at

0.15V/uS.

VTH_OC Internal Current VDD = 16V, I(VIN) = 0.86 V

Limiting Threshold 55uA

Voltage

Oscillator

FOSC Normal Oscillation RI = 100 Kohm 60 65 70 KHZ

Frequency

∆f_Temp Frequency VDD = 16V, RI = 5 %

Temperature 100Kohm, 0oC to 85 oC

Stability

∆f_Volt Frequency Voltage VDD = 15-25V, RI = 5 %

Stability 100Kohm

RI_range Operating RI Range 50 100 250 Kohm

V_RI_open RI open load 2.0 V

voltage

F_GMstop Green Mode Stop VDD = 16V, RI = 22 KHZ

Frequency 100Kohm

Gate Drive Output

VOL Output Low Level VDD = 16V, Io = 20 mA 0.3 V

VOH Output High Level VDD = 16V, Io = 20 mA 11 V

VG_Clamp Output Clamp 18 V

Voltage Level

T_r Output Rising Time VDD = 16V, CL = 1nf 120 nSec

T_f Output Falling VDD = 16V, CL = 1nf 50 nSec

Time

Over Temperature Protection

I_RT Output Current of RI=100K 70 uA

RT pin

VTH_OTP OTP Threshold 1.015 1.065 1.115 V

Voltage

VTH_OTP_off OTP Recovery 1.165 V

Threshold Voltage

TD_OTP OTP De-bounce 100 uSec

Time

V_RT_Open RT Pin Open RI=100K 3.5 V

Voltage

Frequency Shuffling (OB2269 Only)

∆f_OSC Frequency RI=100K -5 5 %

Modulation range

/Base frequency

f_Shuffling Shuffling RI=100K 65 HZ

Frequency

©On-Bright Electronics Confidential

A Lite-on Semiconductor Company

-6- V1.2

OB2268

OB2269

Current Mode PWM Controller

CHARACTERIZATION PLOTS

VDD Start-up Current vs. Voltage VDD UVLO and Operation Current

11 3

S tart-up C urrent (uA )

10

9 2.5

VDD Current (mA)

8

7 2

6

5 1.5

4

3 1

2

1 0.5

0

0 2 4 6 8 10 12 14 16 0

0 2 4 6 8 10 12 14 16 18 20 22 24

VDD VOLTAGE (V) VDD Voltage (V)

VDD Operation Current vs. Load Frequency vs. RI

Fosc 50Khz Fosc 65Khz Fosc 100Khz 140

6 120

I(VDD) (mA)

RI (Kohm)

5 100

4 80

60

3

40

2

20

1 50 80 110 140 170 200 230

0 500 1000 1500 2000

Frequency (KHz)

Gatedrive Loading (pf)

Frequency vs FB Voltage OCP threshold vs. Ivin

0.94

70

Frequency(K H Z)

60 0.89

Vth_OC (V)

50

0.84

40

30 0.79

20

0.74

10

0 0.69

1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300

FB Voltage(V) Ivin(uA)

©On-Bright Electronics Confidential

A Lite-on Semiconductor Company

-7- V1.2

OB2268

OB2269

Current Mode PWM Controller

OPERATION DESCRIPTION

The OB2268/9 is a highly integrated PWM below a preset level and FB input is active to output

controller IC optimized for offline flyback an on state. Otherwise the gate drive remains at off

converter applications in above 20W power range. state to minimize the switching loss thus reduce the

The Green mode and burst mode control greatly standby power consumption to the greatest extend.

reduces the standby power consumption and helps The frequency control also eliminates the audio

the design easily meet the international power noise at any loading conditions.

conservation requirements.

• Oscillator Operation

• Startup Current and Start up Control A resistor connected between RI and GND sets the

Startup current of OB2268/9 is designed to be very constant current source to charge/discharge the

low so that VDD could be charged up above UVLO internal cap and thus the PWM oscillator frequency

threshold level and device starts up quickly. A large is determined. The relationship between RI and

value startup resistor can therefore be used to switching frequency follows the below equation

minimize the power loss yet reliable startup in within the specified RI in Kohm range at nominal

application. For AC/DC adaptor with universal loading operational condition.

input range design, a 2 MΩ, 1/8 W startup resistor

could be used together with a VDD capacitor to FPWM = 6500/RI (KHZ)

provide a fast startup and yet low power dissipation

design solution.

• Current Sensing and Leading Edge Blanking

• Operating Current Cycle-by-Cycle current limiting is offered in

The Operating current of OB2268/9 is low at OB2268/9 current mode PWM control. The switch

2.3mA. Good efficiency is achieved with current is detected by a sense resistor into the sense

OB2268/9 low operating current together with pin. An internal leading edge blanking circuit chops

green mode, burst mode control schemes. off the sense voltage spike at initial MOSFET on

state due to Snubber diode reverse recovery so that

• Frequency shuffling for EMI improvement the external RC filtering on sense input is no longer

The frequency Shuffling/jittering (switching needed. The current limit comparator is disabled

frequency modulation) is implemented in OB2269. and cannot turn off the external MOSFET during

The oscillation frequency is modulated with a the blanking period. The PWM duty cycle is

random source so that the tone energy is spread out. determined by the current sense input voltage and

The spread spectrum minimizes the conduction the FB input voltage.

band EMI and therefore eases the system design.

• Internal Synchronized Slope Compensation

• Green Mode and Burst Mode Operation Built-in slope compensation circuit adds voltage

At light load or zero load condition, most of the ramp onto the current sense input voltage for PWM

power dissipation in a switching mode power generation. This greatly improves the close loop

supply is from switching loss on the MOSFET stability at CCM and prevents the sub-harmonic

transistor, the core loss of the transformer and the oscillation and thus reduces the output ripple

loss on the snubber circuit. The magnitude of voltage.

power loss is in proportion to the switching

frequency. Lower switching frequency leads to the • Over Temperature Protection

reduction on the power loss and thus conserves the An NTC resistor in series with a regular resistor

energy. should connect between RT and GND for

OB2268/9 self adjusts the switching frequency temperature sensing and protection. NTC resistor

(Green-mode) according to the loading condition. value becomes lower when the ambient temperature

The switch frequency reduces at lighter load rises. With the fixed internal current IRT flowing

condition to improve the conversion efficiency. At through the resistors, the voltage at RT pin

light load or no load condition, the FB input drop becomes lower at high temperature. The internal

below burst mode threshold level (1.6V) and the OTP circuit is triggered and shutdown the

device enters Burst Mode control. The Gate drive MOSFET when the sensed input voltage is lower

output switches only when VDD voltage drops than VTH_OTP.

©On-Bright Electronics Confidential

A Lite-on Semiconductor Company

-8- V1.2

OB2268

OB2269

Current Mode PWM Controller

(OTP), on-chip VDD over voltage protection (OVP,

• Gate Drive optional) and under voltage lockout.(UVLO).

OB2268/9 Gate is connected to an external The OCP threshold is input line voltage adjusted to

MOSFET gate for power switch control. Too weak compensate the increased output current limit at

the gate drive strength results in higher conduction higher voltage caused by inherent Over-Current

and switch loss of MOSFET while too strong gate sensing and control delay. A constant output power

drive output compromises the EMI. limit is achieved with recommended reference

A good tradeoff is achieved through the built-in design on OB2268/9.

totem pole gate design with right output strength At overload condition when FB input voltage

and dead time control. The low idle loss and good exceeds power limit threshold value for more than

EMI system design is easier to achieve with this 80mS, control circuit reacts to shut down the output

dedicated control scheme. An internal 18V clamp is power MOSFET. Device restarts when VDD

added for MOSFET gate protection at higher than voltage drops below UVLO limit.

expected VDD input. Similarly, control circuit shuts down the power

MOSFET when an Over Temperature condition is

• Protection Controls detected. OB2268/9 resumes the operation when

Good system reliability is achieved with temperature drops below the hysteresis value.

OB2268/9’s rich protection features including VDD is supplied with transformer auxiliary

Cycle-by-Cycle current limiting (OCP), Over Load winding output. It is clamped when VDD is higher

Protection (OLP), over temperature protection than 30V. The power MOSFET is shut down when

VDD drops below UVLO limit and device enters

power on start-up sequence thereafter.

©On-Bright Electronics Confidential

A Lite-on Semiconductor Company

-9- V1.2

OB2268

OB2269

Current Mode PWM Controller

PACKAGE MECHANICAL DATA

8-Pin Plastic DIP

©On-Bright Electronics Confidential

A Lite-on Semiconductor Company

- 10 - V1.2

OB2268

OB2269

Current Mode PWM Controller

8-Pin Plastic SOP

©On-Bright Electronics Confidential

A Lite-on Semiconductor Company

- 11 - V1.2

OB2268

OB2269

Current Mode PWM Controller

IMPORTANT NOTICE

RIGHT TO MAKE CHANGES

On-Bright Electronics Corp. reserves the right to make corrections, modifications, enhancements,

improvements, and other changes to its products and services at any time and to discontinue any product or

service without notice. Customers should obtain the latest relevant information before placing orders and should

verify that such information is current and complete.

WARRANTY INFORMATION

On-Bright Electronics Corp. warrants performance of its hardware products to the specifications applicable at

the time of sale in accordance with its standard warranty. Testing and other quality control techniques are used

to the extent it deems necessary to support this warranty. Except where mandated by government requirements,

testing of all parameters of each product is not necessarily performed.

On-Bright Electronics Corp. assumes no liability for applications assistance or customer product design.

Customers are responsible for their products and applications using On-Bright’s components, data sheet and

application notes. To minimize the risks associated with customer products and applications, customers should

provide adequate design and operating safeguards.

LIFE SUPPORT

On-Bright Electronics Corp.’s products are not designed to be used as components in devices intended to

support or sustain human life. On-bright Electronics Corp. will not be held liable for any damages or claims

resulting from the use of its products in medical applications.

MILITARY

On-Bright Electronics Corp.’s products are not designed for use in military applications. On-Bright Electronics

Corp. and Lite-on Semiconductor Corp. will not be held liable for any damages or claims resulting from the use

of its products in military applications.

©On-Bright Electronics Confidential

A Lite-on Semiconductor Company

- 12 - V1.2

You might also like

- Joy Twist AirDocument49 pagesJoy Twist AirChris SlyNo ratings yet

- Parts Catalogue: Model Model ModelDocument134 pagesParts Catalogue: Model Model ModelEsteban Elias Marquez EscalanteNo ratings yet

- Ob2262 Datasheet PDFDocument13 pagesOb2262 Datasheet PDFjesus cautivoNo ratings yet

- Ob2262 Ver2.0 Datasheet PDFDocument13 pagesOb2262 Ver2.0 Datasheet PDFjesus cautivoNo ratings yet

- General Description: EMI Filter Ac in DC OutDocument13 pagesGeneral Description: EMI Filter Ac in DC Outjesus cautivoNo ratings yet

- Ob2262 Usado em Fonte Proview MLT 198aDocument13 pagesOb2262 Usado em Fonte Proview MLT 198aHeron Cesar VieiraNo ratings yet

- Ob 2269 CapDocument13 pagesOb 2269 Caporkun burkayNo ratings yet

- OB2273 On BrightDocument12 pagesOB2273 On BrightCarlos PosadaNo ratings yet

- OB2263 On-Bright PDFDocument13 pagesOB2263 On-Bright PDFamaliah bamesuNo ratings yet

- Sunrom 814104Document13 pagesSunrom 814104Valentin LeonteNo ratings yet

- OB2338Document9 pagesOB2338Raul LopezNo ratings yet

- General Description Features: High Performance Current Mode PWM ControllerDocument11 pagesGeneral Description Features: High Performance Current Mode PWM ControllerPhạm Tấn HảiNo ratings yet

- On-Bright Confidential To ACT: General Description FE AturesDocument10 pagesOn-Bright Confidential To ACT: General Description FE AturesJose BenavidesNo ratings yet

- LN3C63 LiemicDocument13 pagesLN3C63 Liemichichem_scribdNo ratings yet

- OB2276A-On-Bright ElectronicsDocument11 pagesOB2276A-On-Bright Electronicsparsastar2010No ratings yet

- OB2273A On BrightDocument10 pagesOB2273A On BrightHamza Abbasi AbbasiNo ratings yet

- Current Mode PWM Controller: General DescriptionDocument12 pagesCurrent Mode PWM Controller: General DescriptionAlex GerasimenkoNo ratings yet

- PRDF OB5269CPDocument11 pagesPRDF OB5269CPtomopiNo ratings yet

- OB2269Document12 pagesOB2269Juan Ballon100% (1)

- OB2362 DatasheetDocument10 pagesOB2362 DatasheetTín SmpsNo ratings yet

- On-Bright Confidential To Bona: Quasi-Resonant Flyback PWM Controller General Description FeaturesDocument14 pagesOn-Bright Confidential To Bona: Quasi-Resonant Flyback PWM Controller General Description FeaturesFlavio Tonello TavaresNo ratings yet

- OB On Bright Elec OB2225MCP - C92008Document9 pagesOB On Bright Elec OB2225MCP - C92008shohanur.waltonbdNo ratings yet

- Description Features: Current Mode PWM ControllerDocument9 pagesDescription Features: Current Mode PWM ControllerAlex GerasimenkoNo ratings yet

- Application Note: SY8286A: General Description FeaturesDocument16 pagesApplication Note: SY8286A: General Description FeaturesRodney RibeiroNo ratings yet

- Silergy-Corp-SY8286ARAC C178251Document16 pagesSilergy-Corp-SY8286ARAC C178251ziya tutuNo ratings yet

- W-5200-5 Low Noise Regulated Charge Pump DC-DC Converter: V V V V V V V V V V V VDocument11 pagesW-5200-5 Low Noise Regulated Charge Pump DC-DC Converter: V V V V V V V V V V V Vcigose8767No ratings yet

- LD5537 LeadtrendTechnologyDocument17 pagesLD5537 LeadtrendTechnologyphetronyo ferreira de oliveiraNo ratings yet

- General Description Features: High Precision Low Cost MCM Power SwitchDocument10 pagesGeneral Description Features: High Precision Low Cost MCM Power SwitchNguyễn TrungNo ratings yet

- Ob 2223 HCDocument11 pagesOb 2223 HCRivaldyNo ratings yet

- LD7523 PDFDocument18 pagesLD7523 PDFAmalio MamaniNo ratings yet

- 1h6VuxLQ OB2216APDocument10 pages1h6VuxLQ OB2216APjaimeNo ratings yet

- Bit 3260Document7 pagesBit 3260prem rajNo ratings yet

- Low Cost Green-Power PWM Controller With Low EMI Technique FeaturesDocument12 pagesLow Cost Green-Power PWM Controller With Low EMI Technique FeaturesRogeriomgoNo ratings yet

- DP2269Document7 pagesDP2269GABRIEL AMORIM ARAUJONo ratings yet

- Current Mode PWM Controller With Frequency Shuffling ME8202Document12 pagesCurrent Mode PWM Controller With Frequency Shuffling ME8202Kukla LossNo ratings yet

- cschip-CSC7224 C2920859Document5 pagescschip-CSC7224 C2920859Sridhar kvv100% (1)

- Ad52060 EsmtDocument23 pagesAd52060 EsmtRoel GloriosoNo ratings yet

- UTC Unisonic Tech UT3232G S16 R - C84913Document7 pagesUTC Unisonic Tech UT3232G S16 R - C84913KURALMOZHI RAMESHNo ratings yet

- OB On Bright Elec OB3350CPA - C81098Document10 pagesOB On Bright Elec OB3350CPA - C81098TCL USERNo ratings yet

- UTRS3088 UnisonicTechnologiesDocument8 pagesUTRS3088 UnisonicTechnologiesAndré PaivaNo ratings yet

- Dual-Phase DC-DC Controller For AMD Mobile CPU: Features General DescriptionDocument7 pagesDual-Phase DC-DC Controller For AMD Mobile CPU: Features General Descriptionlordycarlos8588No ratings yet

- Sheet 12Document9 pagesSheet 12nlNo ratings yet

- Ω Ω Ω Ω Ω, 1.3A Power Switch with Programmable Current LimitDocument14 pagesΩ Ω Ω Ω Ω, 1.3A Power Switch with Programmable Current LimitSurendra SharmaNo ratings yet

- Bd9470xxx eDocument38 pagesBd9470xxx eJose GargaglioneNo ratings yet

- GMT Global Mixed Mode Tech G2898KD1U - C356810Document8 pagesGMT Global Mixed Mode Tech G2898KD1U - C356810ziya tutuNo ratings yet

- L5972DDocument10 pagesL5972DLuis Enrique De los Santos FarfánNo ratings yet

- 1ch Boost Up Type White LED Driver For Large LCD: DatasheetDocument37 pages1ch Boost Up Type White LED Driver For Large LCD: DatasheetWeex HRNo ratings yet

- LD7523Document18 pagesLD7523AssembleiaDeDeusSepherEloahNo ratings yet

- Bit 3269Document6 pagesBit 3269zubiNo ratings yet

- OB2353 Data InglesDocument11 pagesOB2353 Data InglesEAKIT SPAINNo ratings yet

- AD52580B Audio AmplifierDocument3 pagesAD52580B Audio Amplifierhamada13No ratings yet

- OB6563CPDocument13 pagesOB6563CPJarvin Saenz PavónNo ratings yet

- Obgz10mp (z10j19)Document11 pagesObgz10mp (z10j19)SashaNo ratings yet

- OB2279 On Bright PDFDocument13 pagesOB2279 On Bright PDFAmit Biswas0% (1)

- UTC2411Document3 pagesUTC2411Lenon Salazar100% (1)

- MIC5209 500ma Low Noise LDO Regulator DS20005720B-2905047Document31 pagesMIC5209 500ma Low Noise LDO Regulator DS20005720B-2905047jaime elias gil rocaNo ratings yet

- Richtekusainc Rt906950gb Datasheets 6616Document15 pagesRichtekusainc Rt906950gb Datasheets 6616JayR VillaNo ratings yet

- Ds9048a 00Document14 pagesDs9048a 00tumihiesNo ratings yet

- Linear Current Sensing Ic: Product Summary FeaturesDocument6 pagesLinear Current Sensing Ic: Product Summary FeaturesBlackArnabNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Balanza Health o MeterDocument2 pagesBalanza Health o MeterMilena Delgado GomezNo ratings yet

- Detector Humo Direccionable D7050Document2 pagesDetector Humo Direccionable D7050Mario Javier CNo ratings yet

- Extra Questions - Chapter 14Document3 pagesExtra Questions - Chapter 14rachna sharmaNo ratings yet

- HVAC BOQ Muzzafarpur 10.01.2019Document22 pagesHVAC BOQ Muzzafarpur 10.01.2019Gourav SharmaNo ratings yet

- ProtonDocument12 pagesProtonAmruta KharadkarNo ratings yet

- Initial ScrapDocument16 pagesInitial Scrapdeka wardhanaNo ratings yet

- 1 PDFDocument8 pages1 PDFB.Kailash Krishna PrasadNo ratings yet

- Part 3 PDFDocument274 pagesPart 3 PDFAnthonyNColucci100% (1)

- Dual Modular Safety Shutoff Valves DMV-D/602 Series DMV-DLE/602 SeriesDocument6 pagesDual Modular Safety Shutoff Valves DMV-D/602 Series DMV-DLE/602 SeriesAlEjAnDrO CoNtReRaSNo ratings yet

- BETE WaterandAirFlow DataDocument2 pagesBETE WaterandAirFlow DataChevronelleNo ratings yet

- Headlight (Automobile) PDFDocument11 pagesHeadlight (Automobile) PDFRavi KulkarniNo ratings yet

- NVISION CR6400 DatasheetDocument1 pageNVISION CR6400 Datasheetavrelius2012No ratings yet

- Model: KOT-0215U-CA4P: Product FeatureDocument3 pagesModel: KOT-0215U-CA4P: Product Featurewilfredo503No ratings yet

- BIRNS Millennium Interconnect Catalog Rev FDocument61 pagesBIRNS Millennium Interconnect Catalog Rev FquanNo ratings yet

- J1939 01 PDFDocument7 pagesJ1939 01 PDFMauro100% (1)

- Prize Aquanqa Tarjas Recepcion-1Document29 pagesPrize Aquanqa Tarjas Recepcion-1gestor gestionNo ratings yet

- Smart5 NJ4-I 170-220-270 Tech Specs - EenDocument122 pagesSmart5 NJ4-I 170-220-270 Tech Specs - EenHeyres BorgesNo ratings yet

- Empat Berewok Dari Goa SanggrengDocument1 pageEmpat Berewok Dari Goa SanggrengPrima WesiNo ratings yet

- 23CC Top Ten RulesDocument38 pages23CC Top Ten RulesCarlos MoralesNo ratings yet

- Deep Ocean Engineering: Product User's GuideDocument72 pagesDeep Ocean Engineering: Product User's GuideIon OlteanuNo ratings yet

- BDW42 - NPN, BDW46, BDW47 - PNP: Darlington Complementary Silicon Power TransistorsDocument2 pagesBDW42 - NPN, BDW46, BDW47 - PNP: Darlington Complementary Silicon Power Transistorsاحمد زغارىNo ratings yet

- Hanger of Vibrating FeederDocument6 pagesHanger of Vibrating FeederAris SupraptoNo ratings yet

- Samsung Ks1aDocument78 pagesSamsung Ks1aummu aqiellaNo ratings yet

- Mbrf20u200cta PDFDocument2 pagesMbrf20u200cta PDFKevin PalominoNo ratings yet

- The Evolution of Storage DevicesDocument48 pagesThe Evolution of Storage DevicesMitch100% (1)

- Viper Nilfisk KlsDocument6 pagesViper Nilfisk KlsIsma Husni RakhmawatiNo ratings yet

- Rittal DET-AC Plus Extinguishing SystemDocument64 pagesRittal DET-AC Plus Extinguishing SystemAlexandre RezendeNo ratings yet

- 1.VCB MaintenanceDocument82 pages1.VCB MaintenanceElectrical Team100% (1)