Piping and Equipment Insulation

Piping and Equipment Insulation

Uploaded by

Miber MéndezCopyright:

Available Formats

Piping and Equipment Insulation

Piping and Equipment Insulation

Uploaded by

Miber MéndezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Piping and Equipment Insulation

Piping and Equipment Insulation

Uploaded by

Miber MéndezCopyright:

Available Formats

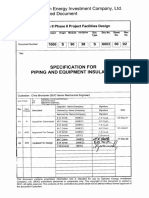

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

Rev 02

REVISION CHANGE DETAILS

Rev

01

Location of Change

General (Any changes on future issues will be Indicated with a ?)

Brief Description of Change

Modified / Developed to reflect Project-wide Interdiscipline Requirements / Comments.

02

General

Reformatted to comply with current document standard format. Revised where indicated thus:

Document No. 1000-S-90-38-S-6003-00

Page 2 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

TABLE OF CONTENTS INTRODUCTION.................................................................................................... 4 SYSTEMS EXCLUDED .......................................................................................... 4 ABBREVIATIONS................................................................................................... 4 CODES, STANDARDS AND REFERENCES ......................................................... 5 ORDER OF PRECEDENCE ................................................................................... 5 SCOPE OF WORK................................................................................................. 5 MATERIALS .......................................................................................................... 6 GENERAL.............................................................................................................. 6 MINERAL WOOL.................................................................................................... 6 CELLULAR GLASS ................................................................................................ 6 FLEXIBLE ELASTOMERIC FOAM ......................................................................... 6 NON-METALLIC INSULATION COVER/NOISE BARRIER COVER ........................ 7 STAINLESS STEEL CLADDING............................................................................. 7 PROPRIETARY INSULATION JACKETS ............................................................... 7 WIRE AND BANDING ............................................................................................ 7 EXPANDED METAL............................................................................................... 7 FASTENINGS ........................................................................................................ 7 S CLIPS................................................................................................................ 7 ADHESIVE, ANTI-ABRASION COMPOUND AND MASTIC SEALANT ................... 8 VAPOUR BARRIER ............................................................................................... 8 PACKAGING AND SHIPMENT............................................................................... 8 INSULATION SYSTEMS........................................................................................ 8 CLASSIFICATION AND DESIGNATION................................................................ 8 INSULATION SELECTION..................................................................................... 8 CLASSIFICATION.................................................................................................. 9 DESIGNATION OF SYSTEMS ............................................................................... 9 APPLICATION REQUIREMENTS ........................................................................ 10 GENERAL............................................................................................................ 10 MINERAL WOOL.................................................................................................. 11 CELLULAR GLASS .............................................................................................. 11 FLEXIBLE ELASTOMERIC FOAM ....................................................................... 11 STAINLESS STEEL CLADDING........................................................................... 11 PAINTING ............................................................................................................ 11 GENERAL............................................................................................................ 11 INSULATION OF HOT SURFACES IN HAZARDOUS AREAS ............................ 12 GENERAL............................................................................................................ 12 QUALITY CONTROL, CERTIFICATION AND GUARANTEES............................. 12 GENERAL............................................................................................................ 12 ACOUSTIC INSULATION SPECIFICATION ........................................................ 12 SCOPE ................................................................................................................ 12 DESIGN AND MATERIALS .................................................................................. 12 WINTERISATION.................................................................................................... 14 - INSULATION THICKNESS - FOR HEAT CONSERVATION OFFSHORE................. 15 - INSULATION THICKNESS - FOR HEAT CONSERVATION ONSHORE................... 16 NUMBER & THICKNESS OF INSULATION LAYERS (MINERAL WOOL)................ 17 PERSONNEL PROTECTION .................................................................................. 18 COLD CONSERVATION......................................................................................... 19 - INSULATION THICKNESS - FOR COLD CONSERVATION ONSHORE .................. 20 - INSULATION THICKNESS - FOR CONDENSATION CONTROL ONSHORE........... 21 HEAT CONSERVATION- ECONOMIC THICKNESS OF FLEXIBLE ELASTOMERIC FOAM (MM).................................................................................. 22

Rev 02

1 1.2 1.4 2 2.2 3 4 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9 4.10 4.11 4.12 4.13 4.14 5 6 6.1 6.2 6.3 7 7.1 7.2 7.3 7.4 7.5 8 8.1 9 9.1 10 10.1 11 11.1 11.2 TABLE 1 TABLE 2 TABLE 3 TABLE 4 TABLE 5 TABLE 6 TABLE 7 TABLE 8 TABLE 9

Document No. 1000-S-90-38-S-6003-00

Page 3 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

Rev 02

1 1.1

INTRODUCTION PURPOSE This document defines the minimum technical requirements for the design, supply, storage, application and inspection of thermal and acoustic insulation of pipe work and equipment for onshore and offshore oil and gas exploration and production facilities to be operated by Sakhalin Energy Investment Company, Ltd (SEIC).

1.2

SYSTEMS EXCLUDED All HVAC and architectural services Risers and sub sea pipe work Proprietary mechanical packages Accommodation areas

1.3

DISTRIBUTION, INTENDED USE AND REGULATORY CONSIDERATIONS Unless otherwise authorised by SEIC, the distribution of this document is confined to the nominated Contractors and Suppliers.

1.4 1.4.1

DEFINITIONS General definitions The standard general definitions below shall be included if the words defined are used in the particular document: The Contractor is the party, which carries out all or part of the design, engineering, procurement, construction, commissioning or management of a project or operation/maintenance of a facility. The Principal may undertake all or part of the duties of the Contractor. The Supplier/Manufacturer is the party, which manufactures or supplies equipment and services to perform the duties specified by the Contractor. The Principal is Sakhalin Energy Investment Company, Ltd. (SEIC) - the party, which initiates the project and ultimately pays for its design and construction. The Principal will generally specify the technical requirements. The Principal may also include an agent or consultant authorised to act for, and on behalf of, the Principal. The word shall indicates a requirement. The word should indicates a recommendation.

1.4

ABBREVIATIONS ASME BS CINI ISO NDE SEIC American Society of Mechanical Engineers British Standard Stichting Isolatie Nederlandse Industrie International Organization for Standardization Non-Destructive Examination Sakhalin Energy Investment Company, Ltd.

Document No. 1000-S-90-38-S-6003-00

Page 4 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

2 2.1 CODES, STANDARDS AND REFERENCES In conjunction with this specification, the latest editions of the Codes, Standards, Regulations and References listed below shall be applicable:

Rev 02

Definitions of terms relating to thermal insulating materials Stainless and heat-resisting chromium steel plate, sheet and strip Test for density of preformed pipe-covering type thermal insulation Test for density of preformed block type thermal insulation Sampling and acceptance of preformed thermal insulation Mineral fibre preformed pipe insulation Mineral fibre blanket insulation and blanket type pipe insulation Mineral fibre block and board thermal insulation Surface burning characteristics Insulation for industries Acoustics; materials for acoustical applications; determinations of airflow resistance

ASTM C168 ASTM C176 ASTM C302 ASTM C303 ASTM C390 ASTM C547 ASTM C592 ASTM C612 ASTM E84 CINI ISO 9053

Standards equivalent to those listed above may be substituted upon specific approval by the Principal. Approval of equivalent standards shall not relieve the Supplier or Contractor from compliance with specific codes and standards applicable to materials offered. 2.2 ORDER OF PRECEDENCE The order of precedence shall be as follows: Material requisition (where applicable) Data sheets This specification SEIC specifications referenced herein Industry codes and standards referenced herein.

In case of any conflict between specifications, data sheets, enquiry documents, scope of work or drawings, or any lack of clear definition as to the applicability of any specification or standard, Supplier shall obtain a written clarification from Purchaser. Purchaser 's approval of Supplier's drawings/specifications in no case absolves Supplier for deviations contained therein, unless such deviations are clearly brought to Purchaser 's attention, and Purchaser s written approval is received. In case of conflict between the English and Russian versions of this specification, the English version shall take precedence. 3 3.1 SCOPE OF WORK The Project facilities design shall include piping and equipment drawings together with the line list, equipment list and other documents deemed necessary to enable the Contractor to measure, plan, organise and install the required insulation. Pipe work and equipment shall be insulated where stated on the line list and isometric for pipe work, and on the equipment data sheet for equipment. Operating temperatures shall be used as the basis for the selection of insulation thickness, as defined on the line lists, or equipment data sheets. Temperature used for the selection of materials shall be the design temperature. This Specification shall not be applied to compressors, pumps and other rotating equipment, including exhausts for turbines. The Contractor shall supply, store and install the insulation in accordance with this specification and the specifications/standards referred within.

3.2 3.3

3.4 3.5

Document No. 1000-S-90-38-S-6003-00

Page 5 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

3.6 3.7 3.8 The insulation shall be applied by competent workmen, with suitable experience in the class of work, and shall be executed in accordance with CINI-Insulation for Industries. The Contractor shall comply with all statutory offshore and onshore health and safety requirements. Where a line or equipment is designated as requiring two classes of insulation, and the insulating system and method is the same for both classes, the most stringent shall apply. If the insulating systems are different for both classes, then both systems shall be applied. Valves, flanges, vessel manway covers, nozzles and flanges on equipment shall only be insulated on the following systems: a) Cold conservation b) Acoustic insulation (Class C) c) Electrically traced lines d) Winterisation e) Lines operating above 205C in hazardous areas 3.9.1 3.9.2 For winterisation and electrically traced lines, the flanges, valves etc shall be insulated using proprietary insulation jackets. For cold insulation, acoustic class C insulation and for lines operating above 205 degree C in hazardous areas, the piping insulation covering over the flanges, valves etc shall be to the same specification and thickness as that applied to the pipe. Upstream of any valve, flange, etc. the system shall be terminated at a distance that would allow the removal of the bolts. The insulation shall then be re-started downstream, so that if the insulation is removed from the valves, flanges etc, the pipe insulation remains sealed and deluge proof. MATERIALS GENERAL All materials shall: a) b) c) d) e) f) 4.2 4.2.1 4.2.2 be of water repellent grade have a low leachable halide concentration be non-combustible have low smoke emission be resistant to sunlight and UV radiation have Lloyds approval for use in all areas of an Offshore platform

Rev 02

3.9

4 4.1 4.1.1

MINERAL WOOL Rigid mineral wool pre formed sections and slabs, having a minimum density 125 kg/m 3 3 (Density range 125 150 kg/m ) For acoustic insulation, only flexible or semi-rigid mineral wool complying with the requirements of Section 11.0 shall be used. CELLULAR GLASS Rigid pre-formed cellular glass shall have a minimum density of 120 kg/m 3, compressive strength of 7 kg/cm and nil vapour permeability. To be a minimum of two coat system. FLEXIBLE ELASTOMERIC FOAM Pre-formed pipe sections shall have a minimum density of 50 kg/m 3 , be closed cell and have nil vapour permeability. To be applied in a single layer

4.3 4.3.1 4.3.2 4.4 4.4.1 4.4.2

Document No. 1000-S-90-38-S-6003-00

Page 6 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

4.5 4.5.1 4.5.2 4.5.3 NON-METALLIC INSULATION COVER/NOISE BARRIER COVER The cover shall be a weatherproof, non-permeable, fire-resistant non-metallic type cover. It shall be a dry applied system Where the cover is used on cold lines, the insulation Manufacturer shall confirm that the covering will also act as a vapour barrier. If this is not the case, a vapour barrier shall be applied prior to the top cover. If the insulation cover is applied at site, it shall be in accordance with the Manufacturers recommendations. The cover thickness shall be as recommended by the insulation Manufacturer, shall be robust to withstand a hostile environment, and be easily repairable without losing its integrity. The cover shall not degrade in sunlight or UV radiation. STAINLESS STEEL CLADDING The use of stainless steel cladding sheets in accordance with BS 1449 Tape 316 S33 shall be allowed for: Areas which are exposed to high levels of mechanical damage This shall be applied in addition to non-metallic covering 4.6.2 4.6.3 4.7 Stainless steel cladding shall be 0.6 mm thick for sizes up to 10 NB and 08.mm thick for sizes above 10 NB and equipment. All low points in cladding shall be provided with drain holes to prevent collection of water. PROPRIETARY INSULATION JACKETS The jackets shall be: a) designed to be suitable for required shape b) easily removable c) prevent ingress of water d) suitable for temperature range, and fire resistant. e) resistant to sunlight and UV radiation 4.8 WIRE AND BANDING All tie wire shall be 316 stainless steel 0.7 mm diameter. All banding shall be 316 stainless steel, for size up to 4 NB banding shall be 13mm wide x 0.4mm thick, for size greater than 4 and equipment banding shall be 20mm wide x 0.4 mm thick. 4.9 EXPANDED METAL Where guards are used for personnel protection, 304 stainless steel expanded metal shall be used. 4.10 FASTENINGS Nuts, bolts self-tapping screws and other fastenings shall be 316 stainless steel. 4.11 4.11.1 S CLIPS S clips shall be of 316 stainless steel and minimum thickness 0.4 mm

Rev 02

4.5.4 4.5.5

4.5.6 4.6 4.6.1

Document No. 1000-S-90-38-S-6003-00

Page 7 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

4.12 ADHESIVE, ANTI-ABRASION COMPOUND AND MASTIC SEALANT Joint sealant, anti-abrasion compound and adhesive used for insulation shall be as recommended by the insulation Manufacturer. 4.12.2 4.13 They shall be suitable for the temperature range and shall be fire-resistant. VAPOUR BARRIER The vapour barrier shall comprise of two layers of vapour barrier compound with scrim cloth in between. The scrim cloth shall be evenly woven fibreglass cloth. The vapour barrier shall be non-permeable, suitable for the temperature range, shall be fire resistant. 4.14 PACKAGING AND SHIPMENT Packaging and shipment of materials shall be in accordance with Suppliers standard. All containers shall be legibly marked with the name of the supplier, insulation size, type, density, quantity contained and gross weight in kilograms. 5 INSULATION SYSTEMS The following basic insulating systems shall be used: System 1 Rigid mineral wool preformed sections or slabs. System 2 Guards fabricated from expanded metal mesh to 0.0794-SF-304 grade stainless steel , maximum mesh dimensions 50mm suitably stiffened for rigidity. Stand-off from surfaces shall be 75 mm wherever possible. Clamps shall be insulated from hot or cold surfaces, to stop heat/cold transfer. Expanded metal shall provide a minimum open area of 75%. System 3 Electrically traced with insulation as defined in System 1. System 4 Flexible or semi-rigid mineral wool System 5 Cellular glass pre-formed sections System 6 Flexible elastomer foam pipe sections System 7 Electrically traced with insulation as defined in System 6.

Rev 02

6 6.1 6.1.1 6.1.2

CLASSIFICATION AND DESIGNATION INSULATION SELECTION The classification and thickness shall be shown on isometrics, line lists P&IDs etc., where applicable. On P&IDs the basic classification shall be added to the line definition number. Example: 8 PL 12135 11490 H, where H denoted Class H heat conversion

Document No. 1000-S-90-38-S-6003-00

Page 8 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

6.2 CLASSIFICATION The following classifications shall be used as applicable to this project: Class H Class HA Class PG Class PP Class PA Class EP Class EW Class EA Class A Class CC Class CA Class PC 6.3 6.3.1 = = = = = = = = = = = = Heat conservation Heat conservation incorporating acoustic Personnel Protection (guards) Personnel Protection (insulation) Personnel Protection incorporating Acoustic insulation Electrical Tracing (Process) Electrical Tracing (Winterisation) Heat Tracing incorporating acoustic insulation Acoustic insulation Cold Conservation Cold Conservation incorporating acoustic insulation Anti- Condensation

Rev 02

DESIGNATION OF SYSTEMS Class H Heat conservation For lines 2 and below, operating from 0C to 115C, select system 6, thickness to table 9. For all other applications select system 1, thickness to Table 2 for Offshore or Table 3 for Onshore.

6.3.2

Class PP/PG Personnel Protection Personnel protection is to be provided for piping (including flanges and valves) and equipment that is operating at temperatures in excess of 65 deg C, and is within 2m vertically and 1 metre horizontally of the deck, platform, ladders, or normal path of travel by personnel. For protection from hot surfaces operating above 65 deg C, use guards as System 2, set at a distance of 75 mm from the surface. For protection from hot surfaces operating above 205 deg C, which are hazardous areas, and, in places where guards are impractical, use System 1 with thickness as in table 5.

6.3.3

Class EP Electrical tracing on Process lines. For lines 2 and below, operating from 0C to 115C, select system 6, thickness to table 9.For all other applications select system 3, thickness to table 2 for Offshore or table 3 for Onshore.

6.3.4

Class EW Winterisation plus electric tracing For lines 2 and below, maintaining a temperature above 0C, select system 6, thickness to table 9.For lines 3 and above select system 3, thickness to table 2 for Offshore or table 3 for Onshore. Note The isometric will show the extent of the insulation for classes EP and EW.

6.3.5

Class A Acoustic Insulation This class has three levels of noise protection that are defined in section 11.0 Class A = AA Class B = AB Class C = AC System 4 to be used in accordance with section 11.0

Document No. 1000-S-90-38-S-6003-00

Page 9 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

6.3.6 Class HA, EA and PA Thermal Incorporating Acoustic Insulation System 4 to be used throughout, the thickness shall be: HAA Thickness in table 2 or 50 mm, whichever is the greater (see section 11.0) HAB - Thickness in table 2 or 100 mm, whichever is the greater (see section 11.0) HAC - Thickness in table 2 or 100 mm, whichever is the greater (see section 11.0) PAA 50 mm (see section 11.0) PAB 100 mm (see section 11.0) PAC 100 mm (see section 11.0) 6.3.7 Class CC Cold Conservation System 5, thickness to table 6.for offshore or table 7 for onshore. 6.3.8 Class CA Cold Conservation plus Acoustic This class is split into three different types CAA (class A), CAB (class B) and CAC (class C). For cold use System 5, thickness to table 5, plus for Acoustic use System 4, thickness see 11.0 The cold system including vapour barrier shall be applied first, and the Acoustic system applied over the cold system. 6.3.9 Class PC Anti-Condensation System 5, thickness to Table 8. Note The three letter designation for acoustic insulation i.e.HAA,HAB etc.shall be referenced on isometric drawings only. 7 7.1 7.1.1 7.1.2 7.1.3 APPLICATION REQUIREMENTS GENERAL The application of insulation shall conform to the requirements of this specification and the codes and specifications referred to within. All surfaces to be insulated shall be dry and clean, free from oil, grease and dirt and shall be painted to the project Specification (see section 8.0). Insulation materials shall be protected from the elements and kept completely dry prior to application and completion using permanent weather barriers. If insulation should get wet it shall be removed and replaced. Pipe work insulation shall be carried out with rigid pre-formed sectional material. All tees shall be insulated with mitred sections of the same material and thickness as that used for straight piping. Bends and elbows can be insulated with mitre sections as above, or preformed bends can be utilised. Insulation shall be installed to the Insulation Manufacturers standard instructions. The thickness of insulation shall be as specified in the appropriate Tables of this specification, as applicable to the duty. The number of layers of mineral wool insulation shall be as specified in Table 4 of this specification, but shall be a minimum of two layers for cold conservation. Permanent terminations shall be fully vapour sealed and waterproofed. All lateral joints between pre-formed insulation sections shall be staggered. Additional layers of insulation shall be applied in the same manner as the first layer, with lateral and end joints staggered over the preceding layer so that no joints coincide, except where they cross at right angles. All joints shall be tightly butted together so as to eliminate voids. At all flanges the insulation shall be cut at a 45 bevel to allow bolt removal without causing damage to the insulation.

o

Rev 02

7.1.4

7.1.5 7.1.6

7.1.7 7.1.8

7.1.9 7.1.10

Document No. 1000-S-90-38-S-6003-00

Page 10 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

Insulation shall be continuous at all points of support. Provision shall be made to prevent seepage of water down pipe hangers into the insulation. 7.1.13 Where paintwork and insulation is damaged or removed, the damaged insulation shall be removed, the paintwork made good, and the insulation re-applied in accordance with this specification. Contraction joints shall be provided as required. MINERAL WOOL Each mineral wool insulation layer shall be secured with stainless steel bands or wire throughout. Equipment shall be insulated with rigid slabs, bevelled lags or flexible mattresses. Standard pipe sections shall be used where diameter permits. Rigid slab insulation shall be laid with staggered joints and secured with banding at 250mm centres. When the bands are in position there shall be no cracks or open joints. Rigid slab insulation for heads of vessels shall be segmental in shape, held together with binding wire. All joints shall be covered with self-adhesive metal foil tape. CELLULAR GLASS Anti-abrasive compound, as recommended by the insulation Manufacturer, shall be applied to the inside surface of the insulation. It shall not be applied directly onto the pipe work. Adhesive, as recommended by the insulation Manufacturer, shall be applied to all butt joints. The selection of the adhesive shall be based on the temperature range of the pipe work/vessel and its compatibility with the protective coating on the pipe work/vessel. Stainless steel bands shall secure the cellular glass. This shall be positioned at centres as recommended by the insulation Manufacturer. All joints shall be covered with self-adhesive metal tape. Vapour barrier, as recommended by the insulation Manufacturer, shall be applied to each layer of insulation. Vapour barrier, as recommended by the insulation Manufacturer, shall be applied to outer coating. FLEXIBLE ELASTOMERIC FOAM Pipe section insulation shall be used throughout, this shall be applied in one layer. The insulation shall be glued with the Manufacturers recommended adhesive and in accordance with his recommendations. All joints shall be covered with self-adhesive metal foil tape. STAINLESS STEEL CLADDING All joints shall be completed with mastic to ensure that the cladding is deluge proof, and the sheeting sections are arranged to shed water. Self-tapping screws shall not be used. PAINTING GENERAL All lines and equipment to be insulated shall be fully painted in accordance with the specification 1000-S-90-38-S-6010-00-Painting and Coating specification.

Rev 02

7.1.14 7.2 7.2.1 7.2.2 7.2.3 7.2.4 7.2.5 7.3 7.3.1 7.3.2

7.3.3 7.3.4 7.3.5 7.3.6

7.4 7.4.1 7.4.2 7.4.3 7.5 7.5.1 7.5.2 8 8.1 8.1.1

Document No. 1000-S-90-38-S-6003-00

Page 11 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

9 9.1 9.1.1 INSULATION OF HOT SURFACES IN HAZARDOUS AREAS GENERAL Where in hazardous areas the surface temperatures of pipe/equipment exceeds 205C, the insulation shall apply to all components and the system shall be sealed to inhibit the possible ingress of gases QUALITY CONTROL, CERTIFICATION AND GUARANTEES GENERAL All work is to be carried out in accordance with the insulation Contractors Quality Control Plan which is to be approved by SEIC or their nominated representative. SEIC or their nominated representative shall have the right to test and inspect all work and materials on site or at the factory, to verify that the requirements of the specifications and codes with regard to manufacture, supply and installation have been met. Such inspection shall not relieve the Contractor from full responsibility for the quality and correctness of the materials and or work. ACOUSTIC INSULATION SPECIFICATION SCOPE This specification covers the minimum requirements for materials and application of acoustic insulation for pipe work and valves with reference to the Acoustic Insulation Schedule. It does not cover acoustic insulation of other equipment (vessels, machinery, etc). DESIGN AND MATERIALS The construction and installation of acoustic pipe insulation shall be generally in accordance with the requirements of ISO 9053 Acoustics;Materials for Acoustical applications;determinations of airflow resistance and with this specification. Where lines have combined classes, with the exception of cold insulation, the greater requirement for thickness and cladding of the two shall apply. The mineral wool insulation layer shall be of a semi-rigid or flexible blanket grade only. Where cold insulation is part of a combined requirement, both cold insulation and mineral wool shall be applied. The full cold system shall be applied first, including the vapour barrier, then the acoustic system shall be applied on top. Acoustic pipe insulation shall be either types A,B, C as defined below: Class A Acoustic insulation shall comprise of an insulating layer of mineral wool, 50 mm thick. The wool shall have a density of between 125-150 kg/m2 and a flow resistivity in the range of 25000-75000 Ns/m4. Flexible noise barrier, min 2.5 mm thick, density min 5 kg/m 2, (by Noisco, Revac or equivalent) Non-metallic top covering. Flanges and valves do not require insulation. Pipe supports shall be insulated down to steel base. Class B Acoustic insulation shall comprise of an insulating layer of mineral wool, 100 mm thick.

Rev 02

10 10.1 10.1.1 10.1.2

11 11.1 11.1.1

11.2 11.2.1

11.2.2

11.2.3

Document No. 1000-S-90-38-S-6003-00

Page 12 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

The wool shall have a density of between 125-150 kg/m3 and a flow resistivity in the range of 25000-75000 Ns/m4. Flexible noise barrier, min 2.5 mm thick, density min 5 k/m2 (by Noisco, Revac or equivalent) Non-metallic top covering. Flanges and valves do not require insulation. Pipe supports shall be insulated down to steel base. Class C Acoustic insulation shall comprise of an insulating layer of mineral wool, 100 mm thick. The wool shall have a density of between 125-150 kg/m3 and a flow resistivity in the range of 25000-75000 Ns/m4. Flexible noise barrier, min 2.5 min thick, density min 10 kg/m2. Non-metallic top covering. Flanges and valves do require insulation Pipe supports shall be insulated down to steel base. 11.2.4 11.2.5 Where localised reduction in thickness may occur, due to space constraints, the construction detail for the specified thickness shall be maintained. All materials shall be suitable for the operating temperatures and for the chemical nature of the environment. They shall conform to the specification for thermal insulation and to any relevant requirements for compatibility and surface spread of flame. To attain the rated performance of the specified insulation, it is essential that the flexible noise barrier is sealed to prevent noise leakage. This shall be achieved by provision of overlapped joints combined with self-adhesive metal foil tape. Suitable materials for anti-vibration seals are synthetic rubber and natural rubber. The antivibration seal may also be required to act as a waterproof seal, and the material shall be suitable for this duty. Where these materials are not compatible with the operating temperature, the seal shall be made from compressed porous-layer material, with continuity of vapour barrier maintained as far as practicable. Rigid spacers, as used in distance rings for thermal insulation, shall not be used in acoustic insulation. Where it is necessary to use spacers, they shall contain a resilient element to reduce the transmission of vibrations from the pipe. Where necessary the resilient element shall have a built-in mechanical stop in the direction normal to the pipe axis in order to limit its mechanical deflection. With vertical pipes, any supports which carry the weight of the cladding shall contain resilient elements to reduce the transmission of vibrations from the pipe. Where necessary, these resilient elements should contain mechanical stops to limit excess movement.

Rev 02

11.2.6

11.2.7

11.2.8

11.2.9

11.2.10 Resilient elements shall not be loaded to such an extent that their operational range of deflections is exceeded. 11.2.11 For Class C insulation, there shall be vibration isolation between the pipe support and the base in order to achieve the specified acoustic performance. The vibration isolating materials shall be selected for the required mechanical properties as well as the acoustic properties.

Document No. 1000-S-90-38-S-6003-00

Page 13 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

Rev 02

TABLE 1 WINTERISATION

Pipe Size (Ins NB) Below 1 1 1/2 2 3 4 6 8 10 12 14 and above Notes: 1) 2)

Insulation Thickness mm 25 25 25 25 25 25 25 25 25 none

The thicknesses stated are insulation only and exclude any finishing material In accordance with BS 5422

Document No. 1000-S-90-38-S-6003-00

Page 14 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

Rev 02

TABLE 2 INSULATION THICKNESS - FOR HEAT CONSERVATION OFFSHORE INCLUDING ELECTRICALLY TRACED PIPING AND EQUIPMENT FOR USE ON OFFSHORE FACILITIES ONLY. ECONOMIC THICKNESS OF MINERAL FIBRE (mm)

PIPE SIZE (INS NB) 1 1 2 3 4 6 8 10 12 14 16 18 20 24 & above Vessels

50 & BELOW 25 25 25 25 25 30 30 30 30 30 30 50 50 50 50 50 50

OPERATING TEMPERATURE (DEG C) 51 100 101 150 151 200

201 250

251 - 300

25 25 30 30 30 30 30 40 40 40 40 50 50 50 50 80 80

30 30 30 30 30 30 40 50 50 60 60 60 60 70 70 100 100

30 30 30 30 40 40 50 50 60 70 70 70 70 70 80 110 110

30 30 30 40 40 50 50 60 70 80 80 80 80 90 90 130 130

30 30 30 40 50 50 60 70 80 90 90 90 100 100 110 140 140

Document No. 1000-S-90-38-S-6003-00

Page 15 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

Rev 02

TABLE 3 - INSULATION THICKNESS - FOR HEAT CONSERVATION ONSHORE INCL. ELECTRICALLY TRACED PIPING AND EQUIPMENT FOR USE ON SAKHALIN II PROJECT ONSHORE PROCESSING FACILITY

Pipe Diameter Inches 1 2 3 4 6 8 10 12/14 16/18 20 24 to Flat Notes: 1) 2) 3)

Fluid Operating Temperature C 50 35 35 40 40 40 40 40 60 60 60 60

100

40 40 40 40 50 50 50 60 60 60 90

150 40 40 40 50 60 60 70 70 80 80 110

200 40 50 50 60 60 70 80 80 80 90 120

250 40 50 60 60 70 80 90 90 100 100 140

300 40 60 60 80 80 90 100 100 110 120 150

350 40 60 80 80 90 100 100 110 120 150 150

Insulation material mineral wool pipe sections and slab, weather covering is mastic. Thicknesses greater than 50mm are to be applied in multiple layers. For temperatures outside the range given use the next highest temperature to determine the required insulation thickness.

Document No. 1000-S-90-38-S-6003-00

Page 16 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

Rev 02

TABLE 4 NUMBER & THICKNESS OF INSULATION LAYERS (MINERAL WOOL)

Total Thickness (mm)

Number of Layers

Inner Layer (mm)

Middle Layer (mm)

Outer Layer (mm)

25 30 40 50 60 70 80 90 100 120 150

1 1 1 1 2 2 2 2 2 3 3

30 30 40 40 50 40 50

40 50

25 30 40 50 30 40 40 40 50 40 50

Document No. 1000-S-90-38-S-6003-00

Page 17 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

Rev 02

TABLE 5 PERSONNEL PROTECTION ECONOMIC THICKNESS OF MINERAL FIBRE (mm)

OPERATING TEMPERATURE (DEG C)

Pipe Size (INS N.B.) 1 and below 1.5 2 3 4 6 8 10 12 14 16 18 20 24 FLAT Use guards (75mm) Use guards (75mm) Use guards (75mm) Use guards (75mm) Use guards (75mm) Use guards (75mm) Use guards (75mm) Use guards (75mm) Use guards (75mm) Use guards (75mm) Use guards (75mm) Use guards (75mm) Use guards (75mm) Use guards (75mm) 205 & Below 206 250 (see note 1) 25 25 25 25 25 25 25 25 25 25 25 25 40 40 40 450 (see note 1) 40 40 40 50 50 50 50 50 50 50 50 50 65 65 65 550

Use guards (75mm)

Notes: 1. Insulation only to be applied on lines/equipment, which are in hazardous areas, operating within this

temperature range.

Document No. 1000-S-90-38-S-6003-00

Page 18 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

Rev 02

TABLE 6 COLD CONSERVATION ECONOMIC THICKNESS OF CELLULAR GLASS (mm)

OPERATING TEMPERATURE (DEG C)

PIPE SIZE (INS N.B.) 0 to -20 -21 TO 40 -41 TO 60 -61 TO 80 -81 TO -100

1 & below 1 2 3 4 6 8 10 12 14 16 18 20 24 Flat

40 50 50 50 50 60 60 60 60 60 60 60 60 60 60

50 50 50 60 60 70 70 70 70 70 70 80 80 80 90

60 65 65 75 75 80 80 90 90 90 90 90 100 100 110

65 80 80 90 90 90 100 100 100 110 110 110 110 110 130

80 80 80 100 100 100 110 110 120 120 120 120 130 130 150

Document No. 1000-S-90-38-S-6003-00

Page 19 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

TABLE 7 - INSULATION THICKNESS - FOR COLD CONSERVATION ONSHORE FOR USE ON SAKHALIN II PROJECT ONSHORE PROCESSING FACILITY

Rev 02

Pipe Diameter Inches 1 2 3 4 6 8 10 12/14 16/18 20 24 to Flat Notes: 1) 2) 3)

Fluid Operating Temperature C 10 to 0 38 38 38 38 38 38 38 38 38 38 38

-20

38 38 50 50 50 50 50 65 65 65 65

-40 50 50 65 65 65 65 80 80 80 90 115

-60 50 65 80 80 80 80 90 90 115 115 125

-80 65 80 80 90 90 90 115 115 125 125 140

-100 80 80 90 90 115 115 125 125 140 140 150

Insulation material cellular glass pipe sections and slabs. Thicknesses greater than 40mm are to be applied in multiple layers. For temperatures outside the range given use the next highest temperature to determine the required insulation thickness.

Document No. 1000-S-90-38-S-6003-00

Page 20 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

TABLE 8 - INSULATION THICKNESS - FOR CONDENSATION CONTROL ONSHORE FOR USE ON SAKHALIN II PROJECT ONSHORE PROCESSING FACILITY

Rev 02

Pipe Diameter Inches 1 2 3 4 6 8 10 12/14 16/18 20 24 to Flat

Fluid Operating Temperature C 10 to 0 25 25 25 25 25 25 25 25 25 25 38

-20

25 25 40 40 40 40 40 50 50 50 50

-40 40 40 50 50 50 50 65 65 65 65 75

-60 40 50 65 65 65 65 75 75 90 90 90

-80 50 65 65 75 75 75 90 90 100 100 100

-100 65 65 75 75 90 90 100 100 100 100 115

-120 65 75 90 90 100 100 115 115 125 125 125

Notes: 1) 2) 3) Insulation material wool pipe sections and slab, weather covering is mastic. Thicknesses greater than 40mm are to be applied in multiple layers. For temperatures outside the range given use the next highest temperature to determine the required insulation thickness.

Document No. 1000-S-90-38-S-6003-00

Page 21 of 22

SPECIFICATION FOR PIPING AND EQUIPMENT INSULATION

Rev 02

TABLE 9 HEAT CONSERVATION- ECONOMIC THICKNESS OF FLEXIBLE ELASTOMERIC FOAM (MM)

OPERATING TEMPERATURE (DEG C)

PIPE SIZE (INS NB)

0 50 25 25 25 25 25

51 100 25 25 30 30 30

101 - 115 30 30 30 30 30

1 1 2

Document No. 1000-S-90-38-S-6003-00

Page 22 of 22

You might also like

- PIP STE05121 (Anchor Bolt Design Guide)Document55 pagesPIP STE05121 (Anchor Bolt Design Guide)bowitchhazel100% (1)

- Insulation of Piping and EquipmentDocument32 pagesInsulation of Piping and Equipmentarjmandquest100% (2)

- PIP STC01018 - 2014 - Blast Resistant Building Design CriteriaDocument51 pagesPIP STC01018 - 2014 - Blast Resistant Building Design Criteriamirko huarancca100% (1)

- S-AAA-CORR (Rev.0-2015) PDFDocument19 pagesS-AAA-CORR (Rev.0-2015) PDFSwathish SivaprasadNo ratings yet

- PIP STS05130 (Erection of Structural & Miscellaneous Steel Specification)Document11 pagesPIP STS05130 (Erection of Structural & Miscellaneous Steel Specification)Hui Liu100% (2)

- Anchor BoltsDocument33 pagesAnchor BoltsAlberico Muratori100% (3)

- Information Security Policy ChecklistDocument2 pagesInformation Security Policy ChecklistRead Rule100% (6)

- Piping and Equipment InsulationDocument22 pagesPiping and Equipment InsulationRampal Rahul Rampal RahulNo ratings yet

- EIA TIA 222 F Structural Standards For Steel Antenna Towers and Antenna Supporting StructuresDocument122 pagesEIA TIA 222 F Structural Standards For Steel Antenna Towers and Antenna Supporting StructuresMala Rattan100% (2)

- 0003 Mi20 00S1 0240 0Document15 pages0003 Mi20 00S1 0240 0Galih Suksmono AdiNo ratings yet

- Insulation Design GuideDocument38 pagesInsulation Design GuideGunawan Suryana100% (2)

- ES-14-102-14 Insulation of Piping and EquipmentDocument31 pagesES-14-102-14 Insulation of Piping and EquipmentVasilica BarbarasaNo ratings yet

- PIP STC01018 (Blast Resistant Building Design Criteria)Document55 pagesPIP STC01018 (Blast Resistant Building Design Criteria)Liu Leo100% (3)

- STF05521Document15 pagesSTF05521lingoalvaNo ratings yet

- DLT 5072-2007-EnDocument74 pagesDLT 5072-2007-EnCourage MurevesiNo ratings yet

- Span TS 3003Document51 pagesSpan TS 3003Muhamad FarhanNo ratings yet

- Code490En 1Document32 pagesCode490En 1Erick MoraNo ratings yet

- HIA Mid-Field Fuel Farm Expansion - Welding of Steel StructuresDocument18 pagesHIA Mid-Field Fuel Farm Expansion - Welding of Steel Structuressrp. mohammedNo ratings yet

- PIP INEG1000 (2019) - Insulation Design GuideDocument25 pagesPIP INEG1000 (2019) - Insulation Design GuideAbimelech SalasNo ratings yet

- ELSSG01Document27 pagesELSSG01Ariel Anibal AparicioNo ratings yet

- Din 1623-05Document11 pagesDin 1623-05dietersimaNo ratings yet

- PIP STF05121 Anchor Fabrication and Installation Into ConcreteDocument6 pagesPIP STF05121 Anchor Fabrication and Installation Into Concretecarrimonn11No ratings yet

- 132 KV Surge Arrester - Technical SpecificationDocument11 pages132 KV Surge Arrester - Technical SpecificationvikasmikkuNo ratings yet

- Pinos HexagonaisDocument32 pagesPinos HexagonaisAdriIaAnuUu CruzNo ratings yet

- Australian Standard: Design of Steel Lattice Towers and MastsDocument7 pagesAustralian Standard: Design of Steel Lattice Towers and Mastsalsager14No ratings yet

- STS05130-B Erection of Structural and Miscellaneous SteelDocument12 pagesSTS05130-B Erection of Structural and Miscellaneous SteelAnaNo ratings yet

- PIP STS02360 (Driven Piles Specification)Document22 pagesPIP STS02360 (Driven Piles Specification)Hui LiuNo ratings yet

- Automation Engineering Practice For Pressure Definitions: AEP-32e 13 January 2010Document25 pagesAutomation Engineering Practice For Pressure Definitions: AEP-32e 13 January 2010arraziy fauzanNo ratings yet

- 015 - NH - 1003 Thermal and Acoustic InsulationDocument26 pages015 - NH - 1003 Thermal and Acoustic InsulationSaif AhmedNo ratings yet

- Nes 111Document46 pagesNes 111FredoMari LC100% (2)

- Sts 02360Document22 pagesSts 02360Sowjanya VenigallaNo ratings yet

- XPIP STE05121 Anchor Bolt Design GuideDocument55 pagesXPIP STE05121 Anchor Bolt Design Guidemacynthia26100% (1)

- Ars 08390Document13 pagesArs 08390Natalie CharlesNo ratings yet

- STS05130Document14 pagesSTS05130Mahather MohamedNo ratings yet

- Pip Sts05130 PDFDocument12 pagesPip Sts05130 PDFFer PabNo ratings yet

- Surface Treatment of Wind Turbine Towers (PDF For Web Site)Document29 pagesSurface Treatment of Wind Turbine Towers (PDF For Web Site)pv cabaretNo ratings yet

- Technical Specification For Compression Lugs and Links: Ergon Energy Corporation LimitedDocument11 pagesTechnical Specification For Compression Lugs and Links: Ergon Energy Corporation LimitedFadi Mohd ShaherNo ratings yet

- S Civ Surf - 00Document10 pagesS Civ Surf - 00HARINo ratings yet

- Mechanical Piping and FittingsDocument19 pagesMechanical Piping and FittingsPinak ProjectsNo ratings yet

- Asme Sec8 Nca 1000Document5 pagesAsme Sec8 Nca 1000sajanchaudhariNo ratings yet

- Ars 08390Document11 pagesArs 08390Abdul HannanNo ratings yet

- ADDC Corrosion Protection StandardDocument23 pagesADDC Corrosion Protection StandardApsi LalNo ratings yet

- INSR1000 - 2015 - Install of Removable Insulation Covers For Hot ServicesDocument20 pagesINSR1000 - 2015 - Install of Removable Insulation Covers For Hot ServicesTom KoubaNo ratings yet

- S-TR-CORR (Rev.0-2015)Document19 pagesS-TR-CORR (Rev.0-2015)Abhinav SinhaNo ratings yet

- Piping Standard and SpecificationDocument22 pagesPiping Standard and SpecificationMuhamad Firdaus Bin Azizan100% (5)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- DC/DC Converter Handbook: SMPS topologies from an EMC point of viewFrom EverandDC/DC Converter Handbook: SMPS topologies from an EMC point of viewNo ratings yet

- Estimator's Piping Man-hours Tool: Estimating Man-hours for Carbon Steel Process Piping Projects. Manual of Man-hours, ExamplesFrom EverandEstimator's Piping Man-hours Tool: Estimating Man-hours for Carbon Steel Process Piping Projects. Manual of Man-hours, ExamplesNo ratings yet

- Engineered Ceramics: Current Status and Future ProspectsFrom EverandEngineered Ceramics: Current Status and Future ProspectsTatsuki OhjiNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsFrom EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Eco Housing Unep FinalDocument126 pagesEco Housing Unep FinalBhupal Singh100% (8)

- 6 VoIP ConfigurationDocument9 pages6 VoIP ConfigurationKrishna GNo ratings yet

- Calcul de Alpha CritiqueDocument20 pagesCalcul de Alpha Critiquelahlou_d9216No ratings yet

- Universal Precision Screws: Sap Erp ImplementationDocument11 pagesUniversal Precision Screws: Sap Erp ImplementationGopinathareddy MudimelaNo ratings yet

- Guidelines For Certification of Lifting Appliances (7-1) - 2013Document116 pagesGuidelines For Certification of Lifting Appliances (7-1) - 2013irmaNo ratings yet

- Foundation PlanDocument34 pagesFoundation PlanMagie MendozaNo ratings yet

- Current LogDocument10 pagesCurrent LogGagandeepNo ratings yet

- Design of Two Way SlabDocument64 pagesDesign of Two Way SlabVINOTHINI100% (1)

- Advanced Internet Application MCQ'SDocument8 pagesAdvanced Internet Application MCQ'SGuruKPONo ratings yet

- Scorpio Fire Control PanelDocument16 pagesScorpio Fire Control PanelJORGE ENRIQUE ARANGONo ratings yet

- UG Refund Policy NotificationDocument1 pageUG Refund Policy NotificationAman JhaNo ratings yet

- Athens in 4 Days Packed ItineraryDocument29 pagesAthens in 4 Days Packed ItineraryMarky GabrielaNo ratings yet

- HSI Calculator Excel-FINALDocument25 pagesHSI Calculator Excel-FINALYudith RachmadiahNo ratings yet

- SafeZone-edge Milestone Xprotect Integration Configuration GuideDocument43 pagesSafeZone-edge Milestone Xprotect Integration Configuration Guidehombres123No ratings yet

- Snadhurst Military Academy GUI NOVEMBER 2021Document4 pagesSnadhurst Military Academy GUI NOVEMBER 2021Tudor GabrielaNo ratings yet

- A Tawpah Enge I Sawi Ve DawnDocument2 pagesA Tawpah Enge I Sawi Ve DawnWilliam LgguiteNo ratings yet

- Indonesia Design - November-December 2016Document270 pagesIndonesia Design - November-December 2016tarnoscribdNo ratings yet

- Q16 051-6338-C.bakDocument40 pagesQ16 051-6338-C.bakmarkbillupsNo ratings yet

- The TrousseauDocument4 pagesThe TrousseauaravindpunnaNo ratings yet

- Crypto 3Document9 pagesCrypto 3sauravkgupta5077No ratings yet

- Protected Mode TutorialDocument20 pagesProtected Mode TutorialfinitebookNo ratings yet

- Ramtech Code For Mold and Tooling Rev2Document17 pagesRamtech Code For Mold and Tooling Rev2Dhenil ManubatNo ratings yet

- Labeling The MotherboardDocument6 pagesLabeling The MotherboardKaan Knight OznacarNo ratings yet

- A Sometimes Minimal FORTH Compiler and Tutorial For LinuxDocument49 pagesA Sometimes Minimal FORTH Compiler and Tutorial For LinuxtblackmonNo ratings yet

- The Blind Man 2 May 1917Document20 pagesThe Blind Man 2 May 1917Leila Kelly GualandiNo ratings yet

- Ocfs2 1 - 6 UsersguideDocument58 pagesOcfs2 1 - 6 UsersguideJoe BuddenNo ratings yet

- TEK 05-07A Floor and Roof Connections To CMU WallsDocument5 pagesTEK 05-07A Floor and Roof Connections To CMU WallsAdam JonesNo ratings yet

- Architectural Policy: Poetic ArchitectureDocument6 pagesArchitectural Policy: Poetic ArchitectureKonZabetas Architects-engineersNo ratings yet

- Template ICDM 2018Document4 pagesTemplate ICDM 2018Ivan TaslimNo ratings yet