CNC Vertical Milling Machine-JOB PROCEDURE

CNC Vertical Milling Machine-JOB PROCEDURE

Uploaded by

praveen_kumar_119Copyright:

Available Formats

CNC Vertical Milling Machine-JOB PROCEDURE

CNC Vertical Milling Machine-JOB PROCEDURE

Uploaded by

praveen_kumar_119Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

CNC Vertical Milling Machine-JOB PROCEDURE

CNC Vertical Milling Machine-JOB PROCEDURE

Uploaded by

praveen_kumar_119Copyright:

Available Formats

FRONTIER SCHOOL DIVISION JOB SAFETY ANALYSIS

Division: Department: Job Title: Job Title: Frontier School Division Facilities and Maintenance Pratical Arts Maintenance CNC Vertical Milling Machine Analysis By: Supervisor: Approved By: Job Performed By: Date: Frequency: JSA Number: Jul/20/2007

REQUIRED PERSONAL PROTECTIVE EQUIPMENT: Safety Glasses, Steel Toe Shoes GENERAL NOTES: JOB SAFETY ANALYSIS:

Step 1 Description CNC Vertical Milling Machine is designed to mill (cut) metal for custom prototype projects and to cut custom metal projects. Mill is operated by means of a computer that is preloaded with data that --operates cutting action of mill. Cutters are selected based upon the specific job to be done. Multiple cutters can be required for --certain projects. Main power is turned off and mill power switch is in off position. Cutter is selected and mounted in Mill Chuck. Hazard N/A Controls N/A

N/A

N/A

N/A

N/A

N/A

N/A

Page 1 of 3

Print Date: Jul/20/2007

Metal blank is mounted in mill material vice and locked into position. Some of the metals used on the milling machine can get quite large. Heavier projects are placed and removed from milling table with the assistance of the Hydraulic Lift. Mill main power is turned on and machine power switch is activated. Computer is programmed to --begin cutting process and mill begins cutting --operation. Machine automatically mists cutting --blade with cutting/cooling oil to prevent blade from overheating. The speed and feed settings are normally programmed to optimize the cutting characteristics of the cutting blade. Cutting blade normally turns at a low speed and although uncommon, fracturing cutting blades and metal cuttings have been known to fly. Following cutting operation, main power is shut down, cutter is removed from machine and --material is removed from vice. Metal cuttings are carefully cleaned up from around mill cutting area with hand broom and dust pan.

Crush

If metal to be milled requires the assistance of the Hydraulic lift, --extreme caution should be used when moving the lift so that load does not shift and fall. --Personal protective equipment (PPE) should include the following; Steel Toe Shoes

Eye

Personal protective equipment (PPE) should include the following; --Safety Glasses--Although cutting oil usually reduces the incidence of flying metal chips, Safety Glasses should be worn at all times when operating milling --machine

Mechanical Energy--Cut--Eye

Personal protective equipment (PPE) should include the following; --Safety Glasses--Training in the correct operation and maintenance of the Milling --Machine should be mandatory for all authorized machine shop --personnel.-Training workers in proper lifting technigues

N/A

N/A

Eye

Personal protective equipment (PPE) should include the following; --Safety Glasses

AUTHORIZED EMPLOYEE INFORMATION:

ID NUMBER: LAST NAME: FIRST NAME: REMARKS:

JOB HISTORY INFORMATION: DATE: REMARKS:

Approval Signature:

Date:

Page 3 of 3

Print Date: Jul/20/2007

You might also like

- Shukrani Yangu-1Document4 pagesShukrani Yangu-1CharleskagayoNo ratings yet

- Detail Pool Asset Configuration StepsDocument34 pagesDetail Pool Asset Configuration Stepsibrahim100% (1)

- Overhead Crane/Hoist Monthly Checklist: Mark The Appropriate BoxesDocument3 pagesOverhead Crane/Hoist Monthly Checklist: Mark The Appropriate BoxesAli HadiNo ratings yet

- Equipment Inspection ChecklistDocument4 pagesEquipment Inspection ChecklistBharathi SilambarasanNo ratings yet

- FMEADocument23 pagesFMEAtbmariNo ratings yet

- Daily Checklist Bulldozerpdf PDF FreeDocument1 pageDaily Checklist Bulldozerpdf PDF FreeRama Asmara TariganNo ratings yet

- Form - 21 - Report of Accident Including, Dangerous Occurrence Resulting in Death or Bodily InjuryDocument5 pagesForm - 21 - Report of Accident Including, Dangerous Occurrence Resulting in Death or Bodily Injuryhdpanchal86No ratings yet

- General: ASTM A351 Gr. CF3MDocument1 pageGeneral: ASTM A351 Gr. CF3MPipeline EngineerNo ratings yet

- 2009 Product Catalogue v2Document261 pages2009 Product Catalogue v2renoyaboNo ratings yet

- Milling Machine - Mill Mate (Bridge Port Style) - JOB PROCEDURDocument5 pagesMilling Machine - Mill Mate (Bridge Port Style) - JOB PROCEDURAshok SureshNo ratings yet

- 26 - Welding Machine ChecklistDocument1 page26 - Welding Machine ChecklistZeeshan AbbasiNo ratings yet

- Standard Operating ProcedureDocument55 pagesStandard Operating Procedureboy tryadi100% (1)

- Bench GrinderDocument1 pageBench GrinderReneeNo ratings yet

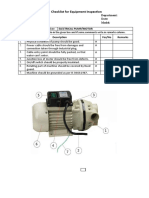

- Checklist For Equipment Inspection Electrical Pump MotorDocument1 pageChecklist For Equipment Inspection Electrical Pump MotorKaif Siddique100% (1)

- AFC Manual700dpr06Document40 pagesAFC Manual700dpr06Alejandro CanoNo ratings yet

- Machinery Inspection ChecklistDocument3 pagesMachinery Inspection ChecklistIvan Dave TorrecampoNo ratings yet

- Electric Generator Inspection Checklist (Insert Your Logo)Document1 pageElectric Generator Inspection Checklist (Insert Your Logo)Kevin MichaelNo ratings yet

- Lathe SopDocument2 pagesLathe SopDilip Kumar K100% (1)

- Work Instruction For Grinding of ToolsDocument1 pageWork Instruction For Grinding of ToolsVIBHOR100% (1)

- Tape Measure Inspection LogDocument5 pagesTape Measure Inspection Logsyahrizal5479No ratings yet

- Preventive Maintenance Checklist: Tool Room & Production SawsDocument2 pagesPreventive Maintenance Checklist: Tool Room & Production SawsValerio Ambrocio Ismael100% (1)

- Punch Press Safety and Operating ProceduresDocument2 pagesPunch Press Safety and Operating ProceduresRAMESH100% (1)

- 9 Forklift Pre-Operational ChecklistDocument2 pages9 Forklift Pre-Operational ChecklistandrewhwNo ratings yet

- As 2400.13-1983 Packaging Tensional StrappingDocument6 pagesAs 2400.13-1983 Packaging Tensional StrappingSAI Global - APACNo ratings yet

- Scissor Lift Pre-Use Inspection ChecklistDocument1 pageScissor Lift Pre-Use Inspection ChecklistHarun SaniNo ratings yet

- Inspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadDocument1 pageInspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadilyasNo ratings yet

- Form Inspeksi Bar Cutter Bar Bender - Fix (SfileDocument1 pageForm Inspeksi Bar Cutter Bar Bender - Fix (Sfilerajatua dramaga.projectNo ratings yet

- Borang Pemeriksaan Air KompressorDocument1 pageBorang Pemeriksaan Air KompressorAndara Asifa YudianaNo ratings yet

- Form - 26A - Test Report Dustfume - Exetration SystemDocument2 pagesForm - 26A - Test Report Dustfume - Exetration Systemhdpanchal86No ratings yet

- Monthly Inspection Report For Cranes and HoistsDocument2 pagesMonthly Inspection Report For Cranes and HoistsGrace PassiniNo ratings yet

- First Aid Risk AssessmentDocument4 pagesFirst Aid Risk AssessmentJohn GeddesNo ratings yet

- Equipment / Machinery Checklist: BlankDocument4 pagesEquipment / Machinery Checklist: BlankJason Maldonado0% (1)

- Pressing Machine Audit Points - v3Document1 pagePressing Machine Audit Points - v3Pampanagouda YadavNo ratings yet

- JD Manager-Machine ShopDocument2 pagesJD Manager-Machine ShopParveen (Atam Valves)No ratings yet

- Ventilation Plan TemplateDocument11 pagesVentilation Plan TemplatePlank89No ratings yet

- Daily Inspection Checklist - Welding MachineDocument1 pageDaily Inspection Checklist - Welding Machinenadeem mallick100% (1)

- MJ164 RIP SAW Operation ManualDocument36 pagesMJ164 RIP SAW Operation ManualEduardo Lopez CastilloNo ratings yet

- DM-PH&SD-P4-TG23 - (Guidelines For Safety Procedures in Metal Finishing Industries) PDFDocument3 pagesDM-PH&SD-P4-TG23 - (Guidelines For Safety Procedures in Metal Finishing Industries) PDFdemie figueroaNo ratings yet

- Objective Name of The Employee / Team DepartmentDocument6 pagesObjective Name of The Employee / Team DepartmentSachin SinghNo ratings yet

- MILLER Continue SpecsDocument12 pagesMILLER Continue Specsjorge murilloNo ratings yet

- Check List - Machine GuardingDocument2 pagesCheck List - Machine GuardingSirley Sanmartín RestrepoNo ratings yet

- Banka Machine - Pillar Drill Machine - P20Document2 pagesBanka Machine - Pillar Drill Machine - P20SalmanShaikhNo ratings yet

- GRC Overhead Crane Daily Checklist - NasaDocument2 pagesGRC Overhead Crane Daily Checklist - NasaFlorfloresta Alfa OneNo ratings yet

- Arbortext IsoDraw Macro Language Reference - 7.2Document343 pagesArbortext IsoDraw Macro Language Reference - 7.2atmelloNo ratings yet

- First Aid Kit Usage FormDocument1 pageFirst Aid Kit Usage FormLarn SottoNo ratings yet

- HSE 05-015a Ladder Inspection RegisterDocument1 pageHSE 05-015a Ladder Inspection RegisterQuentin KlynsmithNo ratings yet

- Pre Use Inspection For Kubota TractorDocument2 pagesPre Use Inspection For Kubota TractorJannie CoetzeeNo ratings yet

- Sop Grinder Angle GrinderDocument2 pagesSop Grinder Angle Grindernur syamimiNo ratings yet

- SOP - Drill PressDocument2 pagesSOP - Drill PressAngga BayuNo ratings yet

- Fork Lift Daily Check: (Only For FL Operated by Batery)Document1 pageFork Lift Daily Check: (Only For FL Operated by Batery)Martin CabelloNo ratings yet

- Standard Operating Procedure Welding machine-MIG: PedestalDocument2 pagesStandard Operating Procedure Welding machine-MIG: PedestalKranthi Kumar Reddy100% (1)

- Coolan Evoxx AL 4250Document1 pageCoolan Evoxx AL 4250Siti FatimahNo ratings yet

- SOP Section Rolling Machine #10011234567891123Document3 pagesSOP Section Rolling Machine #10011234567891123saturnelNo ratings yet

- Wheel Loader Updated Daily Inspection ChecklistDocument1 pageWheel Loader Updated Daily Inspection ChecklistAmir ahmadNo ratings yet

- Policy - Health, Safety and EnvironmentalDocument1 pagePolicy - Health, Safety and EnvironmentalNeo SeeraneNo ratings yet

- Section B: List of Chemicals Hazardous Chemical To HealthDocument4 pagesSection B: List of Chemicals Hazardous Chemical To HealthSzaz Wani100% (1)

- Don Bosco TVET Center-Calauan IncDocument3 pagesDon Bosco TVET Center-Calauan IncJuliet N. Coronado100% (1)

- Elevated Work PlatformsDocument1 pageElevated Work PlatformsRanjan PradhanNo ratings yet

- Sample: Excavator Inspection & Maintenance RecordDocument3 pagesSample: Excavator Inspection & Maintenance RecordbangladragosNo ratings yet

- CartridgeSelectionPoster English HRDocument1 pageCartridgeSelectionPoster English HRTg TarroNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Mto Shear ScriptDocument7 pagesMto Shear ScriptAustria, Gerwin Iver LuisNo ratings yet

- Documentary Requirements Cop PDFDocument5 pagesDocumentary Requirements Cop PDFJayPee DeciertoNo ratings yet

- DevopsDocument8 pagesDevopschaitu592No ratings yet

- Anas VP: Electrical Design EngineerDocument2 pagesAnas VP: Electrical Design EngineerAri MachaNo ratings yet

- Remove Install Inner PaneDocument4 pagesRemove Install Inner PaneAnwar HidayatNo ratings yet

- Aspect eWorkforce-Management-OutboundBlendedCapabilities DSDocument2 pagesAspect eWorkforce-Management-OutboundBlendedCapabilities DSNikhil SinhaNo ratings yet

- Enz Nozzle Catalog 2012Document97 pagesEnz Nozzle Catalog 2012ryanvlopezNo ratings yet

- Productivity Improvement in Apparel Industry .PPT PesentationDocument14 pagesProductivity Improvement in Apparel Industry .PPT Pesentationsudincr100% (3)

- Analysis On Market and Business Strategy of Honda, DHS Motors LimitedDocument30 pagesAnalysis On Market and Business Strategy of Honda, DHS Motors LimitedBadhon JamanNo ratings yet

- Implementing Self-Service Procurement in ERP - SAP DocumentationDocument3 pagesImplementing Self-Service Procurement in ERP - SAP DocumentationShreyaa NarulaNo ratings yet

- ED 00 CPL PRC 0021 Construction QC Procedure Rev.2Document24 pagesED 00 CPL PRC 0021 Construction QC Procedure Rev.2Rahmat Hidayat100% (1)

- Strategic Management - Generic Competitive StrategiesDocument39 pagesStrategic Management - Generic Competitive StrategiesManganNo ratings yet

- Working Safely Powerpoint PresentationDocument60 pagesWorking Safely Powerpoint PresentationAISECT PMKK SalemNo ratings yet

- Trainig RreportDocument74 pagesTrainig RreportomkarNo ratings yet

- Micro Mart - March 12, 2015 UKDocument100 pagesMicro Mart - March 12, 2015 UKDaniel ScurtuNo ratings yet

- Bul OnesDocument32 pagesBul OnesGustavo100% (1)

- WFS Item LabelingDocument2 pagesWFS Item LabelingAhsanur KabirNo ratings yet

- Cost Estimation Manual For Low Rise Buildings: Acfl NymsDocument5 pagesCost Estimation Manual For Low Rise Buildings: Acfl Nymsjhomel garciaNo ratings yet

- Heritage of Bailey ControlsDocument4 pagesHeritage of Bailey ControlsJared CorpuzNo ratings yet

- Resume: Vinay Kumar PandeyDocument2 pagesResume: Vinay Kumar PandeyVini PandeyNo ratings yet

- 2017 U.S. State of Cybercrime SurveyDocument8 pages2017 U.S. State of Cybercrime SurveyIDG_WorldNo ratings yet

- SIS Kontinuitet PoslovanjaDocument35 pagesSIS Kontinuitet PoslovanjaShporet100% (1)

- As Built Quotation ComputationDocument4 pagesAs Built Quotation ComputationIcedTea 71oNo ratings yet

- SQL Quiz-YDocument75 pagesSQL Quiz-Yutagore58No ratings yet

- Workshop Risk AssesmentDocument1 pageWorkshop Risk Assesmentapi-316012376No ratings yet

- Man FXM FKM MotorsDocument148 pagesMan FXM FKM Motorspaula09No ratings yet

- Andrew GroveDocument13 pagesAndrew Groveskaramanlakis100% (1)

- Assignment 2 Unit 2-1 OmDocument8 pagesAssignment 2 Unit 2-1 OmashishthecoolNo ratings yet