0 ratings0% found this document useful (0 votes)

2 viewsUnit 2 - IS

Unit 2 - IS

Uploaded by

godwin joeIndustrial Safety Unit2

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Unit 2 - IS

Unit 2 - IS

Uploaded by

godwin joe0 ratings0% found this document useful (0 votes)

2 views17 pagesIndustrial Safety Unit2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Industrial Safety Unit2

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views17 pagesUnit 2 - IS

Unit 2 - IS

Uploaded by

godwin joeIndustrial Safety Unit2

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 17

PSNA COLLEGE OF ENGINEERING AND TECHNOLOGY, DINDIGUL – 624622.

(An Autonomous Institution Affiliated to Anna University, Chennai)

OPE353 – INDUSTRIAL SAFETY

UNIT 2 – OCCUPATIONAL HEALTH AND HYGIENE

DEFINITION OF THE TERM OCCUPATIONAL HEALTH AND HYGIENE:

Occupational Health:

Definition: Occupational Health is a multidisciplinary field concerned with the safety,

health, and well-being of workers. It involves identifying, assessing, and managing risks

in the workplace to prevent injuries and illnesses.

Occupational Hygiene:

Definition: Occupational Hygiene is the science of anticipating, recognizing, evaluating,

and controlling health hazards in the workplace to prevent illness and injury. It focuses

on chemical, physical, and biological hazards.

CATEGORIES OF HEALTH HAZARDS:

Health hazards in industrial safety can be categorized into various types based on

the nature of the hazard and its potential impact on workers’ health.

Understanding these categories is crucial for implementing effective safety measures

and ensuring a safe work environment.

1. Chemical Hazards:

Definition: Chemical hazards are substances that can cause harm to workers

through inhalation, skin contact, or ingestion.

Examples:

Gases and Vapours: Such as chlorine, ammonia, and solvent vapours.

Liquids: Including acids, alkalis, and other corrosive substances.

Solids: Dusts, fibers, and particulates like silica dust and asbestos.

Health Effects:

Acute Effects: Immediate reactions such as burns, irritation, or poisoning.

Chronic Effects: Long-term health issues such as respiratory diseases,

cancer, and organ damage.

Control Measures:

Engineering Controls: Ventilation systems, fume hoods, and closed systems.

Administrative Controls: Safety training, proper labelling and safe handling

procedures.

Personal Protective Equipment (PPE): Gloves, respirators, and protective

clothing.

2. Physical Hazards:

Definition: Physical hazards are environmental factors that can cause harm to

workers through physical contact or exposure.

Examples:

Noise: Loud machinery, equipment, and processes.

Vibration: From tools and machinery like jackhammers and grinders.

Radiation: Ionizing (X-rays, gamma rays) and non-ionizing (UV light,

microwaves).

Temperature Extremes: Heat stress from high temperatures and heat

sources, and cold stress from working in low-temperature environments.

1 Prepared by M.Kamarajan, AP/CSE, PSNACET

Pressure: High-pressure systems, including compressed gases and hydraulic

equipment.

Health Effects:

Noise-Induced Hearing Loss: Permanent hearing damage from prolonged

exposure to high noise levels.

Hand-Arm Vibration Syndrome (HAVS): Nerve and blood vessel damage in

hands and arms.

Radiation Burns: Skin burns and increased cancer risk from radiation

exposure.

Heat Stroke: Overheating and dehydration from excessive heat exposure.

Frostbite and Hypothermia: From prolonged exposure to cold environments.

Control Measures:

Engineering Controls: Soundproofing, vibration dampening, shielding from

radiation, and climate control systems.

Administrative Controls: Rotating shifts, providing rest breaks, and

conducting regular health monitoring.

Personal Protective Equipment (PPE): Earplugs, thermal clothing, and

radiation shielding.

3. Biological Hazards:

Definition: Biological hazards are organisms or substances produced by

organisms that can cause harm to humans.

Examples:

Bacteria and Viruses: Such as tuberculosis, hepatitis, and influenza.

Fungi and Molds: Which can cause respiratory problems and allergic

reactions.

Parasites: Such as those causing malaria and other parasitic infections.

Biological Toxins: Produced by organisms, like mycotoxins from molds.

Health Effects:

Infections: Bacterial and viral infections leading to illnesses.

Allergic Reactions: From exposure to molds and other allergens.

Chronic Diseases: Long-term health effects like asthma and other respiratory

conditions.

Control Measures:

Engineering Controls: Ventilation, proper waste disposal systems, and

sterilization equipment.

Administrative Controls: Vaccination programs, hygiene practices, and

health surveillance.

Personal Protective Equipment (PPE): Gloves, masks, and biohazard suits.

4. Ergonomic Hazards:

Definition: Ergonomic hazards arise from workplace conditions that pose a risk

to the musculoskeletal system of the worker.

Examples:

Repetitive Motion: Tasks that involve repeated movements, such as typing or

assembly line work.

Poor Posture: Workstations that force awkward positions or movements.

Manual Handling: Lifting, carrying, or moving heavy loads improperly.

2 Prepared by M.Kamarajan, AP/CSE, PSNACET

Inadequate Tool Design: Tools that are difficult to use or require excessive

force.

Health Effects:

Musculoskeletal Disorders (MSDs): Such as carpal tunnel syndrome,

tendonitis, and lower back pain.

Fatigue: From prolonged physical strain and poor ergonomics.

Injuries: Acute injuries from improper lifting techniques or repetitive strain.

Control Measures:

Engineering Controls: Adjustable workstations, ergonomic tools, and

mechanical lifting aids.

Administrative Controls: Job rotation, ergonomic training, and work breaks.

Personal Protective Equipment (PPE): Supports like wrist braces and back

belts.

5. Psychosocial Hazards:

Definition: Psychosocial hazards are aspects of work design and the

organizational and social context that have the potential to cause psychological

or social harm.

Examples:

Work Stress: High workload, tight deadlines, and job insecurity.

Harassment and Bullying: Negative interpersonal interactions in the

workplace.

Work-Life Balance: Poor balance between work demands and personal life.

Job Control: Lack of autonomy and control over work tasks.

Health Effects:

Mental Health Disorders: Such as depression, anxiety, and burnout.

Physical Health Issues: Stress-related conditions like hypertension and

cardiovascular diseases.

Reduced Productivity: Decreased efficiency and increased absenteeism.

Control Measures:

Organizational Policies: Implementing anti-bullying policies, providing

mental health support, and promoting a healthy work-life balance.

Job Design: Enhancing job control, ensuring fair workload distribution, and

providing opportunities for skill development.

Support Systems: Employee assistance programs, counselling services, and

stress management training.

EXPOSURE PATHWAYS AND HUMAN RESPONSES TO HAZARDOUS AND TOXIC

SUBSTANCES:

Exposure to hazardous and toxic substances in industrial settings can occur

through various pathways, leading to different human responses.

Understanding these exposure pathways and the potential health effects is essential

for implementing effective safety measures to protect workers.

Exposure Pathways:

Exposure pathways refer to the routes through which hazardous substances enter

the body.

The primary pathways include inhalation, ingestion, dermal (skin) contact, and

injection.

3 Prepared by M.Kamarajan, AP/CSE, PSNACET

1. Inhalation:

Description: Breathing in airborne contaminants such as gases, vapours,

dust, fumes, and aerosols.

Examples: Inhaling asbestos fibers, chemical vapours, or welding fumes.

Controls: Use of respiratory protection, proper ventilation systems, and air

quality monitoring.

2. Ingestion:

Description: Swallowing hazardous substances, often as a result of hand-to-

mouth behaviour.

Examples: Consuming food or water contaminated with chemicals, or

inadvertently ingesting chemicals from contaminated hands.

Controls: Good hygiene practices, proper labelling and storage of chemicals,

and ensuring clean eating areas.

3. Dermal (Skin) Contact:

Description: Direct contact with hazardous substances through the skin.

Examples: Handling chemicals without gloves, spills or splashes of corrosive

substances.

Controls: Use of personal protective equipment (PPE) such as gloves and

protective clothing, and implementing safety showers and eyewash stations.

4. Injection:

Description: Puncturing the skin and introducing a substance directly into

the bloodstream, usually accidental.

Examples: Needle stick injuries, broken glass, or sharp object injuries that

penetrate the skin.

Controls: Safe handling and disposal of sharp objects, use of puncture-

resistant gloves, and immediate first aid response.

Human Responses to Hazardous and Toxic Substances:

The human body’s response to exposure to hazardous and toxic substances can vary

widely depending on the nature of the substance, the duration and intensity of

exposure, and individual susceptibility.

Responses can be categorized as acute, chronic, or delayed.

1. Acute Responses:

Description: Immediate or short-term reactions following exposure to

hazardous substances.

Symptoms: Include headaches, dizziness, nausea, skin irritation, respiratory

distress, and chemical burns.

Examples:

Inhalation of high concentrations of ammonia can cause immediate

respiratory distress.

Skin contact with strong acids or bases can cause immediate chemical

burns.

2. Chronic Responses:

Description: Long-term health effects that develop after prolonged or repeated

exposure to hazardous substances.

4 Prepared by M.Kamarajan, AP/CSE, PSNACET

Symptoms: Chronic respiratory diseases, cancer, neurological disorders,

reproductive issues, and liver or kidney damage.

Examples:

Long-term exposure to asbestos fibers can lead to chronic respiratory

diseases such as asbestosis, lung cancer, and mesothelioma.

Chronic exposure to benzene, a known carcinogen, can lead to leukemia

and other blood disorders.

3. Delayed Responses:

Description: Health effects that do not appear immediately but manifest after

a latent period.

Symptoms: Similar to chronic responses but can appear after a single

exposure or long after exposure has ceased.

Examples:

Exposure to certain chemicals, like organophosphates, may cause delayed

neurological effects.

Exposure to carcinogens like vinyl chloride may result in cancer many

years after the initial exposure.

Factors Influencing Human Responses:

1. Dose:

Definition: The amount of a substance that enters the body.

Influence: Higher doses typically lead to more severe health effects. Even low

doses of highly toxic substances can cause significant harm.

2. Duration and Frequency:

Definition: The length of time and how often exposure occurs.

Influence: Prolonged or repeated exposure increases the risk of chronic health

effects.

3. Route of Exposure:

Definition: The pathway through which the substance enters the body.

Influence: Different routes of exposure can result in different health effects. For

example, inhalation of a substance might affect the respiratory system more

than skin contact.

4. Individual Susceptibility:

Definition: Variability in individuals’ responses due to genetic factors, age, sex,

health status, and pre-existing conditions.

Influence: Individuals with compromised health, such as those with respiratory

issues, may be more vulnerable to toxic substances.

Examples of Hazardous Substances and Responses:

1. Asbestos:

Exposure Pathway: Inhalation of fibers.

Human Response: Chronic respiratory diseases such as asbestosis, lung

cancer, and mesothelioma.

2. Lead:

Exposure Pathways: Ingestion and inhalation.

Human Response: Neurological effects, developmental delays in children, and

kidney damage.

3. Solvents (e.g., Benzene, Toluene):

Exposure Pathways: Inhalation and skin contact.

5 Prepared by M.Kamarajan, AP/CSE, PSNACET

Human Response: Acute effects include dizziness, headaches, and skin

irritation. Chronic exposure can lead to neurological damage and cancer.

4. Pesticides:

Exposure Pathways: Inhalation, ingestion, and skin contact.

Human Response: Acute poisoning symptoms like nausea and vomiting, chronic

effects like neurological damage and cancer.

Control Measures for Hazardous Substances:

1. Engineering Controls:

Examples: Ventilation systems, enclosed processes, and automated handling

systems to reduce direct exposure.

2. Administrative Controls:

Examples: Safe work procedures, training programs, and regular health

monitoring.

3. Personal Protective Equipment (PPE):

Examples: Respirators, gloves, protective clothing, and safety goggles.

4. Substitution and Elimination:

Examples: Replacing hazardous substances with less harmful ones, or

redesigning processes to eliminate the use of hazardous substances.

ADVANTAGES AND LIMITATIONS OF ENVIRONMENTAL MONITORING AND

OCCUPATIONAL EXPOSURE LIMITS:

Environmental Monitoring:

Environmental Monitoring involves measuring and analyzing the levels of

contaminants in the work environment, such as air, water, and surface

contamination.

It is used to evaluate exposure levels and effectiveness of control measures.

Advantages:

Assessment of Exposure Levels:

Detection of Contaminants: Identifies the presence and concentration of

hazardous substances in the workplace.

Quantitative Data: Provides measurable data on exposure levels, helping to

understand the extent of contamination.

Regulatory Compliance:

Compliance Verification: Ensures that workplace conditions comply with

regulatory standards and guidelines.

Documentation: Provides necessary documentation for regulatory inspections

and audits.

Effectiveness of Control Measures:

Evaluation: Assesses the effectiveness of existing control measures such as

ventilation systems and containment procedures.

Adjustment: Allows for adjustments and improvements to safety measures

based on real-time data.

Health and Safety Planning:

Risk Assessment: Assists in identifying potential health risks and designing

appropriate risk management strategies.

Prevention: Helps in the proactive management of risks by identifying problems

before they result in significant health issues.

6 Prepared by M.Kamarajan, AP/CSE, PSNACET

Worker Safety:

Early Detection: Identifies potential exposure risks before they affect workers’

health.

Health Surveillance: Contributes to the health surveillance programs by

providing data on exposure levels that correlate with health outcomes.

Limitations:

Cost and Resources:

Expense: Environmental monitoring can be costly due to equipment, materials,

and specialized personnel required.

Resource Intensive: Requires significant time and resources for setup,

sampling, analysis, and reporting.

Sampling Limitations:

Frequency: Periodic sampling may not capture peak exposure levels or transient

spikes in contamination.

Representativeness: Sampling may not always be representative of all areas or

times, potentially missing localized or episodic exposure.

Data Interpretation:

Complex Analysis: Interpretation of monitoring data can be complex, requiring

expertise to understand and act on results.

Context-Specific: Data may need to be interpreted in the context of specific

work practices and conditions.

Reliability and Accuracy:

Measurement Errors: Instruments and methods may have limitations in

accuracy and precision, affecting the reliability of results.

Calibration: Regular calibration and maintenance of equipment are essential to

ensure accurate measurements.

Lag in Response:

Delayed Action: There may be a delay between detection of a problem and

implementation of corrective measures, which can impact worker safety.

Occupational Exposure Limits (OELs):

Occupational Exposure Limits (OELs) are regulatory limits set for the maximum

allowable concentration of hazardous substances in the workplace air, to which

workers can be exposed over a specific period.

Advantages:

Health Protection:

Prevention of Adverse Effects: OELs are designed to protect workers from the

harmful effects of exposure to hazardous substances.

Health Standards: Provides a benchmark for acceptable exposure levels to

ensure worker health and safety.

Regulatory Compliance:

Legal Requirements: Compliance with OELs is often mandated by regulatory

agencies, ensuring adherence to legal safety standards.

Consistency: Provides a uniform standard across industries and workplaces for

the protection of workers.

7 Prepared by M.Kamarajan, AP/CSE, PSNACET

Guidance for Safety Measures:

Risk Management: Helps in designing and implementing control measures to

keep exposure levels below the established limits.

Benchmarking: Serves as a benchmark for assessing the effectiveness of control

measures and workplace safety practices.

Health Surveillance:

Monitoring and Evaluation: Provides a basis for health surveillance programs

and helps in evaluating the impact of exposure on worker health.

Preventive Actions:

Early Intervention: Enables early intervention to prevent exceeding exposure

limits, thereby avoiding potential health issues.

Limitations:

Static Nature:

Lag in Updates: OELs may not always be updated promptly to reflect new

scientific knowledge or emerging risks.

Inflexibility: May not account for varying individual susceptibilities or different

exposure scenarios.

Assumptions and Generalization:

One-Size-Fits-All: OELs are based on average worker exposure and may not

account for variations in individual sensitivity or work conditions.

Assumed Exposure: Assumes uniform exposure across a working population,

which may not be the case in all workplaces.

Exposure Variability:

Complex Work Environments: In complex environments with multiple sources

of exposure, maintaining concentrations below OELs can be challenging.

Transient Peaks: OELs may not fully address short-term or peak exposures,

which can be equally harmful.

Enforcement Challenges:

Monitoring: Requires regular and effective monitoring to ensure compliance,

which can be resource-intensive.

Enforcement: Ensuring adherence to OELs can be difficult, particularly in large

or decentralized organizations.

Health Effects Beyond OELs:

Subclinical Effects: Health effects may occur even at exposure levels below

OELs, particularly for sensitive individuals or in cases of cumulative exposure.

HIERARCHY OF CONTROL MEASURES FOR OCCUPATIONAL HEALTH RISKS:

The Hierarchy of Control Measures is a systematic approach used to manage and

mitigate occupational health risks in industrial safety.

It provides a structured framework for identifying and implementing control

measures to reduce or eliminate hazards.

The hierarchy is organized from the most effective control measures to the least

effective, with the goal of minimizing worker exposure to health risks.

1. Elimination:

Definition: The most effective control measure involves completely removing the

hazard from the workplace.

8 Prepared by M.Kamarajan, AP/CSE, PSNACET

Examples:

Substitution of Dangerous Processes: Replacing a hazardous process with a

safer one.

Removal of Hazardous Materials: Eliminating the use of toxic chemicals by

using non-toxic alternatives.

Redesign of Processes: Changing the workflow to eliminate steps that involve

dangerous conditions.

Advantages:

Permanent Solution: Completely removes the risk from the environment.

No Ongoing Exposure: Workers are no longer exposed to the hazard.

Limitations:

Feasibility: Some hazards cannot be completely eliminated due to operational

constraints or technical limitations.

Cost: Can be expensive and may require significant changes to existing

systems or processes.

2. Substitution:

Definition: Substituting a less hazardous material, process, or equipment for

one that is more dangerous.

Examples:

Less Toxic Chemicals: Using a less toxic solvent instead of a highly toxic one.

Safer Equipment: Replacing old machinery with newer, safer models that

have built-in safety features.

Advantages:

Reduced Risk: Lowers the risk associated with the hazard.

Potential Cost Savings: Can sometimes be more cost-effective than other

control measures.

Limitations:

Compatibility: Substitutes must be compatible with existing processes and

systems.

Unanticipated Risks: New substances or processes may introduce new risks

or require additional controls.

3. Engineering Controls:

Definition: Implementing physical changes to the workplace or processes to

reduce or isolate the hazard.

Examples:

Ventilation Systems: Installing local exhaust ventilation systems to remove

harmful vapours or dust from the air.

Enclosures and Guards: Using machine guards and enclosures to prevent

accidental contact with moving parts.

Isolation: Creating barriers or enclosures to separate workers from hazardous

areas or materials.

Advantages:

Effective: Can significantly reduce or eliminate exposure to hazards.

Continuous Protection: Provides ongoing protection as long as the controls

are maintained.

Limitations:

Cost: Can be expensive to install and maintain.

9 Prepared by M.Kamarajan, AP/CSE, PSNACET

Complexity: May require complex modifications to existing systems or

infrastructure.

4. Administrative Controls:

Definition: Implementing changes in work practices and procedures to reduce

exposure to hazards.

Examples:

Work Scheduling: Rotating workers to minimize their exposure to hazardous

tasks or environments.

Training and Education: Providing training on safe work practices,

emergency procedures, and proper use of equipment.

Standard Operating Procedures (SOPs): Developing and enforcing

procedures to ensure safe handling and use of hazardous materials.

Advantages:

Flexibility: Can be adjusted or modified based on changing conditions or

requirements.

Cost-Effective: Generally, less expensive than engineering controls or

personal protective equipment.

Limitations:

Reliance on Compliance: Effectiveness depends on workers following

procedures and protocols.

Temporary Solution: May not fully address the hazard if not combined with

other control measures.

5. Personal Protective Equipment (PPE):

Definition: Using protective gear to shield workers from exposure to hazards.

Examples:

Respirators: Protecting against inhalation of harmful substances.

Gloves: Providing protection from chemicals, cuts, or abrasions.

Protective Clothing: Preventing skin contact with hazardous substances.

Eye Protection: Shields against splashes, flying debris, or harmful radiation.

Advantages:

Immediate Protection: Provides a direct barrier between the worker and the

hazard.

Variety: Wide range of PPE available for different types of hazards.

Limitations

Last Line of Defense: PPE is considered the last line of defense and should

not be the primary control measure.

Comfort and Compliance: PPE can be uncomfortable or cumbersome,

potentially affecting worker compliance.

Maintenance: Requires regular inspection, maintenance, and replacement to

ensure effectiveness.

ROLE OF PERSONAL PROTECTIVE EQUIPMENT AND THE SELECTION CRITERIA:

Personal Protective Equipment (PPE) is crucial in industrial safety as it provides a

barrier between workers and various hazards in the workplace.

It is used when hazards cannot be completely eliminated or controlled through other

means, such as engineering controls or administrative measures.

10 Prepared by M.Kamarajan, AP/CSE, PSNACET

PPE serves as a last line of defense to protect workers from injuries and health

issues.

Role of Personal Protective Equipment (PPE):

1. Protection from Hazards:

Physical Protection: Shields against physical hazards such as cuts, burns,

impacts, and abrasions. For example, gloves protect hands from sharp objects or

chemical burns.

Chemical Protection: Guards against exposure to hazardous chemicals. For

instance, chemical-resistant aprons and gloves prevent skin contact with

corrosive substances.

Biological Protection: Offers protection from biological hazards such as

bacteria, viruses, and other pathogens. Examples include biohazard suits and

face shields.

Respiratory Protection: Protects against inhalation of harmful dust, fumes,

gases, and vapours. Respirators and masks are commonly used for this purpose.

Thermal Protection: Safeguards against extreme temperatures. For example,

insulated gloves and heat-resistant suits protect against high temperatures,

while cold-weather gear protects against freezing conditions.

2. Reduction of Injury Severity:

Prevention of Injuries: Reduces the severity of injuries by providing a protective

barrier. For instance, safety helmets can prevent head injuries from falling

objects.

Mitigation of Health Effects: Reduces the risk of long-term health issues, such

as hearing loss from excessive noise or respiratory diseases from inhaled

contaminants.

3. Compliance with Regulations:

Legal Requirements: Ensures compliance with occupational health and safety

regulations and standards. Many regulations mandate the use of PPE in specific

situations and industries.

Standards Adherence: PPE must meet specific standards and certifications to

ensure its effectiveness and safety. Regulatory bodies often provide guidelines

and requirements for PPE.

4. Employee Assurance:

Increased Confidence: Provides workers with a sense of security, knowing that

they are protected from potential hazards.

Improved Morale: Contributes to overall job satisfaction and morale by

demonstrating the employer’s commitment to worker safety.

Selection Criteria for Personal Protective Equipment (PPE):

Selecting the appropriate PPE is critical to ensure its effectiveness in protecting

workers.

The following criteria should be considered when selecting PPE:

1. Hazard Assessment:

Identification of Hazards: Conduct a thorough assessment of the workplace

to identify potential hazards. This includes evaluating physical, chemical,

biological, and ergonomic risks.

Risk Evaluation: Determine the level of risk associated with each hazard to

select the appropriate type and level of PPE.

11 Prepared by M.Kamarajan, AP/CSE, PSNACET

2. Type of PPE:

Suitability: Choose PPE that is specifically designed to protect against the

identified hazards. For example, use chemical-resistant gloves for handling

hazardous chemicals or hearing protection in noisy environments.

Compatibility: Ensure that the selected PPE is compatible with other

protective gear and does not interfere with job performance or other safety

equipment.

3. Fit and Comfort:

Proper Fit: PPE must fit properly to be effective. Ill-fitting equipment can be

uncomfortable and may not provide adequate protection.

Comfort: Consider the comfort of PPE, as uncomfortable gear can affect

workers’ willingness to wear it consistently.

4. Durability and Maintenance:

Material Quality: Select PPE made from durable materials that can withstand

the conditions of the work environment.

Ease of Maintenance: Choose PPE that is easy to clean, maintain, and

replace when necessary.

5. Standards and Certification:

Compliance: Ensure that PPE meets relevant safety standards and

certifications. For example, respirators should be certified by organizations

like the National Institute for Occupational Safety and Health (NIOSH) or the

European Union (CE) standards.

Quality Assurance: Verify that the PPE has been tested and approved for use

in specific conditions or industries.

6. Training and Usage:

Training: Provide training to workers on the proper use, maintenance, and

limitations of PPE. Proper training ensures that workers know how to use PPE

effectively.

Usage Monitoring: Monitor and enforce the use of PPE in the workplace to

ensure compliance and effectiveness.

7. Cost and Budget:

Cost-Effectiveness: While cost is a consideration, it should not compromise

safety. Invest in high-quality PPE that provides adequate protection.

Budget Allocation: Ensure that the budget allows for the purchase and

regular replacement of PPE as needed.

EFFECTS ON HUMANS:

Understanding the effects of industrial hazards on humans is crucial for

implementing effective safety measures and protecting workers’ health.

These effects can vary widely depending on the type of hazard, the level and duration

of exposure, and individual susceptibility.

1. Physical Hazards:

a. Mechanical Hazards:

Description: Involves moving machinery, equipment, or tools that can

cause physical injuries.

12 Prepared by M.Kamarajan, AP/CSE, PSNACET

Effects: Can result in cuts, lacerations, amputations, crush injuries, and

fractures. For example, accidents involving rotating machinery can cause

severe limb injuries.

b. Ergonomic Hazards:

Description: Relates to repetitive strain, poor posture, and awkward

movements.

Effects: Can lead to musculoskeletal disorders such as carpal tunnel

syndrome, back pain, and repetitive strain injuries. Prolonged exposure to

poor ergonomic conditions can cause chronic pain and reduced

functionality.

c. Noise Hazards:

Description: Exposure to excessive noise levels.

Effects: Can cause hearing loss, tinnitus (ringing in the ears), and

increased stress levels. Chronic exposure to high noise levels can lead to

permanent hearing damage.

d. Vibration Hazards:

Description: Exposure to vibrations from machinery or tools.

Effects: Can cause hand-arm vibration syndrome (HAVS), which includes

symptoms such as numbness, tingling, and loss of dexterity. Whole-body

vibration can also lead to lower back pain and other musculoskeletal

issues.

2. Chemical Hazards:

a. Inhalation:

Description: Breathing in harmful vapours, dust, fumes, or gases.

Effects: Can lead to respiratory issues such as asthma, bronchitis, and

chronic obstructive pulmonary disease (COPD). Long-term exposure can

cause lung cancer and other serious respiratory diseases.

b. Skin Contact:

Description: Direct contact with hazardous chemicals.

Effects: Can cause skin irritation, dermatitis, chemical burns, and allergic

reactions. Prolonged exposure may lead to chronic skin conditions and

systemic toxicity if chemicals are absorbed into the body.

c. Ingestion:

Description: Accidental swallowing of hazardous substances.

Effects: Can result in gastrointestinal issues such as nausea, vomiting,

and abdominal pain. Ingesting toxic substances can lead to more severe

health effects, including organ damage and poisoning.

3. Biological Hazards:

a. Bacteria and Viruses:

Description: Exposure to pathogenic microorganisms.

Effects: Can cause infections such as tuberculosis, hepatitis, and other

communicable diseases. Workers in healthcare or laboratory settings are

particularly at risk.

b. Fungi and Molds:

Description: Exposure to fungal spores or mold.

Effects: Can lead to respiratory problems, allergic reactions, and infections,

particularly in immunocompromised individuals.

13 Prepared by M.Kamarajan, AP/CSE, PSNACET

c. Biological Toxins:

Description: Exposure to toxins produced by living organisms.

Effects: Can cause poisoning and various health issues, depending on the

type of toxin. For example, mycotoxins from molds can cause respiratory

and systemic illnesses.

4. Physical Agents:

a. Radiation:

Description: Exposure to ionizing and non-ionizing radiation.

Effects: Ionizing radiation (e.g., X-rays, gamma rays) can cause cancer,

genetic mutations, and radiation sickness. Non-ionizing radiation (e.g., UV

radiation) can cause skin burns and increase the risk of skin cancer.

b. Temperature Extremes:

Description: Exposure to extreme heat or cold.

Effects: Heat exposure can lead to heat stress, heat exhaustion, or heat

stroke. Cold exposure can cause frostbite, hypothermia, and other cold-

related injuries.

5. Psychosocial Hazards:

a. Stress:

Description: Occupational stress due to workload, deadlines, and job

demands.

Effects: Can lead to mental health issues such as anxiety, depression, and

burnout. Chronic stress can also affect physical health, contributing to

cardiovascular disease and weakened immune function.

b. Workplace Violence:

Description: Exposure to aggressive or violent behaviour.

Effects: Can result in physical injuries, psychological trauma, and long-

term mental health issues such as PTSD (post-traumatic stress disorder).

6. Long-Term Health Effects:

a. Chronic Diseases:

Description: Long-term exposure to hazards can lead to chronic diseases.

Examples: Chronic exposure to asbestos can cause lung cancer and

asbestosis. Long-term exposure to chemicals like benzene can lead to

leukemia.

b. Cumulative Effects:

Description: Gradual accumulation of exposure over time.

Examples: Repeated exposure to low levels of noise or chemicals can result

in significant health issues over time, even if individual exposures do not

cause immediate effects.

7. Acute vs. Chronic Effects:

a. Acute Effects:

Description: Immediate or short-term health effects.

Examples: Chemical burns from a spill, immediate respiratory distress

from inhaling toxic fumes.

b. Chronic Effects:

Description: Long-term health effects resulting from prolonged or repeated

exposure.

14 Prepared by M.Kamarajan, AP/CSE, PSNACET

Examples: Chronic respiratory diseases from long-term exposure to dust,

cancer from prolonged exposure to carcinogens.

CONTROL METHODS AND REDUCTION STRATEGIES FOR NOISE, RADIATION AND

EXCESSIVE STRESS:

Controlling and reducing hazards such as noise, radiation, and excessive stress in

industrial environments is critical to maintaining a safe and healthy workplace.

1. Control Methods and Reduction Strategies for Noise:

Noise is a significant occupational hazard that can lead to hearing loss and other

health issues. Effective control methods focus on reducing noise levels and

protecting workers from excessive exposure.

a. Engineering Controls:

1. Noise Enclosures:

Description: Installing barriers or enclosures around noisy machinery or

equipment to contain and reduce noise.

Examples: Acoustic enclosures for compressors or pumps.

2. Noise Dampening Materials:

Description: Using materials that absorb sound to reduce noise levels.

Examples: Installing acoustic panels, insulation, or sound-absorbing

tiles on walls and ceilings.

3. Maintenance and Upgrades:

Description: Regular maintenance and upgrading of machinery to

reduce noise emissions.

Examples: Replacing worn-out parts, lubricating moving parts, and

upgrading to quieter equipment.

4. Vibration Isolation:

Description: Isolating equipment that generates noise through vibration

isolation mounts or pads.

Examples: Using anti-vibration mounts for motors and compressors.

b. Administrative Controls:

1. Workplace Design:

Description: Designing work processes to minimize noise exposure.

Examples: Arranging noisy machines away from workstations where

employees are present.

2. Job Rotation:

Description: Rotating workers through different tasks or areas to reduce

their overall exposure to noise.

Examples: Shifting workers between noisy and quieter tasks or work

areas.

3. Training and Awareness:

Description: Educating workers about noise hazards and proper use of

hearing protection.

Examples: Providing training on the effects of noise and the importance

of using PPE.

c. Personal Protective Equipment (PPE):

1. Hearing Protection:

Description: Using devices to protect ears from excessive noise.

15 Prepared by M.Kamarajan, AP/CSE, PSNACET

Examples: Earplugs, earmuffs, or combination devices (earplugs and

earmuffs) designed for high noise levels.

2. Control Methods and Reduction Strategies for Radiation:

Radiation exposure in industrial settings can cause serious health issues,

including cancer and radiation sickness. Effective control methods focus on

minimizing exposure and protecting workers.

a. Engineering Controls:

1. Shielding:

Description: Installing physical barriers to block or reduce radiation

exposure.

Examples: Lead shields for X-ray machines, concrete walls for nuclear

reactors.

2. Containment:

Description: Using containment systems to prevent the release of

radioactive materials.

Examples: Containment vessels, glove boxes, and ventilation systems

with filters.

3. Distance:

Description: Increasing the distance between workers and radiation

sources to reduce exposure.

Examples: Remote operation of radiation-producing equipment or

controlling access to radiation areas.

b. Administrative Controls:

1. Access Control:

Description: Restricting access to areas where radiation levels are high.

Examples: Using signage, barriers, and controlled entry points to limit

access to radiation areas.

2. Work Procedures:

Description: Developing and enforcing procedures to minimize radiation

exposure.

Examples: Implementing safe work practices, such as limiting the time

spent near radiation sources.

3. Monitoring and Surveillance:

Description: Regularly monitoring radiation levels and worker exposure.

Examples: Using dosimeters and radiation detectors to measure and

track exposure levels.

c. Personal Protective Equipment (PPE):

1. Radiation Protection Clothing:

Description: Wearing specialized clothing to protect against radiation

exposure.

Examples: Lead aprons, thyroid shields, and protective gloves.

2. Respiratory Protection:

Description: Using respirators or other equipment to protect against

airborne radioactive particles.

Examples: High-efficiency particulate air (HEPA) filters in respirators.

16 Prepared by M.Kamarajan, AP/CSE, PSNACET

3. Control Methods and Reduction Strategies for Excessive Stress:

Excessive stress in the workplace can lead to mental health issues, decreased

productivity, and increased absenteeism. Effective strategies focus on reducing

stressors and promoting mental well-being.

a. Administrative Controls:

1. Workload Management:

Description: Balancing workloads to prevent overwork and burnout.

Examples: Implementing reasonable work hours, avoiding excessive

overtime, and distributing tasks fairly.

2. Support Systems:

Description: Providing support systems to help employees manage

stress.

Examples: Employee assistance programs (EAPs), counseling services,

and stress management workshops.

3. Workplace Culture:

Description: Fostering a positive and supportive workplace culture.

Examples: Encouraging open communication, recognizing and

rewarding employee achievements, and promoting a healthy work-life

balance.

4. Job Design:

Description: Designing jobs to reduce stress factors.

Examples: Incorporating variety in tasks, allowing for autonomy, and

providing opportunities for skill development.

b. Organizational Strategies:

1. Management Training:

Description: Training managers to recognize and address stress-related

issues.

Examples: Providing training on leadership skills, conflict resolution,

and supportive communication.

2. Flexible Work Arrangements:

Description: Offering flexible work options to accommodate employees’

needs.

Examples: Telecommuting, flexible hours, and compressed workweeks.

3. Workplace Design:

Description: Designing work environments that reduce stressors.

Examples: Creating comfortable workspaces, providing quiet areas for

relaxation, and ensuring adequate lighting and ventilation.

c. Personal Coping Strategies:

1. Stress Management Techniques:

Description: Encouraging employees to use stress management

techniques.

Examples: Teaching relaxation techniques, mindfulness, and time

management skills.

2. Health and Wellness Programs:

Description: Providing programs that promote overall well-being.

Examples: Fitness programs, wellness challenges, and healthy eating

initiatives.

17 Prepared by M.Kamarajan, AP/CSE, PSNACET

You might also like

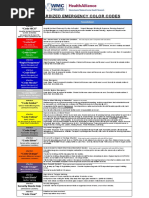

- Standardized Emergency Color CodesDocument1 pageStandardized Emergency Color CodesDivya ToppoNo ratings yet

- Uk Army Cadet Force Manual 2005Document712 pagesUk Army Cadet Force Manual 2005jimothy macaw75% (4)

- Chemical and Biological Health Hazards and ControlDocument5 pagesChemical and Biological Health Hazards and ControlNahum Dave MancillaNo ratings yet

- Industrial Safety - Unit IIDocument23 pagesIndustrial Safety - Unit IIsrinivasan ssmietNo ratings yet

- ENVIRONMENTAL HEALTH AND SAFETYDocument5 pagesENVIRONMENTAL HEALTH AND SAFETYnellychepngetich01No ratings yet

- Hazards Part 1Document1 pageHazards Part 1ranthobuhlebenkosiNo ratings yet

- Fon-1 Presentation 1Document49 pagesFon-1 Presentation 1Abdul AhadNo ratings yet

- Ch6occupational Health and SafetyDocument33 pagesCh6occupational Health and Safetyusmail179No ratings yet

- Hazards and Risk in The Workplace Tle8Document8 pagesHazards and Risk in The Workplace Tle8Arabelle MorilloNo ratings yet

- KPIDocument2 pagesKPIJOBERT TOTANESNo ratings yet

- Seminar Presentation by YaniDocument40 pagesSeminar Presentation by Yaniyounas khanNo ratings yet

- PUH 505 Occupational Health AssignmentDocument6 pagesPUH 505 Occupational Health Assignmentemeka.nn.ceNo ratings yet

- ISOH Part-2Document25 pagesISOH Part-2pixflip16No ratings yet

- Unit II Occupational Health and HygieneDocument13 pagesUnit II Occupational Health and HygieneSelvaraj.s CSENo ratings yet

- OSHADocument20 pagesOSHAesther anyonaNo ratings yet

- Industrial HygieneDocument18 pagesIndustrial HygieneLadyshiela CuberoNo ratings yet

- Experiment 3 Standard PrecautionDocument3 pagesExperiment 3 Standard PrecautionJanson SarmientoNo ratings yet

- 2 Industrial HygieneDocument6 pages2 Industrial HygieneSayed DarwishNo ratings yet

- Occupational Health CourseDocument95 pagesOccupational Health CourseLuminita BarleanuNo ratings yet

- Pharmaceutical Industry Hazards and SafetyDocument23 pagesPharmaceutical Industry Hazards and SafetyfadliNo ratings yet

- Occupational Health Hazards for EmployeesDocument4 pagesOccupational Health Hazards for Employeeswaqasbutter481No ratings yet

- Practice Occupational Health and Safety Procedures: Definition of TermsDocument15 pagesPractice Occupational Health and Safety Procedures: Definition of Termsmico alilayaNo ratings yet

- INDUSTRIALDocument29 pagesINDUSTRIALMeverlyn RoqueroNo ratings yet

- TVL CSS G11-Q1-M10-No CoverDocument10 pagesTVL CSS G11-Q1-M10-No CoverSergio B. Goco Jr.No ratings yet

- Enviormental Safety (Concept of Safety Risk Management) Presentation by M.ahadDocument29 pagesEnviormental Safety (Concept of Safety Risk Management) Presentation by M.ahadhehahaho90No ratings yet

- Occupational HygieneDocument6 pagesOccupational HygieneCressa M.No ratings yet

- Industrial Hygiene1Document14 pagesIndustrial Hygiene1Jhynne Xalve PorcionculaNo ratings yet

- Presentation by Ahad FONDocument27 pagesPresentation by Ahad FONhehahaho90No ratings yet

- Lec-02 HACCPDocument14 pagesLec-02 HACCPmuhib11.fensNo ratings yet

- Detecting Pharmaceutical Health Hazards and ActDocument55 pagesDetecting Pharmaceutical Health Hazards and Actdawitm115No ratings yet

- Lecture 5 Occupational Hazards and DiseasesDocument11 pagesLecture 5 Occupational Hazards and Diseasessalome gergedavaNo ratings yet

- EHE PPT (OHS)Document29 pagesEHE PPT (OHS)Ramzi JamalNo ratings yet

- Practice Occupational Health and Safety Procedures Q4 EIMDocument3 pagesPractice Occupational Health and Safety Procedures Q4 EIMAki Kazuko (ImNotABot)No ratings yet

- Occupational Health and SafetyDocument7 pagesOccupational Health and Safetykimbeerlyn doromasNo ratings yet

- Oshap NotesDocument30 pagesOshap Notesrobert azihembaNo ratings yet

- Ohs Group 6Document8 pagesOhs Group 6Nizah MajanNo ratings yet

- CLEANINGDocument25 pagesCLEANINGshmekebeNo ratings yet

- Occupational Hazard (Work Place Hazard) : Physical HazardsDocument6 pagesOccupational Hazard (Work Place Hazard) : Physical HazardsAbdelrahman NasimNo ratings yet

- Occupational Hazard (Work Place Hazard) : Physical HazardsDocument6 pagesOccupational Hazard (Work Place Hazard) : Physical HazardsAbdelrahman NasimNo ratings yet

- Midterm Study GuideDocument68 pagesMidterm Study GuideAimee ChantengcoNo ratings yet

- Module OverviewDocument4 pagesModule OverviewJeoferson Jose ValdezNo ratings yet

- DC1 Notes 14.12.2024Document52 pagesDC1 Notes 14.12.2024Shiva Sankar BeharaNo ratings yet

- Unit 4 Industrial Health and SafetyDocument32 pagesUnit 4 Industrial Health and Safetyipatel272005No ratings yet

- IS 106 PYQ&ADocument12 pagesIS 106 PYQ&Amanish kumarNo ratings yet

- STANDARD SAFETY MEASURES ContentDocument10 pagesSTANDARD SAFETY MEASURES ContentAnusikta PandaNo ratings yet

- Occupational DiseasesDocument22 pagesOccupational DiseasesKomalNo ratings yet

- CHN III 7,8 Occupational & Environmental Health-1-1Document32 pagesCHN III 7,8 Occupational & Environmental Health-1-1Sonia khanNo ratings yet

- Occ Health L2Document16 pagesOcc Health L2wakyereza derickNo ratings yet

- Mechanical,Biological and Psycomatic HazardsDocument32 pagesMechanical,Biological and Psycomatic Hazardssanahafeezahmad321No ratings yet

- HazardDocument91 pagesHazardbekeletafabalchaaNo ratings yet

- Philippine Occupational Health and Safety StandardsDocument41 pagesPhilippine Occupational Health and Safety StandardsTrisha Bermejo100% (1)

- Airbone hazards_TrainingDocument31 pagesAirbone hazards_Trainingjafers04No ratings yet

- Occupational Health and Safety ProceduresDocument10 pagesOccupational Health and Safety ProceduresSergio B. Goco Jr.No ratings yet

- Report-OHSDocument28 pagesReport-OHSlgrmshnnhjyNo ratings yet

- Industrial HygieneDocument2 pagesIndustrial HygieneJuvelyn DaculaNo ratings yet

- Occupational HealthDocument33 pagesOccupational HealthTureNo ratings yet

- SAFETYDocument4 pagesSAFETYSaad FaheemNo ratings yet

- 01 Occupational Hazards-Intro (7-2-2017) - LectureDocument25 pages01 Occupational Hazards-Intro (7-2-2017) - LectureJenna QfNo ratings yet

- Element 7 (Notes)Document7 pagesElement 7 (Notes)Mid HunNo ratings yet

- UNIT - 1.1 EMPLOYEE HEALTHDocument7 pagesUNIT - 1.1 EMPLOYEE HEALTHknowledgeeducationcenterNo ratings yet

- ilovepdf_merged (1)Document56 pagesilovepdf_merged (1)knowledgeeducationcenterNo ratings yet

- AW101-Occupational Safety and Health Ergonomic - Tools: Name Registration NoDocument9 pagesAW101-Occupational Safety and Health Ergonomic - Tools: Name Registration NoRaigaz MegatenNo ratings yet

- F3Walline 1114Document7 pagesF3Walline 1114kompleksqNo ratings yet

- Cocu 1 (Safety, Health and Hygiene Practise)Document15 pagesCocu 1 (Safety, Health and Hygiene Practise)nadyaNo ratings yet

- Unit 3Document42 pagesUnit 3HEMAN PRASADNo ratings yet

- Formation Day 3Document21 pagesFormation Day 3Mokhtar MahboubeNo ratings yet

- 39 Pressure Test PermitDocument1 page39 Pressure Test PermitMUhammad RanaNo ratings yet

- NR GN Civ 003Document55 pagesNR GN Civ 003omar sarairehNo ratings yet

- RG HSE Bulletin (Working in Rainy Weather)Document2 pagesRG HSE Bulletin (Working in Rainy Weather)Ihtisham UlhaqNo ratings yet

- Risk Assessment - Zeroswing ExcavatorDocument8 pagesRisk Assessment - Zeroswing ExcavatorSayed AbbasNo ratings yet

- Code of Practice-FormworkDocument32 pagesCode of Practice-FormworkChung Yiung YungNo ratings yet

- Work at Height ChecklistDocument3 pagesWork at Height ChecklistThillai8975No ratings yet

- BFP Safety ReportDocument14 pagesBFP Safety ReportKent NabzNo ratings yet

- G06 - Ena Nens 04 Safe Approach Distances To Electrical Apparatus Solo ContenidoDocument7 pagesG06 - Ena Nens 04 Safe Approach Distances To Electrical Apparatus Solo ContenidoJairo FlechasNo ratings yet

- BBS Report Q3 2020Document9 pagesBBS Report Q3 2020Andrey ParchukNo ratings yet

- Fire Safety Training: The Loss Prevention Unit of The Office of Risk ManagementDocument53 pagesFire Safety Training: The Loss Prevention Unit of The Office of Risk ManagementAhmed Idrees100% (1)

- SDS-Sodium Nitrite Solution 40 CHE-2021SDocument9 pagesSDS-Sodium Nitrite Solution 40 CHE-2021SpibemauNo ratings yet

- Routing SlipDocument2 pagesRouting Sliproyal painNo ratings yet

- CHAPTER 6 AssessmentDocument51 pagesCHAPTER 6 AssessmentMahad AbdullahiNo ratings yet

- Anthony L. Vignolo StatementDocument1 pageAnthony L. Vignolo StatementKatelyn StarkNo ratings yet

- General Safety: Please Read This Guide Carefully Before Operating The EquipmentDocument2 pagesGeneral Safety: Please Read This Guide Carefully Before Operating The EquipmentDenny ChermingNo ratings yet

- Assessment Mitigation: Biorisk ManagementDocument28 pagesAssessment Mitigation: Biorisk Managementfatima malikNo ratings yet

- Earthquake Is One of The Most Dangerous Natural DisasterDocument1 pageEarthquake Is One of The Most Dangerous Natural DisasterAce MylNo ratings yet

- 007-Line British Paints Decking Stain Water Based-Nz SDSDocument6 pages007-Line British Paints Decking Stain Water Based-Nz SDSardiansyah putra DaulayNo ratings yet

- Work Immersion: Republic of The Philippines Zambales Academy IncorporatedDocument19 pagesWork Immersion: Republic of The Philippines Zambales Academy IncorporatedRhayca Zharell100% (5)

- 4 Pillars of Safety Management System SMSDocument5 pages4 Pillars of Safety Management System SMSraja ahmedNo ratings yet

- Driving Safety For First RespondersDocument11 pagesDriving Safety For First RespondersIlyes FerenczNo ratings yet

- Nicenstripy Gardening Risk AssessmentDocument38 pagesNicenstripy Gardening Risk AssessmentVirta Nisa100% (2)

- GE1301 Professional Ethics and Human ValuesDocument39 pagesGE1301 Professional Ethics and Human ValuesSiva ReddyNo ratings yet