09 eurammon symposium_2017_herunter_dujardin_f3

- 1. Schaffhausen, 22nd / 23rd June, 2017 Page 1 eurammon Symposium 2017 Water- and Air Cooled Chiller with Propane R-290 Johann Herunter, Frigopol Kälteanlagen GmbH Kevin Dujardin, Alpiq InTec West AG Schaffhausen, 22nd/23rd June, 2017

- 2. Schaffhausen, 22nd / 23rd June, 2017 Page 2 Cooperation Frigopol and Alpiq • since 2014 • Main focus is on water and air cooled chiller solutions with natural refrigerants • Total range between 20KW – 1,5MW • Range with R290 from 20KW -340KW • Special solutions on demand Frigopol and Alpiq

- 3. Schaffhausen, 22nd / 23rd June, 2017 Page 3 Part 1: (presented by Johann Herunter) 1. Reminder about „Phase Down Scenario“ 2. Technical features with R290 3. Safety Concept 4. Water - Cooled Chillers 5. Air -Cooled Chillers 6. Applications & Examples Agenda

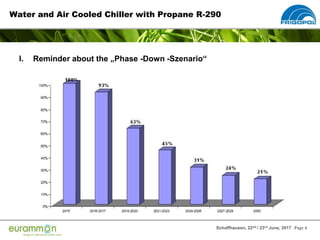

- 4. Schaffhausen, 22nd / 23rd June, 2017 Page 4 Water and Air Cooled Chiller with Propane R-290 I. Reminder about the „Phase -Down -Szenario“

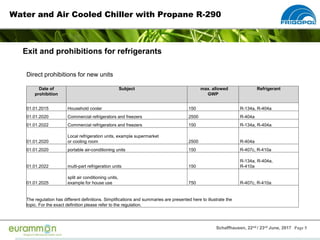

- 5. Schaffhausen, 22nd / 23rd June, 2017 Page 5 Exit and prohibitions for refrigerants Direct prohibitions for new units Date of prohibition Subject max. allowed GWP Refrigerant 01.01.2015 Household cooler 150 R-134a, R-404a 01.01.2020 Commercial refrigerators and freezers 2500 R-404a 01.01.2022 Commercial refrigerators and freezers 150 R-134a, R-404a 01.01.2020 Local refrigeration units, example supermarket or cooling room 2500 R-404a 01.01.2020 portable air-conditioning units 150 R-407c, R-410a 01.01.2022 multi-part refrigeration units 150 R-134a, R-404a, R-410a 01.01.2025 split air conditioning units, example for house use 750 R-407c, R-410a The regulation has different definitions. Simplifications and summaries are presented here to illustrate the topic. For the exact definition please refer to the regulation. Water and Air Cooled Chiller with Propane R-290

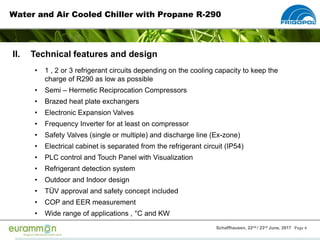

- 6. Schaffhausen, 22nd / 23rd June, 2017 Page 6 II. Technical features and design • 1 , 2 or 3 refrigerant circuits depending on the cooling capacity to keep the charge of R290 as low as possible • Semi – Hermetic Reciprocation Compressors • Brazed heat plate exchangers • Electronic Expansion Valves • Frequency Inverter for at least on compressor • Safety Valves (single or multiple) and discharge line (Ex-zone) • Electrical cabinet is separated from the refrigerant circuit (IP54) • PLC control and Touch Panel with Visualization • Refrigerant detection system • Outdoor and Indoor design • TÜV approval and safety concept included • COP and EER measurement • Wide range of applications , °C and KW Water and Air Cooled Chiller with Propane R-290

- 7. Schaffhausen, 22nd / 23rd June, 2017 Page 7 Machine room Electric cabinet Water Cooled Chiller with refrigerant R-290 III. Safety Concept

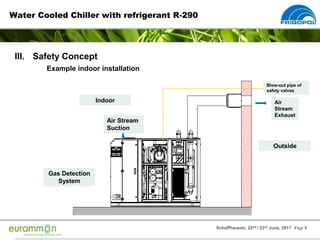

- 8. Schaffhausen, 22nd / 23rd June, 2017 Page 8 Indoor Blow-out pipe of safety valves Outside Air Stream Exhaust Air Stream Suction Water Cooled Chiller with refrigerant R-290 III. Safety Concept Example indoor installation Gas Detection System

- 9. Schaffhausen, 22nd / 23rd June, 2017 Page 9 Water Cooled Chiller with refrigerant R-290 IV. Water – Cooled Chillers „Energy Station“ for heating, cooling and sanitary water Indoor Unit Outdoor Unit

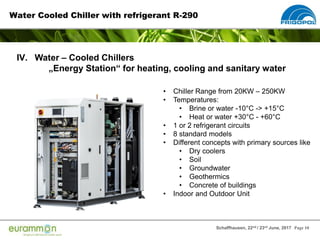

- 10. Schaffhausen, 22nd / 23rd June, 2017 Page 10 IV. Water – Cooled Chillers „Energy Station“ for heating, cooling and sanitary water • Chiller Range from 20KW – 250KW • Temperatures: • Brine or water -10°C -> +15°C • Heat or water +30°C - +60°C • 1 or 2 refrigerant circuits • 8 standard models • Different concepts with primary sources like • Dry coolers • Soil • Groundwater • Geothermics • Concrete of buildings • Indoor and Outdoor Unit Water Cooled Chiller with refrigerant R-290

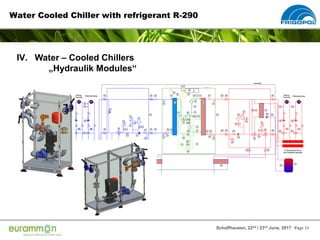

- 11. Schaffhausen, 22nd / 23rd June, 2017 Page 11 IV. Water – Cooled Chillers „Hydraulik Modules“ Water Cooled Chiller with refrigerant R-290

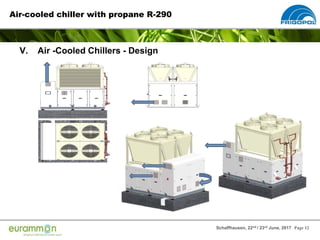

- 12. Schaffhausen, 22nd / 23rd June, 2017 Page 12 V. Air -Cooled Chillers - Design Air-cooled chiller with propane R-290

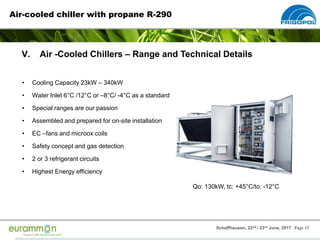

- 13. Schaffhausen, 22nd / 23rd June, 2017 Page 13 • Cooling Capacity 23kW – 340kW • Water Inlet 6°C /12°C or –8°C/ -4°C as a standard • Special ranges are our passion • Assembled and prepared for on-site installation • EC –fans and microox coils • Safety concept and gas detection • 2 or 3 refrigerant circuits • Highest Energy efficiency V. Air -Cooled Chillers – Range and Technical Details Qo: 130kW, tc: +45°C/to: -12°C Air-cooled chiller with propane R-290

- 14. Schaffhausen, 22nd / 23rd June, 2017 Page 14 • Aircooled Chiller, R-290, Qo: 180kW, tc: +45°C / to: -19°C VI. Examples and Applications „DAIRY – AUSTRIA“ Air-cooled chiller with propane R-290

- 15. Schaffhausen, 22nd / 23rd June, 2017 Page 15 Compact energy station for process water cooling 40kW / brine -10°C and Air conditioning at 180kW / brine +6°C 15 Redundant execution Cooling Water temperature +35°C Refrigerant charge 1 x 5,7kg und 2 x per circle 11kg Power control 25-100% Example: Meat Factory with 2 redundant units 40kW and 180kW Air-cooled chiller with propane R-290

- 16. Schaffhausen, 22nd / 23rd June, 2017 Page 16 eurammon Symposium 2017 Water- und Air Cooled Chiller with Propane R-290 – Part 2 Mr. Kevin Dujardin – Alpiq InTec Schweiz AG Schaffhausen, 22nd/23rd June, 2017

- 17. Schaffhausen, 22nd / 23rd June, 2017 Page 17 Table of Contents 1. Brief Alpiq introduction A. As an Actor in cooling systems B. Our Commitment in natural refrigerant 2. The fruit of our Commitment A. Partnership B. Our Propane Chiller 3. Project reference „Lüthi & Portmann“ A. Lüthi & Portmann needs B. Why Propane C. Pictures

- 18. Schaffhausen, 22nd / 23rd June, 2017 Page 18 Brief Alpiq introduction As an Actor in cooling systems CommercialSupermarket Small Commerce • Migros • Coop • Aldi • Lidl • Prodega • Growa • Howeg • … • Restaurant and Hotel • Hospital, Homes and Panel institutions • Bakeries, Butcheries and Flowers Shop • Convenience Shop’s • Research Institute and Laboratories • … • Plug and play cooling cabinet • Plug and play cold rooms • Ice machines • …

- 19. Schaffhausen, 22nd / 23rd June, 2017 Page 19 Brief Alpiq introduction As an Actor in cooling systems Industry Air Conditioning After Sales Service • Logistic center • Cold and Freezer Hall • Food and production Industry • Chemical Industry • Ice Rink • … • Data Centers • Offices, Houses and Retail spaces • Production rooms • … • 24/7/365 • Customer Service • Maintenance • Remote monitoring • …

- 20. Schaffhausen, 22nd / 23rd June, 2017 Page 20 Brief Alpiq introduction Our Commitment in natural refrigerant R744 – As a reference for Supermarket technology 2003 : First CO2 Subcritical Unit in Switzerland 2006 : First CO2 Transcritical Cascade Unit in Switzerland 2009 : First CO2 Transcritical Booster in Switzerland R717 – As a reference for Industry high cooling power Technology Active since 2009 in Ammonia Heat pump Technology References from 300kW to 3MW Specialty such as Valorization of Waste Water Energy R290 – As a new Reference for the future small to mid-size Units We have a strategy !

- 21. Schaffhausen, 22nd / 23rd June, 2017 Page 21 The fruit of our Commitment Partnership Since 2014, we are working together with Frigopol Kälteanlagen GmbH as Partner in Switzerland to push our new Technology with Natural Refrigerants.

- 22. Schaffhausen, 22nd / 23rd June, 2017 Page 22 The fruit of our Commitment Our Propane Chiller Alpiq InTec Schweiz AG and Frigopol GmbH has developed a new product range for mid-size Industry Propane Chiller. Power Range from 40 to 350kW for Glycol from +6°C to -15°C.

- 23. Schaffhausen, 22nd / 23rd June, 2017 Page 23 Project reference Meat Products – Lüthi & Portmann AG

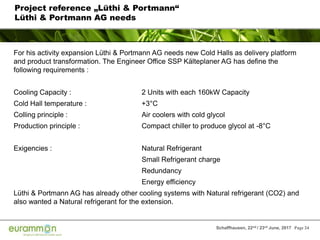

- 24. Schaffhausen, 22nd / 23rd June, 2017 Page 24 Project reference „Lüthi & Portmann“ Lüthi & Portmann AG needs For his activity expansion Lüthi & Portmann AG needs new Cold Halls as delivery platform and product transformation. The Engineer Office SSP Kälteplaner AG has define the following requirements : Cooling Capacity : 2 Units with each 160kW Capacity Cold Hall temperature : +3°C Colling principle : Air coolers with cold glycol Production principle : Compact chiller to produce glycol at -8°C Exigencies : Natural Refrigerant Small Refrigerant charge Redundancy Energy efficiency Lüthi & Portmann AG has already other cooling systems with Natural refrigerant (CO2) and also wanted a Natural refrigerant for the extension.

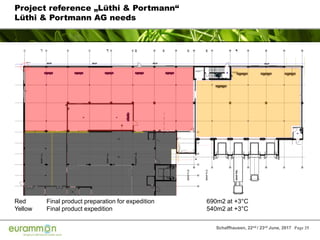

- 25. Schaffhausen, 22nd / 23rd June, 2017 Page 25 Red Final product preparation for expedition 690m2 at +3°C Yellow Final product expedition 540m2 at +3°C Project reference „Lüthi & Portmann“ Lüthi & Portmann AG needs

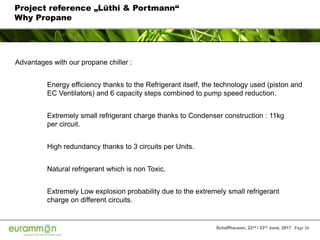

- 26. Schaffhausen, 22nd / 23rd June, 2017 Page 26 Project reference „Lüthi & Portmann“ Why Propane Advantages with our propane chiller : Energy efficiency thanks to the Refrigerant itself, the technology used (piston and EC Ventilators) and 6 capacity steps combined to pump speed reduction. Extremely small refrigerant charge thanks to Condenser construction : 11kg per circuit. High redundancy thanks to 3 circuits per Units. Natural refrigerant which is non Toxic. Extremely Low explosion probability due to the extremely small refrigerant charge on different circuits.

- 27. Schaffhausen, 22nd / 23rd June, 2017 Page 27 Project reference „Lüthi & Portmann“ Pictures

- 28. Schaffhausen, 22nd / 23rd June, 2017 Page 28 Project reference „Lüthi & Portmann“ Pictures

- 29. Schaffhausen, 22nd / 23rd June, 2017 Page 29 Project reference „Lüthi & Portmann“ Pictures

- 30. Schaffhausen, 22nd / 23rd June, 2017 Page 30 Project reference „Lüthi & Portmann“ Pictures

- 31. Schaffhausen, 22nd / 23rd June, 2017 Page 31 We thank you for your attention! Please do not hesitate to contact us for further information!

- 32. Schaffhausen, 22nd / 23rd June, 2017 Page 32 Contact: Frigopol Kälteanlagen GmbH Gamserstraße 21, 8523 Frauental Austria +43/3462/70000 +43/3462/70000-50 office@frigopol.com