Compact - T - 90 - Turbo - Ds - Ds PF 056 25032024 1744 en 8555

Compact - T - 90 - Turbo - Ds - Ds PF 056 25032024 1744 en 8555

Uploaded by

Cristina Ordonez PachecoCopyright:

Available Formats

Compact - T - 90 - Turbo - Ds - Ds PF 056 25032024 1744 en 8555

Compact - T - 90 - Turbo - Ds - Ds PF 056 25032024 1744 en 8555

Uploaded by

Cristina Ordonez PachecoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Compact - T - 90 - Turbo - Ds - Ds PF 056 25032024 1744 en 8555

Compact - T - 90 - Turbo - Ds - Ds PF 056 25032024 1744 en 8555

Uploaded by

Cristina Ordonez PachecoCopyright:

Available Formats

COMPACT POCKET FILTER T 90 TURBO

MAXIMUM PERFORMANCE WITH INNOVATIVE

MEDIA TECHNOLOGY

APPLICATION

for supply, exhaust and recirculated air filtration in ventilation systems posing special safety

requirements for arrestance capability, such as

in intake air filtration of gas turbines and compressors on- and off-shore

in sophisticated air-conditioning systems (hospitals, laboratories, libraries, museums,

airports, etc.)

in industrial processes (chemicals, pharmaceuticals, foods and beverages, optics,

electronics, paint shops, etc.)

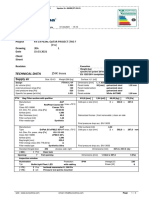

KEY DATA T 90 1/1 12L T 90 1/1 8L T 90 PRE 1/1 12L

Article number 53555917 53555918 53449490

Dimensions (W x H x D) [mm] 592 x 592 x 650

Number of pockets 12 8 12

Filter class acc. to EN 779:2012 F7 F7 M6

Filter class acc. to ISO 29461-1 ISO T7 ISO T7 ISO T5

Class to ISO 16890 ISO ePM2,5 65% ISO ePM2,5 65% ISO ePM10 75%

Particulate matter efficiency ISO

54 53 38

ePM1 [%]

Particulate matter efficiency

66 65 47

ISO ePM2,5 [%]

Particulate matter efficiency ISO

86 86 77

ePM10 [%]

Nominal volume flow

4,250 3,400 4,250

[m³/h]

Face velocity

3.2 2.5 3.2

[m/s]

Initial pressure drop [Pa] 100 80 80

Recommended final pressure drop

450

[Pa]

Bursting strength acc. to ISO

>6000

29461-3 [Pa]

Dust holding capacity (AC Fine /

1,400 950 1,800

300 Pa) [g]

COMPACT POCKET FILTER T 90 TURBO Page 2/3

KEY DATA T 90 1/1 12L T 90 1/1 8L T 90 PRE 1/1 12L

Dust holding capacity (AC Fine /

2,500 1,900 3,000

800 Pa) [g]

Filter area [m²] 9.0 6.0 9.0

Weight [kg] 3.2 2.5 3.1

Thermal stability [°C] 70

Moisture resistance (rel. hum.) [%] 100

Filter medium Polyolefine

Frame PUR

Fractional collection efficiency curve Initial pressure drop curve

T 90 1/1 12L T 90 1/1 12L

Nominal air flow [m³/h] : 4,250

Fractional collection efficiency [%]

Pressure drop [Pa]

Particle size [µm] Volume flow rate [m³/h]

COMPACT POCKET FILTER T 90 TURBO Page 3/3

MEDIA AND CONSTRUCTION CHARACTERISTICS FEATURES AND PLUSES

unique inherent stiffness of the pockets due to high-performance filter continuously excellent mechanical filtration performance.

DS-PF-056-25032024-1744-EN

medium from tear-resistant synthetic organic fibers.

highly robust and maximum performance gives high resilience and low

free of glass fibers, non-corroding and microbiologically inactive. pressure differences and excellent efficiency.

meets all the criteria laid down in VDI Guideline 6022 “Hygiene high dust-holding capacity and moisture resistance results in a long

Requirements for HVAC systems and units”. service life and economic efficiency.

functional reliability due to leak-proof welded configuration of the filter frame and filter medium are self-extinguishing to DIN 53438 (Fire class

pockets, foamed-in polyurethane front frame. F 1).

aerodynamically optimized welded-in spacers (long-pocket filters only). In the supply air for turbomachinery, T 90 pocket filters can be relied

upon to arrest aggressive, abrasive particles, thus minimizing blade

dimensionally stable construction of the filter element as a whole.

fouling and erosion, and upgrading the efficiency and availability of the

uniformly high quality of the filters is assured by our certified quality turbomachinery involved.

management system to ISO 9001, as well as by type-testing to EN 779

due to their 12 pockets, T 90 12L and T 90 PRE 12L pocket filters are

and ISO 16890.

suitable for applications with the highest service life requirements.

Viledon® is a registered and protected trademark of Carl Freudenberg KG. © Freudenberg Filtration Technologies GmbH & Co. KG

For cost-efficiency or system-specific reasons it may be appropriate to change the filters before reaching the final pressure drop stated. It can also be exceeded in certain applications.

The information or figures given are subject to tolerances due to normal production fluctuations. Our explicit written confirmation is required in each case for the correctness of the information. Subject to technical

alterations. You will find instructions on how to handle and dispose of loaded filters in our information on product safety and eco-compatibility.

Contact us www.freudenberg-filter.com

You might also like

- LAA Step Guide: Love Addicts AnonymousDocument147 pagesLAA Step Guide: Love Addicts Anonymouspaul preciadoNo ratings yet

- E Commerce QsDocument4 pagesE Commerce QsRoseanneNo ratings yet

- KYB and Showa Shock ServiceDocument4 pagesKYB and Showa Shock ServiceJose Luis SabinoNo ratings yet

- Fleetguard OptiairDocument28 pagesFleetguard OptiairDaniel CasillasNo ratings yet

- Terminal Report - FilipinoDocument3 pagesTerminal Report - FilipinoHillary Ann AbuelNo ratings yet

- Compact - T - 95 - Ds - Ds PF 057 07082023 1700 en 8556Document3 pagesCompact - T - 95 - Ds - Ds PF 057 07082023 1700 en 8556Cristina Ordonez PachecoNo ratings yet

- Compact - T - 90 - Hygiene - Ds - Ds PF 054 28032024 1450 en 8554Document3 pagesCompact - T - 90 - Hygiene - Ds - Ds PF 054 28032024 1450 en 8554Cristina Ordonez PachecoNo ratings yet

- Compact - T - 60 - Ds - 02 CC 025 25032024 1740 en 8552Document3 pagesCompact - T - 60 - Ds - 02 CC 025 25032024 1740 en 8552Cristina Ordonez PachecoNo ratings yet

- WinTech 95 Pocket Filters Data SheetDocument3 pagesWinTech 95 Pocket Filters Data Sheet7v4rpy95p7No ratings yet

- Compact - F - 50 - Ds - Ds PF 053 25032024 1739 en 8551Document3 pagesCompact - F - 50 - Ds - Ds PF 053 25032024 1739 en 8551Cristina Ordonez PachecoNo ratings yet

- Pages From AHU DATASHEET@T-10254 Rev.12Document1 pagePages From AHU DATASHEET@T-10254 Rev.12basheer9No ratings yet

- Compact - F - 40 - F - 45 - Ds - Ds PF 052 29092023 1025 en 8558Document3 pagesCompact - F - 40 - F - 45 - Ds - Ds PF 052 29092023 1025 en 8558Cristina Ordonez PachecoNo ratings yet

- Compact - G - 35 - Ds - DS-PF - 033 - 28092023-1357-En-8557Document3 pagesCompact - G - 35 - Ds - DS-PF - 033 - 28092023-1357-En-8557Cristina Ordonez PachecoNo ratings yet

- 3 PocketDocument3 pages3 Pocketmikael8118No ratings yet

- 0. FILTRO LAVABLE ROLLO g4 THENOWDocument3 pages0. FILTRO LAVABLE ROLLO g4 THENOWservicio.atymiNo ratings yet

- MX 75-98Document2 pagesMX 75-98Compras WConexNo ratings yet

- Product Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)Document4 pagesProduct Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)ademgsNo ratings yet

- Omega Air Product Data Sheet Filter Element XR AF and AAF v4.00Document2 pagesOmega Air Product Data Sheet Filter Element XR AF and AAF v4.00amin.saadaoui19No ratings yet

- Report 10 10 2024 5 18 07 PMDocument13 pagesReport 10 10 2024 5 18 07 PMrehab.emaraaNo ratings yet

- XM Filter ElementDocument2 pagesXM Filter ElementhafsakrknNo ratings yet

- Clearcurrent BP Fact SheetDocument2 pagesClearcurrent BP Fact Sheetmazouz.lmfNo ratings yet

- Xs Filter ElementDocument2 pagesXs Filter ElementhafsakrknNo ratings yet

- Filmtec BW30-2540Document3 pagesFilmtec BW30-2540PT Deltapuro IndonesiaNo ratings yet

- Flex-03nl 5.9m Datasheet 5Document2 pagesFlex-03nl 5.9m Datasheet 5Power EngNo ratings yet

- Filter Mats AcelanDocument1 pageFilter Mats AcelanLGTNo ratings yet

- Technical Data: Date Rev. Date Project ID Tracking Number Project Name AHU Name AHU ModelDocument3 pagesTechnical Data: Date Rev. Date Project ID Tracking Number Project Name AHU Name AHU ModelAiman AliNo ratings yet

- Coralon Max Long Life DatasheetDocument2 pagesCoralon Max Long Life DatasheetPat YNo ratings yet

- Dwg.20A+20B B-AHU-10Document8 pagesDwg.20A+20B B-AHU-10GengaNo ratings yet

- GATED TurboShield DatasheetDocument2 pagesGATED TurboShield DatasheetMohamed AhmedNo ratings yet

- Technical Data: Date Rev. Date Project ID Tracking Number Project Name AHU Name AHU ModelDocument3 pagesTechnical Data: Date Rev. Date Project ID Tracking Number Project Name AHU Name AHU ModelAiman AliNo ratings yet

- E) DSF1000 AlDocument5 pagesE) DSF1000 AlAgeng A. PooNo ratings yet

- Thebault Dop01 Teboply Ext GBDocument2 pagesThebault Dop01 Teboply Ext GBDumitrache IulianNo ratings yet

- AE5312959 Rev0Document1 pageAE5312959 Rev0rafaleo84No ratings yet

- Data Sheet - Polyfelt® TS HD (100 600-td-02-19)Document1 pageData Sheet - Polyfelt® TS HD (100 600-td-02-19)andriarisetiawanNo ratings yet

- Omega Air Product Data Sheet Filter Element XS AF and AAF v4.00Document2 pagesOmega Air Product Data Sheet Filter Element XS AF and AAF v4.00amin.saadaoui19No ratings yet

- TDS Sfap-0088 - 200420Document1 pageTDS Sfap-0088 - 200420Mochammad SofyanNo ratings yet

- CO2 Free Air Generators K MTLABDocument2 pagesCO2 Free Air Generators K MTLABWASAN KUNG KLAMTETNo ratings yet

- Scheuch Folder Ligno Entstauber E 120116 01Document8 pagesScheuch Folder Ligno Entstauber E 120116 01MagdalenaNo ratings yet

- Datasheet D042 D062 30.10 EN USDocument7 pagesDatasheet D042 D062 30.10 EN USSak 8bitsNo ratings yet

- RO-FilmTec-BW30-PRO-400-34-PDS-45-D03745-enDocument2 pagesRO-FilmTec-BW30-PRO-400-34-PDS-45-D03745-enEstibensonMaestreNo ratings yet

- TFM AIRsyntex ePM10 65 M6 500 6 eDocument1 pageTFM AIRsyntex ePM10 65 M6 500 6 elsisniegasNo ratings yet

- Compressed Air Filters: Sullair Distributor Conference 2001Document47 pagesCompressed Air Filters: Sullair Distributor Conference 2001MauroNo ratings yet

- HVAC 终版4Document32 pagesHVAC 终版4budi santosoNo ratings yet

- Reusable & Disposable Respirator For Particle: Japanese Government StandardsDocument1 pageReusable & Disposable Respirator For Particle: Japanese Government StandardsDrGurkirpal Singh MarwahNo ratings yet

- Suez Ae 1Document1 pageSuez Ae 1Luis Alberto Castillo MaurtuaNo ratings yet

- Fine Dust-AircubeDocument12 pagesFine Dust-Aircubesparthiban89No ratings yet

- AAF Leaflet BioCel VXL AstroCel VXLDocument2 pagesAAF Leaflet BioCel VXL AstroCel VXLsoumya saswatNo ratings yet

- Torayfil Hfu 2020an 1Document2 pagesTorayfil Hfu 2020an 1RenatoNo ratings yet

- FAHU's SelectionDocument44 pagesFAHU's SelectionHafeez RehmanNo ratings yet

- AHU Casing Characteristics, Design Details For Outdoor Installation and Increased Hygiene RequirementsDocument8 pagesAHU Casing Characteristics, Design Details For Outdoor Installation and Increased Hygiene RequirementsAzher ANo ratings yet

- Polylon 1900 (3853091)Document4 pagesPolylon 1900 (3853091)JOCELYN MEDINANo ratings yet

- Revetment Use Geotextile - MC TS70Document1 pageRevetment Use Geotextile - MC TS70jurieskNo ratings yet

- Drytec Aluminium Range Fine FiltersDocument4 pagesDrytec Aluminium Range Fine FiltersDragoslav DzolicNo ratings yet

- Untitled 3Document1 pageUntitled 3sohaieb7No ratings yet

- TheNow Cataelogo ActualizadoDocument20 pagesTheNow Cataelogo ActualizadoronnysiguasNo ratings yet

- Eips 2 en 0120Document8 pagesEips 2 en 0120Athanasios LazaridisNo ratings yet

- Dwg.38 B-AHU-19Document4 pagesDwg.38 B-AHU-19GengaNo ratings yet

- Verso S 20 X H PM - Ie5 - 1 - 4 - X F7 X X R1 C5 - 1 XDocument5 pagesVerso S 20 X H PM - Ie5 - 1 - 4 - X F7 X X R1 C5 - 1 XrkibNo ratings yet

- Ultipor® III Filter Elements DescriptionDocument3 pagesUltipor® III Filter Elements DescriptionjeliocNo ratings yet

- Hfug-2020an BrochureDocument2 pagesHfug-2020an BrochureAzis Purnama GintingNo ratings yet

- Duct Mounted EAC AHU DM2000 - DM1000Document4 pagesDuct Mounted EAC AHU DM2000 - DM1000Keshor KiittuNo ratings yet

- Rs Pro Ultima Filters: DatasheetDocument3 pagesRs Pro Ultima Filters: DatasheetXAVIER RUBIONo ratings yet

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesFrom EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerNo ratings yet

- Chapter 2 RRLDocument18 pagesChapter 2 RRLcelmae150% (1)

- 2024 Prospectus School of Agriculture and Fisheries SciencesDocument332 pages2024 Prospectus School of Agriculture and Fisheries SciencesqualityrepeatNo ratings yet

- Integer Linear ProgrammingDocument10 pagesInteger Linear Programminglmsm0% (1)

- FL958GHEE1B2X1A101Document153 pagesFL958GHEE1B2X1A101Bruno RodriguesNo ratings yet

- Does A Competent Leader Make A Good Friend Conflict, Ideology and The Psychologies of Friendship and FollowershipDocument8 pagesDoes A Competent Leader Make A Good Friend Conflict, Ideology and The Psychologies of Friendship and FollowershipGABRIEL ELIAS TOLEDO FERREIRANo ratings yet

- SINTEROM-2013 Company PresentationDocument26 pagesSINTEROM-2013 Company Presentationgika12345No ratings yet

- NeuroSolutions InfinityDocument36 pagesNeuroSolutions InfinityAmmarGhazaliNo ratings yet

- Design of ConcreteDocument146 pagesDesign of ConcreteMhariecriszReazo100% (1)

- Courtesy Costs Nothing But Buys EverythingDocument3 pagesCourtesy Costs Nothing But Buys EverythingImani AinaNo ratings yet

- Research Proposal PDFDocument7 pagesResearch Proposal PDFammaraNo ratings yet

- Wipro - SIM 2022 - Sample ItemsDocument6 pagesWipro - SIM 2022 - Sample ItemsSh'Jil100% (1)

- A Review On Solid Dispersion A Modern Fo 032208c9Document6 pagesA Review On Solid Dispersion A Modern Fo 032208c9Anggun NurhidayahNo ratings yet

- LCP Cdi 2Document12 pagesLCP Cdi 2Mandy AstillaNo ratings yet

- Aswich Electrical: EDS6EL DC Isolator IP66 Enclosure (1500V 50A)Document3 pagesAswich Electrical: EDS6EL DC Isolator IP66 Enclosure (1500V 50A)AswichElectricalNo ratings yet

- Vishal 35426455tyre Changer Machine NEWDocument22 pagesVishal 35426455tyre Changer Machine NEWSushant ManeNo ratings yet

- sieve analysis mahmoud alsuht 140330 (3+4)Document6 pagessieve analysis mahmoud alsuht 140330 (3+4)mahdalsuhtNo ratings yet

- Vodafone USB Classic (K3773) Upgrade Guide V4.6Document7 pagesVodafone USB Classic (K3773) Upgrade Guide V4.6Bobby ChippingNo ratings yet

- Basement Roof Beam Plan: Project:-Mahesh Atithi NiwasDocument1 pageBasement Roof Beam Plan: Project:-Mahesh Atithi NiwasCMM INFRAPROJECTS LTDNo ratings yet

- AFCONA - 2501 TDS EngDocument1 pageAFCONA - 2501 TDS EngHamood AbdoNo ratings yet

- Chapter 3.0 - Block DiagramDocument37 pagesChapter 3.0 - Block DiagramAzyan Wafiqah AzmiNo ratings yet

- Resume: Murali - BolliniDocument2 pagesResume: Murali - BollinisleopauldineshNo ratings yet

- LatexDocument11 pagesLatexJefara GhostNo ratings yet

- Cable NetworksDocument32 pagesCable NetworksEsakki Muthuvel VNo ratings yet

- Final Bionformatics Practical - 17034103Document28 pagesFinal Bionformatics Practical - 17034103Manpreet KaurNo ratings yet

- The Mathematical Parent: Parental Scaffolding, Parenting Style, and Learning Outcomes in Long-Division Mathematics HomeworkDocument18 pagesThe Mathematical Parent: Parental Scaffolding, Parenting Style, and Learning Outcomes in Long-Division Mathematics Homeworksuharyadi suwakburNo ratings yet