Final Sample

Final Sample

Uploaded by

Joshua ArrojoCopyright:

Available Formats

Final Sample

Final Sample

Uploaded by

Joshua ArrojoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Final Sample

Final Sample

Uploaded by

Joshua ArrojoCopyright:

Available Formats

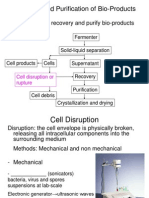

DOWNSTREAM

PROCESSING

INTRODUCTION

The extraction and purification of a biotechnological product

from fermentation is referred to as Downstream Processing

(DPS) or Product Recovery

Downstream processing mainly refers to the recovery and

purification of biosynthetic products, particularly

pharmaceuticals, from natural sources such as animal or plant

tissue or fermentation broth, including the recycling of

salvageable components and the proper treatment and

disposal of waste.

It is an essential steps in the manufacture of pharmaceuticals

such as antibiotic, hormones (e.g. insulin and human growth

hormone), antibodies (e.g. infliximab and abciximab) and

vaccines; antibodies and enzyme used in diagnostics;

industrial enzymes; and natural fragrance and flavor

compounds.

STAGES IN DOWNSTREAM PROCESSING

SOLID-LIQUID SEPARATION

The first step in product recovery is the separation

of whole cells (biomass) and other insoluble

ingradients from the culture broth.

Several methods for solid-liquid separation are:

Flotation

Flocculation

Filtration

Centrifugation

FLOTATION

When a gas is introduced into the liquid broth it

forms bubbles. The cells an other solid particles get

adsorbed on the gas bubbles. These gas bubbles

rise to the foam layer which can be collected and

removed.

FLOCCULATION

In the flocculation the cells for cell debrise from

large aggregates to settle down for easy removal.

The process of flocculation depends on the nature

of cells and the ionic constituents of the medium.

Addition of flocculating agents (inorganic salt

organic polyelectrolyte, mineral hydrocolloid is often

necessary to achieve appropriate flocculation.

FILTRATION

Filtration is the most commonly used technique for

separating the biomass and culture filtrate.

The efficiency of filtration depends on many factors-

the size of organism, presence of other organism,

viscosity of the medium and temperature. Several

filters such as:

Depth filters

Absolute filters

Rotary drum vacuum filters

CENTRIFUGATION

Use of the centrifugal force foe the separation of

mixtures

More-dense components migrate away from the

axis of the centrifuge

Less-dense components migrate toward the axis

CENTRIFUGATION

DECANTER CENTRIFUGE

RELEASE OF INTRACELLULAR PRODUCT

Cell Disruption: Cell disruption is a method or

process for releasing biological molecules from the

inside a cell. The main aim is that the disruption

must be effective and the method should not be too

harsh so that the product recovered remains in its

active form.

Cell disrupted by three methods:

Physical method

Chemical method

Enzymatic method

PHYSICAL METHOD

Physical method such as:

Mechanical:

Ultrasonication

High-pressure homogenisation

Impigment

Grinding with glass beads

Non-mechanical:

Osmotic Shock

Heat shock

ULTRASONICATION

It is common laboratory-scale method for cell

disruption applies ultrasound (typically 20-50 kHz)

to the sample (sonication). In principle, the high

frequency is generated electronically and the

mechanical energy is transmitted to the sample via

a metal probe that oscillates with high frequency.

The probe is placed into the cell-containing sample

and the high-frequency oscillation causes a

localized low pressure region resulting in cavitation

and impaction, ultimately breaking open the cells.

HIGH-PRESSURE HOMOGENISATION

The high-pressure homogeniger consists of a

positive displacement piston pump with one or

more plungers. The cell suspension is drawn

through a check vale into the pump cylinder and, on

the pressure stroke, is forced through an adjustable

discharge valve with restricted orifice.

IMPINGEMENT

In this procedure, a stream of suspended cells at

high velocity and pressure are forced to hit either a

stationary surface or a second stream of

suspended cells (impinge literally mean to stroke or

hit). The cell are disrupted by the forces created at

the point of contact Microfluidizer is a device

developed based on the principle of impingement.

GRINDING WITH GLASS BEADS

The cells mixed with glass beads are subjected to

a very high speed in a reaction vessel. The cells

break as they are forced against the wall of the

vessel by the beads.

OSMOTIC SHOCK

This method involves the suspension of cells (free

from growth medium) in 20% buffered sucrose. The

cell are then transferred to water at about 4 C.

Osmotic shock is used for the release of hydrolytic

enzymes and binding proteins gram negative

bacteria.

HEAT SHOCK

Breakage of cells by subjecting them to heat is

relatively easy and cheap. But this tech. can be

used only for a very few heat stable intracellular

products.

CHEMICAL METHOD

Treatment with alkalies, organic solvents and

detergents can lyse the cells to release the

contents.

ENZYMATIC METHOD

Cells desruption by enzymatic method has certain

advantages i.e., lysis of cells occurs under mild

conditions in selective manner.

CONCENTRATION

The filtrate that is free from suspended particles (cells,

cell debris etc.) usually 80-90% of water. The desired

product is a very minor constituent. The water has to be

removed to achieved the product concentration.

The methods for concentrating biological products by:

Evaporation

Liquid-liquid extraction

Membrane filtration

Precipitation and adsorption

The actual procedure adopted depends on the nature of

the desired product and cost of factor.

PURIFICATION

The biological products of fermentation are very

effectively purified by chromatography. It is basically

an analytical technique dealing with the separation

of closely related compounds from a mixture.

FORMULATION

Formulation broadly refers to the maintenance of

activity and stability of biotechnolical product during

storage and distribution. The formulation of low

molecular weight products (solvents and organic

products) can be achieved by concentrating them

with removal of most of the water. For certain small

molecules, (antibiotic, critic acid), formulation can

be done by crystallization by adding salts.

REFERENCES

U. Satyanarayana, Biotechnology; Downstream

Processing, pg no: 270-280.

http:google.com/images

You might also like

- Upstream and Downstream ProcessesDocument52 pagesUpstream and Downstream ProcessesRonald Tyson100% (3)

- Bioreactor 2020 PPT PDFDocument76 pagesBioreactor 2020 PPT PDFAbrar Ali Sitab100% (3)

- Down Stream ProcessingDocument15 pagesDown Stream ProcessingChithra ChandranNo ratings yet

- Downstream ProcessingDocument20 pagesDownstream ProcessingDrishti MalhotraNo ratings yet

- Rajalakshmi Engineering College, Thandalam Department of Biotechnology Finalyear-Vii Semester Sec A&B Bt-2401 Downstream ProcessingDocument54 pagesRajalakshmi Engineering College, Thandalam Department of Biotechnology Finalyear-Vii Semester Sec A&B Bt-2401 Downstream ProcessingsumiNo ratings yet

- 160 16SCCBT8 2020052605345882Document25 pages160 16SCCBT8 2020052605345882jeevalakshmanan29No ratings yet

- Cell DisruptionDocument14 pagesCell DisruptionAathira AjeeshNo ratings yet

- Recovery and Purification of Intracellular and Extra Cellular ProductsDocument25 pagesRecovery and Purification of Intracellular and Extra Cellular ProductsGanesh V Gaonkar100% (1)

- Unit Operation & Unit Process in BiotechnologyDocument52 pagesUnit Operation & Unit Process in BiotechnologyKailash Kumar100% (1)

- Downstream ProcessingDocument53 pagesDownstream ProcessingNaevisweloveuNo ratings yet

- Lec5.Recovery and Purification of Fermentation ProductsDocument26 pagesLec5.Recovery and Purification of Fermentation Productsannaduraipillai50% (2)

- Downstream ProcessingDocument5 pagesDownstream ProcessingLuis Hernandez AlvarezNo ratings yet

- Recovery and Purification of Bio-ProductsDocument26 pagesRecovery and Purification of Bio-ProductsAmrie Iam100% (2)

- Downstream Processing (DSP) of ProductsDocument5 pagesDownstream Processing (DSP) of Productsjeevalakshmanan29No ratings yet

- Biosep Short OverviewDocument9 pagesBiosep Short OverviewMeyakorberNo ratings yet

- Presentation1 22Document24 pagesPresentation1 22Hadia ShahidNo ratings yet

- Cell Disruption Techquines: By: Ritika SharmaDocument20 pagesCell Disruption Techquines: By: Ritika SharmaArup ChakrabortyNo ratings yet

- Downstream Processing: Reported By: Angela Marie M. DiwaDocument20 pagesDownstream Processing: Reported By: Angela Marie M. DiwaAngela Miranda DiwaNo ratings yet

- Lab Report - 12b239Document11 pagesLab Report - 12b239santhanalaxmi karthikvelNo ratings yet

- Upstream and Downstream Processing UpdatedDocument20 pagesUpstream and Downstream Processing UpdatedSara AsgharNo ratings yet

- Chapter 10Document59 pagesChapter 10MADHUMITHRA KUGANESANNo ratings yet

- Cell DisruptionDocument62 pagesCell DisruptionSreejesh P C100% (3)

- Biopharmaceuticals Chapter 3-2023Document75 pagesBiopharmaceuticals Chapter 3-2023Anh NguyễnNo ratings yet

- Organic Chemistry: Basra University College of Science and Technology Pharmacy DepartmentDocument10 pagesOrganic Chemistry: Basra University College of Science and Technology Pharmacy DepartmentcrtgyhujikNo ratings yet

- Extraction of Plant MaterialDocument14 pagesExtraction of Plant Materialsb00163100% (2)

- Downstream ProcessingDocument45 pagesDownstream ProcessingRelyboy de Fiesta100% (2)

- Chap9 Downstream ProcessingDocument25 pagesChap9 Downstream ProcessingsadatrafiaNo ratings yet

- The Recovery and Purification of Fermentation ProductsDocument30 pagesThe Recovery and Purification of Fermentation ProductsputriNo ratings yet

- Purification of ProteinsDocument17 pagesPurification of ProteinsArrianne Jaye Mata100% (1)

- AssignmentFile 867 05092023144343Document11 pagesAssignmentFile 867 05092023144343Prince DograNo ratings yet

- BTH 401 AssignmentDocument15 pagesBTH 401 AssignmentMelissa lhingnunhoi SimteNo ratings yet

- Module 1Document22 pagesModule 1aathiraNo ratings yet

- Bioseperation 12Document47 pagesBioseperation 12César D. Ybarra MeléndezNo ratings yet

- BCH 415-Lecture Note 2023Document23 pagesBCH 415-Lecture Note 2023Saheed DanielNo ratings yet

- Aspergillus Niger Citric Acid Lactobacillus Delbruckii Lactic Acid Lactobacillus Shirota Strain YakultDocument6 pagesAspergillus Niger Citric Acid Lactobacillus Delbruckii Lactic Acid Lactobacillus Shirota Strain YakultRoxan Bueno MoraNo ratings yet

- " Seperation Process": Seminar OnDocument28 pages" Seperation Process": Seminar OnKabilanNo ratings yet

- Bio ReactorsDocument8 pagesBio ReactorsSomya SomuNo ratings yet

- Bioprocess Technology in The Genomics EraDocument35 pagesBioprocess Technology in The Genomics EraYuvaraj KingNo ratings yet

- Immobilization of Cell and EnzymesDocument13 pagesImmobilization of Cell and Enzymesjefina agnesNo ratings yet

- Downstream ProcessingDocument36 pagesDownstream Processingjeevalakshmanan29No ratings yet

- Methods To Study Cell BiochemistryDocument13 pagesMethods To Study Cell BiochemistryShahnaz AhmedNo ratings yet

- ATC Lab Set UpDocument84 pagesATC Lab Set UpKrithika BalasubramanianNo ratings yet

- Tissue Processing For TEM: Fixation, Rinsing, Dehydration and EmbeddingDocument30 pagesTissue Processing For TEM: Fixation, Rinsing, Dehydration and EmbeddingBhaskar Ganguly100% (1)

- Word MtoDocument7 pagesWord MtoAvani TaiwadeNo ratings yet

- Downstream ProcessingDocument4 pagesDownstream ProcessingVachaspatiMishraNo ratings yet

- Primary SeparationDocument34 pagesPrimary SeparationPia CabatinganNo ratings yet

- Water Analysis LabDocument22 pagesWater Analysis LabJeremy100% (1)

- Protein Isolation and PurificationDocument14 pagesProtein Isolation and PurificationZiauddin Azimi100% (1)

- Downstream ProcessDocument40 pagesDownstream ProcessVamsi KrishnaNo ratings yet

- Cell Disruption Extracting Target Product: Location of Biological ProductsDocument88 pagesCell Disruption Extracting Target Product: Location of Biological ProductsRoshan jaiswalNo ratings yet

- Ptt203 Recovery and Purification of ProductsDocument33 pagesPtt203 Recovery and Purification of ProductsEmier VillanuevaNo ratings yet

- A) State and Describe Various Stages of A Biodegradation StudyDocument6 pagesA) State and Describe Various Stages of A Biodegradation StudyAbdulkadir AlbabaNo ratings yet

- Conventional & Modern Extraction TechniquesDocument17 pagesConventional & Modern Extraction Techniquesmithilshah66.msNo ratings yet

- The Water Purification Process 2Document4 pagesThe Water Purification Process 2Yue YingNo ratings yet

- DSP Step 3, 4,, 5 2022Document26 pagesDSP Step 3, 4,, 5 2022AshwiniNo ratings yet

- Bio SepDocument55 pagesBio SepPooja Singh JainNo ratings yet

- Some Terms of Purification Methods' in ChemistryDocument8 pagesSome Terms of Purification Methods' in ChemistryMd.Mehdi MasudNo ratings yet

- BioproductsDocument41 pagesBioproductschristina raju100% (1)

- 3.2 Cell LysisDocument19 pages3.2 Cell LysisAstra BeckettNo ratings yet

- HIV-1 Reverse TranscriptaseDocument3 pagesHIV-1 Reverse TranscriptaseJoshua ArrojoNo ratings yet

- DWSIM Flash Algorithm AboutDocument6 pagesDWSIM Flash Algorithm AboutJoshua ArrojoNo ratings yet

- 200lb Pig Produces 13lbs Manure/day Density of Pig Manure Approximately 108 LB/FTDocument2 pages200lb Pig Produces 13lbs Manure/day Density of Pig Manure Approximately 108 LB/FTJoshua ArrojoNo ratings yet

- Sample Problem 16 PDFDocument9 pagesSample Problem 16 PDFJoshua Arrojo100% (1)

- OmanDocument10 pagesOmanJoshua ArrojoNo ratings yet

- Seq. NO. Name Helix StrandDocument13 pagesSeq. NO. Name Helix StrandJoshua ArrojoNo ratings yet

- Energy of The StripperDocument1 pageEnergy of The StripperJoshua ArrojoNo ratings yet

- Work SkillsDocument2 pagesWork SkillsJoshua ArrojoNo ratings yet

- Report (Hist003)Document1 pageReport (Hist003)Joshua ArrojoNo ratings yet

- Assignment Chep 353l1Document4 pagesAssignment Chep 353l1Joshua Arrojo100% (3)

- Zeosil - Dados TécnicosDocument9 pagesZeosil - Dados Técnicossamuk171No ratings yet

- Rebar Steel Bar Detail For Grade 1Document29 pagesRebar Steel Bar Detail For Grade 1talatzahoorNo ratings yet

- Evaluation Exam 9Document7 pagesEvaluation Exam 9Michael MercadoNo ratings yet

- Buckling of Thin Metal Shells 152Document1 pageBuckling of Thin Metal Shells 152pawkomNo ratings yet

- Automated Operation of Topsoe Steam Reformers LTMDocument8 pagesAutomated Operation of Topsoe Steam Reformers LTMrajuNo ratings yet

- Material Product Data Sheet Metcolite Grits: Quick FactsDocument3 pagesMaterial Product Data Sheet Metcolite Grits: Quick Factsfrdn100% (1)

- Foam Behaviour of An Aqueous Solution of Piperazine Nmethyldiethanolamine Mdea Blend As A Function of The Type of Impurities and ConcentrationsDocument6 pagesFoam Behaviour of An Aqueous Solution of Piperazine Nmethyldiethanolamine Mdea Blend As A Function of The Type of Impurities and ConcentrationsFraz RizviNo ratings yet

- Experimental Study of Water Wetting in Oil Water Two Phase Flow - JCaiDocument11 pagesExperimental Study of Water Wetting in Oil Water Two Phase Flow - JCaiSyafiqah IsmailNo ratings yet

- Biochemical MeasurementsDocument25 pagesBiochemical Measurementsulaga nathanNo ratings yet

- PolybitpolyprimeDocument2 pagesPolybitpolyprimerazeeth1212No ratings yet

- Nanosized Magnesium Doped Copper Chromites Spinel Particles Synthesis and CharacterizationDocument7 pagesNanosized Magnesium Doped Copper Chromites Spinel Particles Synthesis and CharacterizationSikander AzamNo ratings yet

- Energy Balnce For Unsteady State SystemsDocument39 pagesEnergy Balnce For Unsteady State SystemsAbdulRehman VirkNo ratings yet

- Skee 1063 Week 11 EmosfetDocument13 pagesSkee 1063 Week 11 EmosfetMuhammad HafizNo ratings yet

- ដំណើរការផលិតទឹកស្អាត - English PDFDocument13 pagesដំណើរការផលិតទឹកស្អាត - English PDFKhmer Spider GamingNo ratings yet

- Fundamental Nature and Family of Materials: Relationship With Other ScienceDocument2 pagesFundamental Nature and Family of Materials: Relationship With Other ScienceAnore James IvanNo ratings yet

- Band GapDocument6 pagesBand GapAnonymous 5C0YOjvNo ratings yet

- General Chemistry Module 18Document20 pagesGeneral Chemistry Module 18Junelle Ramos AquinoNo ratings yet

- Hydro FormingDocument17 pagesHydro FormingvengadeshNo ratings yet

- Coatings 12 00533 v2Document14 pagesCoatings 12 00533 v2DewiNo ratings yet

- ACI 334.3R-05 - Construction of Concrete Shells Using Inflated FormsDocument13 pagesACI 334.3R-05 - Construction of Concrete Shells Using Inflated FormsGgcs ConStruct100% (2)

- Permeometro - 1Document6 pagesPermeometro - 1Hassan RodriguezNo ratings yet

- Influence of Vane Size and Equipment On The Results in The Vane Shear TestDocument7 pagesInfluence of Vane Size and Equipment On The Results in The Vane Shear TestNabucodonosor1980No ratings yet

- Metric Handbook Planning and Design Data PDFDocument8 pagesMetric Handbook Planning and Design Data PDFAhmed NabilNo ratings yet

- PMRDA BOQ Inquiry With ScopeDocument8 pagesPMRDA BOQ Inquiry With ScopeAkd DeshmukhNo ratings yet

- Polyvinyl-Chloride (PVC) Externally Coated Galvanized Rigid Steel Conduit and Intermediate Metal ConduitDocument5 pagesPolyvinyl-Chloride (PVC) Externally Coated Galvanized Rigid Steel Conduit and Intermediate Metal ConduitVICENTENo ratings yet

- Laser Beam MEACHINING PPT Final 2Document16 pagesLaser Beam MEACHINING PPT Final 2hari ananthagiri67% (3)

- Section 10 QuestionsDocument6 pagesSection 10 QuestionsSameer MohammadNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- Buffer SolutionsDocument2 pagesBuffer SolutionsEki MegaraniNo ratings yet