Compressor

Compressor

Uploaded by

sjois_hsCopyright:

Available Formats

Compressor

Compressor

Uploaded by

sjois_hsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Compressor

Compressor

Uploaded by

sjois_hsCopyright:

Available Formats

Compressor control menu

Main Menu Help Fwd Previous Rew

Cost of operating turbo compressors

Compressor operation

Maintenance cost

Operating cost

Commissioning cost

Putting it in perspective

Centrifugal compressors

Axial compressors

Compressor system classifications

Developing the compressor curve

The surge phenomena

Compressor control

Acrobat

Repairs are expensive

$50,000

$25,000

$750,000

Costs of repairs - materials and labor

3,000 hp

Process gas compressor

20,000 hp

Axial air blower

Seals

Bearings

Rotor Assembly

$20,000

$10,000

$200,000

Fwd Previous Rew Compressors Help Menu

Operating costs are large

Cost to operate one turbo compressor per year:

Plant air compressor 1,000 HP (746 kW) $457,000

Wet gas compressor 4,000 HP(2,984 kW) $1,830,000

Propylene refrigeration comp. 40,000 HP(29,480 kW) $18,300,000

Assumes power at $.07 per kilowatt hour or $457 per horsepower per year.

Energy costs vary due to local conditions.

Energy Saving Examples Fwd Previous Rew Energy Savings Predictions Compressors Help Menu

Energy savings examples

resulting from reduced recycle or blow-off

Actual Energy Savings Result From

Improved Antisurge Protection and Capacity Control

$1,200,000

$155,000

$78,000

Compressor

shaft power

Actual achieved

savings

Propylene refrigeration

FCCU air blower

Centac air compressor

40,000 hp ( 29 MW)

15,000 hp (11.2 MW)

1,500 hp (1.1 MW)

Compressor

application

Fwd Previous Rew Energy Savings Predictions Compressors Menu Help

Available energy savings can be predicted

Less than one year pay-backs* typical by reducing recycle of blow-Off

Pay-back

Period

(Months)

Reduced Recycle

(Per Cent of Maximum Compressor Flow)

*Assumes electro motor power At $0.05 US per kilowatt hour or turbine power at $327

per horsepower per year. Tax consequences are not considered in pay-back period

due to varying tax policies around the world.

12

11

10

9

8

7

6

5

4

3

2

1

0 5 10 15 20 25 30 35

Pay-back approximately 1

Month with 15% Reduction

1000 HP

3,500 HP

20,000 HP

Energy Saving Examples Fwd Previous Rew

Pay-back less than 10

Months with 15% Reduction

Pay-back less than 6

Months with 15% Reduction

Compressors Menu Help

Downtime costs can be enormous!

60,000 BPD Cat Cracker: $90,000 per hour, lost sales plus

fixed expenses. The biggest units are twice this size!

Natural Gas Production, 100 MMSCFD: $12,500 per hour

lost sales plus fixed expenses.

Consequences of downtime: Lost profit, lost customer

goodwill, repair costs, attention of top management.

Fwd Previous Rew Compressors Menu Help

Includes lost sales plus fixed operating expenses.

Most turbo compressor control system design problems are

discovered during commissioning.

Delays due to turbomachinery control problems are not unusual.

Startups are faster with a properly designed turbomachinery

control system.

Commissioning costs are large

Fwd Previous Rew

$2,300,000

100 MMSCFD

Natural Gas Plant

60,000 BPD

Cat Cracker

Start-up Cost Per Day $375,000

Process

Compressors Menu Help

Putting it in perspective

30-year life cycle costs for a 20,000 hp compressor

Energy Costs

$180 Million

Initial Cost

$1.5 Million

Maintenance Costs

$4.5 Million

97%

of total costs

Source: Experiences in Analysis and Monitoring Compressor Performance

Ben Duggan & Steve Locke

E.I. du Pont, Old Hickory, Tennessee

24th Turbomachinery Symposium

Costs in constant dollars

Fwd Previous Rew Compressors Menu Help

Putting it in perspective

30-year cost per 1,000 hp

?

What can we control?

0.0

5.0

10.0

15.0

Initial Cost Maintenance Energy Lost

Production

$ Millions

Controllable

Uncontrollable

Source: Experiences in Analysis and Monitoring Compressor Performance

Ben Duggan & Steve Locke, E.I. du Pont, Old Hickory, Tennessee

24th Turbomachinery Symposium

Costs in constant dollars

Fwd Previous Rew Compressors Menu Help

Centrifugal compressors

Widespread use, many applications

Gas is accelerated outwards by rotating impeller

Can be built for operation as low as 5 psi, or operation

as high as 8,000 psi (35 kPa or 55,000 kPa)

Sizes range from 300 hp to 50,000 hp

Single Case Compressor Centrifugal Impeller

DIFFUSERS

IMPELLERS

Cross Section of Horizontal Split

Fwd Previous Rew

Picture of Horizontal Split

Cross Section of Barrel Type

Picture of Barrel Type

Cross Section of Integrally Geared

Picture of Gear and Impellers

Picture of Integrally Geared

Compressors Menu Help

Cross section of horizontal split

Picture of Horizontal Split Fwd Previous Rew Centrifugals

Compressor inlet nozzle

Thrust bearing

Journal bearing

Shaft and labyrinth seal

Impeller inlet labyrinth seals

Discharge volutes

Impellers

Drive coupling

Casing

(horizontally split flange)

Compressor discharge nozzle

Menu Help

Picture of horizontal split

Fwd Previous Rew Centrifugals Cross Section of Horizontal Split Menu Help

Cross section of barrel type compressor

Fwd Previous Rew Centrifugals Picture of Barrel Type Menu Help

Picture of barrel type compressor

Fwd Previous Rew Centrifugals Cross Section of Barrel Type Menu Help

Cross section of bull gear compressor

Fwd Previous Rew Centrifugals Picture of Integrally Geared Picture of Gear and Impellers

Compressor volutes

Gear casing

Pinion shafts

Journal bearing

Impellers

Drive coupling

Labyrinth seals

Main gear

Inlet guide vanes

Menu Help

Picture of bull gear compressor

Fwd Previous Rew Centrifugals Cross Section of Integrally Geared Picture of Gear and Impellers Menu Help

Picture of (bull) gear and impellers

Fwd Previous Rew Centrifugals Cross Section of Integrally Geared Picture of Integrally Geared Menu Help

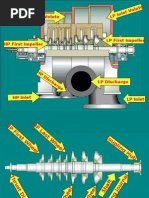

Gas flows in direction of rotating shaft

Can be built for lower pressures only

10 to 100 psi (0.7 to 6.8 Bar)

High flow rate

Efficient

Not as common as centrifugals

Axial compressors

Stator Blades

Rotor

Blades

Casing

Rotor Blades

Stator

Blades

Casing

Shaft

Fwd Previous Rew Cross Section of Axial Picture of Axial Compressors Menu Help

Cross section of axial compressor

Fwd Previous Rew Axials Picture of Axial

Compressor outlet nozzle

Rotor blades

Labyrinth seals

Guide-vane actuator linkage

Compressor rotor

Compressor inlet nozzle

Thrust bearing

Adjustable guide vanes

Menu Help

Picture of axial compressor

Fwd Previous Rew Axials Cross Section of Axial Menu Help

Compressor system classifications

Single-Section, Three-Stage Single-Case, Two-Section, Six-Stage

Two-Case, Two-Section, Six-Stage

Series Network

Fwd Previous Rew

Parallel Network

Compressors Menu Help

Developing the compressor curve

P

d

Discharge Pressure (P

2

) AP

c

Differential Pressure

(P

d

- P

s

) or (P

2

- P

1

) R

c

Pressure Ratio (P

d

/P

s

) or (P

2

/P

1

) H

p

Polytropic Head R

c

Q

s, normal

Q

s, mass

Q

s, vol

Compressor curve

for a specific

speed N1

R

process,1

Q

1

R

c1

Fwd Previous Rew

R

process,2

Q

2

R

c2

Compressors Menu Help

Q

s, vol

R

c

minimum speed

maximum speed

surge limit

stonewall or

choke limit

power limit

process limit

Developing the compressor curve

Fwd Previous Rew

stable zone

of operation

adding control

margins

Actual available

operating zone

Compressors Menu Help

How an airplane wing develops lift

Fwd Previous Rew

Bernoullis law

p

static

+

1

/

2

v

2

+ gH = Constant

The term gH is negligible for the wing

Then: p

static

+

1

/

2

v

2

= Constant

Due to the shape of the

wing: v

2

< v

1

thus p

2

> p

1

v

1

,

p

1

v

2,

p

2

As a result there is Ap or

lift

Lift

And the plane can

fly

Compressors Menu Help

How the airplane develops stall

Fwd Previous Rew

Lift

As the wing tilts back the Av changes and thus the Ap

This leads to more lift

Lift

Lift

When the wing is tilted too much the streaming profile

suddenly changes from laminar to turbulent

Lift

The air no longer sticks to the wing and the lift is lost

The plane starts to fall down

Compressors Menu Help

Developing the surge cycle on the compressor curve

Fwd Previous Rew

Q

s, vol

P

d

Machine shutdown

no flow, no pressure

Electro motor is started

Machine accelerates to nominal

speed

Compressor reaches performance

curve

Note: Flow goes up faster because

pressure is the integral of flow

Pressure builds

Resistance goes up

Compressor rides the curve

P

d

= P

v

+ R

losses

A

Compressor reaches surge point A

Compressor looses its ability to make

pressure

Suddenly P

d

drops and thus P

v

> P

d

Plane goes to stall - Compressor surges

B

Because P

v

> P

d

the flow reverses

Compressor operating point goes to point B

C

Result of flow reversal is that pressure goes

down

Pressure goes down => less negative flow

Operating point goes to point C

D

System pressure is going down

Compressor is again able to overcome P

v

Compressor jumps back to

performance curve and goes to point D

Forward flow is re-established

P

d

P

v

R

losses

P

d

= Compressor discharge pressure

P

v

= Vessel pressure

R

losses

= Resistance losses over pipe

Compressor starts to build pressure

Compressor rides curve towards surge

Point A is reached

The surge cycle is complete

From A to B 20 - 50 ms Drop into surge

From C to D 20 - 120 ms Jump out of surge

A-B-C-D-A 0.3 - 3 seconds Surge cycle

Compressors Menu Help

Rapid flow oscillations

Thrust reversals

Potential damage

Rapid pressure oscillations

with process instability

Rising temperatures inside

compressor

Major process parameters during surge

FLOW

PRESSURE

TIME (sec.)

1 2 3

TEMPERATURE

Fwd Previous Rew

TIME (sec.)

1 2 3

TIME (sec.)

1 2 3

Compressors Menu Help

Surge description

Flow reverses in 20 to 50 milliseconds

Surge cycles at a rate of 0.3 s to 3 s per cycle

Compressor vibrates

Temperature rises

Whooshing noise

Trips may occur

Conventional instruments and human operators

may fail to recognize surge

Fwd Previous Rew Compressors Menu Help

Some surge consequences

Unstable flow and pressure

Damage in sequence with increasing severity

to seals, bearings, impellers, shaft

Increased seal clearances and leakage

Lower energy efficiency

Reduced compressor life

Fwd Previous Rew Compressors Menu Help

Factors leading to onset of surge

Startup

Shutdown

Operation at reduced throughput

Operation at heavy throughput with:

- Trips - Power loss

- Operator errors - Process upsets

- Load changes - Gas composition changes

- Cooler problems - Filter or strainer problems

- Driver problems

Surge is not limited to times of reduced throughput. Surge

can occur at full operation

Fwd Previous Rew Compressors Menu Help

Compressor control

Fwd Previous Rew

Objectives

Antisurge control

Performance control

Other topics

Loadsharing for parallel compressors Major challenges of compressor control

Location of the surge limit

High speed of approaching surge

Control loop interactions

Loadsharing of multiple compressors

Protection #1: PI control

Protection #2: Recycle Trip

Protection #3: Safety On

Output linearization

The tight shut-off line

Fall-back strategies

Compressor networks

Base loading parallel compressors

Equal flow division system

CCCs equidistant Loadsharing system

Limiting control

Pressure Override Control (POC)

Flow Measuring Devices (FMDs)

Antisurge control valve

Piping lay-out considerations

Dynamic simulation single compressor

Dynamic simulation parallel compressors

Basic antisurge control system

Influence of controller execution time

Menu Help

Major control system objectives

(user benefits)

1. Increase reliability of machinery and process

Prevent unnecessary process trips and

downtime

Minimize process disturbances

Prevent surge and surge damage

Simplify and automate startup and shutdown

2. Increase efficiency of machinery and process

Operate at lowest possible energy levels

Minimize antisurge recycle or blow-off

Minimize setpoint deviation

Maximize throughput using all available

horsepower

Optimize loadsharing of multiple units

Energy Saving Examples

Fwd Previous Rew Compressor control Menu Help

Calculating the distance between the Surge

Limit Line and the compressor operating point

The Ground Rule

The better we can measure the distance to surge, the closer we can

operate to it without taking risk

The Challenge

The Surge Limit Line (SLL) is not a fixed line in the most commonly used

coordinates. The SLL changes depending on the compressor inlet

conditions: T

s

, P

s

, MW, k

s

Conclusion

The antisurge controller must provide a distance to surge calculation that

is invariant of any change in inlet conditions

This will lead to safer control yet reducing the surge control margin which

means:

Bigger turndown range on the compressor

Reduced energy consumption during low load conditions

Fwd Previous Rew Compressor control Menu Help

Typical compressor maps include: (Q

s

, H

p

), (Q

s

, R

c

), or (Q

s

, p

d

)

coordinates, where:

Commonly used (OEM provided) coordinate

systems of the compressor map

Q

s

= Suction flow and can be expressed as actual

or standard volumetric flow

H

p

= Polytropic Head

R

c

= Compressor Ratio (p

d

/ p

s

)

p

d

= Discharge pressure of the compressor

p

s

= Suction pressure of the compressor

k

s

= Exponent for isentropic compression

These maps are defined for (1) specific set of inlet conditions:

p

s

, T

s

, MW and k

s

Fwd Previous Rew Compressor control Menu Help

The problem with commonly used (OEM provided)

coordinate systems of the compressor map

These coordinates are NOT invariant to suction conditions as shown

Fwd Previous Rew

For control purposes we want the SLL to be presented by a single

curve for a fixed geometry compressor

Compressor control Menu Help

Developing invariant coordinates

The following variables are used to design and to characterize

compressors

Fwd Previous Rew

Fundamental variables

characterizing compressor

operation

H

p

= f

0

(Q, e, , , a, d, o)

J = f

1

(Q, e, , , a, d, o)

where:

H

p

= Polytropic head

J = Power

Q = Volumetric flow rate

- e = Rotational speed

- = Viscosity

- = Density

a = Local acoustic velocity

d

= Characteristic length

- o = Inlet guide vane angle

Through dimensional analysis (or similitude) we can derive two

sets of invariant coordinates

Dimensional analysis

or Similitude

Set 1

h

r

q

r

N

e

o

j

r

Re

Invariant coordinates

Set 2

R

c

q

r

N

e

o

j

r

Re

where:

h

r

= Reduced head

q

r

= Reduced flow

N

e

= Equivalent speed

- o = Guide vane angle

j

r

= Reduced power

Re

= Reynolds number

R

c

= Pressure Ratio

Compressor control Menu Help

Coordinates (H

p

, Q

s

) and (h

r

, q

r

2

)

(H

p

, Q

s

)

NOT invariant coordinates

(h

r

, q

r

2

)

Invariant coordinates

Fwd Previous Rew

where:

H

p

= Polytropic head

Q

s

= Volumetric suction flow

h

r

= Reduced head

q

r

2

= Reduced flow squared

Compressor control Menu Help

Coordinates (R

c

, Q

s

) and (R

c

, q

r

2

)

Fwd Previous Rew

(R

c

, Q

s

)

NOT invariant coordinates

where:

R

c

= Pressure ratio

Q

s

= Volumetric suction flow

q

r

2

= Reduced flow squared

Compressor control Menu

(R

c

, q

r

2

)

Invariant coordinates

q

r

2

Help

Coordinates (R

c

, j

r

) and (R

c

, N

e

2

)

Fwd Previous Rew

(R

c

, j

r

)

Invariant coordinates

(R

c

, N

e

2

)

Invariant coordinates

where:

R

c

= Pressure ratio

j

r

= Reduced power

N

e

2

= Equivalent speed squared

Compressor control Menu Help

Representing the SLL as a single curve

using reduced coordinates

A coordinate system that is invariant to suction conditions is:

h

H

(ZRT)

r

p

s

= and

q

Q

ZRT

r

s

s

=

( )

Squaring the flow will still keep coordinates invariant:

h

H

(ZRT)

r

p

s

= and q

Q

ZRT

r

s

s

2

2

=

( )

Fwd Previous Rew

q

r

2

h

r

Design Nitrogen Off-gas

MW MW MW

P

s

P

s

P

s

T

s

T

s

T

s

k

s

k

s

k

s

Compressor control Menu Help

Calculating q

r

2

(reduced flow squared)

Fwd Previous Rew

q

r

2

=

Q

s

2

(ZRT)

s

=

K

.

Z

s

.

R

u

.

T

s

MW

Ap

o,s

.

p

s

where:

R = R

u

/ MW

R

u

= Universal gas constant

R = Specific gas constant

MW = Molecular Weight of the gas

p

s

= Suction pressure

K = Orifice plate constant

- Ap

o,s

= Differential pressure across orifice plate

T

s

= Temperature of the gas in suction

Z

s

= Compressibility of gas in suction of compressor

(ZRT)

s

=

Ap

o,s

p

s

The antisurge controller calculates q

r

2

using p

s

and Ap

o,s

transmitters

Compressor control Menu Help

Calculating h

r

(reduced head)

For polytropic compression R

t

= R

c

o

thus o =

R = R

u

/ MW

R

t

= T

d

/ T

s

Temperature ratio

R

c

= p

d

/ p

s

Pressure ratio

where:

R

u

= Universal gas constant

R = Specific gas constant

MW = Molecular Weight of the gas

p

d

= Discharge pressure

p

s

= Suction pressure

Z

s

= Suction compressibility

- o = Exponent for polytropic compression

log(R

t

)

log(R

c

)

The antisurge controller calculates h

r

using p

d

, p

s

, T

d

and T

s

transmitters

(ZRT)

s

h

r

=

Z

s

.

R

u

.

T

s

MW

R

c

o

-1

o

H

p

=

.

(ZRT)

s

=

R

c

o

-1

o

Fwd Previous Rew Compressor control Menu Help

Building the Surge Limit Line

Any curvature of the Surge Limit Line can be characterized as a

function of the ordinate h

r

Fwd Previous Rew

q

r

2

h

r

The surge parameter is defined as:

S

f

q

s

r

r op

=

1

2

(h )

,

The function f

1

returns the value of q

r

2

on the SLL for input h

r

h

r

q

r,SLL

2

Compressor control Menu Help

The surge parameter S

s

The function f

1

returns the value of q

r

on the SLL for input h

r

2

q

r

2

h

r

Fwd Previous Rew

h

r

q

r,SLL

2

As a result: S

s

=

q

r,op

2

q

r,SLL

2

q

r,op

2

OP

OP = Operating Point

S

s

< 1 : stable operating zone

S

s

< 1

S

s

= 1 : surge limit line (SLL)

S

s

> 1 : surge region

S

s

> 1

Compressor control Menu Help

Introducing the distance between the operating

point and the Surge Control Line

Step 1: Introduce parameter d = 1 - S

s

q

r

2

h

r

S

s

< 1

S

s

> 1

S

s

= 1

Fwd Previous Rew

d

= 0

d

> 0

d

< 0

Step 2: Introduce parameter DEV = d - surge margin

DEV

= 0

Surge margin

DEV

> 0

DEV

< 0

The parameter DEV is independent of the size of the compressor

and will be the same for each compressor in the plant

Benefits:

One standard surge parameter

in the plant

No operator confusion:

DEV > 0 Good

DEV = 0 Recycle line

DEV < 0 Bad

Compressor control Menu Help

Simplifying the surge parameter

by replacing h

r

with R

c

Reduced Head h

r

can be replaced by R

c

while keeping the

coordinate system invariant to suction conditions

Fwd Previous Rew

The surge parameter S

s

now becomes

S

s

=

f

1

(R

c

)

q

r,op

2

where the function f

1

( ) returns the value of q

r,SLL

on the SLL for the input R

c

2

This eliminates the need for T

d

and T

s

transmitters for control

Important Note: CCC still strongly recommends T

d

and T

s

transmitters as well as rotational speed N for compressor

monitoring purposes

Compressor control Menu Help

The simplest CCC surge parameter

An antisurge algorithm can be designed around two transmitters:

Ap

o

and Ap

c

The parameter

Fwd Previous Rew

S

s

=

f

1

(R

c

)

q

r

2

is invariant to inlet conditions and speed

For two transmitters choose the function f

1

to be (R

c

- 1)

S

s

=

f

1

(R

c

)

q

r

2

=

R

c

- 1

Ap

o

p

s

p

d

p

s

- 1

( )

.

p

s

Ap

o

= =

p

d

- p

s

Ap

o

=

Ap

o

Ap

c

Selecting the specific function for f

1

(R

c

) to be (R

c

- 1) keeps the

map invariant to inlet conditions and speed

Compressor control Menu Help

Disadvantage of the Ap

c

/Ap

o

surge parameter

The SLL is rarely a straight line in the coordinates q

r

2

and R

c

Fwd Previous Rew

q

r

2

R

c

Actual Surge Limit Line (SLL)

The parameter Ap

c

/Ap

o

represents a straight line in the invariant

coordinates q

r

2

and R

c

SLL calculated by antisurge

controller using

Ap

c

/Ap

o

= constant

The Ap

c

/Ap

o

approach results in loss of turn down and

unnecessary recycle

loss of operating envelope

Compressor control Menu Help

Actual field data showing disadvantage of

Ap

c

/Ap

o

surge parameter

Fwd Previous Rew Compressor control Menu Help

Surge parameter for compressor with sidestream

Problem definition

Ap

o,1

P

1

T

1

Fwd Previous Rew

Ap

o,2

P

2

T

2

1 2 3

q

3

and T

3

are internal to the compressor and cannot be measured

Compressor control Menu Help

Derive a new surge parameter for compressor with

sidestream: q

r

N

e

Any combination of invariant parameters results in another

invariant parameter

Derive equation for surge parameter that does not require

measurement of T and q

r

at point 3

Step 1: Reduced flow

q

r

m

p

ZRT

=

.

.

where:

m = mass flow

Z = Compressibility

R = Gas constant

N

e

= Equivalent speed

q

r

= Reduced flow

N = Rotational speed

p = Pressure

T = Temperature

Step 2: Equivalent speed N

e

N

ZRT

=

Step 3: Combine q

r

and N

e

Fwd Previous Rew

q

r

N

e

m

p

ZRT

=

N

ZRT

.

.

m N

=

p

.

Compressor control Menu Help

Calculating the invariant parameter q

r

N

e

q

3

Ap

o,1

p

1

T

1

Ap

o,2

p

2

T

2

Fwd Previous Rew

m

1

.

m

2

.

(m

1

+ )

.

N

.

m

2

.

p

2

=

m

3

.

N

.

p

3

= N

A p

p

T

A p

p

T

N

p

e,3

1 o,1

1

1

2 o,2

2

2

2

=

+

|

\

|

.

|

|

\

|

.

|

|

(

(

(

(

(

(

A A

1 2 3

Compressor control Menu Help

r

Developing invariant surge patameter

R

c

vs. q

r

N

e

Fwd Previous Rew Compressor control Menu Help

The approach to surge is fast

Typically, performance curves are

extremely flat near surge

Even small changes in compressor

pressure differential cause large

flow changes.

The speed of approaching surge is

high. In only 0.4 seconds, AP

O

dropped by 14%, with a 2% change

in AP

c

P

d

Q

s

A

D

100%

0

100%

0

AP

c

100%

P

d

0

1 SEC.

AP

o

Fwd Previous Rew

A

C

D

B

A

C

B

Compressor control Menu Help

The approach to surge is fast - another example

For a 2% increase in pressure differential

(APc), flow rate AP

o

dropped 9% in 0.3 sec.

100%

0

0

AP

o

AP

c

100%

1 sec.

Fwd Previous Rew Compressor control Menu Help

Surge parameter based on invariant

coordinates R

c

and q

r

Flow measured in suction (AP

o

)

P

s

and P

d

transmitters used to

calculate R

c

Basic antisurge control system

Fwd Previous Rew Compressor control

1

UIC

VSDS

Compressor

1

FT

1

P

s

T

1

P

d

T

The antisurge controller UIC-1 protects the compressor against surge by

opening the recycle valve

Discharge Suction

R

c

q

r

2

Opening of the recycle valve lowers the resistance felt by the compressor

R

process

R

process+valve

This takes the compressor away from surge

Menu Help

Antisurge controller operation

Protection #1: The Surge Control Line (SCL)

Fwd Previous Rew

A

R

c

B

When the operating point

crosses the SCL, PI control

will open the recycle valve

PI control will give adequate

protection for small

disturbances

PI control will give stable

control during steady state

recycle operation

Slow disturbance example

SLL = Surge Limit Line

SCL = Surge Control Line

q

r

2

Compressor control Menu Help

Adaptive Gain

Enhancing the effectiveness of the PI controller

A

R

c

B

When the operating point

moves fast towards the SCL,

adaptive gain moves the SCL

towards the operating point.

This allows the PI controller

to react earlier

As a result a smaller steady

state surge control margin

can be achieved without

sacrificing reliability

Fast disturbance example

Fwd Previous Rew

q

r

2

Compressor control Menu Help

Antisurge controller operation

Protection #2: The Recycle Trip

Line (RTL)

Disturbance arrives the Operating

Point (OP) moves towards the SCL

Fwd Previous Rew

R

c

q

r

2

SLL = Surge Limit Line

RTL = Recycle Trip

Line

SCL = Surge Control Line

Output

to Valve

Time

When OP hits SCL the PI controller

opens valve based on proportional

and integral action

Operating point keeps moving

towards surge and hits Recycle

Trip Line (RTL)

When the operating point hits the

Recycle Trip Line (RTL) the

conclusion is:

We are close to surge

The PI controller is too slow to

catch the disturbance

Get out of the dangerous zone

An open loop response is

triggered

Operating point Moves back to the

safe side of the RTL

The RT function decays out the

step response

PI controller integrates to stabilize

OP on SCL

Recycle Trip

Response

PI Control Response

Total response of controller is the

sum of the PI control and Recycle

Trip action

PI Control

Recycle Trip

Action

+

To antisurge

valve

Total Response

Benefits:

Energy savings due to smaller

surge margin

Compressor has more turndown

before recycle or blow-off

Surge can be prevented for

virtually any disturbance

Compressor control Menu Help

Improving the accuracy of Recycle Trip

open loop control

Recycle Trip

is the most powerful method known for antisurge

protection

But, open loop control lacks the accuracy needed to precisely

position the antisurge valve

Open loop corrections of a fixed magnitude (C

1

) are often either too

big or too small for a specific disturbance

The rate of change (derivative) of the compressor operating point

has been proven to be an excellent predictor of the strength of the

disturbance and the magnitude required from the Recycle Trip

response

Therefore, the magnitude of actual step (C) of the Recycle Trip

response is a function of the rate of change of the operating point

or d(S

s

)/dt

Fwd Previous Rew Compressor control Menu Help

Recycle Trip

based on derivative of S

s

d(S

s

)

dt

C = C

1

T

d

Output

to valve

Time

where:

C = Actual step to the valve

C

1

= Constant - also defines maximum step

T

d

= Scaling constant

d(S

s

)/dt = Rate of change of the operating point

Medium disturbance

PI Control

Recycle Trip

Total

Large disturbance

Output

to valve

Time

PI Control

Recycle Trip

Total

Benefits

Maximum protection

No surge

No compressor damage

Minimum process disturbance

No process trips

Fwd Previous Rew

Recycle Trip

Response calculation

100%

0%

Compressor control Menu Help

What if one Recycle Trip

step response is not enough?

After time delay C

2

controller checks if Operating Point is back to

safe side of Recycle Trip

Line (RTL)

If Yes: Exponential decay of Recycle Trip

response

If No: Another step is added to the Recycle Trip

response

Fwd Previous Rew

Output

to valve

Time

One step response

PI Control

Recycle Trip

Total

100%

0%

C

2

Multiple step response

Output

to valve

Time

PI Control

Recycle Trip

Total

C

2

C

2

C

2

Compressor control Menu Help

Antisurge controller operation

Protection #3: The Safety On

Line (SOL)

If Operating Point crosses the Safety

On

Line the compressor is in surge

Fwd Previous Rew

R

c

q

r

2

SLL = Surge Limit Line

RTL = Recycle Trip

Line

SCL = Surge Control Line

The Safety On

response shifts the

SCL and the RTL to the right

New SCL

New RTL

Additional safety or surge margin is

added

Additional surge margin

PI control and Recycle Trip

will

stabilize the machine on the new SCL

SOL = Safety On

Line

Compressor can surge due to:

Transmitter calibration shift

Sticky antisurge valve or actuator

Partially blocked antisurge valve or

recycle line

Unusual large process upset

Benefits of Safety On

response:

Continuous surging is avoided

Operators are alarmed about surge

Compressor control Menu Help

Pressure and Flow Variations

During a Typical Surge Cycle

Built in surge detector

100%

100%

0%

0%

P

d

AP

o

20 to 50

milli-seconds

1 TO 2 SECONDS

Fwd Previous Rew

Surge signature is recorded during

commissioning

Rates of change for flow and pressure

during surge are determined

Thresholds are configured slightly more

conservative than the actual rates of

change during surge

Surge is detected when the actual rates of

change exceed the configured thresholds

The following methods can be used:

Rapid drops in flow and pressure

Rapid drop in flow or pressure

Rapid drop in flow only

Rapid drop in pressure only

When surge is detected a Safety On

response is triggered

A digital output can be triggered upon a

configurable number of surge cycles

Compressor control Menu Help

Increase compressor system reliability and

availability with fall-back strategies

Over 75% of the problems are in the field and not in the controller

The CCC control system has fall-back strategies to handle these field

problems

The controller continuously monitors the validity of its inputs

If an input problem is detected the controller ignores this input and

automatically switches to a fall-back mode

Benefits

Avoids nuisance trips

Alarms operator of latent failures

Increases machine and process availability

Fwd Previous Rew Compressor control Menu Help

Fall-back strategies for the antisurge and

performance controller

Antisurge controller

If a pressure transmitter fails, a minimum q

2

r

algorithm is used

If a temperature transmitter fails, h

r

is characterized as a function

of compression ratio

If the speed transmitter fails, a conservative speed setting is used

If the flow transmitter fails

Redundant transmitter is used

Output is driven to:

Last value OR

Last Value selected: If Last Value >Pre-selected fixed value OR

Pre-selected fixed value selected: If Pre-selected fixed value>Last

Value

Performance controller

Switches to redundant transmitter upon primary transmitter

failure

Output goes to pre-selected value if all transmitters fail or is

frozen

All transmitter failures are alarmed

Fwd Previous Rew Compressor control Menu Help

Output linearization

Controller

output

Flow rate

through

valve

For antisurge control a linear valve

is preferred

Linear valve gives the same

dynamic flow response over its

complete stroke

Existing valve has equal percentage

trim

Valve trim

equal percentage

Controller output is characterized as

mirror image in the linear valve line

Controller output

Dynamic flow response becomes

linear

Existing valve has quick opening

trim

Valve trim

quick opening

Controller output is characterized

as mirror image in the linear valve

line

Controller output

Dynamic flow response becomes

linear

Notes

Used to improve controllers operation when non-linear valves are

used

Used on retrofits to avoid additional investment in new valve

Works well with equal percentage characteristics

Works less satisfactory with quick opening characteristics

Fwd Previous Rew Compressor control Menu Help

The Tight Shut-off Line (TSL)

Controller

output

Flow rate

through

valve

Many antisurge valves have the

following characteristic:

from 0% to low clamp value the

flow rate through the valve is

(almost) zero and does not

change

Once the low clamp is reached

the characteristic is linear

Typical low clamp value can be

5% - we will use the 5% as the

value throughout in this example

0% to the valve

Low clamp on controller output

For dynamic control we want to use

the range 5% - 100% on the valve

Dynamic control range

The 5% or low clamp value represents

the closed position for control

purposes

At the low clamp value the valve

Usually still leaks which results

in energy waste

Makes an annoying noise

Typical for worn valves and valves

with Teflon seat

CCC antisurge controller has a Tight

Shut-off Line (TSL) that eliminates

the disadvantages

TSL = Tight Shut-off Line

When the operating point is to the

right of the TSL the controller closes

the valve at 0% - point A

This is below the low clamp value

A

A

When the controller crosses the TSL

the output of the controller jumps to

the low clamp value - point B

B

B

The controller is now ready to go

when the operating points hits the

SCL - point C

C

Fwd Previous Rew

R

c

q

r

2

SLL RTL

SCL

SOL

C

PI Control

Benefits

No leakage and noise when controller

is far away from surge - point A

Eliminates noise and energy waste

Eliminates dead time in the response

of the antisurge valve when the

operating point is close to the SCL

Time

Controller

output

Compressor control Menu Help

Compressor performance control

Also called:

Throughput control

Capacity control

Process control

Matches the compressor throughput to the load

Can be based on controlling:

Discharge pressure

Suction pressure

Net flow to the user

Fwd Previous Rew Compressor control Menu Help

Performance control by blow-off or recycle

Compressor operates in point A

P

d

q

r

2

Shaft

power

Fwd Previous Rew

q

r

2

Curve 1

A

R

process

+ R

valve

Required power in point A is P

1

Curve 1

P

1

Pressure is controlled by blow-off

PIC - SP

Point B represents the point that

would deliver the pressure for R

process

Curve 2

R

process

B

Required power in point B is P

2

Curve 2

P

2

PT

1

PIC

1

Process

Power loss is P

1

- P

2

Q

loss

represents energy waste

Q

loss

Notes

Most inefficient control method

Regularly found in plant air systems

Rare in other systems

Not recommended

Compressor control

Notes

Curve 2 represents:

Lower speed on variable speed

systems

IGVs closed on variable geometry

compressors

Inlet throttle valve closed on fixed

speed compressors

Menu Help

Performance control by discharge throttling

Compressor operates in point A

P

d

q

r

2

Shaft

power

Fwd Previous Rew

q

r

2

Curve 1

A

R

process

+ R

valve

Required power is P

1

Curve 1

P

1

Pressure is controlled by

pressure drop over valve

PIC - SP

Pressure loss

across valve

Opening of valve would reduce

resistance to R

process

R

process

Lower resistance would require

less speed and power

Curve 2

Curve 2

P

2

PT

1

PIC

1

Process

Power loss is P

1

- P

2

Notes

Extremely inefficient (consumes

approx. the same power for every load)

Rarely used

Not recommended

Compressor control

Notes

Curve 2 represents:

Lower speed on variable speed

systems

IGVs closed on variable geometry

compressors

Inlet throttle valve closed on fixed

speed compressors

Menu Help

Performance control by suction throttling

Inlet valve manipulates suction

pressure

P

d

q

r

2

Shaft

power

q

r

2

Changing suction pressure

generates a family of curves

Suction valve open

Suction valve throttled

Pressure is controlled by inlet

valve position

PIC - SP

Compressor operates in point A

for given R

process

A

R

process

Required power is P

1

P

1

PT

1

PIC

1

Process

Fwd Previous Rew

Notes

Common on electric motor machines

Much more efficient than discharge

throttling

Power consumed changes proportional

to the load

Throttle losses are across suction valve

Compressor control Menu Help

Performance control by adjustable guide vanes

Change of guide vanes angle o

results in different compressor

geometry

P

d

q

r

2

Shaft

power

q

r

2

Different geometry means

different performance curve

o

min

o

OP

o

max

Pressure is controlled by inlet

guide vane position

PIC - SP

Compressor operates in point A

for given R

process

A

R

process

Required power is P

1

P

1

PT

1

PIC

1

Process

Fwd Previous Rew

Notes

Improved turndown

More efficient than suction throttling

Power consumed is proportional to the

load

Power loss on inlet throttling is

eliminated

Compressor control Menu Help

Performance control by speed variation

Changing speed generates a

family of curves

P

d

q

r

2

Shaft

power

q

r

2

N

min

N

OP

N

max

Pressure is controlled by speed of

rotation

PIC - SP

Compressor operates in point A

for given R

process

A

R

process

Required power is P

1

P

1

PT

1

PIC

1

Process

Fwd Previous Rew

SIC

1

Notes

Most efficient (Power ~ f(N)

3

)

Steam turbine, gas turbine or variable

speed electric motor

Typically capital investment higher than

with other systems

No throttle losses

Compressor control Menu Help

Limiting control to keep the machine in its stable

operating zone

While controlling one primary variable, constrain the

performance control on another variable

CONTROL BUT DO NOT EXCEED

Discharge Pressure

Max. Motor Current

Suction Pressure

Max. Discharge Pressure

Net Flow

Min. Suction Pressure

Suction Pressure Max. Discharge Temperature

Exceeding limits will lead to machine or process damage

Performance controller controls one variable and can limit

two other variables.

Fwd Previous Rew Compressor control Menu Help

Power limiting in the performance controller

an example

Primary variable P

d

PIC-SP

Limiting variable Power

Power limit

Compressor operates in point

A for R

1

at N

1

N

1

A

R

1

Q

s, vol

R

c

Fwd Previous Rew

Process resistance changes

from R

1

to R

2

B

R

2

PIC will speed machine up to

N

2

in order to control pressure

P

d

N

2

Machine hits power limit

Compressor operates in point

B for R

2

at N

2

Process resistance decreases

further to R

3

R

3

PIC would like to speed

machine up to N

4

and operate

in point D

N

4

D

However power limiting loop

takes control and controls

machine at speed N

3

Compressor will operate in

point C for R

3

at N

3

N

3

C

Benefits

Maximum protection

No machinery damage

Maximize production

Machine can be pushed to the

limits without risk of damage

Note: Same approach for other variables (pressures, temperatures, etc.)

Compressor control Menu Help

Limiting P

s

or P

d

using the antisurge controller

1

UIC

VSDS

Compressor

1

FT

1

P

s

T

1

P

d

T

The antisurge controller can be configured to limit:

Maximum discharge pressure (P

d

)

Minimum suction pressure (P

s

)

Both maximum P

d

and minimum P

s

This does NOT conflict with antisurge protection

Fwd Previous Rew

Discharge Suction

Compressor control Menu Help

Interaction starts at B

Performance controller on

discharge pressure reduces

performance to bring

pressure back to setpoint

Unless prevented, PIC can

drive compressor to surge

Antisurge controller starts to

operate at B

Even if surge is avoided,

interaction degrades pressure

control accuracy

Results of interaction

Large pressure deviations

during disturbances

Increased risk of surge

Interacting antisurge and performance loops

A

C

AP

o

PIC-SP

R

c

P

s

Fwd Previous Rew

B

Compressor control Menu Help

The performance controller interacts with

the antisurge controller

Both controllers manipulate the same variable - the

operating point of the compressor

The controllers have different and sometimes

conflicting objectives

The control action of each controller affects the other

This interaction starts at the surge control line - near

surge - and can cause surge

Fwd Previous Rew Compressor control Menu Help

Ways to cope with antisurge and

performance loop interactions

De-tune the loops to minimize interaction. Result is

poor pressure control, large surge control margins and

poor surge protection

Put one loop on manual so interaction is not possible.

Operators will usually put the Antisurge Controller on

manual. Result - no surge protection and often partially

open antisurge valve

Decouple the interactions. Result - good performance

control accuracy, good surge protection and no energy

wasted on recycle or blow off

Fwd Previous Rew Compressor control Menu Help

Interacting antisurge control loops

Fwd Previous Rew Compressor control

1

PIC

2

UIC

R

c,2

q

r,2

2

R

R

c,1

q

r,1

2

R

Disturbance comes from the

discharge side

P

d,2

increases

P

s,2

remains constant

R

c,2

increases

Section 2 moves towards surge

Disturbance

R

Antisurge controller UIC-2 will open

the recycle valve to protect section 2

against surge

P

d,2

decreases

P

s,2

increases

R

c,2

decreases

Section 2 moves away from surge

Opening of recycle valve on section 2

caused P

s,2

= P

d,1

to increase

Result:

P

d,1

increases

P

s,1

remains constant

R

c,1

increases

Section 1 moves towards surge

1

UIC

VSDS

Section 1 Section 2

R

Antisurge controller UIC-1 will open

the recycle valve to protect section 1

against surge

P

d,1

decreases

P

s,1

increases

R

c,1

decreases

Section 1 moves away from surge

Opening of recycle valve on section 1

caused P

d,1

= P

s,2

to decrease

Result:

P

s,2

decreases

P

d,2

remains constant

R

c,2

increases

Section 2 moves towards surge

The system is oscillating

Slowing down the controller tuning would lead to:

Increased risk of surge

Compressor damage

Process trips

Bigger surge margins

Energy waste

Menu Help

Loop decoupling between multiple antisurge controllers

1

PIC

2

UIC

1

UIC

VSDS

Section 1 Section 2

Fwd Previous Rew Compressor control

All CCC controllers are connected on a serial network

Serial

network

Serial

network

This allows them to coordinate their control actions

When UIC-2 opens the recycle valve:

Section 2 will be protected against surge

Section 1 will be driven towards surge

How much section 1 is driven towards surge depends on how much the

recycle valve on section 2 is opened

The output of UIC-2 is send to UIC-1 to inform UIC-1 about the

disturbance that is arriving

UIC-1 anticipates the disturbance by immediately opening its valve

Note: The same applies when the antisurge

valve on section 1 is opened first Menu Help

Loop decoupling simplified block diagram

FA

Mode

PI RT

Loop

Decoupling

Antisurge

Controller 1

Analog Inputs

DEV1

Fwd Previous Rew Compressor control

FA

Mode

PI RT

Antisurge

Controller 2

Analog Inputs

DEV2

2

UIC

1

UIC

VSDS

Section 1 Section 2

Serial

network

Antisurge controller UIC-2 opens its valve to protect

section 2 against surge

To antisurge valve 2

+

UIC-1 is protecting section 1 against surge using PI

and Recycle Trip

+

To antisurge valve 1

UIC-2 reports PI and Recycle Trip

output to UIC-1 Loop decoupling block multiplies reported PI and

Recycle Trip

values with decoupling gain M

2

PI

2

.

M

2

+

RT

2

.

M

2

Loop decoupling value is added to output to

antisurge valve 1

+

Loop decoupling values of other controllers

(performance and antisurge) are added to output to

antisurge valve 1

From other

controllers

PI

n

.

M

n

+

RT

n

.

M

n

Each controller has its own decoupling gain M

n

to

allow for tuning of relative loop gains between

different controllers

UIC-1 reports its PI and Recycle Trip values to UIC-2

Same decoupling takes place

Loop

Decoupling

PI

1

.

M

1

+

RT

1

.

M

1

PI

n

.

M

n

+

RT

n

.

M

n

+

From other

controllers

Benefits

Avoids control system oscillations

Allows faster tuning of control system

Reduced risk of surge

Allows closer operation to surge limits

without taking risk

Menu Help

Compressor networks

Compressors are often operated in parallel and, less

frequently, in series

The purposes of networks include:

Redundancy

Flexibility

Incremental capacity additions

Usually, each compressor is controlled, but the network is

ignored

Compressor manufacturers often focus on individual

machines

Control of the network is essential to achieve good surge

protection and good performance control of the network

Fwd Previous Rew Compressor control Menu Help

Control system objectives

for compressors in parallel

Maintain the primary performance variable (pressure or flow)

Optimally divide the load between the compressors in the

network, while:

Minimizing risk of surge

Minimizing energy consumption

Minimizing disturbance of starting and stopping individual

compressors

Fwd Previous Rew Compressor control Menu Help

Process Flow Diagram for base load control

Process

PIC

1

1

UIC

VSDS

Compressor 1

2

UIC

VSDS

Compressor 2

HIC

1

Suction

header

Fwd Previous Rew

Swing machine

Base machine

Notes

All controllers act independently

Transmitters are not shown

Compressor control Menu Help

Parallel compressor control by base loading

R

c,1

q

r,1

2

R

c,2

q

r,2

2

Fwd Previous Rew

Compressor 1 Compressor 2

Machines operate at same R

c

since suction and discharge of both

machines are tied together

PIC-SP

Base load one or more compressors and let the other(s) absorb the

load swings

Swing machine Base machine

Base machine is fully loaded and runs without recycle

Q

C,2

=

Q

P,2

Swing machine can be running with recycle

Q

C,1

Q

P,1

where:

Q

P

= Flow to process

Q

C

= Total compressor flow

Q

C

- Q

P

= Recycle flow

Load could be re-divided to eliminate recycle

Q

P,1

Q

P,2

Q

P,1

+

Q

P,2

= Q

P,1

+

Q

P,2

Notes

Base loading is inefficient

Base loading increases the risk of surge since

compressor #1 will take the worst of any disturbance

Base loading requires frequent operator intervention

Base loading is NOT recommended

Compressor control Menu Help

Process Flow Diagram for equal flow division

Process

PIC

1

1

UIC

VSDS

Compressor 1

VSDS

Compressor 2

Suction

header

Fwd Previous Rew

Notes

Performance controllers act

independent of antisurge control

Higher capital cost due to extra

Flow Measurement Devices (FMD)

Higher energy costs due to

permanent pressure loss across

FMDs

1

FIC

2

FIC

2

UIC

out

out

RSP

RSP

out

RSP

Compressor control Menu Help

Parallel compressor control by equal flow division

R

c,1

q

r,1

2

R

c,2

q

r,2

2

Fwd Previous Rew

Compressor 1 Compressor 2

Machines operate at same R

c

since suction and discharge of both

machines are tied together

PIC-SP

Machine 2 operates with recycle while machine 1 still has turn

down

Q

P,1

Q

P,2

Q

C,2

Equal flow Equal flow

Q

P,1

=

Q

P,2

where:

Q

P

= Flow to process

Q

C

= Total compressor flow

Q

C

- Q

P

= Recycle flow

Equal flow division might work if both machines are identical Machines are never identical except by coincidence - different

resistance due to piping arrangments

Bias relay on remote setpoint would only work if curves have

same steepness

Notes

Requires additional capital investment in FMDs

Requires additional energy due to permanent pressure

loss across FMDs

Poor pressure control due to positive feedback in

control system (see next)

Equal flow division is NOT recommended

Compressor control Menu Help

Dynamic control problem with pressure to flow

cascade system

Fwd Previous Rew

q

r

2

R

c

N

1

N

3

N

2

Pressure controller (PIC) provides

Remote SetPoint (RSP) for Flow

controller (FIC)

PIC

1

OUT

RSP

FIC

1

The FIC provides the RSP for the

speed controller, suction throttle

valve or guide vanes

OUT

RSP

SIC

1

The PIC is the master and the FIC is

the slave

Master Slave

In a typical master-slave control

scheme the slave needs to be

approx. 5 times faster than the

master

A

The machine is operating in point A

This is the intersection of 4 lines:

Resistance line R

1

Performance curve N

1

PIC-SP

FIC-SP = Output of PIC

R

1

PIC-SP

FIC-SP

Process disturbance causes the

resistance to change from R

1

to R

2

R

2

As a result the machine moves to

point B

B

Since the PIC is slow it does not

move its output yet which is the FIC-

SP

The FIC reacts fast and will try to

maintain its SP

The FIC will speed up the machine to

point C at speed N

3

C

The disturbance is amplified

Positive feedback system

Only as the PIC starts to reduce its

output to control pressure the FIC-

SP comes down and the pressure is

restored

D

Notes

Requires additional capital

investment in FMDs

Requires additional energy due to

permanent pressure loss across

FMDs

Poor pressure control due to positive

feedback in control system

Equal flow division is NOT

recommended

Compressor control Menu Help

Process Flow Diagram for equidistant control for

parallel compressors

Process

1

UIC

VSDS

Compressor 1

VSDS

Compressor 2

Suction

header

Fwd Previous Rew

Notes

All controllers are coordinating

control responses via a serial

network

Minimizes recycle under all

operating conditions

1

LSIC

2

UIC

out

RSP

Serial

network

out

RSP

2

LSIC

1

MPIC

Serial

network

Serial

network

Compressor control Menu Help

Parallel compressor control by equidistant operation

R

c,1

q

r,1

2

R

c,2

q

r,2

2

Fwd Previous Rew

Compressor 1 Compressor 2

Machines operate at same R

c

since suction and discharge of both

machines are tied together

PIC-SP

The DEV is a dimensionless number representing the distance between the

operating point and the Surge Control Line

Lines of equal DEV can be plotted on the performance curves as shown

.1

.2

.3

DEV = 0

.1

.2

.3

Machines are kept at the same relative distance to the Surge Control Line

(SCL)

This means in practice the same DEV for both machines

DEV

1

DEV

2

Recycle will only start when all machines are on their SCL

Since DEV is dimensionless all sorts of machines can be mixed: small,

big, axials, centrifugals

The DEV will be the same for all machines but they will operate at

different speeds and flow rates

SCL = Surge Control Line

Dev

1

= Dev

2

Q

1

=

Q

2

N

1

= N

2

Notes

Maximum turndown (energy savings) without recycle or blow-off

Minimizes the risk of surge since all machines absorb part of the

disturbance

Automatically adapts to different size machines

CCC patented algorithm

Compressor control Menu Help

Compressors in parallel - the primary response

Master Controller

Loadsharing

Controller

Loop

Decoupling

FA

Mode

PI RT

Loop

Decoupling

+

Antisurge

Controller

Fwd Previous Rew

Analog Inputs

+

DEV

To antisurge valve To performance

control element

Master controller controls the main Process

Variable (PV) via its PID control block

PID

PV

SP

The output of the master controller PID goes

to the primary response block in the

loadsharing controller

Primary

response

In the primary response block the controller

checks if the machine is close to the SCL:

Yes: dont reduce capacity - keep output

constant

No: reduce capacity as necessary

Apply loadsharing gain M

0

The output of the master controller goes via

the primary response block directly to the

performance control element

DEV > 0

Dont change

output

x

Yes

No

Apply loadsharing

gain

To performance

control element

Primary response

In order to check if the machine is close to

the SCL the primary response block needs

the DEV

The DEV is reported by the antisurge

controller

DEV DEV

When the machine is close to the SCL the

master controller will no longer reduce

performance to control the primary variable

The master controller will start to open the

recycle valve to control the primary variable

Primary

response

If DEV <= 0 apply loadsharing gain

Output goes to antisurge valve

DEV < 0

Dont change

output

x

Yes

No

Apply loadsharing

gain

To antisurge valve

Primary response

Compressor control Menu Help

The load balancing response

Master Controller

Loadsharing

Controller

Loop

Decoupling

FA

Mode

PI RT

Loop

Decoupling

+

Antisurge

Controller

Fwd Previous Rew

Analog Inputs

+

DEV

To antisurge valve To performance

control element

The fast master controller controls the

primary process variable by directly

manipulating the final control elements

PID

In order to balance the machines they need

to be kept at the same DEV

The antisurge controller reports the actual

DEV to the load balancing block in the

loadsharing controller

This reported DEV becomes the Process

Variable (PV) for the load balancing PID

loop

Load

balancing

PV

PV

SP

Primary

response

The loadsharing controller reports this

DEV PV also to the master controller

DEV DEV

D

E

V

Other loadsharing controllers also report

their DEV PV to the master controller

DEV from other

loadsharing controllers

Primary

response

The master controller calculates the

average of all reported DEV PVs

Average

This average DEV is sent out to all

loadsharing controllers to become the SP

for all load balancing blocks

SP

The load balancing block is a slow

controller that will equalize all DEVs for all

parallel compressors

Its output is added to the total output to

the performance control element

Compressor control Menu Help

The Pressure Override Control (POC) response

Master Controller

Loadsharing

Controller

Loop

Decoupling

Load

balancing

FA

Mode

PI RT

Loop

Decoupling

+

Antisurge

Controller

Fwd Previous Rew

Analog Inputs

Average

+

SP PV

DEV from other

loadsharing controllers

DEV

D

E

V

To antisurge valve To performance

control element

When a large disturbance occurs it can

happen that the performance control

element (e.g. speed) is too slow to keep the

pressure under control

PID

PV

SP

The operating point rides the curve and the

pressure rises sharply

Primary

response

There is a high chance to exceed the relief

valve setting and trip the process

The CCC master controller has a Pressure

Override Control (POC) mode that will open

the antisurge valve to get the disturbance

under control quickly

DEV DEV

POC-SP

PI

(One-Sided)

SP

PV

Opening of the antisurge valve is much

faster than a reduction in speed

As soon as the operating point drops under

the POC-SP line the antisurge valves start

to close again

Primary

response

The primary PID loop will stabilize the

operating point on the PIC-SP line

R

c

q

r

2

PIC-SP

Relief valve

setting

Benefits

Fast response during fast upsets

Avoid process trips due to lack of

response in performance control elements

Allows closer operation to process limits

without taking risk

Compressor control Menu Help

Loadsharing for multi-section compressors

Process

1A

UIC

VSDS

Section 1

VSDS

Section 1

Suction

Header

Fwd Previous Rew

A

LSIC

out

RSP

Serial

network

RSP

B

LSIC

1

MPIC

Serial

network

Serial

network

Section 2

Section 2

2A

UIC

1B

UIC

1B

UIC Serial

network

Serial

network

out

Train B

Train A

How to operate equidistant from the Surge Control Line (SCL) when there is

more than one section per machine ???

Select per train -- in the loadsharing controller -- the section closest to the

SCL

By selecting the section closest to the SCL it is guaranteed that the other

section on the same train is not in recycle

Share the load -- equal DEVs for both trains -- on the section closest to the

SCL

Compressor control Menu Help

Selecting the section closest to SCL for parallel operation

Master Controller

Loadsharing

Controller

Loop

Decoupling

Load

balancing

FA

Mode

PI RT

Loop

Decoupling

+

Antisurge

Controller

Fwd Previous Rew

Analog Inputs

Average

+

SP PV

DEV from other

loadsharing controllers

DEV1

To antisurge valve-1 To performance

control element

PID

PV

SP

Primary

response

DEV1 DEV2

Both antisurge controllers

report their DEV to the

loadsharing controller

PI

(One-Sided)

SP

PV

Primary

response

FA

Mode

PI RT

Loop

Decoupling

+

Antisurge

Controller

DEV2

To antisurge valve-2

Primary

response

The lowest DEV is selected:

the section closest to the

SCL

<

The selected DEV is

reported to:

Primary control

response blocks

Load balancing block

Master controller

averaging block

Compressor control Menu Help

Flow Measuring Device (FMD) selection criteria

Main selection criteria for FMD in antisurge control system:

Repeatability

Sufficient signal-to-noise ratio

Accuracy of the FMD is not critical

FMD delays must be absolutely minimal

Present state-of-the-art limits the choice of FMD to head flow meters

or to other devices that are based on the principle of velocity

measurement:

Orifice plates

Venturis

Pitot tubes

etc.

Recommended flow range for FMD and transmitter is maximum

compressor flow

Recommended Ap corresponding to Q

max, compressor

is 10 WC (250

mmH

2

O) or more

Fwd Previous Rew Compressor control Menu Help

Flow Measuring Device (FMD) location

Fwd Previous Rew

The preferred location of the FMD:

Suction of compressor

As close to the inlet flange as

possible

VSDS

Compressor

Discharge Suction

minimum possible

Less preferable location of the FMD:

Discharge of compressor

As close to the discharge flange as

possible

minimum possible

Selection of the location should be based on:

Necessity of surge detection

Often more difficult with flow measured in discharge

Capital cost of flow measuring device

Operating cost of the FMD (permanent pressure loss)

Compressor control Menu Help

Response time of the FMD transmitter

The speed of approaching surge is high

Fwd Previous Rew

100%

0

100%

0

APc

100%

Ps

0

1 SEC.

APo

A

C

D

B

A

C B

In only 400 ms, AP

O

dropped by 14%,

with a 2% change in AP

c

The transmitter type and brand should be

selected based on two major factors:

Reliability

Speed of response

Desired rise time for Ap (flow) transmitters

is 200 ms or less

Pressure step is 100%

The first order response (63%) is less

than 200 ms

Time

Actual

pressure

Transmitter

output

63% response

1- (1/e)

t

1

is less than 200 ms

Desired rise time for pressure transmitters

is 500 ms or less

Compressor control Menu Help

The effect of damping the Ap

o

(flow) transmitter

Knowing the flow is essential to determine the distance between the

operating point and the SCL

Damping the Ap

o

(flow) transmitter destroys essential information

50

0

-50

0

1.25 2.50 3.75 5

Time (seconds)

Fwd Previous Rew

Flow

Start of Surge

Actual Flow

t = 16.0 s

t = 1.70 s

t = 0.20 s

t = 0.03 s

Damping the Ap

o

(flow) transmitter can paralyze the

complete antisurge control system!!!

Compressor control Menu Help

Sizing the antisurge control valve

Criteria for antisurge valve sizing based on CCCs experience

Provide adequate antisurge protection for worst possible disturbances

Provide adequate antisurge protection in all operating regimes

Sized to provide flow peaks greater than what is required in steady state to

operate on the Surge Control Line

Sized to avoid choke zone

Not be oversized from controllability point of view

Fwd Previous Rew

Take point A at the intersection of the

maximum speed performance curve and

the Surge Limit Line (SLL)

Calculate C

v,calc

(or equivalent) for point A

Select standard valve size using the

following criteria:

1.8

.

C

v, calc

< C

v,selected

< 2.2

.

C

v, calc

R

c

Q

vol

A

Compressor control Menu Help