PEL-J4946-GA-002_REV.0

PEL-J4946-GA-002_REV.0

Uploaded by

qaCopyright:

Available Formats

PEL-J4946-GA-002_REV.0

PEL-J4946-GA-002_REV.0

Uploaded by

qaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

PEL-J4946-GA-002_REV.0

PEL-J4946-GA-002_REV.0

Uploaded by

qaCopyright:

Available Formats

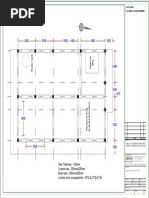

~11114 OVERALL LENGTH

`V1' 50 620 130 107 2500 2500 1775 180 180 600 400 210 116 210 508 159

S.F. SHELL-1 SHELL-2 SHELL-3 SHELL-4 SHELL-5 TORI. CONE REF. REF. TORI. CONE REF.

360 5THK 150 35 550 330 5THK 5THK T3B S3B S2B

2:1 ELLIPSOIDAL HEAD

18 THK.(NOM.), GASKET GASKET GASKET

DAVIT T1A S2A S3A T3A

14.9 THK.(MIN.) T1A DAVIT S2A S3A T3A

R80 0°

2NOS. CUTOUT IN MAIN

SHELL@ 180° APART 2NOS. CUTOUT IN MAIN KNUCLE

X

O

X X

O

X X

O

X

O

X

O

X

O

X X

O

X X O

X

O

X O

X

O

X

SHELL@ 180° APART X X RADIUS R60 X X

O

O O

O O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

THK

THK

KNUCLE

16

14

RADIUS

T2A

688

688

ELBOW 10"

X

O

610

90° LR

X

O

X

O

X

O

X O

X O

X O

X O

X O

X O

X O

X O

X

O

X

X

X

O

O

O

O

X

O

X

O

X

X

O

O

X

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

O

X X X X X X X X X X X X

O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O X

O O O O O O O O O O O O O

X

X

X

O

O

X

X

O

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X O

X

X

O

O

O

X

O

ID 620

ID 620

ID 800

270° 90° T2A

X

O

O

X

O

X

X

O

X

O

O

X

O

X

O

O

X

X

O

O

X

O

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X O

X

SADDLE HEIGHT

O

X

O

X

O

X

X

O

SHEAM PLATE

X

610

O

710

X

745

O

12THK

X

O

X

O

X

O

X

O

X

O

(E-1117A HOT SHELL) 24" x 10"

X

O

X

O

CONCENTRIC

T4A REDUCER

THK

X

O

X

O X X

20

O O

360 S4A

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

EXPANSION BELLOW

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

S1A

1431.5

20THK (NOM.)

2861.5

DAVIT DAVIT

305 18THK (MIN.)

S3B 2NOS. CUTOUT IN MAIN

2NOS. CUTOUT IN MAIN SHELL@ 180° APART S2B 2:1 ELLIPSOIDAL HEAD

T3B

SADDLE HEIGHT

X X X

O

X

O

O O

X X X X X X X X X X X X X X X X X X X X

THK

THK

O O O O O O O O O O O O O O O O O O O O

SHELL@ 180° APART 16 THK.(NOM.),

14

12

X

O

X

O

14 THK.(MIN.)

710

X X X X X

682

O O O O O

610

X

X

O

O

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

X

X

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

O

O

O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O

O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O

X

X

O

O

O

X O

X

O

ID 620

ID 620

ID 620

270° 90° T1B

X

O

X

O

X O

X

O

X

X

O

X

X

O

O

X

300

O

X

O

X

X

O

O

X O

X

X

O

O

SADDLE HEIGHT

X

X

O

O

X O

X

O

ELBOW 10"

X

X

O

O

90° LR

X

566

O

610

742

EARTHING T1B

(E-1117B COLD SHELL)

THK

X O

X

O

LUG

14

125

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

250 250

BASE PLATE

4NOS. Ø23 HOLE 4NOS. W23 x 46 SLOTTED

S4B T4B

16THK

400 FOR FIXED SADDLE HOLE FOR FIXED SADDLE 400 210 180°

2:1 ELLIPSOIDAL HEAD T2B S1B 4NOS. W23 x 46 SLOTTED

14 THK.(NOM.), 356 964 690 4862 1200 HOLE FOR FIXED SADDLE T2B S3A S4B T4B

11.7 THK.(MIN.) SADDLE C.L TO C.L DISTANCE REF. S1A T4A S4A

50 600 120 87 2500 2500 2125 87 120 500 50 500

`V1'

S.F. S.F. 500

5THK 5THK

GASKET GASKET 650

ELEVATION VIEW VIEW - 'V1-V1'

(E-1117A/B) (E-1117A/B)

±1 +5 ±1 SHELL

2 45° -0 2

W E D1 S2A TOP S3A TOP T3A TOP

T1A TOP FPW

±1

2

T2A

t

X

X

S

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

±1

X

O

X

(THK)

O

X

X

O

X

X

O

X

O

O

O

X

X X X X X X X X X X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O O

45°

O O O O O O O O O X

FPW

O

t

X

O

X

X

O

O

O

CLOSURE

X

O

O

X

O

INSIDE

X

O

O

PLATE

X

I.D

O

X

O

X

O

O

X

O

X

X

O

O

O

O

t t

X

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

O

O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O

X

O

X

X

O

O

(THK)

X

O

X

X

O

O

SADDLE

CLOSURE PLATE TO

SLIDING

TYP. CLOSURE PLATE TO

SADDLE

FIXED

BOTT. T4A S4A BOTT.

(E-1117A HOT SHELL) BOTT. S1A V/B SHELL WELD JOINT SHELL JOINT

HOLD LIST

1 NORTH DIRECTION

S2B TOP

T3B TOP S3B TOP. 2 NOZZLE LOCATION

3 NOZZLE OUTSIDE PROJECTION

4 WIND / SEISMIC DESIGN PARAMETER

X

X

O

O

X X X X X X X X

X O

X O

X O

X O

X O

X O

X O

X O

X O

X

O

X O

X O

X O

X O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

XO

XO

XO

XO

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

XO

X

O

X

O

XO

XO

XO

XO

XO

X

O

X

O

XO

XO

X

O

XO

XO

X

O

X

O

XO

X

O

X

O

XO

XO

X

O

XO

XO

X

O

X

O

XO

XO

X

O

XO

X

O

X

O

X

O

O O O O O O O O

5 VAPOR BELT CUTOUT HOLE SIZE IN SHELL

X

X

O

X

X

O

O

X

O

X

O

X

X

O

O

X

X

6 INSULATION REQUIREMENT

O

O

X

O

X

X

O

O

X

O

X

O

X

X

O

X

O

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

O

X

X

O

O

SADDLE

SLIDING

FIXED

SADDLE

(E-1117B COLD SHELL) T1B

T2B BOTT. S1B BOTT. BOTT. S4B BOTT. T4B

ELEVATION VIEW

±5° NOZZ. * : WITH BLIND FLANGE/GASKET/FASTENERS

+5

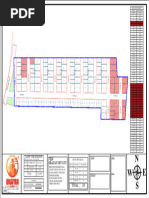

1:3 TAPER -0 45° OD. T4A DRAIN 1 50 (2") XXS/11.07 600# WNRF 610 - - *

±5° 45° ±5°

(IF REQUIRED) 60° T P.O. BOX 11882, AL-RUWAIS, ABU-DHABI

±5° +1.0

-0.5 45° T3A VENT 1 50 (2") XXS/11.07 600# WNRF 610 - - *

60° DISH 1.5 FPW UNITED ARAB EMIRATES

SHELL HEAD 9 1/4" NPT TELL

TALE HOLE 10 9

T2A OUTLET 1 250 (10")

200 (8")

80/15.09 600# WNRF SEE DWG. 50 x 50 - -

Fertil TEL : 971-2-6026660, FAX : 971-2-6026600

T1A INLET 1 80/12.7 600# WNRF 688 55 x 35 - -

±1.0

T

3.5

S4A DRAIN 1 50 (2") XXS/11.07 600# WNRF 610 - - *

T

14 3~4 MANUFACTURER :

±5°

T

75°

50 (2") XXS/11.07

==

±1.0 S3A VENT 1 600# WNRF 610 - - *

ID

Max.

3.5 R3 PRESTIGE ENGINEERING L.L.C

T

2

S2A OUTLET 1 250 (10") 80/15.09 600# WNRF 688 - 55 x 20 -

ID

ID

Max.

±1.0 ±1

3.5

2

3 S1A INLET 1 250 (10") 80/15.09 600# WNRF 745 - 55 x 20 - P. O. BOX NO. 33359 Tel.: 0971-6-5349951

±1

INSIDE ±1.0

R3

3.5

1.6

Fax.: 0971-6-5349952

1.6

E-1117A (HOT SHELL) SHARJAH, U.A.E

SHELL LONG / CIRC. SEAM FLANGE TO NOZZLE NECK/ T4B DRAIN 1 50 (2") XXS/11.07 600# WNRF 610 - - * ENGINEERING Web:-www.prestigeengg.com Email: prestigeco@prestigeengg.com

TYP NOZZLE TO SHELL WELD DETAIL TYP NOZZLE TO SHELL WELD DETAIL

SHELL TO DISH HEAD JOINT WELD JOINT SHELL WELD DETAIL WITHOUT RF PAD WITH RF PAD T3B VENT 1 50 (2") XXS/11.07 600# WNRF 610 - - *

+5 +2.5

-5 +2.5 T2B OUTLET 1 200 (8") 80/12.7 600# WNRF 742 - - -

1-0 45° +5° 60° .0 -5.0

-0° BASE. LINE BASE. LINE BASE. LINE BASE. LINE 60° T1B INLET 1 250 (10") 80/15.09 600# WNRF SEE DWG. - - -

FPW SHELL

CHANNEL SIDE SHELL SIDE SHELL SIDE CHANNEL SIDE 37. ±2 CONE ±2.5 S4B DRAIN 1 50 (2") XXS/11.07 600# WNRF 610 - - *

5° .5°

CONE 37.5° SHELL

B.L.

B.L.

B.L.

B.L.

S3B VENT 1 50 (2") XXS/11.07 600# WNRF 610 - - *

S2B OUTLET 1 250 (10") 80/15.09 600# WNRF 682 - - -

THK

CHECKED APPROVED

t

DRAWN BY

2±1

200 (8")

(THK.)

S1B INLET 1 80/12.7 600# WNRF 742 - 50 x 14 -

THK

ACN MT RAC

THK

t

E-1117B (COLD SHELL) 03.01.2025 03.01.2025 03.01.2025

±1

SHELL I.D.

2

TUBESHEET

±1

SELF

SHELL I.D.

±2 SIZE DN

NOZZ. SCH/THK RF. PAD

2

GAP

1st TIG 3

1.5

RATING TYPE REINFORCED

I.D.

±2 PROJ. FROM

2.0000

3 MARK SERVICE QTY. (NPS) (mm) WIDTH/THK. REMARKS

CENTRE LINE NOZZLE

No. NOZZLE FLANGE (THK x HEIGHT) (mm)

DIMENSION MEASUREMENT WELD DETAIL CONE LARGE WELD DETAIL CONE SMALL

TYP TUBESHEET TO SHELL WELD JOINT BASE LINE END TO SHELL WELD DETAIL END TO SHELL WELD DETAIL NOZZLE TABLE

NOTES DESIGN DATA (TOP HEAT EXCHANGER) (HOT SHELL) DESIGN DATA (BOTTOM HEAT EXCHANGER) (COLD SHELL) LIST OF REFERENCE DOCUMENTS (FROM CLIENT)

ASME SECTION VIII DIV.1 2023 ED. ASME SECTION VIII DIV.1 2023 ED.

GENERAL CONSTRUCTION CODE API 660 9TH ED., ADDENDUM 1 2020 CONSTRUCTION CODE API 660 9TH ED., ADDENDUM 1 2020 SR.No. DESCRIPTION DOCUMENT NUMBER

G1 ALL DIMENSIONS ARE IN MILLIMETERS, UNLESS OTHERWISE SPECIFIED. TEMA 10TH EDITION 2023 TEMA 10TH EDITION 2023 2 MECHANICAL DATASHEET FOR FEED/EFFLUENT EXCHANGER (E-1117A/B) 24409R-DS-E-1117_REV.3

ASME CERTIFICATION MARK YES (U-CERTIFICATE DESIGNATOR) ASME CERTIFICATION MARK YES (U-CERTIFICATE DESIGNATOR)

G2 ALL OF FLANGE BOLT HOLES TO BE ALWAYS STRADDLE THE PRINCIPAL CENTER-LINE OF THE HEAT EXCHANGER OR THEIR PARALLEL LINE.

NATIONAL BOARD REGISTRATION YES

LIST OF REFERENCE SPECIFICATION / STANDARD

NATIONAL BOARD REGISTRATION YES

G3 ALL WELDING SURFACES TO BE THOROUGHLY CLEANED OFF SCALE, RUST, OIL OR OTHER FOREIGN MATERIALS BEFORE WELDING.

CODE CASE NOT APPLICABLE REV.

CODE CASE NOT APPLICABLE SR. No. DESCRIPTION DOCUMENT NUMBER

G4 FABRICATION TOLERANCE SHALL BE IN ACCORDANCE WITH TEMA `R', PRESTIGE TOLERANCES FOR SHELL & TUBE HEAT EXCHANGERS DRG. No. PEL-STD-002_REV.3 (2 SHEETS), LOCATION OF INSTALLATION UNITED ARAB EMIRATES LOCATION OF INSTALLATION UNITED ARAB EMIRATES

No.

EXCEPT PASS PARTITION GROOVE, UNLESS OTHERWISE SPECIFIED. PRESTIGE ENGINEERING LLC, 1 DESIGN CRITERIA FOR STATIC EQUIPMENT AGES-SP-06-001 1

G5 FLANGED OPENINGS SHALL BE PROTECTED WITH METAL COVER PLATES TO PREVENT DAMAGE DURING SHIPMENT. COVERS SHALL BE A MINIMUM OF 6 mm THICK. MANUFACTURER'S NAME PRESTIGE ENGINEERING LLC,

SHARJAH, UAE MANUFACTURER'S NAME SHARJAH, UAE 2 PRESSURE VESSEL SPECIFICATION AGES-SP-06-002 1

G6 PRIOR TO FINAL INSPECTION, ALL SLAGS, DIRT, GRITS, WELD SPATTERS, OIL AND OTHER FOREIGN MATERIALS ARE TO BE REMOVED FROM INSIDE AND OUTSIDE OF THE SHELL & MANUFACTURER'S JOB NUMBER J4946 3 SHELL AND TUBE HEAT EXCHANGER SPECIFICATION AGES-SP-06-003 1

MANUFACTURER'S JOB NUMBER J4946

TUBE HEAT EXCHANGER. MANUFACTURER'S SERIAL NUMBER J4946-460-2024

MANUFACTURER'S SERIAL NUMBER J4946-461-2024 4 MATERIAL SELECTION GUIDELINES AGES-GL-07-001 1

G7 SURFACE FINISH : d : ~12.6 µ m (500 µ inch. Ra) MAX. YEAR BUILT 2025

dd : (REFER NOTE - G8) YEAR BUILT 2025 5 QA & QC REQUIREMENT AGES-GL-13-001 1

QUANTITY NO 1

G8 GASKET CONTACT SURFACE : GIRTH FLANGES : 125~250 µ inch. (3.2 TO 6.3 µ m) Ra. TAG NUMBER E-1117A QUANTITY NO 1 6 PMI OF EQUIPMENT & PIPING AGES-GL-13-002 1

NOZZLE FLANGES : 125~250 µ inch. (3.2 TO 6.3 µ m) Ra. CRITICALITY / INSPECTION CLASS 2/2 TAG NUMBER E-1117B 7 PAINTING AND COATING SPECIFICATION AGES-SP-07-004 1

G9 SERVICE GASKETS, BOLTS & NUTS SHALL BE USED DURING HYDROSTATIC TESTING. INSPECTION BY PEL / AI (HSB) / CLIENT CRITICALITY / INSPECTION CLASS 2/2 8 WELDING AND NDE AGES-SP-07-007 1

G10 GASKET CONTACT SURFACES SHALL NOT BE COATED OR PAINTED UNLESS OTHERWISE SPECIFIED. SPECIAL SERVICE [UG-120(d)] NOT APPLICABLE INSPECTION BY PEL / AI (HSB) / CLIENT 9 PRESERVATION & EXPORT PACKING SPECIFICATION AGES-SP-07-011 1

G11 ALL SHARP EDGES & CORNERS SHALL BE SMOOTHENED. SOUR / AMINE / CAUSTIC / HYDROGEN / CYCLIC NOT APPLICABLE SPECIAL SERVICE [UG-120(d)] NOT APPLICABLE 1

10 CRITICALITY RATING SPECIFICATION AGES-SP-13-001

SURFACE AREA (GROSS / EFF.) m² 636.11 / 629.38 SOUR / AMINE / CAUSTIC / HYDROGEN / CYCLIC NOT APPLICABLE

G12 NOZZLE FLANGE FACES SHALL BE PROTECTED AGAINST CORROSION AND DAMAGE WITH A READILY REMOVABLE RUST-PREVENTIVE COATING. 11 PROCUREMENT INSPECTION AND CERTIFICATION REQUIREMENT 1

INSTALLATION HORIZONTAL SURFACE AREA (GROSS / EFF.) m² 641.47 / 637.37 AGES-SP-13-002

G13 ALL ATTACHMENT PADS TO BE PROVIDED WITH 1 No. 1/4" NPT TELL-TALE HOLE SHALL BE PNEUMATICALLY TESTED AT 1 BARG. ALL ATTACHMENT PADS SHALL BE PLUGGED WITH IN PROJECTS

TEMA TYPE TEMA "R" TYPE-BET INSTALLATION HORIZONTAL 12 RULES FOR CONSTRUCTION OF PRESSURE VESSELS ASME SECTION VIII DIV. 1 2023 ED. -

GREASE/WOODEN, PLUGS AFTER TESTING TO PREVENT MOISTURE FROM ENTERING.

SHELL SIDE TUBE SIDE TEMA TYPE TEMA "R" TYPE-BET

G14 NOZZLE PROJECTIONS ARE FROM EXCHANGER CENTER LINE TO EXTREME FACE OF FLANGE, UNLESS OTHERWISE NOTED. 13 FERROUS MATERIAL SPECIFICATION ASME Section II Part A 2023 ED. -

DESUFURIZED

FLUID NATURAL GAS SHELL SIDE TUBE SIDE 14 NON-FERROUS MATERIAL SPECIFICATION ASME Section II Part B 2023 ED.

G15 CORROSION ALLOWANCE IS NOT APPLICABLE FOR TUBES, EXPANSION BELLOW & STANDARD NOZZLE FLANGES/BLIND FLANGES. NATURAL GAS

FLUID PHYSICAL STATUS (IN / OUT) VAPOR VAPOR DESUFURIZED

G16 SINCE CHANNEL IS IN BOLTED CONNECTION, ADDITIONAL INSPECTION OPENING IS NOT REQUIRED. SHELL SIDE OF FIXED TUBE SHEET HEAT EXCHANGER, INSPECTION OPENING IS FLUID NATURAL GAS 15 MATERIAL PROPERTIES ASME Section II Part D 2023 ED. -

NATURAL GAS

EXEMPTED AS PER UG 46(a). DENSITY (INLET/OUTLET) Kg/m³ (- / -) (- / -) 16 NON DESTRUCTIVE EXAMINATION ASME Section V 2023 ED. -

FLUID PHYSICAL STATUS (IN / OUT) VAPOR VAPOR

G17 MARK INDICATES THE NOZZLE MARK NUMBER. NUMBER OF PASSES 1 1 17 -

DENSITY (INLET/OUTLET) Kg/m³ (- / -) (- / -) QUALIFICATION STANDARD FOR WELDING, BRAZING AND FUSING

OPERATING PRESSURE (INT.) Mpa(kg/cm²)(g) 3.826 (39.008) 3.643 (37.147) PROCEDURES; WELDERS; BRAZERS; AND WELDING, BRAZING, ASME Section IX 2023 ED.

G18 T DENOTES MATCH MARK FOR ASSEMBLY. NUMBER OF PASSES 1 1

DESIGN PRESSURE (INT./EXT.) Mpa(kg/cm²)(g) 4.315 (44.0) / NA 4.315 (44.0) / NA UG-21 AND FUSING OPERATORS

G19 HYDROTEST WATER CHLORIDE CONTENT SHALL BE LESS THEN 50 PPM MAX M.A.W.P. (INT.) (CORR. & HOT) Mpa(kg/cm²)(g) @°C 4.373 (44.59) @ 380 4.354 (44.398) @ 400 OPERATING PRESSURE (INT.) Mpa(kg/cm²)(g) 3.835 (39.107) 3.630 (37.002)

18 PIPE FLANGE AND FLANGE FITTINGS (NPS 12 THROUGH NPS 24) ASME B16.5 2020 ED. -

DESIGN PRESSURE (INT./EXT.) Mpa(kg/cm²)(g) 4.315 (44.0) / NA 4.315 (44.0) / NA UG-21

FABRICATION M.A.W.P. (EXT.) Mpa(kg/cm²)(g) @°C NOT APPLICABLE NOT APPLICABLE

19 METALLIC GASKET FOR PIPE FLANGES ASME B16.20 2023 ED. -

M.A.P. (INT.) (NEW & COLD) Mpa(kg/cm²)(g) 4.929 (50.26) 4.693 (47.85) M.A.W.P. (INT.) (CORR. & HOT) Mpa(kg/cm²)(g) @°C 4.493 (45.81) @ 300 4.467 (45.55) @ 300

F1 ALL FILLET WELDS TO PRESSURE CONTAINING COMPONENTS SHALL BE GROUND TO SMOOTH.

HYDROTEST SHOP Mpa(kg/cm²)(g) 6.6 (67.30) 6.6 (67.30) UG-99 (b) M.A.W.P. (EXT.) Mpa(kg/cm²)(g) @°C NOT APPLICABLE NOT APPLICABLE 20 NONMETALLIC FLAT GASKETS FOR PIPE FLANGES ASME B16.21 2021 ED.

F2 ALL EXTERNAL SURFACES OF EXCHANGER EXCEPT MACHINED SURFACES SHALL BE CLEANED, PRIMED AND FINISH PAINTED IN ACCORDANCE WITH THE PROJECT PAINTING

SPECIFICATION. UNLESS OTHERWISE SPECIFIED. PRESSURE FILED Mpa(kg/cm²)(g) 6.6 (67.30) 6.6 (67.30) UG-99 (b) M.A.P. (INT.) (NEW & COLD) Mpa(kg/cm²)(g) 5.221 (53.23) 5.189 (52.91) 21 WELDED AND SEAMLESS WROUGHT STEEL PIPE ASME B36.10 2022 ED. -

F3 NOZZLES SHALL BE CUT FINISH WITH THE INSIDE SURFACE OF THE SHELL. OPERATING TEMPERATURE (IN/OUT) °C 231.5 / 346.1 369.2 / 261.3 HYDROTEST SHOP Mpa(kg/cm²)(g) 6.78 (69.13) 6.74 (68.72) UG-99 (c) 22 WELDED AND SEAMLESS WROUGHT STAINLESS STEEL PIPE ASME B36.19 2018 ED. -

F4 PAINTING : EXTERNAL SURFACE PAINTING (EXCLUDE MACHINED SURFACE & SCREW THREAD) AS PER COATING SYSTEM A16 AS PER PAINTING SPECIFICATION AGES-SP-07-004 DESIGN TEMPERATURE (IN/OUT) °C 380 400 UG-20 PRESSURE FILED Mpa(kg/cm²)(g) 5.87 (59.85) 5.81 (59.21) UG-99 (b) 23 STANDARDS OF THE TUBULAR EXCHANGER MANUFACTURERS -

MINIMUM DESIGN METAL TEMPERATURE @ TEMA 11TH EDITION

-10 @ 4.373 (44.59) -10 @ 4.354 (44.398) UG-20 OPERATING TEMPERATURE (IN/OUT) °C 98.8 / 231.5 261.3 / 128.6 ASSOCIATION

F5 M.A.W.P ° C @ Mpa(kg/cm²)(g)

ALL ATTACHMENT WELDS SHALL BE TWO PASS MINIMUM. DESIGN TEMPERATURE (IN/OUT) °C 300 300 UG-20 24 SHELL AND TUBE HEAT EXCHANGERS API 660 9TH EDITION -

MEAN METAL TEMPERATURE °C REFER TABLE -" X "

NDT

HYDROTEST TEMPERATURE °C

MORE THAN 17 & MORE THAN 17 & UG-99 (h)

MINIMUM DESIGN METAL TEMPERATURE @

M.A.W.P ° C @ Mpa(kg/cm²)(g)

-10 @ 4.493

(45.81)

-10 @4.467

(45.55) UG-20 MATERIAL OF CONSTRUCTION (E1117A/B)

T1 TUBE TO TUBESHEET JOINT : STRENGTH WELD + LIGHT EXPANSION WITH 2 GROOVES. LESS THAN 48 LESS THAN 48 COMPONENT MATERIAL COMPONENT MATERIAL

RADIOGRAPHY RT-1 (100%) RT-1 (100%) UW-11 (a) MEAN METAL TEMPERATURE °C REFER TABLE -" X "

T2 PMI FOR EXPANSION BELLOW SHALL BE PERFORMED. MORE THAN 17 & MORE THAN 17 & CHANNEL SHELL / DISH END /

T3 JOINT EFFICIENCY 1 1 HYDROTEST TEMPERATURE °C UG-99 (h) SA 516 GR 70 NAME PLATE/BRACKET SS 304 / SA 516 GR.70

TUBES SHALL BE SEAMLESS AND EDDY CURRENT TESTED OVER THEIR FULL LENGTH. LESS THAN 48 LESS THAN 48 TORI. CONE / RF PAD

CORROSION ALLOWANCE (INTERNAL) 1.5 (EXCEPT STD. 1.5 (EXCEPT TUBES &

T4 100% UT FOR TUBESHEET BEFORE DRILLING HOLES. RADIOGRAPHY RT-1 (100%) RT-1 (100%) UW-11 (a) GIRTH FLANGE SA 266 GR 2 EARTHING LUG SS 304

mm BLIND FLANGE) STD. BLIND FLANGE)

T5 100% PT FOR TUBESHEET AFTER DRILLING HOLES. UG-20 (f), JOINT EFFICIENCY 1 1 5mm THK GROOVE METAIL

IMPACT TESTING EXEMPTED EMEMPTED GIRTH FLANGE GASKET TUBE SHEET SA 266 GR 2

UCS-66, 1.5 (EXCEPT WITH GRAPHITE FACING

T6 THE INTERNAL WELD SURFACES SHALL BE MADE AS SMOOTH AND AS NEARLY FLUSH AS POSSIBLE TO REDUCE STRESS RISERS, REMOVE BUILT-IN NOTCHES, AND TO FACILITATE WET CORROSION ALLOWANCE (INTERNAL) 1.5 (EXCEPT STD.

YES NORMALIZING TUBES & STD. CHANNEL NOZZLE GASKET 5mm THK GROOVE METAIL SB-443 N06625 GR. 1 + SA

MAGNETIC PARTICLE TESTING (MT). mm BLIND FLANGE) EXPANSION BELLOW

(ONLY FOR FLOATING BLIND FLANGE) SIDE WITH GRAPHITE FACING 516 GR. 70 WELED END

T7 100% RT IS APPLICABLE FOR NOZZLE FABRICATION FROM PLATE. UG-20 (f), GIRTH FLANGE/STD. NOZZLE SA 193 GR.B7 / SA 194 GR. SA 193 GR.B7 / SA 194 GR.

POST WELD HEAT TREATMENT EXEMPTED FLANGE TO UCS-56 IMPACT TESTING EXEMPTED EMEMPTED TIE ROD / NUT

T8 100% MT / PT SHALL BE APPLICABLE FOR SURFACE AFTER REMOVAL OF TEMPORARY ATTACHMENTS. FLOATING DISH UCS-66, FASTENERS 2H (HDG) 2H (HDG)

T9 THE WELD JOINT PREPARATION IN THE FLAT PLATE SHALL BE EXAMINED BEFORE WELDING BY THE DPT. AFTER WELDING, BOTH THE PERIPHERAL EDGE OF THE FLAT PLATE & ANY HEAD JOINT) POST WELD HEAT TREATMENT EXEMPTED EMEMPTED UCS-56 NOZZLE FLANGE / FORGING SA 105

YES YES NORMALIZING SA 179 (LOW FINNED TUBES)

REMAINING EXPOSED SURFACE OF THE WELD JOINT PREPARATION SHALL BE REEXAMINED BY THE DPT. YES (ONLY FOR UG-79, NOZZLE NECK (FROM PIPE) SA 106 GR B

NORMALIZING (ONLY FOR DISH UG-79, POST FORMING HEAT TREATMENT EXEMPTED FIN DENSITY 26FINS/INCH,

T10 100% MPI/DPT SHALL BE PERFORMED FOR ALL WELD JOINT. POST FORMING HEAT TREATMENT BOTH DISH HEAD) UCS-79

(ONLY FOR CONE) HEAD & CONE) UCS-79 FITTINGS SA 234 GR. WPB FIN HEIGHT 1.245mm,

T11 MOCK TEST SHALL BE PERFORMED FOR TUBE TO TUBESHEET JOINT. INSULATION (THK/TYPE) mm HOLD HOLD SHELL / VAPOR BELT / RF PAD FIN THICKNESS 0.33mm,

INSULATION (THK/TYPE) mm HOLD HOLD FIREPROOFING mm NOT APPLICABLE NOT APPLICABLE SA 516 GR 70 FIN ROOT DIAMETER

T12 TUBESHEET/BAFFLE HOLE SHALL BE CHECKED WITH GO-NO-GO GAUGE. / TORI. CONE TUBES

FIREPROOFING mm NOT APPLICABLE NOT APPLICABLE REFER 16.561 mm,

T13 TUBE TO TUBESHEET EXPANSION RATIO RANGE: 5% TO 7% (MAX ALLOWABLE TUBE WALL THICKNESS REDUCTION). REFER NOZZLE FLANGE SA 105 WALL THICKNESS UNDER

PAINTING (INTERNAL / EXTERNAL) (NONE / YES) (YES / YES) GENERAL

T14 ALL NDT TESTING SHALL BE AS PER AGES-SP-06-001, AGES-SP-06-002, AGES-SP-06-003. PAINTING (INTERNAL / EXTERNAL) (NONE / YES) (NONE / YES) GENERAL NOTES NOZZLE NECK (FROM PIPE) SA 106 GR B FINS 2.108 mm,

NOTES DESIGN CODE ASCE-7 22 SEALING STRIP SS 316 PLAIN END WALL THICKNESS

MATERIAL DESIGN CODE ASCE-7 22 WIND 2.769 mm.

M1 MATERIAL TEST CERTIFICATES FOR ALL PRESSURE PART AND PARTS IN CONTACT WITH SERVICE FLUID SHALL BE AS PER EN10204 3.1 AND ALL OTHER COMPONENTS, NON-PRESSURE WIND BASIC SPEED km/hr 160 SHELL SIDE GIRTH FLANGE SA 266 GR 2

BASIC SPEED km/hr 160 5mm THK GROOVE METAIL

PARTS AS PER EN10204 3.1 / 2.2. SEISMIC DESIGN CODE ASCE-7 22 SEISMIC DESIGN CODE ASCE-7 22 GIRTH FLANGE GASKET SPACER CARBON STEEL

UG-46 (f)(5) WITH GRAPHITE FACING

M2 IMPACT TEST IS EXEMPTED AS PER UCS-66(a), UCS-66(c), UCS-66 GENERAL NOTE (c) & UNF-65. UG-46 (f)(5) INSPECTION OPENING YES, AVAILABLE EXEMPTED 5mm THK GROOVE METAIL

INSPECTION OPENING YES, AVAILABLE EXEMPTED & UG-46 (a) NOZZLE GASKET BAFFLES SA 516 GR.70

M3 STUD BOLTS SHALL HAVE THREADS IN ACCORDANCE TO STD. ASME B1.1 2019 ED. WITH TOLERANCE CLASS 2A FOR STUDS AND 2B FOR NUTS. & UG-46 (a) WITH GRAPHITE FACING

HYDROTEST POSITION (SHOP / FIELD) HORIZONTAL HORIZONTAL HYDROTEST POSITION (SHOP / FIELD) HORIZONTAL HORIZONTAL

M4 ALL MATERIAL SHALL BE NEW, UNUSED & FREE OF DEFECTS. GIRTH FLANGE/STD. NOZZLE SA 193 GR.B7 / SA 194 GR. SADDLE WRAPPER PLATE / SA 516 GR .70 / SA 36

HYDROTEST TIME Hr. 1 1 HYDROTEST TIME Hr. 1 1 FASTENERS 2H (HDG) SADDLE

M5 MATERIAL FOR ALL INTERNAL/EXTERNAL ATTACHMENT DIRECTLY WELDED TO WET PARTS SHALL BE OF THE SAME MATERIAL AS THAT PART ATTACHED TO IT. UNLESS OTHERWISED EMPTY WEIGHT Kg ~ 8800

EMPTY WEIGHT Kg ~ 12600

SPECIFIED.

OPERATING WEIGHT Kg ~ 12600 OPERATING WEIGHT Kg ~ 8800 REFERNECE DOCUMENTS (PRESTIGE)

PACKING AND DISPATCH SHOP TEST WEIGHT Kg ~ 15200 SHOP TEST WEIGHT Kg ~ 11200

P1 REQUIREMENTS OF PACKING, MARKING AND SHIPPING OF EQUIP. SHALL BE IN ACCORDANCE WITH ADNOC LNG SPEC. No. AGES-SP-07-011. DESCRIPTION CLIENT DOC. No. PRESTIGE DOC. No.

P2 EQUIPMENT SHALL BE THOROUGHLY CLEANED AND BLOWN DRY AND PRESSURIZED WITH DRY NITROGEN FOR SHIPPING FOR LONG TERM STORAGE. A POSITIVE NITROGEN THERMAL DESIGN CALCULATIONS FOR FEED/EFFLUENT

FA-E-1117AB-CL-001 PEL-J4946-TD-002

PRESSURE 0.5 barg. SHALL BE MAINTAINED & ON ANY ONE NOZZLE TO BE PROVIDED WITH PRESSURE GAUGE & FILLING NIPPLE IN THE UNIT FOR THE ENTIRE SHIPPING AND EXCHANGER (E-1117A (HOT SHELL) & E-1117B (COLD SHELL))

STORAGE PERIOD. MECHANICAL DESIGN CALCULATIONS FOR FEED/EFFLUENT

P3 SPARE BOLTING SHIPPED SEPARATELY SHALL BE WRAPPED IN POLYETHYLENE OR OTHER SUITABLE WRAPPING & PACKED IN STURDY WOOD BOXES TO INSURE AGAINST DAMAGE FA-E-1117AB-CL-002 PEL-J4946-MDC-002

EXCHANGER (E-1117A (HOT SHELL) & E-1117B (COLD SHELL)

AND CONTACT WITH SEAWATER DURING SHIPMENT. BOXES SHALL BE MARKED WITH PURCHASE ORDER No. & EXCHANGER ITEM No. & SHALL BE SECURELY ATTACHED TO THE GENEARAL ARRANGEMENT DRAWING FOR FEED/EFFLUENT

EXCHANGER. FA-E-1117AB-CD-001 PEL-J4946-GA-002

EXCHANGER (E-1117A (HOT SHELL) & E-1117B (COLD SHELL)

P4 MACHINE SURFACE, FLANGE FACES OTHER THAN THOSE FURNISHED WITH PERMANENT BLINDS, BEVELLED EDGES & OTHER FINISHED OR DELICATE PARTS SHALL BE PROTECTED FABRICATION DETAIL DRAWING FOR FEED/EFFLUENT EXCHANGER

AGAINST RUSTING & DAMAGE DURING SHIPMENT. SERRATED FACE SHALL BE COATED WITH RUST BAN 373 OR APPROVED EQUIVALENT BEFORE SEALING WITH COVER PLATE. FA-E-1117AB-CD-002 PEL-J4946-FD-002

(E-1117A (HOT SHELL) & E-1117B (COLD SHELL)

MARKING TUBE BUNDLE DRAWING FOR FEED/EFFLUENT EXCHANGER

(E-1117A (HOT SHELL) & E-1117B (COLD SHELL) FA-E-1117AB-CD-003 PEL-J4946-TB-002

X1 PAINT ITEM TAG No., WEIGHT & P.O. No. PRINTED ON THE OUTSIDE OF THE SHELL (SUITABLE LOCATION) @ 50mm HIGH.

X2 STENCIL ON SHIPPING COVERS FOR NOZZLES `CAUTION' NITROGEN INSIDE. NAME PLATE DRAWING FOR FEED/EFFLUENT EXCHANGER (E-1117A

(HOT SHELL) & E-1117B (COLD SHELL) FA-E-1117AB-CD-004 PEL-J4946-NP-002

X3 PAINT A (1 1/2") 38 WIDE BAND AROUND EXCHANGER AT CENTER OF GRAVITY. MARK W/LETTERS ``CG'' 4 PLACES AROUND BAND 90° APART.

SPARES

ERECTION, PRE-COMMISSIONING & COMMISSIONING SPARE

GASKETS (BLINDED NOZZLE & BODY FLANGE) 200%

FASTENERS (BLINDED NOZZLE & BODY FLANGE) 10% (MIN. 2 FASTENERS)

2 - YEARS NORMAL OPERATION AND MAINTENANCE SPARE

GASKETS (BLINDED NOZZLE & BODY FLANGE) 200%

FASTENERS (BLINDED NOZZLE & BODY FLANGE) 10% (MIN. 2 FASTENERS)

TABLE - X (MEAN METAL TEMPERATURE)

CASE COLD SHELL (BOTTOM HEAT

HOT SHELL (TOP HEAT EXCHANGER)

EXCHANGER)

DESCRIPTION P.O. BOX 11882, AL-RUWAIS, ABU-DHABI

SHELL SIDE TUBE SIDE SHELL SIDE TUBE SIDE

(°C) (°C) (°C) (°C) UNITED ARAB EMIRATES

1 DESIGN 291.16 296.22 165.32 170.97

Fertil TEL : 971-2-6026660, FAX : 971-2-6026600

2 SHELL SIDE STARTUP 291.16 296.22 165.32 170.97

3 TUBE SIDE START UP MANUFACTURER :

291.16 296.22 165.32 170.97

4 NORMAL OPERATION 291 295 165 170 PRESTIGE ENGINEERING L.L.C

5 START UP 261 295 135 170 P. O. BOX NO. 33359 Tel.: 0971-6-5349951

6 VENT OPEN 261 150 140 105 SHARJAH, U.A.E Fax.: 0971-6-5349952

7 HOT RESTART 150 261 105 140 ENGINEERING Web:-www.prestigeengg.com Email: prestigeco@prestigeengg.com

FR EXTERNAL NOZZLE LOADS

MT NOZZLE (SIZE) MAXIMUM ALLOWABLE NOZZLE LOADS

VL VC FORCES (N) MOMENT (N-m)

MC ML FR FC FL MC ML MT

T3A,T4A,T3B,T4B,S3A,S4A,

S3B & S4B (DN 50) ±1485 1820 1820 335 335 470

DRAWN BY CHECKED APPROVED

T1A,T2B & S1B (DN 200) ±7100 8700 8700 6595 6595 9325

ACN MT RAC

S1A,S2A,S2B,T1B & T2A

(DN 250) ±12840 15730 15730 13760 13760 19460 03.01.2025 03.01.2025 03.01.2025

You might also like

- KR 1Document1 pageKR 1emmanuelNo ratings yet

- Asa Bagc 971arch SD CV PT RC 340 ReinforcementDocument1 pageAsa Bagc 971arch SD CV PT RC 340 ReinforcementvipinvnairNo ratings yet

- 2L100x8 2L60x5Document1 page2L100x8 2L60x5Châu Thư NguyễnNo ratings yet

- Collection Pit Plan and DetailsDocument1 pageCollection Pit Plan and DetailsdaNo ratings yet

- DRB RD-1670Document1 pageDRB RD-1670digital lifeNo ratings yet

- Frame4 1Document1 pageFrame4 1Hasan AlhasanNo ratings yet

- Makeni FootingDocument3 pagesMakeni FootingJack HaamboteNo ratings yet

- CJP (TYP.) : Sample TextDocument1 pageCJP (TYP.) : Sample TextGHULAM NABINo ratings yet

- ST 02-ModelDocument1 pageST 02-Modelbitaniyamesfin7No ratings yet

- 04 Tel & Data Layout Plan-Tel & DataDocument1 page04 Tel & Data Layout Plan-Tel & DataPhúc Đinh TấnNo ratings yet

- 1550 MTDocument1 page1550 MTLuis Eugenio Hernandez QuijaiteNo ratings yet

- Fuentevestel17pw20 Descripcin Delfuncionamiento y MtodosdereparacinDocument16 pagesFuentevestel17pw20 Descripcin Delfuncionamiento y MtodosdereparacinlluissbNo ratings yet

- Gedung Parkir LT. 1 - 4Document1 pageGedung Parkir LT. 1 - 4aditya pramestuNo ratings yet

- E-500 Telephone Layout-E-500Document1 pageE-500 Telephone Layout-E-500mahmoud mohamedNo ratings yet

- Ramp ViewDocument1 pageRamp ViewMd Mukul MiahNo ratings yet

- Zeiss CeilingDocument1 pageZeiss CeilingShantanuNo ratings yet

- Mesin Papper Core Opsi 1Document1 pageMesin Papper Core Opsi 1Muhammad IlhamNo ratings yet

- End UnitDocument3 pagesEnd Unitaaa777dxbNo ratings yet

- Rtb-Basement 1a-Slab Reinf - Details-Sheet 09Document1 pageRtb-Basement 1a-Slab Reinf - Details-Sheet 09DarsHan MoHanNo ratings yet

- F 1646 A-4 Elevator Sections May 01 2018Document1 pageF 1646 A-4 Elevator Sections May 01 2018autocadplease6213No ratings yet

- Batching Plant PlanDocument1 pageBatching Plant PlanMd Mukul MiahNo ratings yet

- Hps2007b EeDocument1 pageHps2007b Eeapi-3709639No ratings yet

- CCE TV HPS-2023 Diagrama EsquematicoDocument1 pageCCE TV HPS-2023 Diagrama EsquematicoFlorian LeordeanuNo ratings yet

- DN#1200-tp 9Document1 pageDN#1200-tp 9Arbaz KhanNo ratings yet

- DRAWINGDocument2 pagesDRAWINGopulitheNo ratings yet

- DRAWINGDocument2 pagesDRAWINGopulitheNo ratings yet

- RVNL DD P3 PFD D 0206 CDocument1 pageRVNL DD P3 PFD D 0206 CPamela Paz Donoso MatusNo ratings yet

- Niles - 29.01.2024Document1 pageNiles - 29.01.2024Chamindika AbeysingheNo ratings yet

- 9572-109-PVC-B-XXX (SHT-1) - R0 - Grde Slab LVL - 09042020Document1 page9572-109-PVC-B-XXX (SHT-1) - R0 - Grde Slab LVL - 09042020MRITYUNJOY DUTTANo ratings yet

- GAD_ULUBERIA_FOB(12M_WIDE)-R3(05.07.2024)-841X1600Document1 pageGAD_ULUBERIA_FOB(12M_WIDE)-R3(05.07.2024)-841X1600kgp.gsuserNo ratings yet

- 4th Floor (28-06-19) @ 1000 PDFDocument1 page4th Floor (28-06-19) @ 1000 PDFNitin AgnihotriNo ratings yet

- 21M RTT Proposed Location - Arawwala East (CM 1748) - 2023-7-28 - R2Document1 page21M RTT Proposed Location - Arawwala East (CM 1748) - 2023-7-28 - R2samithaNo ratings yet

- Slop e 1.5:1Document1 pageSlop e 1.5:1santosh yevvariNo ratings yet

- HA-Tower AB-COL & WALL-Plan (With Archi N Topo) - 20240805Document1 pageHA-Tower AB-COL & WALL-Plan (With Archi N Topo) - 20240805hannenconstructionsbNo ratings yet

- To Grundfos - With Data Sheet (PHX)Document9 pagesTo Grundfos - With Data Sheet (PHX)Robert LazaroNo ratings yet

- Site Plan MRPLDocument1 pageSite Plan MRPLsijus2125No ratings yet

- Mac - Tar-Ndl - Ac Layout-052923Document1 pageMac - Tar-Ndl - Ac Layout-052923Jay MarkNo ratings yet

- 6884.016 - LAYOUT PLANS-C11 LAYOUT PLAN - 19+50 TO 23+00Document1 page6884.016 - LAYOUT PLANS-C11 LAYOUT PLAN - 19+50 TO 23+00jessbcheungNo ratings yet

- Hps141c EeDocument1 pageHps141c Eeapi-3709639No ratings yet

- Workshop_p3-0 additional window door and plugDocument1 pageWorkshop_p3-0 additional window door and plugMiftah kenzieNo ratings yet

- BLOCK YARD (90m X 58m) : To OhtlDocument1 pageBLOCK YARD (90m X 58m) : To OhtlClaudius TumoeNo ratings yet

- ORAIYAN NEW CITYDocument1 pageORAIYAN NEW CITYnavee.suryaaNo ratings yet

- 3R-OB-003-029-3024 (Sheet 02 of 04) - Rev ADocument1 page3R-OB-003-029-3024 (Sheet 02 of 04) - Rev AKumar AtrayNo ratings yet

- Column LayoutDocument1 pageColumn LayoutAugustine yigaNo ratings yet

- Employer Operation Village Sports Area - Netball, Basket Ball & Tennis Court Structural ArrangementsDocument6 pagesEmployer Operation Village Sports Area - Netball, Basket Ball & Tennis Court Structural Arrangementslawrence.shirima.sbctNo ratings yet

- 06 PKG EDWDocument66 pages06 PKG EDWRajeshNo ratings yet

- Л. 2Document1 pageЛ. 2caglarsamatNo ratings yet

- CH BB SLD El 01 06Document1 pageCH BB SLD El 01 06Ahmed MarzokNo ratings yet

- 1Document1 page1santosh yevvariNo ratings yet

- Landscape Irrigation LayoutDocument1 pageLandscape Irrigation LayoutroadserviceforasphaltNo ratings yet

- Y56 820-Sayfa1Document1 pageY56 820-Sayfa1Díaz Rivero Cesar EnriqueNo ratings yet

- ASF 607-02 - AD-518 (Rev - A)Document1 pageASF 607-02 - AD-518 (Rev - A)Haseeb RazviNo ratings yet

- Project Information Company InformationDocument2 pagesProject Information Company InformationHasrudin UsmanNo ratings yet

- EM G8316 APD V1 0-TopDocument1 pageEM G8316 APD V1 0-Topblotob64No ratings yet

- 6starmhplatform-004 (Sheet 1 of 6)Document1 page6starmhplatform-004 (Sheet 1 of 6)Jacob FryeNo ratings yet

- 000 Prel 5s TRSP ModeDocument1 page000 Prel 5s TRSP Modeakshay kadbeNo ratings yet

- CRTICAL_CARE_BIKANER_STRUCTURE_DRAWING_19-12-2024-ModelDocument1 pageCRTICAL_CARE_BIKANER_STRUCTURE_DRAWING_19-12-2024-ModelRajendra MittalNo ratings yet

- Ready to Go Guided Reading: Determine Importance, Grades 1 - 2From EverandReady to Go Guided Reading: Determine Importance, Grades 1 - 2No ratings yet

- L - CAS-2024-288741 - Pretech Metal Cleaning - Product Performance Letter- 11.01.2024Document1 pageL - CAS-2024-288741 - Pretech Metal Cleaning - Product Performance Letter- 11.01.2024qaNo ratings yet

- PPE Consumable Tracking 2024Document6 pagesPPE Consumable Tracking 2024qaNo ratings yet

- PEL-J4946-GA-003_REV.0 (1)Document2 pagesPEL-J4946-GA-003_REV.0 (1)qaNo ratings yet

- PEL-J4946-GA-001_REV.0Document2 pagesPEL-J4946-GA-001_REV.0qaNo ratings yet

- Piping Paint Report-49Document7 pagesPiping Paint Report-49qaNo ratings yet