bottom-up methods.pptx

- 1. Author: Hashami Muhammad Student of Master In NCTs 2023 Obtaining nanoparticles with Bottom up approach Kazakh National Named Al- Farabi University

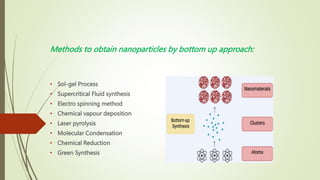

- 2. 1. Bottom up approach means small to big (i.e. nanoparticles are made from atoms or molecules by self assembly. Atoms/molecules CVlusters Nanoparticles Obtaining nanoparticles with Bottom up approach

- 3. Methods to obtain nanoparticles by bottom up approach: • Sol-gel Process • Supercritical Fluid synthesis • Electro spinning method • Chemical vapour deposition • Laser pyrolysis • Molecular Condensation • Chemical Reduction • Green Synthesis

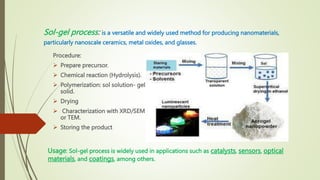

- 4. Sol-gel process: is a versatile and widely used method for producing nanomaterials, particularly nanoscale ceramics, metal oxides, and glasses. Usage: Sol-gel process is widely used in applications such as catalysts, sensors, optical materials, and coatings, among others. Procedure: Prepare precursor. Chemical reaction (Hydrolysis). Polymerization: sol solution- gel solid. Drying Characterization with XRD/SEM or TEM. Storing the product

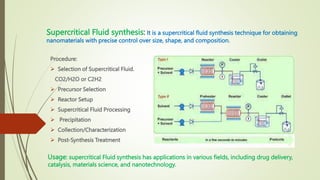

- 5. Supercritical Fluid synthesis: It is a supercritical fluid synthesis technique for obtaining nanomaterials with precise control over size, shape, and composition. Procedure: Selection of Supercritical Fluid. CO2/H2O or C2H2 Precursor Selection Reactor Setup Supercritical Fluid Processing Precipitation Collection/Characterization Post-Synthesis Treatment Usage: supercritical Fluid synthesis has applications in various fields, including drug delivery, catalysis, materials science, and nanotechnology.

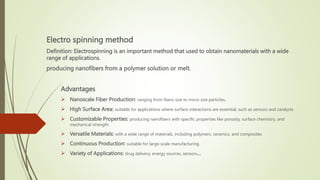

- 6. Electro spinning method Definition: Electrospinning is an important method that used to obtain nanomaterials with a wide range of applications. producing nanofibers from a polymer solution or melt. Advantages Nanoscale Fiber Production: ranging from Nano size to micro size particles. High Surface Area: suitable for applications where surface interactions are essential, such as sensors and catalysts. Customizable Properties: producing nanofibers with specific properties like porosity, surface chemistry, and mechanical strength. Versatile Materials: with a wide range of materials, including polymers, ceramics, and composites Continuous Production: suitable for large-scale manufacturing. Variety of Applications: drug delivery, energy sources, sensors…

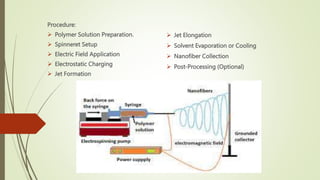

- 7. Procedure: Polymer Solution Preparation. Spinneret Setup Electric Field Application Electrostatic Charging Jet Formation Jet Elongation Solvent Evaporation or Cooling Nanofiber Collection Post-Processing (Optional)

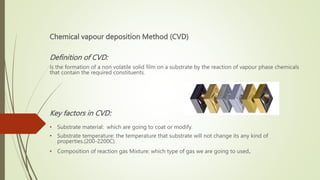

- 8. Chemical vapour deposition Method (CVD) Definition of CVD: Is the formation of a non volatile solid film on a substrate by the reaction of vapour phase chemicals that contain the required constituents. Key factors in CVD: • Substrate material: which are going to coat or modify. • Substrate temperature: the temperature that substrate will not change its any kind of properties.(200-2200C) • Composition of reaction gas Mixture: which type of gas we are going to used.

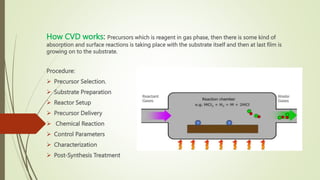

- 9. How CVD works: Precursors which is reagent in gas phase, then there is some kind of absorption and surface reactions is taking place with the substrate itself and then at last film is growing on to the substrate. Procedure: Precursor Selection. Substrate Preparation Reactor Setup Precursor Delivery Chemical Reaction Control Parameters Characterization Post-Synthesis Treatment

- 10. Laser pyrolysis Definition: Laser pyrolysis is an advanced technique used for the synthesis of nanoparticles with precise control over size, composition, and morphology. How it works: Using laser beam In this method using a high-energy laser beam to rapidly heat and vaporize precursor materials in a reactive gas atmosphere. Breaks Chemical bonds The laser energy breaks chemical bonds within the precursor molecules, leading to the formation of atomic and molecular species. Forming new Particles particles recombine and condense to form nanoparticles.

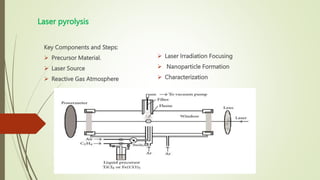

- 11. Laser pyrolysis Key Components and Steps: Precursor Material. Laser Source Reactive Gas Atmosphere Laser Irradiation Focusing Nanoparticle Formation Characterization

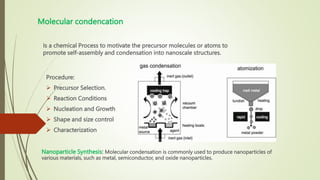

- 12. Molecular condencation Is a chemical Process to motivate the precursor molecules or atoms to promote self-assembly and condensation into nanoscale structures. Procedure: Precursor Selection. Reaction Conditions Nucleation and Growth Shape and size control Characterization Nanoparticle Synthesis: Molecular condensation is commonly used to produce nanoparticles of various materials, such as metal, semiconductor, and oxide nanoparticles.

- 13. Chemical Reduction Chemical reduction methods are based on the fundamental principle of using reducing agents to convert precursor compounds into nanomaterials. Procedure: Precursor Selection. Reduction Reaction/ introducing the agent Nucleation and Growth Nanoparticle Synthesis: is used to produce metal nanoparticles (e.g., gold, silver, platinum) and metal oxide nanoparticles (e.g., iron oxide, titanium dioxide).and we synthesized quantum dots, energy materials, nanowire. etc Nucleation and Growth Shape and size control Characterization

- 14. Green synthesis In green synthesis we use natural product such as leaves of tree/crops or fruits for the synthesis of metal or metal oxide NPs impotance: Eco-friendly Sustainable Free of chemical contamination Less expensive Can be used for mass production Nanoparticle Synthesis: Green-synthesized NPs, particularly using plant extracts, in drug delivery, imaging, and cancer therapy, other kind of medicine etc.

- 15. Thank you from your attention ?