100%(1)100% found this document useful (1 vote)

49 viewsPermanent Magnet DC Motor

Permanent Magnet DC Motor

Uploaded by

Jesse Jones Seraspe- The permanent magnet DC motor uses magnets to produce field flux instead of field windings, giving it excellent starting torque and good speed regulation but limiting the load it can drive.

- Common permanent magnet materials are Alnico, ferrites, and rare earth magnets like neodymium.

- Applications include computers, toys, portable tools, appliances like toothbrushes and vacuums, electric vehicles, and industrial motors.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Permanent Magnet DC Motor

Permanent Magnet DC Motor

Uploaded by

Jesse Jones Seraspe100%(1)100% found this document useful (1 vote)

49 views7 pages- The permanent magnet DC motor uses magnets to produce field flux instead of field windings, giving it excellent starting torque and good speed regulation but limiting the load it can drive.

- Common permanent magnet materials are Alnico, ferrites, and rare earth magnets like neodymium.

- Applications include computers, toys, portable tools, appliances like toothbrushes and vacuums, electric vehicles, and industrial motors.

Original Title

R

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

- The permanent magnet DC motor uses magnets to produce field flux instead of field windings, giving it excellent starting torque and good speed regulation but limiting the load it can drive.

- Common permanent magnet materials are Alnico, ferrites, and rare earth magnets like neodymium.

- Applications include computers, toys, portable tools, appliances like toothbrushes and vacuums, electric vehicles, and industrial motors.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

100%(1)100% found this document useful (1 vote)

49 views7 pagesPermanent Magnet DC Motor

Permanent Magnet DC Motor

Uploaded by

Jesse Jones Seraspe- The permanent magnet DC motor uses magnets to produce field flux instead of field windings, giving it excellent starting torque and good speed regulation but limiting the load it can drive.

- Common permanent magnet materials are Alnico, ferrites, and rare earth magnets like neodymium.

- Applications include computers, toys, portable tools, appliances like toothbrushes and vacuums, electric vehicles, and industrial motors.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 7

Permanent Magnet DC Motor

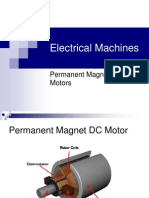

The Permanent Magnet DC Motor (also known as a PMDC motor) consists of an armature winding

as in case of an usual motor, but does not necessarily contain the field windings. The

construction of these types of DC motor are such that, radially magnetized permanent magnets

are mounted on the inner periphery of the stator core to produce the field flux.

• The permanent magnet motor uses a magnet to supply field flux.

• Permanent magnet DC motors have excellent starting torque capability with good speed regulation.

• A disadvantage of permanent magnet DC motors is they are limited to the amount of load they can

drive. These motors can be found on low horsepower applications.

• Another disadvantage is that torque is usually limited to 150% of rated torque to prevent

demagnetization of the permanent magnets.

Types of Permanent Magnet Materials

• There are three types of Permanent Magnet Materials used in PMDC Motor. The detailed

information is given below.

• Alnicos

- Alnicos has a low coercive magnetizing intensity and high residual flux density. Hence, it is

used where low current and high voltage is required.

• Ferrites

- They are used in cost sensitive applications such as Air conditioners, compressors, and

refrigerators.

• Rare earths

- Rare earth magnets are made of Samarium cobalt, neodymium-iron-boron. They have a high

residual flux and high coercive magnetizing intensity. The rare earth magnets are exempted

from demagnetizing problems due to armature reaction. It is an expensive material.

> The Neodymium iron boron is cheaper as compared to Samarium cobalt. But it can withstand

higher temperature. Rare earth magnets are used for size-sensitive applications. They are used

in automobiles, servo industrial drives and in large industrial motors.

Applications of the Permanent Magnet DC Motor

• The PMDC motors are used in various applications ranging from fractions

to several horsepower. They are developed up to about 200 kW for use in

various industries. The following applications are given below.

• PMDC motors are mainly used in automobiles to operate windshield

wipers and washers, to raise the lower windows, to drive blowers for

heaters and air conditioners etc.

• They are also used in computer drives.

• These types of motors are also used in toy industries.

• PMDC motors are used in electric toothbrushes, portable vacuum

cleaners, food mixers.

• Used in a portable electric tool such as drilling machines, hedge trimmers

etc.

DC Series Motor

- The DC Series Motor is similar to any other motor because the main function of this

motor is to convert electrical energy to mechanical energy. The operation of this motor

mainly depends on the electromagnetic principle. Whenever the magnetic field is formed

approximately, a current carrying conductor cooperates with an exterior magnetic field,

and then a rotating motion can be generated.

* In a series DC motor the field is connected in

series with the armature.The field is wound with

a few turns of large wire because it must carry

the full armature current.

* A characteristic of series motors is the motor

develops a large amount of starting torque.

However, speed varies widely between no load

and full load. Series motors cannot be used

where a constant speed is required under

varying loads.

* Series-connected motors generally are not suitable for use on most variable

speed drive applications.

DC Series Motor Advantages

• The advantages of the DC series motor include the following.

• Vast starting torque

• Easy assembly and simple design

• Protection is easy

• Cost-effective

DC Series Motor Disadvantages

• The disadvantages of DC series motor include the following.

• The motor speed regulation is fairly poor. When the load speed increases then the machine

speed will decrease

• When the speed is increased, then the DC series motor’s torque will be decreased sharply.

• This motor always needs the load before running the motor. So these motors are not suitable

for where the motor’s load is totally removed.

Compound

Motors

- Compound motors have a field connected in series with the armature and a

separately excited shunt field. The series field provides better starting

torque and the shunt field provides better speed regulation.

Briefly, we can say that Dc compound motor

is a combination of both a shunt wound Dc

motor and series wound Dc motor which

means that compound motor has the

advantage of high starting torqueand efficient

speed regulation so it can be used in

industrial applications include: Drivers,

Freight elevators, Stamping Presses, Rolling

mills, Mixers, Reciprocating machines, And

metal shears.

END

You might also like

- MRI Made Easy 2nd Ed - Govind B. Chavhan - JaypeeDocument229 pagesMRI Made Easy 2nd Ed - Govind B. Chavhan - Jaypeeunicornfeels79% (29)

- Klein 3e CH 15 Testbank FINALDocument76 pagesKlein 3e CH 15 Testbank FINALMareline MendietaNo ratings yet

- Relation Between Input and Output Voltage and Number of Turns in The Secondary Coil and Primary Coil of A Self Designed TransformerDocument22 pagesRelation Between Input and Output Voltage and Number of Turns in The Secondary Coil and Primary Coil of A Self Designed TransformerBharati patil63% (19)

- Classification of MotorSDocument17 pagesClassification of MotorSHumaid Shaikh50% (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Workshop II 1Document20 pagesWorkshop II 1Tesfahun AntenehNo ratings yet

- Module 2 - DC Motor DrivesDocument61 pagesModule 2 - DC Motor DrivesMohammad Amirul Shafiq100% (1)

- Classification of Electric Motors: Electrical Motors Basic ComponentsDocument89 pagesClassification of Electric Motors: Electrical Motors Basic ComponentsSarada Sankar DasNo ratings yet

- Permanent Magnet DC MotorDocument4 pagesPermanent Magnet DC MotorPulkit ChaudhariNo ratings yet

- PMDC MotorDocument2 pagesPMDC MotorAdnan KhanNo ratings yet

- Sigma Institute of Engineering Department of Electrical Engineering Bakrol, VadodaraDocument52 pagesSigma Institute of Engineering Department of Electrical Engineering Bakrol, VadodaraBhavik PrajapatiNo ratings yet

- DC MotorsDocument2 pagesDC Motorsmateobobby112502No ratings yet

- BLDCDocument4 pagesBLDCabhik DasNo ratings yet

- DC MotorDocument6 pagesDC MotorUjjawal ParasarNo ratings yet

- Unit 2 - EDDocument42 pagesUnit 2 - EDMohit L.E. 008No ratings yet

- Presentation 8QUIJANO FLORI AN PAQUERODocument5 pagesPresentation 8QUIJANO FLORI AN PAQUEROQUIJANO, FLORI-AN P.No ratings yet

- Permanent Magnet DC MotorsDocument25 pagesPermanent Magnet DC MotorsShreyansh Vishwakarma100% (1)

- Types of DC Motors Notes Electric DrivesDocument77 pagesTypes of DC Motors Notes Electric DrivesJyothish VijayNo ratings yet

- Advantages and Disadvantages of DC MotorDocument6 pagesAdvantages and Disadvantages of DC MotorMuhd Izwan Ikhmal RosliNo ratings yet

- EM ch-9 DC MOTORS AND GENERATORSDocument65 pagesEM ch-9 DC MOTORS AND GENERATORSmuhammad.anas2007No ratings yet

- Task 4Document33 pagesTask 4Vishnu SasidharanNo ratings yet

- Hercules M. Biacoraelectrical-MachinesDocument8 pagesHercules M. Biacoraelectrical-MachinesBiacora Manalo HerculesNo ratings yet

- DC MotorDocument45 pagesDC MotorRayz C.ONo ratings yet

- Electric Motor: Types of MotorsDocument8 pagesElectric Motor: Types of MotorsPlutoNo ratings yet

- Different Types of Special Motors: ServomotorDocument5 pagesDifferent Types of Special Motors: ServomotorYoussef SamehNo ratings yet

- 6 Motor Basics HandoutDocument18 pages6 Motor Basics HandoutTan Yit KeongNo ratings yet

- Types of DC MotorsDocument5 pagesTypes of DC MotorsRolen GeocadinNo ratings yet

- Dcmotor 121120082910 Phpapp01Document11 pagesDcmotor 121120082910 Phpapp01Faheem IjazNo ratings yet

- Permanent Magnet DC MotorDocument3 pagesPermanent Magnet DC Motorayie94_fox8792No ratings yet

- MotorsDocument16 pagesMotorsHassan Iftekhar AhmedNo ratings yet

- Permanent Magnet Synchronous MotorDocument30 pagesPermanent Magnet Synchronous Motormyresearchworkeee2023No ratings yet

- HMRD - Single Phase AC Motor DiscussionDocument10 pagesHMRD - Single Phase AC Motor DiscussionRika HernandezNo ratings yet

- Motor IqDocument4 pagesMotor IqPaul HkloNo ratings yet

- Group 6 - DC Motors PDFDocument22 pagesGroup 6 - DC Motors PDFRashen DilNo ratings yet

- Ev & HVDocument9 pagesEv & HVsuhas2002kulkarniNo ratings yet

- AC and DC MotorDocument13 pagesAC and DC MotorrikechNo ratings yet

- What Are The Basic Parts of An Induction Motor?Document6 pagesWhat Are The Basic Parts of An Induction Motor?purbasha kanchan ghoshNo ratings yet

- 4 Types of DC Motors and Their CharacteristicsDocument5 pages4 Types of DC Motors and Their CharacteristicsNuno HenriquesNo ratings yet

- Iam PPT FHD MotorsDocument25 pagesIam PPT FHD MotorsShreeNo ratings yet

- 6 Motor Basics HandoutDocument18 pages6 Motor Basics Handoutmaherianto 29No ratings yet

- Electrical Machines2Document11 pagesElectrical Machines2ARVINDNo ratings yet

- All Types of Motors Used in Electric TractionDocument3 pagesAll Types of Motors Used in Electric TractionMöstafa MohamedNo ratings yet

- DC MotorDocument3 pagesDC MotorShubham AgrawalNo ratings yet

- Types of DC MotorsDocument6 pagesTypes of DC MotorsErwin Lobiano BalduezaNo ratings yet

- The Advantages and Hazards of DC MotorsDocument6 pagesThe Advantages and Hazards of DC MotorsGalco IndustrialNo ratings yet

- Kaizen - Motor Selection GuideDocument11 pagesKaizen - Motor Selection GuideAmory Sabri AsmaroNo ratings yet

- Ev Engine ResearchDocument15 pagesEv Engine ResearchAnshul YadavNo ratings yet

- Permanent Magnet DC Motor or PMDC MotorDocument4 pagesPermanent Magnet DC Motor or PMDC MotorRushikesh WandhekarNo ratings yet

- A PM Motor Does Not Have A Field Winding On The Stator FrameDocument4 pagesA PM Motor Does Not Have A Field Winding On The Stator FrameAnfield FaithfulNo ratings yet

- Parts of An Electric VehicleDocument12 pagesParts of An Electric Vehiclearvin jay sumbongNo ratings yet

- Universal MotorDocument4 pagesUniversal MotorNeofito Victor RodriguesNo ratings yet

- Cam Operated HammerDocument52 pagesCam Operated HammerSRL MECH100% (1)

- Types of Ac GeneratorDocument10 pagesTypes of Ac GeneratorJherel BerinNo ratings yet

- BLDC MotorsDocument45 pagesBLDC Motorswicked_not_meNo ratings yet

- Presentation On Motors & VFD: Submitted To:-Submitted ByDocument32 pagesPresentation On Motors & VFD: Submitted To:-Submitted Byparth dosi100% (1)

- Direct Current (DC) Motors: OperationDocument6 pagesDirect Current (DC) Motors: OperationckyprianouNo ratings yet

- Electrical Science-2: Term Paper of Ele102Document7 pagesElectrical Science-2: Term Paper of Ele102shailesh singhNo ratings yet

- Term Paper On DC MotorDocument4 pagesTerm Paper On DC Motorc5qfb5v5100% (1)

- Permanent Magnet DC Commutator MotorDocument20 pagesPermanent Magnet DC Commutator MotorPavan KumarNo ratings yet

- Name Roll No Class: Arbaz Mulla 216 Joule's (Group 3)Document9 pagesName Roll No Class: Arbaz Mulla 216 Joule's (Group 3)Alex WarnerNo ratings yet

- SM Unit 3 Universal MotorDocument10 pagesSM Unit 3 Universal MotorlokoNo ratings yet

- Kaizen - Motor Selection GuideDocument10 pagesKaizen - Motor Selection GuideKarrar HussainNo ratings yet

- Two-Stroke Mastery: Beginner's Guide to Repairing and Maintaining Small EnginesFrom EverandTwo-Stroke Mastery: Beginner's Guide to Repairing and Maintaining Small EnginesNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Runge Kutta MethodDocument3 pagesRunge Kutta MethodJesse Jones SeraspeNo ratings yet

- Ecological ConceptsDocument2 pagesEcological ConceptsJesse Jones SeraspeNo ratings yet

- Presidential Decree No. 979: WhereasDocument21 pagesPresidential Decree No. 979: WhereasJesse Jones SeraspeNo ratings yet

- Characteristics of Electrical DrivesDocument17 pagesCharacteristics of Electrical DrivesJesse Jones SeraspeNo ratings yet

- Special Electrical MachineDocument15 pagesSpecial Electrical MachineJesse Jones SeraspeNo ratings yet

- Basic Principles of Synchronous Motor OperationDocument16 pagesBasic Principles of Synchronous Motor OperationJesse Jones SeraspeNo ratings yet

- This Study Resource Was: Refrigeration HW #1 Due Date: 9/29/2016Document1 pageThis Study Resource Was: Refrigeration HW #1 Due Date: 9/29/2016Jesse Jones SeraspeNo ratings yet

- Methods, Processes and Equipment of Size Reduction of SolidsDocument12 pagesMethods, Processes and Equipment of Size Reduction of SolidsJesse Jones SeraspeNo ratings yet

- What Is A Storage Silo?Document2 pagesWhat Is A Storage Silo?Jesse Jones SeraspeNo ratings yet

- What Is Solid?Document5 pagesWhat Is Solid?Jesse Jones SeraspeNo ratings yet

- Conveying System: Industrial ProcessesDocument10 pagesConveying System: Industrial ProcessesJesse Jones SeraspeNo ratings yet

- Two Processes: SteelmakingDocument15 pagesTwo Processes: SteelmakingJesse Jones SeraspeNo ratings yet

- Pacakaging Processes and EquipmentsDocument4 pagesPacakaging Processes and EquipmentsJesse Jones SeraspeNo ratings yet

- What Is Plastic?: Manufacturing Processes For PlasticsDocument2 pagesWhat Is Plastic?: Manufacturing Processes For PlasticsJesse Jones SeraspeNo ratings yet

- Rubber and Its Equipments: Rubbers Are Loosely Described As Materials Which Show "Elastic" Properties. TheseDocument2 pagesRubber and Its Equipments: Rubbers Are Loosely Described As Materials Which Show "Elastic" Properties. TheseJesse Jones SeraspeNo ratings yet

- Series Motors: by Engr. John Joseph A. TolentinoDocument38 pagesSeries Motors: by Engr. John Joseph A. TolentinoJhi Ghi RawringNo ratings yet

- Electrical Machines I Assignment 2Document2 pagesElectrical Machines I Assignment 2Aina MwadhinaNo ratings yet

- Lab Report 2Document5 pagesLab Report 2KEZIA MAE JALANDONINo ratings yet

- ASD CSDX SFC Synchronous Reluctance MotorDocument23 pagesASD CSDX SFC Synchronous Reluctance MotorAldhair Perseo Oliva EscobedoNo ratings yet

- DC WindingDocument49 pagesDC Windingdivya158775% (4)

- Electrical Machines1 PDFDocument178 pagesElectrical Machines1 PDFnivashini a0% (1)

- Complete 1H and 13C NMR Spectral Assignment of D-GlucofuranoseDocument6 pagesComplete 1H and 13C NMR Spectral Assignment of D-Glucofuranosegordana1988No ratings yet

- Modelling and Simuation of BLDC Motor in MATLAB GUIDocument5 pagesModelling and Simuation of BLDC Motor in MATLAB GUIvishiwizardNo ratings yet

- Energy Losses inDocument33 pagesEnergy Losses insuman dahalNo ratings yet

- Trafoindo Catalogue Instrument TransformersDocument6 pagesTrafoindo Catalogue Instrument TransformersHeryNo ratings yet

- Ex501 Electrical Machines Ii: Unit-I D.C. Machine-IDocument25 pagesEx501 Electrical Machines Ii: Unit-I D.C. Machine-IDeependra SinghNo ratings yet

- 02 - Machine Dynamics - Lec2 - DC Motor2Document25 pages02 - Machine Dynamics - Lec2 - DC Motor2Ahmed ArfaNo ratings yet

- Brushless DC Motor Design PDFDocument3 pagesBrushless DC Motor Design PDFtejas9280No ratings yet

- Masilang - Experiment 1 - DynamoDocument8 pagesMasilang - Experiment 1 - DynamoPHILIPANTHONY MASILANGNo ratings yet

- PP3 PDFDocument42 pagesPP3 PDFLeTung95No ratings yet

- Laboratory Final Practical Exam: Pamantasan NG Cabuyao College of Computing and EngineeringDocument3 pagesLaboratory Final Practical Exam: Pamantasan NG Cabuyao College of Computing and EngineeringKrizalene ResurreccionNo ratings yet

- 3phase Induction Motor PrincipleDocument23 pages3phase Induction Motor Principleoutreach constructions100% (1)

- Hall Effect Sensor Placement For Permanent Magnet Brushless DC MotorsDocument4 pagesHall Effect Sensor Placement For Permanent Magnet Brushless DC Motorsmarco.dado2700No ratings yet

- Group Assignment 2Document12 pagesGroup Assignment 2saumya desaiNo ratings yet

- Three Phase Induction MotorDocument3 pagesThree Phase Induction Motor780ANAY GUPTANo ratings yet

- MRI Parameters and OptionsDocument10 pagesMRI Parameters and Optionsjitendra guptaNo ratings yet

- Three-Phase Induction Motor: Instructional ObjectivesDocument33 pagesThree-Phase Induction Motor: Instructional Objectiveskricks92No ratings yet

- Electric Motors Total Source 2006Document20 pagesElectric Motors Total Source 2006MMM-MMMNo ratings yet

- Type of NC SystemDocument20 pagesType of NC Systemamit kumarNo ratings yet

- NMR SpectrosDocument1 pageNMR SpectrosFaiza SibtainNo ratings yet