9 Detail of Part 9: WWW - Fineprint.cn

9 Detail of Part 9: WWW - Fineprint.cn

Uploaded by

kaiser hamid sazidCopyright:

Available Formats

9 Detail of Part 9: WWW - Fineprint.cn

9 Detail of Part 9: WWW - Fineprint.cn

Uploaded by

kaiser hamid sazidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

9 Detail of Part 9: WWW - Fineprint.cn

9 Detail of Part 9: WWW - Fineprint.cn

Uploaded by

kaiser hamid sazidCopyright:

Available Formats

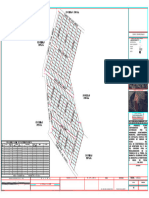

件9详图 Detail of Part 9 Ⅰ

δ=12

8-Ø78

0

Ø2

Ø190

12

1 0

00

2 Ø17

3

Ø2100 12

200

6

300

12 2/1

Ⅰ

800

2650

200

N8

14

6

2/1

16

60°

(2491)

6 Ⅱ Ⅲ

2300

Ø1600

N3

4 Nc2

Ø78

5

6

1000

6

Ø1700 6

500

6

12

160

1

520

13

600

60°

60°

Ø76x6

1200

2

1000

2

Ⅱ

4000

<DN50接管与支撑筋板连接示意图

Ø5000 2/16

<DN50 Schematic diagram of connecting the nozzle to the support rib plate

( 9535)

9 A向 view

A向 View

200

Np3

45 °

30

20 3

60°

1300

1300

200 200

技 术 要 求

N7 Np2

300

300

1、本部件按照GB/T150-2011《压力容器》的要求进行制造、检验和验收。

10

2

2、焊接完毕后全部内表面焊接接头应打磨平整,然后进行无损检测,检测要求见总图说明。

100

Ⅲ

500

3、检验合格后全部不锈钢表面应进行酸洗、钝化处理,经蓝点法进行检测,以表面无蓝点为合格。

300

60°

4、支座垫板应在制造时与设备壳体先焊接完毕,并按NB/T47013-2015《承压设备无损检测》的要求进行磁粉检测,

210 以I级为合格;支座肋板待设备安装校直后再与支座垫板焊接就位,同时保证各支座均匀承力。

1500

(1732)

2/ 1 5、人孔的不锈钢部分采用S22053,筒节壁厚为10mm。

6

6、丝网除沫器为外购件,包含环形丝网内(外)支撑圈、丝网、压条、支撑条(按需设置)。供货厂家需确保:

200 1)支撑圈有足够的强度;2)压条能够有效防止除沫器网块翻转或脱落;3)合适的丝网分块,以便丝网能顺利进

600

Ø3000 Np1 入人孔。

Nc1

2

Technical requirements

100

1 The assembly should be manufactured,inspected and accepted according to GB/T150-2011.

11

1006

2 Inside of welding joints should be grinded smoothly,then make the nondestructive testing which is instructed

2/1

2

by the documents.

3 The surface of stainless steel shall be treated with acid pickling passivation,deactivation and inspected by

12 blue dot method which is qualified without blue dot after the equipment acceptable.

700 4 The support plate should be welded with the equipment shell in the manufacturing, and according to NB/T47013-2015

N10 N9 non-destructive inspection of pressure equipment Test requirements for magnetic particle detection, with grade I

as qualified; The support rib plate shall be connected with the support plate after the equipment is installedand

straightened Welding in place, while ensuring the uniform bearing of each support.

5 The stainless material of manhole is S22053,the thickness of cylinder is 10mm.

6 The demister for purchased parts, including ring screen inside (outside) support ring, screen, laminate,

support strip (set on demand).The supplier shall ensure that:

0° 1) the support ring has sufficient strength;

25° 2) The laminate can effectively prevent the net block of the defroster from turning over or falling off;

N10

3) Suitable screen partition, so that the screen can smoothly enter the manhole.

N8

315° 45° NB/T 11025-2022 Q345R 2 15.6 31.2

Nc2

Nc1 HG/T21596-2014 2 128.0 256.0

Np3 HG/T20592-2009 法兰 Flange PL50(A)-16RF S22053 1 2.5

Np2 接管 Nozzle Ø60.3x6-212 S22053 2 1.6 3.2

HG/T20592-2009 法兰 Flange PL50(A)-16RF S22053 2 2.5 5.0

Np1 接管 Nozzle Ø60.3x6-229 S22053 1 1.69

290°

56

Np3 HG/T20592-2009 法兰 Flange PL150(A)-16RF S22053 1 7.0

00

Np2 70°

Np1 Nc1 N10 接管 Nozzle OD Ø168.3x6-349 S22053 1 8.4

HG/T20592-2009 法兰 Flange PL50(A)-16RF S22053 1 2.5

N9 接管 Nozzle Ø60.3x6-196 S22053 1 1.57

HG/T20592-2009 法兰 Flange PL50(A)-16RF S22053 1 2.5

N8 接管 Nozzle Ø60.3x6-229 S22053 1 1.69

270° Nc2 N7 90° S22053 2 0.6 1.2 L现场定

HG/T20592-2009 法兰 Flange PL25(A)-16RF S22053 1 1.0

N7 接管 Nozzle Ø33.7x4-214 S22053 1 0.6

NB/T 11025-2022 Q345R 1 144.0

N3 S22053 1 781.6

单 总

图号或标准号 名 称 材 料 单位 数量 SINGLE TOTAL 备 注

SYMBOL DWG. NO./STD. NO. PARTS NAME MATERIAL UNIT QTY. 质量 MASS(kg) REMARKS

管口明细表 NOZZLE MATERIAL SCHEDULE

14 S22053 1

13 HG-S-M-1-VS01-2.2 支座 Lug support 4

12 GB/T25198-2010 S22053/Q345R 1 163.3

11 Q345R 1

10 S22053/Q345R 1

225° 135°

9 S22053 2 239.7

8 接管 Nozzle OD Ø76x6.1-3894 S22053 8 326.4

N3 7 Q345R 2

6 S22053/Q345R 1

N9 5 HG-S-M-1-VS01-2.1 丝网除沫器组件 Demister 1 720.43

180° 4 S22053

筒节 Cylinder ID Ø1700x6-600 1 152.93

3 S22053/Q345R 1

2 Q345R 1 54.82

1 筒节 Cylinder ID Ø2100x12-800 S22053 1

序 号 单 总

(件 号)

图号或标准号 名 称 材 料 单位 数量 SINGLE TOTAL 备 注

PARTS NO. DWG. NO./STD. NO. PARTS NAME MATERIAL UNIT QTY. 质量 MASS(kg) REMARKS

总重量 kg 26474.5 设备位号 SC-200

Date Rev. REVISION NOTE

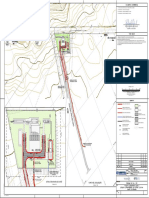

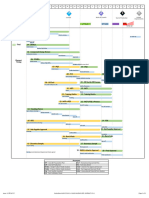

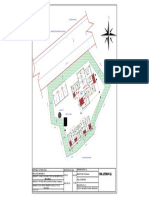

孟加拉CONFIDENCE SEA RESOURCE

LTD.30t/h MVR制盐项目 STAGE

SCALE

SIZE

设计证书编号:甲级A143000226 REV NO.

CERTIFICATE NO. : A143000226 CLASS A

DATE

本文件产权属中国轻工业长沙工程有限公司所有,未经中国轻工业长沙工程有限公司书面许可不准复用或转让第三方。

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

You might also like

- Hindi Tayo Pwede PDFDocument7 pagesHindi Tayo Pwede PDFThe illusionistNo ratings yet

- Assembly1 1 PDFDocument1 pageAssembly1 1 PDFgalih chandra wiradhikaNo ratings yet

- TE COMP R19 Sem VI DEC23Document8 pagesTE COMP R19 Sem VI DEC23SnehaNo ratings yet

- A Straight Pipe Details: T1 T2 T3 T4Document1 pageA Straight Pipe Details: T1 T2 T3 T4hoanghc98hn1 hoanghc98hn1No ratings yet

- MuniDocument1 pageMuniSaurav LamichhaneNo ratings yet

- DRW SOHO AK Blok A, B, C-LAYOUTDocument1 pageDRW SOHO AK Blok A, B, C-LAYOUTAdji ShonNo ratings yet

- (Ver Doc. DE-D09-B14-0002) : RAMO 100Document1 page(Ver Doc. DE-D09-B14-0002) : RAMO 100Fernando Da RosNo ratings yet

- Second Floor PlanDocument1 pageSecond Floor PlanMark Kristoffer HilarionNo ratings yet

- TRAMO II - KM 32 - KM 33Document6 pagesTRAMO II - KM 32 - KM 33Diego Pimentel AparicioNo ratings yet

- Lote Carabayllo-Lote 13aDocument1 pageLote Carabayllo-Lote 13aPcas lNo ratings yet

- Be Mechanical Engineering Semester 3 2023 May Strength of Materials Rev 2019 C SchemeDocument2 pagesBe Mechanical Engineering Semester 3 2023 May Strength of Materials Rev 2019 C SchemeAditya PatilNo ratings yet

- 1531-00.00 A Bock SchweisskonsDocument1 page1531-00.00 A Bock SchweisskonsMuharem KolićNo ratings yet

- Marmac 304 - Gen. ArrangementDocument1 pageMarmac 304 - Gen. ArrangementR. ADOLFO GARCIA RESENDIZNo ratings yet

- CHAFLÁNDocument3 pagesCHAFLÁNcarlos arturo sierra diosaNo ratings yet

- Line 5 Line 5: Key PlanDocument1 pageLine 5 Line 5: Key PlanRistaNo ratings yet

- Mid STA.2+342.91Document1 pageMid STA.2+342.91Julian SandovalNo ratings yet

- Be Electronics Engineering Semester 3 2024 May Engineering Mathematics III Rev 2019 C SchemeDocument2 pagesBe Electronics Engineering Semester 3 2024 May Engineering Mathematics III Rev 2019 C Schemeiamsamith124No ratings yet

- Colonia Los Sauces Completo2, 2024 90 X 60Document1 pageColonia Los Sauces Completo2, 2024 90 X 60luis ambrosNo ratings yet

- Be Chemical Engineering Semester 7 2022 December Chemical Engineering Equipment Design Rev 2019 C SchemeDocument3 pagesBe Chemical Engineering Semester 7 2022 December Chemical Engineering Equipment Design Rev 2019 C SchemeMitesh ThakurNo ratings yet

- Stepper Datasheetsfsahj PDFDocument1 pageStepper Datasheetsfsahj PDFpatil_ameyaNo ratings yet

- Ego Death Riff (6 Strings)Document2 pagesEgo Death Riff (6 Strings)Sebastian ArbajeNo ratings yet

- Ego Death Riff (6 Strings)Document2 pagesEgo Death Riff (6 Strings)Satanatomic100% (1)

- 30 SongsDocument6 pages30 SongsHenning FüllerNo ratings yet

- Aquellas Pequeñas CosasDocument1 pageAquellas Pequeñas Cosasmatiaszloto4118No ratings yet

- Vía Secundaria A Portal de Ingreso de Túnel: Río El GolpeDocument1 pageVía Secundaria A Portal de Ingreso de Túnel: Río El Golpejenifercajamarca97No ratings yet

- R2 SECTION: Sta. 0+000 - Sta. 1+100: Scale A1: 1/1500, A3: 1/3000 Ring 2 - 1Document12 pagesR2 SECTION: Sta. 0+000 - Sta. 1+100: Scale A1: 1/1500, A3: 1/3000 Ring 2 - 1ကိုနေဝင်းNo ratings yet

- Des Fer Hid 001 F01 02 R00Document2 pagesDes Fer Hid 001 F01 02 R00Pedro Almi da Costa FreireNo ratings yet

- 428 05634 O DRW en - 1 BallDocument1 page428 05634 O DRW en - 1 BallJose Maria HernandezNo ratings yet

- DE D09 B41 0001 - Reva1Document1 pageDE D09 B41 0001 - Reva1Fernando Da RosNo ratings yet

- 01 OppDocument1 page01 OppAntonio MignoniNo ratings yet

- 《色香水》吉他指弹-by菜主公Document2 pages《色香水》吉他指弹-by菜主公neal12295No ratings yet

- Tá Chorando Porquê Preto No Branco Tablatura Gospel FácilDocument3 pagesTá Chorando Porquê Preto No Branco Tablatura Gospel FácilFernandes SalesNo ratings yet

- Bottom Euro Type Tray: Assembly Drg. NoDocument2 pagesBottom Euro Type Tray: Assembly Drg. NoJohn AlexanderNo ratings yet

- SBFZ Adc-Sbfz Adc 20240418Document2 pagesSBFZ Adc-Sbfz Adc 20240418LIKE GAMER ™No ratings yet

- Mollier R744Document1 pageMollier R744Pau Massutí BallesterNo ratings yet

- 2018 ASME International Pipeline Conference - Breathing New Life To Aging Pipeline Infrastructure With Tite Liner™Document47 pages2018 ASME International Pipeline Conference - Breathing New Life To Aging Pipeline Infrastructure With Tite Liner™Alex Gutierrez100% (1)

- Ar 100 Architectural Bungalow House Plan RevDocument1 pageAr 100 Architectural Bungalow House Plan RevGenalyn DomantayNo ratings yet

- Moon RiverDocument4 pagesMoon River黄锦华No ratings yet

- Banal Na Aso, Santong KabayoDocument6 pagesBanal Na Aso, Santong KabayoHazel Anne LopezNo ratings yet

- OHCx531 ODocument2 pagesOHCx531 OikanlelecpnsdkiNo ratings yet

- P Ple Als 240 30139 0Document1 pageP Ple Als 240 30139 0AslaouiNo ratings yet

- Module 1 Programming Machining REVDocument1 pageModule 1 Programming Machining REVriscaawalia08No ratings yet

- Trái Tim Bên Lề - Guitar TabsDocument3 pagesTrái Tim Bên Lề - Guitar Tabsvuongluu2301No ratings yet

- 19-Alignment Plan &profile KM 100-110Document1 page19-Alignment Plan &profile KM 100-110Tamrayehu KuremaNo ratings yet

- archivoDocument1 pagearchivoFacuNo ratings yet

- Nov 2024 Health GridDocument1 pageNov 2024 Health Gridsiddhant.soniNo ratings yet

- 6.6 THRU' 2 Nos: Forbes & Company LimitedDocument1 page6.6 THRU' 2 Nos: Forbes & Company LimitedChandru ChristurajNo ratings yet

- Ceiling Layout 34 Sds LTC 015-23-004 34Document1 pageCeiling Layout 34 Sds LTC 015-23-004 34almamoura.eaNo ratings yet

- Site PlanDocument1 pageSite PlanEng. NKURUNZIZA ApollinaireNo ratings yet

- (Masaaki K) A Boy and Baby DeerDocument5 pages(Masaaki K) A Boy and Baby DeermiromarkoNo ratings yet

- Revelator Eyes: The Piper KitesDocument8 pagesRevelator Eyes: The Piper KitesEinar UtreraNo ratings yet

- IP May 2023 Questio PaperDocument1 pageIP May 2023 Questio Papergpmumbai123No ratings yet

- Crime and PunishmentDocument5 pagesCrime and PunishmentBrian CobenasNo ratings yet

- LBP and DBP Floor Plan GFDocument1 pageLBP and DBP Floor Plan GFKarl Anton ClementeNo ratings yet

- Raindrop FlowerDocument4 pagesRaindrop Flowerbaebro1699No ratings yet

- Greensleeves: Anónimo (S. XVI)Document1 pageGreensleeves: Anónimo (S. XVI)Manuel P.No ratings yet

- Autumn Leaves - Eva Cassidy - Book - Piano - BBM - OrgDocument4 pagesAutumn Leaves - Eva Cassidy - Book - Piano - BBM - OrgAfra FredNo ratings yet

- 204.PLTM Citarik (Geologi) S ALLDocument1 page204.PLTM Citarik (Geologi) S ALLlord rangedNo ratings yet

- ELEV. +814.12: Moa EngenhariaDocument1 pageELEV. +814.12: Moa EngenhariaLeonardo AmaralNo ratings yet